The global industrial air blower market is experiencing steady expansion, driven by increasing demand across wastewater treatment, manufacturing, power generation, and chemical processing sectors. According to Mordor Intelligence, the market was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Similarly, Grand View Research estimates the market to reach USD 7.5 billion by 2030, reflecting a CAGR of 4.6%, fueled by rising industrial automation and stricter environmental regulations requiring efficient aeration and pneumatic conveying systems. As industries prioritize energy efficiency and operational reliability, the role of advanced blower technologies has become increasingly critical. This growing demand has elevated the prominence of leading manufacturers that combine innovation, durability, and sustainability. Based on market presence, technological capabilities, global reach, and customer reviews, the following are the top 10 industrial air blower manufacturers shaping the future of the sector.

Top 10 Industrial Air Blower Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 New York Blower Company

Domain Est. 1996

Website: nyb.com

Key Highlights: The New York Blower Company has the most complete portfolio of industrial fans and blowers in the industrial and OEM markets. Contact us today to learn ……

#2 Air Deviser Industrial Co., Ltd.

Domain Est. 2020

Website: airblowerfan.com

Key Highlights: Air Deviser Industrial is a well-known air blower fan manufacturer in Taiwan, mainly providing various centrifugal blowers suitable for industrial ……

#3 Custom Industrial Fan & Blower Manufacturer

Domain Est. 2023 | Founded: 1978

Website: ib-int.com

Key Highlights: Air movement solutions for the most demanding conditions. Exceptional expertise to maximize performance and longevity. Proudly made in the USA since 1978….

#4 Twin City Fan & Blower

Domain Est. 1997

Website: tcf.com

Key Highlights: Twin City Fan & Blower is an industry-leading designer and manufacturer of high-quality custom, semi-custom and standard fans ranging from heavy-duty industrial ……

#5 Industrial Centrifugal Blower

Domain Est. 1997

Website: sonicairsystems.com

Key Highlights: Sonic Air Systems is a leading manufacturer of industrial-grade centrifugal blowers, catering to a wide range of air, gas, and air knife applications….

#6 Industrial Centrifugal Fans & Blowers Manufacturer

Domain Est. 2002

Website: airprofan.com

Key Highlights: Explore industry-leading industrial fans and blowers—engineered for performance, built to spec, and backed by fast lead times and expert support….

#7 IAP Fan

Domain Est. 1999 | Founded: 1974

Website: iapfan.com

Key Highlights: Since 1974, IAP has been your complete resource for custom industrial fans, blowers, and dampers, from initial design engineering to fabrication and delivery….

#8 Blowers, Compressors & Turbos – Made by AERZEN

Domain Est. 2001

Website: aerzen.com

Key Highlights: Compressed air, gas and vacuum solutions. Our core business: compressing gases. Since 1864, AERZEN has engineered high performing machines for the industry….

#9 Inovair

Domain Est. 2016

Website: inovairblowers.com

Key Highlights: Inovair designs and manufactures modern high-efficiency, compact, integrally geared centrifugal blowers and compressors, as well as blower packages….

#10 Fans & Blowers

Domain Est. 2021

Website: fairbanksmorsedefense.com

Key Highlights: Durable, high-efficiency air movement solutions for demanding marine environments. Browse FMD’s trusted range of fans and blowers….

Expert Sourcing Insights for Industrial Air Blower

H2: 2026 Market Trends for Industrial Air Blowers

The industrial air blower market is poised for significant transformation by 2026, driven by technological innovation, sustainability mandates, and expanding industrial automation. As industries worldwide prioritize energy efficiency and emission reduction, the demand for advanced air blowers is expected to rise across key sectors such as wastewater treatment, manufacturing, chemical processing, and power generation.

One of the primary trends shaping the 2026 landscape is the increasing adoption of energy-efficient and smart blower systems. Manufacturers are integrating variable frequency drives (VFDs), IoT-enabled monitoring, and predictive maintenance capabilities into their products. These features enable real-time performance tracking, optimize energy consumption, and reduce operational downtime, making smart blowers highly attractive to industrial users aiming to lower total cost of ownership.

