The global outboard engine market is experiencing steady growth, driven by rising demand for recreational boating, coastal patrol operations, and advancements in marine propulsion technology. According to a report by Mordor Intelligence, the outboard motors market was valued at USD 4.85 billion in 2023 and is projected to reach USD 6.73 billion by 2029, growing at a CAGR of approximately 5.7% during the forecast period. A key technological differentiator among leading manufacturers is the integration of impeller-based propulsion systems, which offer improved fuel efficiency, lower maintenance, and enhanced maneuverability—especially in shallow waters. As innovation accelerates and environmental regulations tighten, manufacturers are focusing on compact, high-performance impeller-driven outboards to capture emerging market opportunities. This data-driven momentum underscores the importance of identifying the top 10 impeller outboard engine manufacturers shaping the future of marine propulsion.

Top 10 Impeller Outboard Engine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Johnson Water Pump Impeller

Domain Est. 2023

Website: jlmmarine.com

Key Highlights: Buy Johnson Water Pump Impeller at JLM Marine Boat Parts Limited. Check Price and Buy Online. ✓ Free Shipping ✓ Direct from Factory ✓ OEM Quality ✓ Best ……

#2 Mercury Marine

Domain Est. 1995

Website: mercurymarine.com

Key Highlights: Mercury Marine is the world’s leading manufacturer of recreational marine propulsion engines. Get sales, service and parts info, and find a local dealer ……

#3 Propulsion

Domain Est. 1997

Website: indmar.com

Key Highlights: Official Site of Indmar Marine Engines. The world’s most awarded and largest privately held manufacturer of gasoline powered inboard marine engines. POPULAR ……

#4 Boat Engine Impellers & Parts

Domain Est. 1998

Website: fisheriessupply.com

Key Highlights: Free delivery over $99 · Free 30-day returnsMarine impellers from manufacturers such as Johnson Pump and Jabsco are engineered for durability, but all flexible impellers degrade o…

#5 Boat Impellers and Water Pumps

Domain Est. 1998

Website: wholesalemarine.com

Key Highlights: Browse Wholesale Marine’s line of boat impellers and water pumps. Our inventory fits all engine manufacturers, including Evinrude, Mercruiser, and Mercury….

#6 Seawater Pump Impellers

Domain Est. 2004

Website: sbmar.com

Key Highlights: Free delivery over $250Keep your engine cool with SMX Seawater Pump Impellers. Impellers made from synthetic based neoprene impervious to greases – allows simple installation …Mi…

#7 Impellers

Domain Est. 1996

Website: solas.com

Key Highlights: With features like a large blade area and a unique geometric blade design, the SOLAS Concord Impeller delivers remarkable thrust and extraordinary efficiency….

#8 Boat Engine Parts and Marine Supplies

Domain Est. 2003

Website: sierraparts.com

Key Highlights: Search Sierra’s catalog of aftermarket engine boat parts, fuel systems, instrumentation, electrical supplies, and marine supplies for inboard and outboard ……

#9 JMP Marine USA

Domain Est. 2012

Website: jmpusamarine.com

Key Highlights: JMP Marine replacement engine cooling water pumps, flexible bronze impellers, seawater strainers, generator engine cooling pumps, multi purpose pumps, ……

#10 Original Impeller Kits

Domain Est. 2014

Website: spxflow.com

Key Highlights: SPX FLOW’s Johnson Pump Marine brand impellers are developed and manufactured for maximum flow and long life. With a genuine spare impeller you can also be sure ……

Expert Sourcing Insights for Impeller Outboard Engine

H2: 2026 Market Trends for Impeller Outboard Engines

The global market for impeller outboard engines is poised for notable evolution by 2026, driven by technological innovation, shifting consumer preferences, and regulatory pressures focused on sustainability. Impeller outboard engines—also known as jet-driven outboards—offer distinct advantages over traditional propeller-based systems, particularly in shallow water navigation, debris resistance, and safety, making them ideal for specific recreational, commercial, and utility applications.

