The global laser marking machine market is experiencing robust growth, driven by increasing demand for precision, traceability, and permanent identification across manufacturing sectors. According to Grand View Research, the market size was valued at USD 1.46 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This upward trajectory reflects the growing integration of laser marking technologies in industries such as automotive, electronics, medical devices, and aerospace, where regulatory compliance, product authenticity, and supply chain transparency are critical. As manufacturers prioritize automation and Industry 4.0 adoption, laser marking has evolved from a niche capability to a strategic necessity—enabling high-speed, non-contact, and eco-friendly identification solutions. The following analysis explores the top eight reasons why laser marking has become indispensable for modern manufacturing operations, underpinned by technological advancements and shifting industry demands.

Top 8 Importance Of Laser Marking In Manufacturing Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

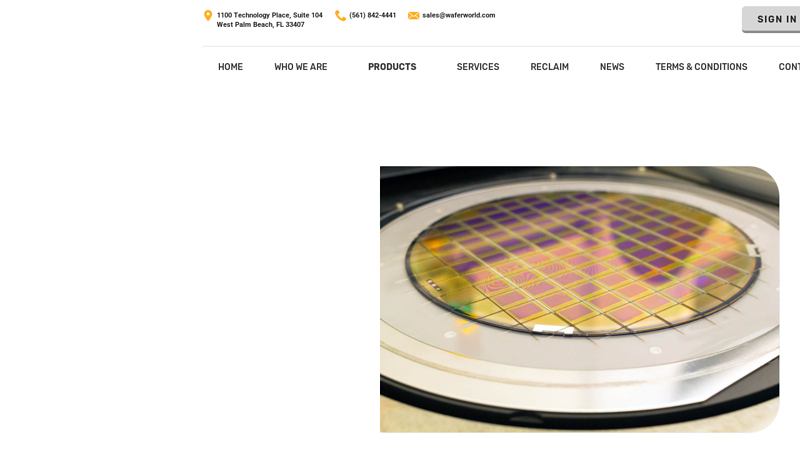

#1 Lighting the Way: The Significance of Laser Marking …

Website: waferworld.com

Key Highlights: Laser marking technology offers unparalleled precision. It enables manufacturers to create microscopic, indelible marks on semiconductor wafers….

#2 Laser marking

Website: trumpf.com

Key Highlights: Laser marking meets the more stringent demands on traceability and raw materials, for forgery protection and customized products. Laser marking can even satisfy …Missing: import…

#3 Permanent Labelling With Lasers

Website: datalogic.com

Key Highlights: Through the use of laser marking devices, manufacturers increase production efficiency, achieve precision quality and highly accurate labelling of work pieces….

#4 Aerospace industry moving to laser marking

Website: telesis.com

Key Highlights: The aerospace industry leads the way into the future by switching to laser marking technology for traceability and reliability….

#5 FDA Encourages Laser Marking in Manufacturing

Website: laserstar.net

Key Highlights: Laser marking is a great method of identifing parts for control, tracing or tracking permanently! Especially in the medical or military fields ……

#6 Everything You Need to Know About Laser Marking

Website: applerubber.com

Key Highlights: Laser marking makes it easy for companies to identify parts during replacement or repair and gives customers security in knowing that they are receiving the ……

#7 Traceability in Today’s Manufacturing Optimized by Laser Marking

Website: laserphotonics.com

Key Highlights: Laser marking ensures the creation of durable, high-quality identifiers vital for meeting stringent traceability standards and optimizes ……

#8 Laser Marking in Modern Manufacturing

Website: packagingtechtoday.com

Key Highlights: Laser marks are highly resistant to wear, fading, and environmental factors such as heat, chemicals, and UV exposure. This permanence ensures ……

Expert Sourcing Insights for Importance Of Laser Marking In Manufacturing

H2: Rising Demand for Precision and Traceability Driving Laser Marking Adoption in 2026 Manufacturing

In 2026, the importance of laser marking in manufacturing is expected to grow significantly, driven by increasing demand for precision, product traceability, and compliance with global regulatory standards. As industries shift toward smart manufacturing and Industry 4.0 integration, laser marking has emerged as a critical technology for ensuring product authenticity, enhancing supply chain transparency, and improving operational efficiency.