Another critical trend is the global push toward decarbonization and compliance with stricter environmental regulations. Governments and industrial players are investing in low-emission technologies, favoring oil-free and high-efficiency blowers that reduce carbon footprints. This shift is particularly evident in Europe and North America, where regulatory frameworks like the EU Green Deal and U.S. Clean Air Act amendments are accelerating the retirement of outdated, energy-intensive systems.

Additionally, emerging markets in Asia-Pacific and Latin America are expected to contribute significantly to market growth. Rapid industrialization, urbanization, and infrastructure development—especially in wastewater management and HVAC systems—are driving demand for reliable and scalable air blower solutions. Local manufacturing and strategic partnerships with global players are enabling faster market penetration and cost-effective deployment.

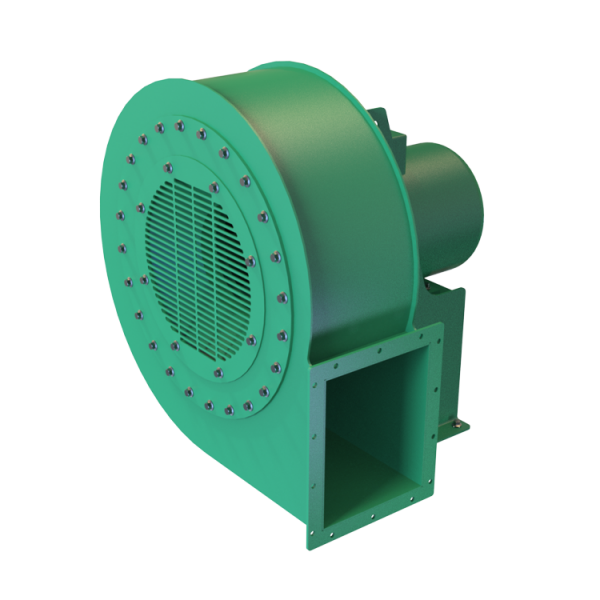

Furthermore, advancements in materials science and aerodynamic design are leading to lighter, more durable, and quieter blower models. Centrifugal and positive displacement blowers continue to dominate, but innovations in magnetic and regenerative blowers are gaining traction in niche applications requiring precision and minimal maintenance.

By 2026, the integration of digital twins, AI-driven diagnostics, and cloud-based control platforms is expected to become standard, further enhancing system reliability and performance. Overall, the industrial air blower market will be characterized by a strong emphasis on sustainability, digitalization, and operational efficiency, positioning it as a critical enabler of next-generation industrial processes.

Common Pitfalls When Sourcing Industrial Air Blowers (Quality & IP)

Sourcing industrial air blowers involves more than just matching flow and pressure specifications. Overlooking critical quality and intellectual property (IP) aspects can lead to performance failures, safety hazards, increased downtime, and legal risks. Below are key pitfalls to avoid:

1. Prioritizing Price Over Build Quality and Materials

One of the most frequent mistakes is selecting a blower based solely on the lowest upfront cost. Low-priced units often use inferior materials (e.g., substandard cast iron, cheap bearings, or thin housings), leading to premature wear, vibration, and failure under continuous operation. This results in higher total cost of ownership due to frequent repairs and reduced efficiency.

Best Practice: Evaluate the manufacturer’s material specifications, component sourcing, and certifications (e.g., ISO 9001). Consider lifecycle costs, including energy consumption and maintenance.

2. Ignoring IP Infringement Risks

Many low-cost manufacturers produce “clone” blowers that mimic patented designs from established brands. Using such equipment can expose your company to intellectual property litigation, especially in regulated industries or export markets. Infringing on patents may lead to equipment seizure, fines, or supply chain disruption.