-

Growing Demand in Recreational and Coastal Watercraft

By 2026, the recreational marine sector is expected to be a primary growth driver for impeller outboard engines. Increasing popularity of personal watercraft, shallow-draft fishing boats, and eco-tourism vessels will boost demand. Regions with extensive inland waterways, coastal shallows, or weedy environments—such as parts of North America, Southeast Asia, and Northern Europe—will see heightened adoption due to the superior maneuverability and safety of jet propulsion systems. -

Technological Advancements and Efficiency Improvements

Ongoing R&D efforts are expected to result in more compact, fuel-efficient, and powerful impeller engines by 2026. Integration of digital controls, remote diagnostics, and smart propulsion systems will enhance user experience. Manufacturers are also focusing on improving thrust-to-weight ratios and reducing cavitation, expanding the usability of impeller engines across a broader range of boat sizes and applications. -

Shift Toward Electrification and Hybrid Systems

Environmental regulations and consumer demand for low-emission solutions are pushing the marine industry toward electrification. By 2026, electric and hybrid impeller outboard engines are expected to gain traction, particularly in emission-sensitive zones like lakes, national parks, and urban waterways. Companies investing in electric jet propulsion—such as Torqeedo and Pure Watercraft—are likely to capture early market share in this niche. -

Expansion in Commercial and Utility Applications

Impeller outboards are increasingly being adopted in commercial sectors such as search-and-rescue, river patrol, aquaculture, and survey operations. Their ability to operate in debris-filled, shallow, or unpredictable waters makes them ideal for these use cases. Government and institutional procurement is expected to grow, supported by infrastructure investments and disaster preparedness initiatives. -

Regional Market Growth and Emerging Economies

While North America and Europe remain key markets due to high recreational boating participation and stringent emission norms, Asia-Pacific—particularly countries like Thailand, Indonesia, and Vietnam—is projected to emerge as a high-growth region. Expanding tourism industries and rising disposable incomes are fueling demand for personal and small commercial watercraft equipped with reliable impeller systems. -

Challenges and Competitive Landscape

Despite growth potential, impeller outboards face challenges including higher initial costs, limited top-end speed compared to traditional outboards, and maintenance complexity. However, leading manufacturers such as Yamaha, BRP (Evinrude formerly), and Mercury Marine are investing in innovation to address these limitations. Consolidation and partnerships with electric drivetrain developers may shape the competitive dynamics by 2026.

In conclusion, the 2026 market for impeller outboard engines is set for steady expansion, underpinned by their operational advantages in niche environments and the broader marine industry’s shift toward efficiency and sustainability. Strategic advancements in electrification, digital integration, and regional market development will be key determinants of long-term success.

Common Pitfalls Sourcing Impeller Outboard Engine (Quality, IP)

Sourcing impellers for outboard engines—especially from low-cost manufacturing regions—exposes buyers to significant risks related to both product quality and intellectual property (IP) protection. Understanding these pitfalls is critical to ensuring reliable engine performance and avoiding legal and financial exposure.

