The global ice rink refrigeration market is experiencing steady growth, driven by increasing investments in recreational infrastructure and the expansion of indoor ice sports facilities. According to Grand View Research, the global ice rink market size was valued at USD 32.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is supported by rising demand for energy-efficient and environmentally sustainable refrigeration technologies, as facility operators prioritize low global warming potential (GWP) refrigerants and smart system controls. With North America and Europe leading in ice rink construction and retrofitting, manufacturers are innovating to meet performance, regulatory, and efficiency demands. As the market evolves, a select group of refrigeration system providers has emerged as leaders in reliability, technical expertise, and global reach—shaping the standards for modern ice production and maintenance.

Top 9 Ice Rink Refrigeration System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Zero Zone, Inc.

Domain Est. 1996

Website: zero-zone.com

Key Highlights: Zero Zone is a leading manufacturer in the refrigeration industry, specializing in display cases and refrigeration systems. … Ice Rink Chiller System · Explore ……

#2 Industrial Frigo Ice USA: Ice Rinks

Domain Est. 2019

Website: industrialfrigoiceusa.com

Key Highlights: Permanent or mobile ice skating rinks, snow playgrounds, ice parks, ice slides. Available for rent or purchase, indoor or outdoor use, ……

#3 Ice Rink & Low Temperature Chillers

Domain Est. 1995

Website: tecogen.com

Key Highlights: We provide a range of in-stock and custom low temperature chillers built for ice making with hot water recovery….

#4 Ice Rink Supply (Official)

Domain Est. 2001

Website: icerinksupply.com

Key Highlights: We provide rink refrigeration pipes grids, chillers, rink perimeter boards, hockey dasher boards, ice resurfacing machines and other ice maintenance equipment, ……

#5 Custom ice rink refrigeration system

Domain Est. 1997

Website: berg-group.com

Key Highlights: Berg custom designs, manufactures, installs, and services cost-effective cooling solutions for recreational ice rink refrigeration system….

#6 Ice Rink Water Treatment Solutions

Domain Est. 1997

Website: chardonlabs.com

Key Highlights: Explore Chardon Laboratories’ expert water treatment solutions for ice rinks. Contact us today for reliable service and maintenance….

#7 CIMCO Refrigeration

Domain Est. 1998

Website: cimcorefrigeration.com

Key Highlights: We can design, engineer and install a range of thermal systems to meet a variety of technical, environmental, and financial goals….

#8 Opteon™ Refrigerants Partnership

Domain Est. 2000

Website: opteon.com

Key Highlights: Opteon™ refrigerants offer advanced next generation solutions for ice rinks, food retail, food service, cold storage, and comfort cooling applications ……

#9 Ice Rink Refrigeration and Chillers

Domain Est. 2007

Website: everything-ice.com

Key Highlights: The most energy efficient and sustainable chillers for ice rinks, using only the most technologically advanced systems….

Expert Sourcing Insights for Ice Rink Refrigeration System

H2: Projected Market Trends for Ice Rink Refrigeration Systems in 2026

The global ice rink refrigeration system market is poised for significant transformation by 2026, driven by technological innovation, environmental regulations, and shifting consumer demand for sustainable and energy-efficient infrastructure. As climate change awareness grows and governments enforce stricter emissions standards, the industry is pivoting toward low-global warming potential (GWP) refrigerants and integrated smart cooling technologies.

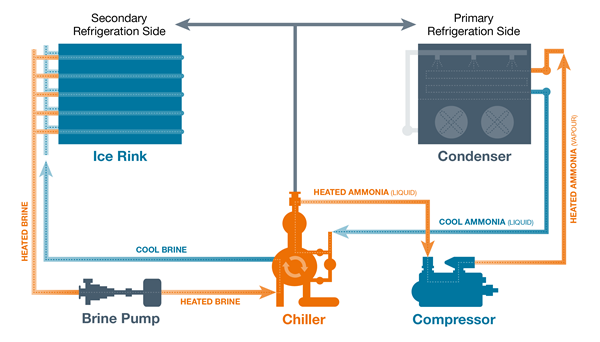

One of the most prominent trends shaping the 2026 landscape is the increasing adoption of natural refrigerants such as ammonia (R717), carbon dioxide (CO₂), and hydrocarbons. These alternatives are gaining favor over traditional fluorinated gases (HFCs), which are being phased down under international agreements like the Kigali Amendment to the Montreal Protocol. Ice rinks, particularly in Europe and North America, are retrofitting or designing new facilities with ammonia-based systems due to their high efficiency and minimal environmental impact.