Best Practice: Source blowers from reputable manufacturers with verifiable IP rights or proper licensing. Request documentation confirming design originality or patent compliance.

3. Overlooking Certification and Compliance Standards

Industrial environments often require blowers to meet specific safety and performance standards (e.g., ATEX for explosive atmospheres, CE marking, or UL certification). Choosing a non-compliant unit—even if it performs well—can violate workplace safety regulations and insurance policies.

Best Practice: Confirm that the blower meets all relevant regional and industry-specific certifications. Verify test reports and compliance documentation.

4. Underestimating Noise and Vibration Specifications

Poorly engineered blowers often generate excessive noise and vibration due to imbalanced rotors, inadequate mounting, or insufficient sound insulation. This not only affects workplace safety and comfort but can also damage surrounding equipment and infrastructure.

Best Practice: Request noise level (dB) and vibration data under operating conditions. Consider integrated silencers or vibration-damping mounts, especially in sensitive environments.

5. Assuming All OEMs Provide Genuine Spare Parts

Counterfeit or reverse-engineered spare parts are common with popular blower models. Using non-genuine components can degrade performance, void warranties, and increase failure rates.

Best Practice: Confirm the availability of OEM spare parts and maintenance support. Establish a direct relationship with the manufacturer or authorized distributor.

6. Failing to Verify Performance Data Authenticity

Some suppliers provide inflated performance curves (e.g., airflow, pressure, efficiency) that don’t reflect real-world operation. These discrepancies become evident only after installation, leading to process inefficiencies or the need for costly replacements.

Best Practice: Request third-party test reports or conduct performance validation through pilot testing. Cross-check data against independent industry benchmarks.

7. Neglecting After-Sales Support and Warranty Terms

Choosing a supplier with weak customer support or ambiguous warranty coverage can result in prolonged downtimes and unresolved technical issues. Limited local service networks exacerbate the problem, especially in remote locations.

Best Practice: Evaluate the supplier’s service network, technical support availability, and warranty conditions (duration, coverage, response time) before purchase.

By proactively addressing these quality and IP-related pitfalls, companies can ensure reliable, compliant, and legally sound operations while optimizing long-term operational efficiency.

Logistics & Compliance Guide for Industrial Air Blower

Product Classification and Identification

Industrial air blowers are mechanical devices used to move air or gas at high volumes and low pressures. They are commonly employed in wastewater treatment, pneumatic conveying, aeration systems, and industrial process applications. Proper identification using standardized classification systems is essential for international shipping and regulatory compliance.

- HS Code (Harmonized System Code): Typically classified under 8414.59 – “Other fans, blowers and ventilating or recycling hoods with a fan.” Confirm the exact subcategory based on specifications (e.g., motor power, airflow capacity, and intended use).

- UN Number (if applicable): Not usually assigned unless the blower includes hazardous components (e.g., lubricants with flammable properties).

- Model & Serial Numbers: Maintain accurate records for traceability and warranty compliance.

Export and Import Regulations

Compliance with national and international trade regulations is mandatory for smooth cross-border transportation.

- Export Controls: Verify if the air blower contains dual-use technologies (e.g., high-efficiency motors or advanced control systems) that may be subject to export control regimes such as EAR (Export Administration Regulations) in the U.S. or EU Dual-Use Regulation.

- Import Requirements: Research destination country regulations, including:

- Customs documentation (commercial invoice, packing list, bill of lading/air waybill)

- Import duties and VAT

- Local product standards (e.g., CE in Europe, CCC in China, PSE in Japan)

- Trade Sanctions: Ensure the destination country, end-user, and end-use are not restricted under international sanctions (e.g., OFAC, EU sanctions lists).

Packaging and Handling Requirements

Proper packaging ensures equipment integrity during transit and meets carrier and regulatory standards.

- Crate or Wooden Pallet: Secure the blower on a sturdy wooden pallet; use export-grade crates for ocean freight to prevent moisture and physical damage.