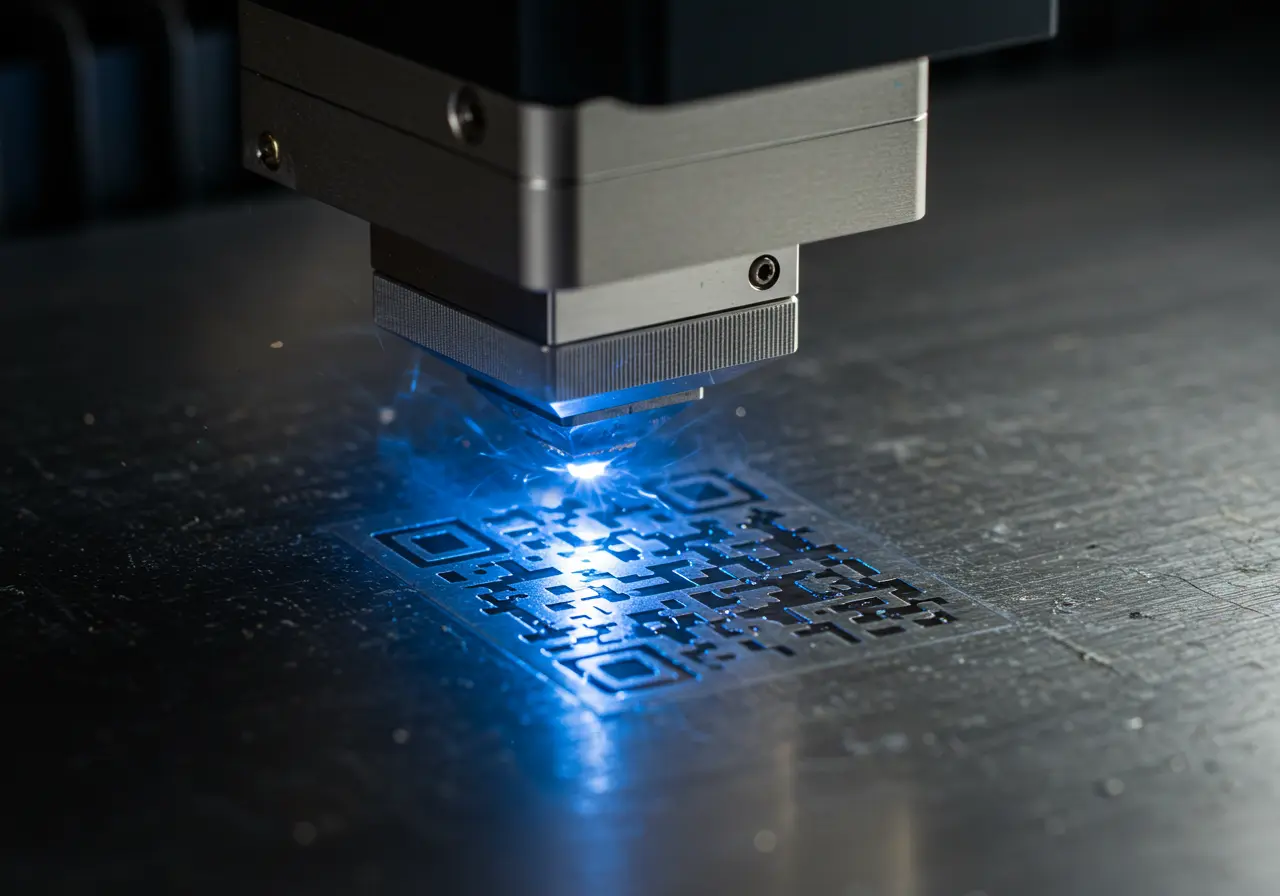

One of the key trends shaping the 2026 market is the heightened focus on traceability across sectors like automotive, aerospace, medical devices, and electronics. Permanent, high-contrast laser marks—such as Data Matrix codes, serial numbers, and barcodes—enable seamless tracking throughout a product’s lifecycle. This traceability is essential for quality control, recalls, and anti-counterfeiting measures, making laser marking indispensable in regulated environments.

Additionally, advancements in fiber and ultrafast laser technologies have enhanced marking speed, precision, and compatibility with a broader range of materials—including metals, plastics, and composites. These improvements support high-throughput production lines and reduce downtime, aligning with the manufacturing sector’s push for automation and lean operations.

Sustainability is another driving factor. Unlike ink-based marking systems, laser marking is a non-contact, chemical-free process that produces no waste, supporting environmentally responsible manufacturing practices— a growing priority for consumers and regulators alike.

In summary, by 2026, laser marking will be a cornerstone of modern manufacturing, enabling digital traceability, ensuring compliance, and supporting the scalability and sustainability goals of global production systems.

Common Pitfalls When Sourcing Laser Marking Systems for Manufacturing (Quality & IP)

When integrating laser marking into manufacturing processes, businesses often focus heavily on speed and cost, overlooking critical factors that directly impact product quality and intellectual property (IP) protection. Here are common pitfalls to avoid:

Overlooking Mark Permanence and Legibility

Many manufacturers prioritize initial cost over long-term reliability, choosing lower-powered or poorly configured laser systems. This can result in marks that fade, wear off, or become illegible under environmental stress (heat, chemicals, abrasion). In regulated industries—such as aerospace, automotive, or medical devices—illegible part markings can lead to traceability failures, compliance violations, and costly recalls.

Neglecting Material Compatibility

Different materials (metals, plastics, ceramics) require specific laser types (fiber, CO₂, UV) and parameters. Sourcing a laser without thorough material testing can lead to poor mark contrast, surface damage, or incomplete marking. This compromises both aesthetic quality and functional durability, weakening brand reputation and potentially voiding warranties.

Underestimating Integration Complexity

Laser marking systems must seamlessly integrate with existing production lines, automation, and software (e.g., MES, ERP). Failing to assess communication protocols, footprint, or cycle time alignment can lead to bottlenecks, downtime, or manual intervention—undermining efficiency and quality consistency.