Energy efficiency remains a critical driver. Advances in variable frequency drives (VFDs), heat recovery systems, and intelligent control platforms enable ice rinks to reduce power consumption by up to 30%. By 2026, a growing number of facilities are expected to integrate IoT-enabled monitoring systems that optimize refrigeration cycles in real time based on ice conditions, occupancy, and ambient temperature.

Another emerging trend is the modularization and prefabrication of refrigeration units. These factory-built systems reduce installation time and costs while improving reliability—appealing to both new construction and renovation projects. This shift is especially beneficial in regions with labor shortages or tight project timelines.

Geographically, North America and Europe will continue to lead the market due to strong ice sports cultures and stringent environmental policies. However, the Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth, fueled by investments in winter sports infrastructure in preparation for international events and rising urban recreational demand.

Lastly, sustainability certifications such as LEED and ISO 50001 are becoming key differentiators. Ice rink operators are increasingly prioritizing refrigeration systems that contribute to broader environmental goals, including carbon neutrality. By 2026, the convergence of regulatory pressure, technological innovation, and consumer expectations will position eco-friendly, smart refrigeration systems as the new industry standard.

Common Pitfalls When Sourcing an Ice Rink Refrigeration System (Quality & Intellectual Property)

Sourcing an Ice Rink Refrigeration System involves significant technical, financial, and legal considerations. Overlooking key aspects related to quality and intellectual property (IP) can lead to performance failures, safety hazards, cost overruns, and legal disputes. Below are critical pitfalls to avoid:

Inadequate Assessment of System Quality and Reliability

One of the most frequent and costly mistakes is failing to thoroughly evaluate the quality and long-term reliability of the refrigeration system. Low-quality components or poor engineering can result in frequent breakdowns, inconsistent ice conditions, and high maintenance costs. Key issues include:

- Use of Substandard Materials: Suppliers may cut costs by using inferior piping, valves, or compressors that degrade quickly under the demanding conditions of ice rink operation.

- Insufficient Capacity or Poor Design: Systems undersized for the rink’s geographic location or usage intensity lead to inadequate cooling, especially during peak periods or warmer climates.

- Lack of Third-Party Certification: Not verifying compliance with recognized standards (e.g., ASHRAE, ISO, CE, or pressure equipment directives) increases the risk of safety hazards and non-compliance with local regulations.

Ignoring Intellectual Property (IP) Rights and Licensing

Refrigeration systems, particularly those using advanced controls or proprietary refrigerant cycles, often incorporate protected technology. Overlooking IP issues can expose the buyer to legal liability:

- Unauthorized Use of Patented Technology: Procuring a system that uses patented compressors, control algorithms, or heat recovery systems without proper licensing can result in infringement claims against the rink operator.

- Proprietary Software and Control Systems: Many modern systems rely on proprietary software for monitoring and automation. Buyers may unknowingly accept restrictive licenses that limit maintenance options or require ongoing vendor support at inflated costs.

- Lack of Documentation and IP Transfer: In some cases, especially with custom-engineered systems, the buyer assumes ownership of design documents or process know-how. If IP rights are not clearly assigned or licensed in the contract, future modifications or repairs may require permission from the original supplier.

Failure to Vet Supplier Credentials and Track Record

Choosing a supplier based solely on price or proximity without verifying their experience with ice rink projects can lead to significant setbacks:

- Limited Industry Experience: Suppliers without a demonstrated history in ice rink applications may lack understanding of unique requirements such as load cycling, humidity control, and ammonia safety protocols.

- No Reference Projects or Case Studies: Inability to provide verifiable references or site visits to similar installations is a red flag for potential quality or reliability issues.