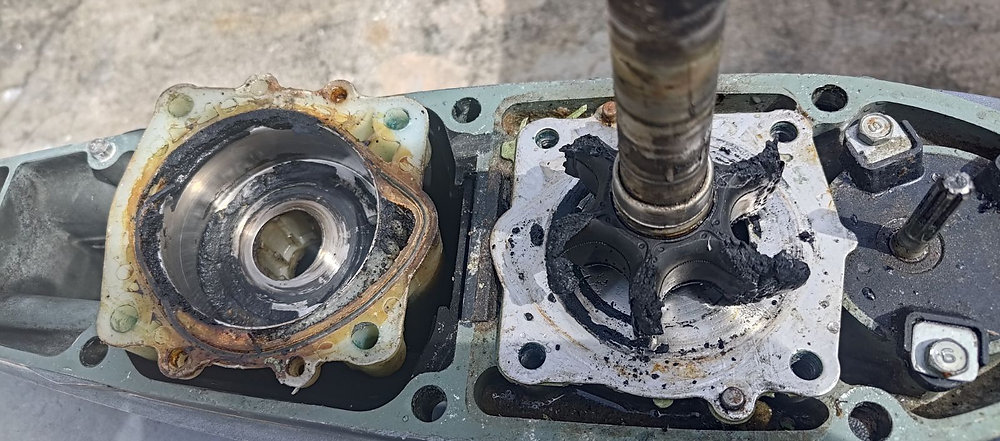

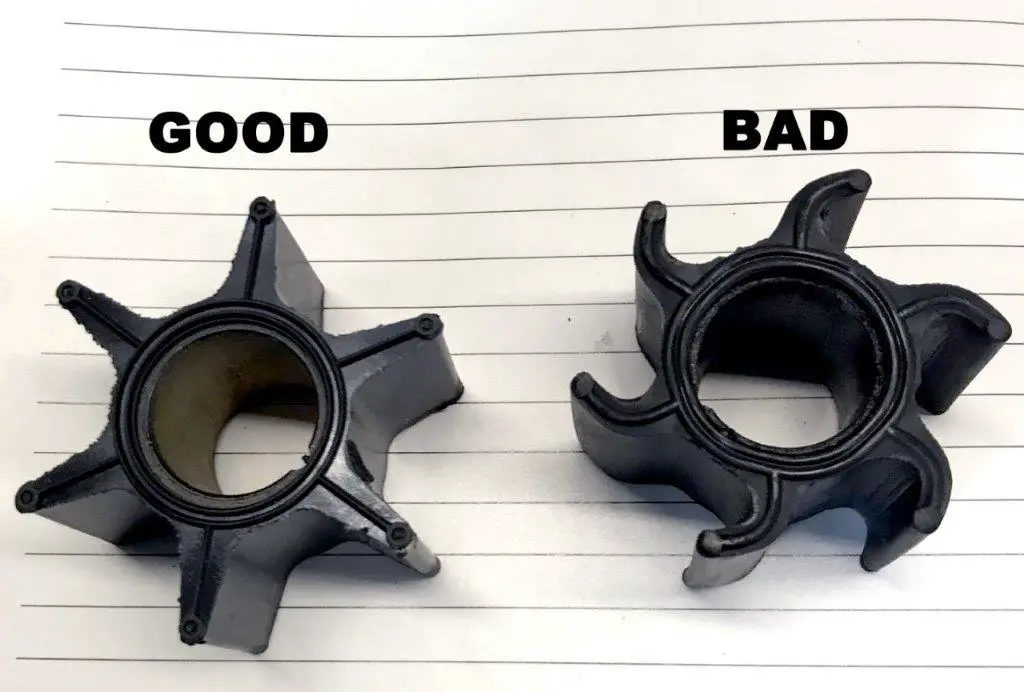

Poor Material Quality and Inconsistent Manufacturing

One of the most prevalent quality issues is the use of substandard elastomeric materials in impeller construction. Inferior rubber compounds degrade quickly when exposed to heat, saltwater, and UV radiation, leading to premature cracking, loss of flexibility, and reduced pumping efficiency. Additionally, inconsistent molding processes can result in dimensional inaccuracies—such as uneven vane thickness or misaligned hub geometry—compromising the impeller’s fit and function. These defects often go undetected during initial inspection but manifest as engine overheating and performance decline in the field.

Non-Compliance with OEM Specifications

Many third-party suppliers produce impellers that only approximate original equipment manufacturer (OEM) designs. These “compatible” parts may differ in critical dimensions, vane angle, or rotational direction, leading to inefficient water flow and increased strain on the water pump housing. While such impellers may appear to fit, their underperformance can invalidate warranties and cause collateral damage to other engine components, ultimately costing more than the initial savings.

Lack of Traceability and Certification

Sourced impellers frequently lack proper documentation, material certifications, or batch traceability. Without evidence of quality control testing (e.g., durometer hardness, tensile strength), buyers cannot verify compliance with marine-grade standards. This opacity makes it difficult to hold suppliers accountable when failures occur and raises concerns about long-term reliability and safety.

Intellectual Property Infringement

A major IP risk involves the unauthorized replication of OEM impeller designs, which are often protected by design patents, utility models, or trade dress. Sourcing counterfeit or cloned parts—even unknowingly—can expose buyers and distributors to legal liability, including cease-and-desist orders, customs seizures, and infringement lawsuits. In some jurisdictions, importing or selling such parts may violate international trade agreements and trademark laws.

Weak Contractual Protections and Enforcement Challenges

Supply agreements for impellers often lack robust IP indemnification clauses or quality assurance provisions. When disputes arise, enforcing contracts across international borders can be costly and time-consuming. Suppliers in certain regions may be unresponsive to warranty claims or resistant to audits, leaving buyers with little recourse in cases of IP violation or defective goods.

Recommendations to Mitigate Risks

To avoid these pitfalls, buyers should:

– Require material certifications and dimensional validation reports.

– Conduct on-site supplier audits and sample performance testing.

– Ensure suppliers provide IP warranties and confirm design freedom-to-operate.

– Work with legal counsel to include enforceable IP and quality clauses in contracts.

– Prefer reputable suppliers with documented OEM licensing or partnerships.

Proactive due diligence is essential to secure high-quality, IP-compliant impellers that ensure engine longevity and legal compliance.

Logistics & Compliance Guide for Impeller Outboard Engine

This guide outlines the critical logistics considerations and regulatory compliance requirements for the transportation, handling, import/export, and use of the Impeller Outboard Engine. Adherence to these guidelines ensures safe operations, avoids delays, and supports environmental and legal standards.

Product Classification & Documentation

Proper classification and documentation are foundational for smooth logistics and compliance. The Impeller Outboard Engine must be accurately categorized under international trade and transport regulations.