Ignoring Traceability and Data Security Needs

Laser marking is a key enabler of product traceability, crucial for combating counterfeiting and managing recalls. Sourcing systems without secure data handling—such as encrypted marking files or protected communication channels—risks IP theft. Unauthorized replication of serial numbers, barcodes, or proprietary logos can lead to counterfeit goods and loss of competitive advantage.

Failing to Validate IP Protection Capabilities

For high-value or patented products, laser marks often include covert features like micro-text, 2D data matrices, or unique identifiers. Choosing a system without the resolution or software support for such features diminishes IP protection. Moreover, relying on third-party integrators without proper IP agreements can expose proprietary designs during setup.

Skipping Vendor Due Diligence on Support and Compliance

Selecting vendors based solely on price can backfire when post-sale support is inadequate. Lack of training, poor documentation, or limited software updates affects mark consistency and system uptime. Additionally, failing to verify that the laser complies with safety (e.g., FDA, CE, IEC) and environmental standards risks regulatory non-compliance and liability.

Conclusion

Sourcing laser marking technology requires a strategic evaluation beyond upfront cost. Ensuring compatibility, durability, integration readiness, and robust IP protection safeguards both product quality and intellectual assets. A well-considered investment prevents costly rework, enhances compliance, and strengthens brand integrity in competitive markets.

Importance of Laser Marking in Manufacturing: A Logistics & Compliance Guide

Laser marking has become an indispensable process in modern manufacturing, playing a critical role not only in product identification but also in ensuring supply chain integrity, regulatory compliance, and operational efficiency. This guide outlines the key logistics and compliance benefits of laser marking across various industries.

Ensuring Traceability and Supply Chain Visibility

Laser marking enables permanent, high-contrast identification of products, components, and packaging throughout the supply chain. By engraving unique identifiers such as batch numbers, serial numbers, and barcodes directly onto materials, manufacturers can efficiently track items from production through distribution to end users. This traceability is essential for managing inventory, preventing counterfeiting, and executing targeted recalls. In global logistics, the durability of laser marks ensures readability despite exposure to moisture, heat, and abrasion during transport and storage.

Meeting Regulatory and Industry Compliance Standards

Many industries are subject to strict regulatory requirements that demand permanent and tamper-proof product marking. Laser marking supports compliance with standards such as:

- FDA (U.S. Food and Drug Administration): Required for medical devices under the Unique Device Identification (UDI) rule.

- EU MDR (Medical Device Regulation): Mandates permanent UDI marking on medical instruments.

- REACH & RoHS: Laser marking avoids chemical additives, supporting compliance with environmental regulations.

- Automotive (AIAG, IATF 16949): Requires traceable part marking for quality control and recalls.

- Aerospace (AS9100): Demands permanent part identification for safety and maintenance tracking.

Because laser marks are non-contact and do not involve inks or solvents, they meet stringent hygiene and safety standards in regulated environments.

Enhancing Anti-Counterfeiting and Brand Protection

Counterfeit goods pose a significant risk to brand reputation and consumer safety. Laser marking allows for the integration of covert features such as micro-text, 2D data matrix codes, and encrypted markings that are difficult to replicate. These security features support authentication throughout the distribution chain and empower end users and regulators to verify product legitimacy, reducing the risk of fraud and ensuring brand integrity.

Supporting Sustainable and Lean Manufacturing

From a logistics and environmental standpoint, laser marking is a clean, chemical-free process that generates no consumables like inks or labels. This reduces waste, lowers storage needs for marking materials, and aligns with sustainable manufacturing goals. Additionally, the high-speed and automation compatibility of laser systems streamline production lines, minimizing downtime and improving throughput—key factors in efficient logistics operations.

Facilitating Automation and Digital Integration

Laser marking systems seamlessly integrate with Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Industry 4.0 platforms. Real-time data exchange allows dynamic marking of variable information such as serial numbers and expiration dates, ensuring accuracy and reducing human error. This digital connectivity strengthens quality control, supports just-in-time (JIT) logistics, and enables end-to-end digital traceability.

Conclusion

Laser marking is more than a labeling solution—it is a strategic enabler of compliance, traceability, and operational excellence in manufacturing. By adopting laser marking technologies, companies strengthen their logistics frameworks, meet global regulatory demands, and build resilient, transparent supply chains.

In conclusion, the importance of sourcing laser marking in manufacturing cannot be overstated. As industries continue to demand higher precision, traceability, and efficiency, laser marking emerges as a critical technology for ensuring product quality, compliance, and brand integrity. Its ability to produce permanent, high-contrast marks on a wide range of materials makes it ideal for applications in aerospace, automotive, medical devices, and electronics. Furthermore, laser marking supports serialization, anti-counterfeiting measures, and regulatory requirements, enhancing supply chain transparency and consumer safety. By strategically sourcing reliable laser marking solutions, manufacturers can improve operational productivity, reduce long-term costs, and maintain a competitive edge in an increasingly automated and regulated global market. Investing in advanced laser marking technology is not just a technical upgrade—it is a strategic move toward smarter, more sustainable manufacturing practices.