- Weak After-Sales Support: Poor service networks or limited spare parts availability can drastically increase downtime and operational risk, affecting both quality and safety.

Overlooking Lifecycle Costs and Long-Term Maintenance

Focusing only on the initial purchase price often results in higher total cost of ownership due to poor system quality:

- High Energy Consumption: Inefficient designs or outdated components increase electricity and refrigerant use, driving up operating costs over time.

- Frequent Maintenance Needs: Poor-quality systems require more frequent servicing, increasing labor costs and downtime.

- Short Equipment Lifespan: Inferior materials and construction lead to premature failure, necessitating early replacement.

Insufficient Contractual Safeguards for Quality and IP

Procurement contracts that lack clear provisions on quality assurance and IP rights leave buyers exposed:

- Ambiguous Performance Guarantees: Contracts without measurable performance criteria (e.g., temperature stability, energy efficiency metrics) make it difficult to hold suppliers accountable.

- Missing IP Clauses: Agreements that don’t specify ownership or licensing of software, designs, or process documentation can limit operational flexibility and future upgrades.

- Inadequate Warranty Terms: Limited or poorly defined warranties may not cover critical components or real-world operating conditions.

By proactively addressing these pitfalls—through rigorous supplier evaluation, detailed technical specifications, comprehensive due diligence on IP, and robust contractual terms—organizations can ensure the acquisition of a high-quality, legally sound refrigeration system that supports safe and efficient ice rink operations over the long term.

Logistics & Compliance Guide for Ice Rink Refrigeration System

This guide outlines the key logistics and compliance considerations for the procurement, transportation, installation, operation, and maintenance of ice rink refrigeration systems. Adherence to these guidelines ensures safety, regulatory compliance, system efficiency, and long-term reliability.

System Overview and Key Components

An ice rink refrigeration system typically consists of chillers, refrigerant piping, brine or direct refrigerant circulation systems, pumps, control systems, and safety equipment. These systems often use refrigerants such as ammonia (R-717), carbon dioxide (R-744), or low-GWP synthetic refrigerants, each with specific handling and regulatory requirements.

Regulatory Compliance Framework

All aspects of the refrigeration system must comply with local, national, and international regulations. Key regulatory bodies and standards include:

- Environmental Protection Agency (EPA) – Enforces regulations under the Clean Air Act, particularly Section 608 for refrigerant management and leak prevention.

- Occupational Safety and Health Administration (OSHA) – Governs workplace safety, including Process Safety Management (PSM) for systems containing significant quantities of ammonia.

- American Society of Mechanical Engineers (ASME) – Provides standards for pressure vessel construction (e.g., ASME Boiler and Pressure Vessel Code).

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) – Offers guidance on system design, safety codes (ASHRAE Standard 15), and refrigerant classification.

- International Institute of Ammonia Refrigeration (IIAR) – Publishes best practices and safety standards for ammonia systems.

- National Fire Protection Association (NFPA) – NFPA 55 (Compressed and Liquefied Gases) and NFPA 70 (National Electrical Code) apply to system design and installation.

- Local Building and Fire Codes – Must be reviewed and followed for permits, zoning, and facility layout.

Refrigerant Handling and Environmental Compliance

Proper refrigerant management is critical due to environmental and safety concerns:

- Refrigerant Selection – Choose low-GWP (Global Warming Potential) refrigerants where feasible to align with environmental regulations (e.g., AIM Act in the U.S.).

- Leak Detection and Repair (LDAR) – Implement a formal LDAR program. Mandatory for systems exceeding threshold quantities (e.g., 50 lbs for ammonia under EPA PSM).

- Refrigerant Reclamation and Disposal – Use EPA-certified technicians for refrigerant recovery. Never vent refrigerants into the atmosphere.

- Recordkeeping – Maintain logs of refrigerant usage, leak inspections, repairs, and personnel certification per EPA and local requirements.

Transportation and Logistics

Transporting refrigeration system components and refrigerants requires careful planning:

- Hazardous Material Transport – Ammonia and other refrigerants are classified as hazardous materials (HazMat). Compliance with Department of Transportation (DOT) 49 CFR regulations is mandatory.