- HS Code: Identify the correct Harmonized System (HS) code for customs declarations—typically under Chapter 89 (Boats, ships, and floating structures) or Chapter 84 (Nuclear reactors, boilers, machinery), depending on engine specifications (e.g., 8407.21 or 8408.10 for internal combustion engines).

- Commercial Invoice: Must include engine model, serial number, net/gross weight, country of origin, value, and buyer/seller details.

- Packing List: Detail packaging type (e.g., wooden crate, pallet), dimensions, and quantity per shipment.

- Certificate of Origin: Required for preferential tariff treatment under trade agreements.

- Bill of Lading/Air Waybill: Accurately reflect shipment terms (Incoterms® 2020 such as FOB, CIF, or DDP).

Transport & Packaging Requirements

Secure packaging and appropriate transport methods are essential to prevent damage and ensure safety during transit.

- Packaging: Use weather-resistant, shock-absorbent materials. Engines should be crated or palletized with corner protectors. Include desiccants to prevent internal corrosion during ocean freight.

- Labeling: Clearly mark packages with:

- “Fragile”

- “This Side Up”

- “Keep Dry”

- Engine model and serial number

- Weight and center of gravity indicators

- Modes of Transport:

- Ocean Freight: Secure crated engines to container floors; use moisture barriers. Comply with IMDG Code if fuel system contains residual flammable substances.

- Air Freight: Subject to IATA Dangerous Goods Regulations if shipped with fuel or oil. Most outboard engines must be drained and cleaned to qualify as non-hazardous.

- Ground Transport: Ensure secure loading and tie-downs compliant with local DOT (or equivalent) regulations.

Hazardous Materials & Environmental Compliance

Even though the Impeller Outboard Engine is primarily mechanical, certain components may trigger hazardous materials regulations.

- Fuel and Oil Residues: Engines shipped with fuel or oil may be classified as hazardous under IATA, IMDG, or ADR. Best practice: drain and cap all fuel, oil, and coolant lines before shipment.

- Battery Shipping: If shipped with a battery, comply with UN 3090/3480 regulations (lithium or lead-acid). Batteries must be protected from short circuits and securely packaged.

- Environmental Standards:

- Ensure compliance with emissions regulations (e.g., EPA Tier 3, EU Stage V) based on the destination market.

- Engines must meet noise emission standards (e.g., ISO 8295) where applicable.

- Provide EPA or EU Declaration of Conformity with each unit.

Import & Export Regulations

Cross-border shipments require strict adherence to national and international trade laws.

- Export Controls:

- Verify if the engine or components are subject to export control lists (e.g., U.S. Commerce Control List, EU Dual-Use Regulation). Most outboard engines are not controlled, but confirm based on technology specifications.

- Import Duties & Taxes:

- Research destination country’s import tariffs, VAT/GST, and anti-dumping measures.

- Use binding tariff information (BTI) for certainty in classification.

- Customs Clearance:

- Provide complete documentation package to customs brokers.

- Prepare for potential inspections; ensure engines are accessible for verification.

- Country-Specific Requirements:

- United States: EPA and CARB certification may be required for sale.

- European Union: CE marking, EU Type Approval, and registration under Recreational Craft Directive (2013/53/EU).

- Australia: Comply with AMSCA standards and obtain Marine Engine Emission Label (MEEL).

- Canada: Meet requirements of the Canadian Environmental Protection Act (CEPA).

Installation & End-User Compliance

Ensure end-users can legally and safely operate the Impeller Outboard Engine.

- Owner’s Manual: Include multilingual instructions covering installation, operation, maintenance, and compliance statements.

- Emissions Labeling: Affix permanent labels indicating compliance with emissions standards (e.g., EPA, EU).

- Noise Labeling: Attach noise emission data per ISO standards.

- Registration Support: Provide documentation to assist customers with vessel registration and engine titling where required.

Quality & Recall Compliance

Maintain traceability and readiness for regulatory actions.

- Serial Number Tracking: Record all engine serial numbers and shipment details for recall management.

- Warranty & Service: Align service network with local regulations and provide authorized technician training.

- Recall Procedures: Establish a global recall protocol compliant with consumer safety laws (e.g., CPSC in the U.S., RAPEX in the EU).

Summary

Successful logistics and compliance for the Impeller Outboard Engine depend on accurate classification, proper packaging, adherence to hazardous materials rules, and fulfillment of regional import/export requirements. Proactive planning and documentation ensure efficient global distribution while maintaining environmental and safety standards. Always consult local regulatory authorities or legal experts when entering new markets.