- Weatherproofing: Apply moisture barriers (e.g., VCI paper, desiccants) and waterproof wrapping for sea transport.

- Lifting Points: Mark designated lifting points clearly; provide rigging instructions if oversized.

- Fragile & Orientation Labels: Affix standard handling labels (e.g., “This Side Up,” “Do Not Stack,” “Fragile”).

Transportation Modes and Carrier Selection

Choose the appropriate transportation method based on product size, weight, delivery timeline, and cost.

- Ocean Freight: Preferred for heavy or bulky units; use FCL (Full Container Load) or break-bulk for oversized blowers.

- Air Freight: Suitable for urgent, lightweight units or spare parts; higher cost but faster delivery.

- Road/Rail: Used for regional or domestic delivery; ensure compliance with weight and dimension regulations (e.g., ADR in Europe).

- Carrier Compliance: Select carriers with experience in industrial equipment and proper insurance coverage.

Regulatory Compliance and Certifications

Ensure the industrial air blower meets all applicable safety, environmental, and performance standards.

- CE Marking (EU): Required for sale in the European Economic Area; demonstrates conformity with health, safety, and environmental protection standards (e.g., Machinery Directive 2006/42/EC, EMC Directive).

- UL/CSA Certification (North America): Required for electrical safety compliance in the U.S. and Canada.

- RoHS & REACH (EU): Confirm compliance with restrictions on hazardous substances (RoHS) and chemical registration (REACH).

- Energy Efficiency Standards: Comply with regional efficiency regulations (e.g., EU Ecodesign Directive, U.S. DOE standards).

- Noise Emission Compliance: Meet local noise level requirements (e.g., EU Noise Directive 2000/14/EC).

Documentation Checklist

Accurate and complete documentation is critical for customs clearance and regulatory compliance.

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Test and Inspection Reports (e.g., performance, vibration, noise)

- Compliance Certificates (CE, UL, RoHS, etc.)

- Export License (if required)

- Warranty and User Manual (multilingual versions as needed)

Risk Management and Insurance

Protect against loss, damage, or delay during transit.

- Marine Cargo Insurance: Cover all risks (e.g., ICC-A clauses) for international shipments.

- Incoterms Selection: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP).

- Force Majeure Planning: Include contingency plans for port delays, customs hold-ups, or natural disasters.

After-Sales and Warranty Compliance

Ensure post-delivery support meets regulatory and customer expectations.

- Warranty Registration: Provide clear instructions for registration and claim procedures.

- Spare Parts Logistics: Maintain inventory of critical components in strategic locations.

- Service and Compliance Updates: Notify customers of regulatory changes or required maintenance to remain compliant.

Environmental and Disposal Compliance

Address end-of-life responsibilities under environmental regulations.

- WEEE Directive (EU): Provide take-back or recycling information for electrical components.

- Local Disposal Laws: Advise customers on proper decommissioning and recycling procedures in their region.

By adhering to this logistics and compliance guide, manufacturers, distributors, and logistics providers can ensure the safe, legal, and efficient global movement of industrial air blowers.

Conclusion for Sourcing Industrial Air Blower:

Sourcing the right industrial air blower is a critical decision that significantly impacts operational efficiency, energy consumption, and long-term maintenance costs. A thorough evaluation of application requirements—such as airflow volume, pressure needs, duty cycle, environmental conditions, and noise restrictions—is essential to select the most suitable blower type, whether it be positive displacement (e.g., rotary lobe or screw), centrifugal, or regenerative. Additionally, factors like energy efficiency, reliability, ease of maintenance, and total cost of ownership should guide the procurement process.

Engaging with reputable suppliers, comparing technical specifications, and considering support services such as installation assistance and warranty coverage further ensure a successful acquisition. By aligning technical needs with performance and cost-effectiveness, organizations can enhance process reliability and sustainability. Ultimately, a well-informed sourcing strategy leads to optimal system performance, reduced downtime, and improved return on investment in industrial air blower applications.