- Packaging and Labeling – Use DOT-approved containers, proper labeling (e.g., UN number, hazard class), and shipping documentation.

- Carrier Certification – Engage only certified HazMat carriers with appropriate training and insurance.

- Site Access and Handling – Coordinate delivery schedules with site availability. Ensure adequate crane or lift equipment for heavy components (e.g., chillers, pressure vessels).

Installation and Commissioning

Installation must follow manufacturer specifications and applicable codes:

- Permitting – Obtain all required mechanical, plumbing, electrical, and environmental permits prior to work.

- Qualified Personnel – Use licensed contractors and certified refrigeration technicians (e.g., EPA 608 Type II or III certification).

- Pressure Testing – Conduct hydrostatic and pneumatic tests on piping systems in accordance with ASME B31.5.

- Electrical and Control Integration – Ensure compliance with NEC (NFPA 70) and proper grounding, especially in wet environments.

- Emergency Systems – Install ammonia detection sensors, ventilation systems, emergency shutoffs, and eye wash stations where required.

Operational Safety and Maintenance

Ongoing compliance and safety depend on a structured operations and maintenance program:

- Operator Training – Train staff on system operation, emergency procedures, and PPE use (especially for ammonia systems).

- Preventive Maintenance – Follow manufacturer-recommended schedules for inspections, lubrication, filter changes, and system tuning.

- Process Safety Management (PSM) – Required for ammonia systems above threshold quantities. Includes hazard analysis (HAZOP), management of change (MOC), mechanical integrity, and emergency response planning.

- Ammonia Monitoring – Install fixed gas detectors with alarms and automatic ventilation activation.

- Emergency Response Plan – Develop and regularly drill a site-specific emergency plan in coordination with local fire and HAZMAT teams.

Decommissioning and End-of-Life

At end-of-life, proper decommissioning ensures environmental and safety compliance:

- Refrigerant Recovery – Extract and reclaim refrigerant using certified recovery equipment.

- System Depressurization and Cleaning – Safely purge and clean components to prevent residue hazards.

- Disposal of Components – Recycle metals and dispose of contaminated materials per EPA and local regulations.

- Documentation – Archive system records, including refrigerant disposition certificates and final inspection reports.

Documentation and Auditing

Maintain comprehensive records to demonstrate compliance:

- Refrigerant logs (additions, recovery, leaks)

- Equipment manuals and as-built drawings

- Inspection and maintenance records

- Training and certification records

- Emergency drill reports

- Regulatory correspondence and permits

Regular internal and third-party audits should be conducted to verify compliance and identify improvement opportunities.

Conclusion

Successful logistics and compliance for ice rink refrigeration systems require proactive management of regulatory requirements, safety protocols, and supply chain coordination. By adhering to established standards and maintaining rigorous documentation, facility operators can ensure safe, efficient, and legally compliant operations throughout the system lifecycle.

Conclusion: Sourcing the Ice Rink Refrigeration System

After a thorough evaluation of technical requirements, energy efficiency, cost considerations, and long-term operational sustainability, sourcing a reliable and high-performance refrigeration system is critical to the success and efficiency of an ice rink. The refrigeration system is the core component responsible for maintaining a consistent ice surface quality, ensuring user safety, and minimizing environmental impact.

Based on the analysis, it is recommended to source a refrigeration system that utilizes environmentally friendly refrigerants—such as ammonia (NH₃) or low-GWP synthetic alternatives—combined with energy recovery features and advanced control systems. These systems not only comply with current environmental regulations but also offer significant long-term savings through reduced energy consumption and maintenance costs.

Partnering with an experienced and reputable supplier that provides comprehensive installation, commissioning, training, and after-sales support ensures seamless integration and sustained performance. Additionally, considering modular or scalable designs allows for future expansion or upgrades as operational needs evolve.

In conclusion, a strategic approach to sourcing the ice rink refrigeration system—balancing upfront investment with lifecycle value, sustainability, and operational reliability—will ensure optimal ice quality, energy efficiency, and environmental responsibility, ultimately contributing to the rink’s operational success and reputation.