Conclusion for Sourcing Impeller for Outboard Engine:

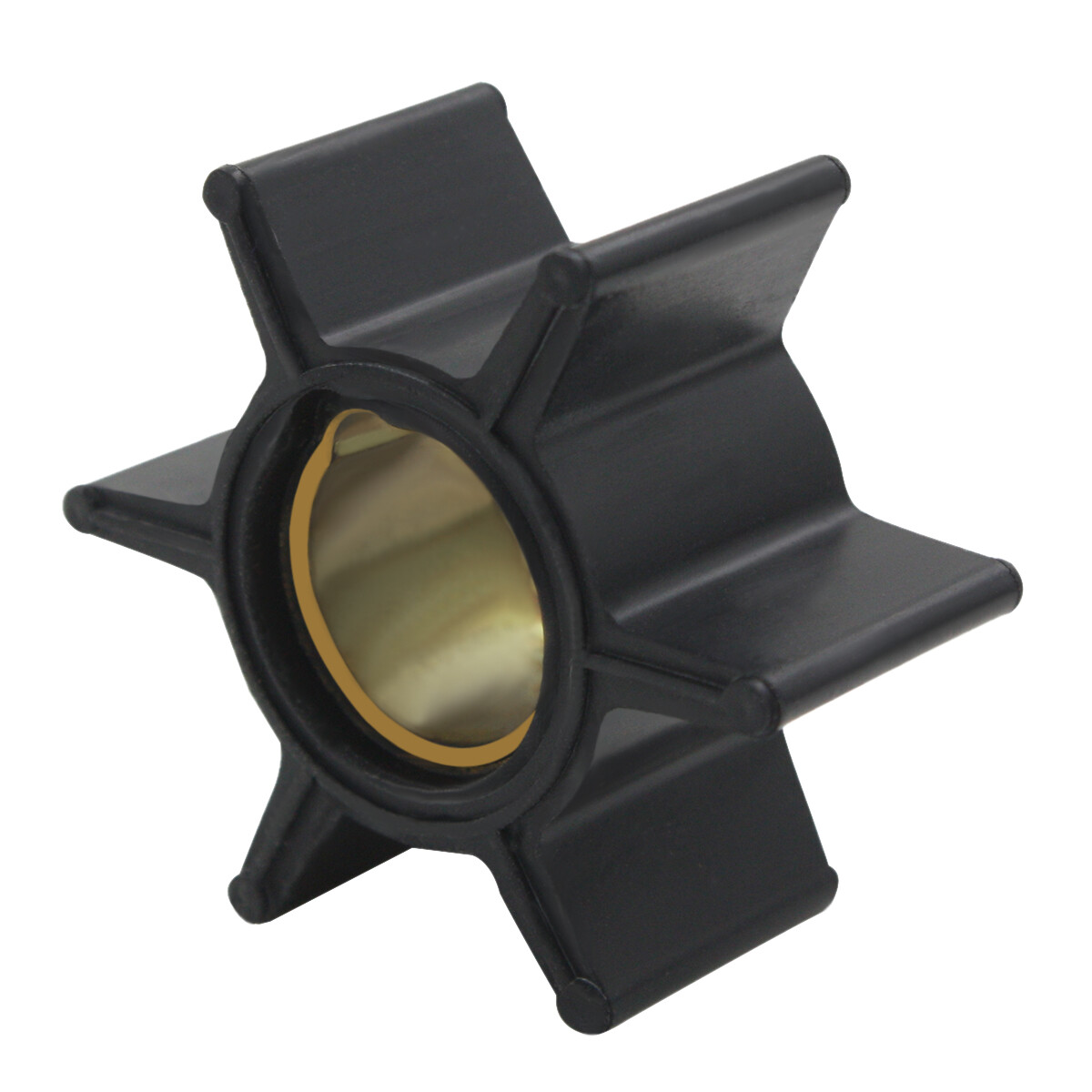

Sourcing the correct impeller for an outboard engine is a critical maintenance task that directly impacts the engine’s cooling efficiency and overall longevity. After evaluating original equipment manufacturer (OEM) parts versus aftermarket alternatives, it is evident that while OEM impellers offer guaranteed compatibility and reliability, high-quality aftermarket options can provide a cost-effective solution without compromising performance—provided they meet technical specifications and material standards. Key considerations when sourcing include engine model compatibility, impeller material (typically rubber compound resilience), and supplier reputation. Regular inspection and timely replacement of the impeller, typically every 1–2 years, are essential to prevent overheating and potential engine damage. Ultimately, a well-sourced impeller ensures optimal engine performance, reliability, and reduced risk of costly repairs, making it a worthwhile investment in the outboard engine’s operational lifespan.