The global ice maker solenoid market is experiencing steady expansion, driven by rising demand for reliable refrigeration and commercial ice-making equipment. According to Grand View Research, the global commercial refrigeration equipment market—of which ice maker solenoids are a critical component—was valued at USD 44.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects continued growth in the household and commercial appliance sector, citing increased urbanization, food service modernization, and advancements in cooling technology as key drivers. As solenoid valves play an essential role in regulating water flow and ensuring efficient ice production, manufacturers specializing in high-precision, durable solenoids are seeing heightened demand. This growing market momentum underscores the importance of identifying leading ice maker solenoid suppliers who combine innovation, reliability, and scalability—qualities that are shaping the future of cold chain and on-demand ice production systems.

Top 7 Ice Maker Solenoid Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Custom Ice Maker Solenoid Manufacturers, Companies …

Domain Est. 2024

Website: drsolenoid.com

Key Highlights: Discover reliable Ice Maker Solenoids at Dongguan Asite Technology Co., Ltd. Enhance your ice production with our durable, high-performance solutions!…

#2 OEM Frigidaire 241675704 Refrigerator Ice Dispenser Solenoid

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery 365-day returnsShop for genuine 241675704 Frigidaire Refrigerator Ice Dispenser Solenoid today. Find factory authorized parts, great repair advice and same–day shi…

#3 United Refrigeration Inc.

Domain Est. 1995

Website: uri.com

Key Highlights: United Refrigeration is one of the largest wholesale distributors of HVACR equipment, parts, & supplies. Trusted among contractors, supermarkets, mechanics, ……

#4 Johnstone Supply

Domain Est. 1996

Website: johnstonesupply.com

Key Highlights: Johnstone Supply is a leading wholesale distributor for HVACR equipment, parts and supplies available and in-stock at local branches….

#5 Water Feed Solenoid Valve

Domain Est. 1998

Website: follettice.com

Key Highlights: Follett authorized service agent installation, maintenance and repair series – how to replace a water feed solenoid valve….

#6 Solenoid valves, flow meters, pressure regulators and filters

Domain Est. 1999

Website: rpesrl.com

Key Highlights: RPE’s solenoid valves have been developed for many different applications, such as: Irrigation, Food Equipment, Steam, Coffee & Tea, Beverage & Filtration….

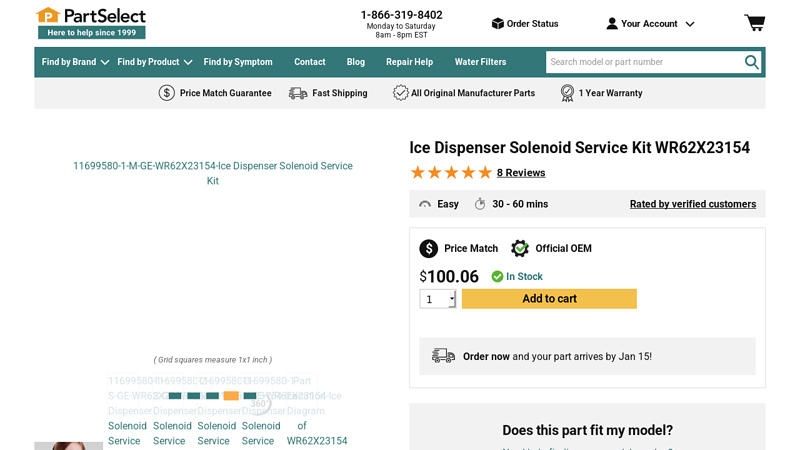

#7 Official GE WR62X23154 Ice Dispenser Solenoid Service Kit

Domain Est. 1999

Website: partselect.com

Key Highlights: In stock Rating 5.0 (8) Ice Dispenser Solenoid Service Kit Specifications: This kit includes 1 cube solenoid, 1 armature, 2 tooth washers and 2 1/4 hex head screws….

Expert Sourcing Insights for Ice Maker Solenoid

H2: 2026 Market Trends for Ice Maker Solenoid

The global ice maker solenoid market is projected to experience steady growth through 2026, driven by increasing demand for advanced refrigeration and ice-making technologies across residential, commercial, and industrial sectors. Key trends shaping the market include:

-

Rising Demand in Commercial Applications: Expansion of the foodservice industry—including restaurants, hotels, and convenience stores—continues to fuel demand for reliable and efficient ice maker systems. Solenoid valves, which control water flow in ice makers, are becoming more critical as businesses prioritize uptime and energy efficiency. This trend is expected to accelerate through 2026, particularly in emerging economies across Asia-Pacific and Latin America.

-

Integration with Smart Appliances: The growing adoption of smart home and connected appliances is influencing solenoid valve design. By 2026, manufacturers are increasingly incorporating IoT-compatible solenoids that allow remote monitoring, predictive maintenance, and improved water usage control. This shift supports energy conservation and enhances user experience, aligning with consumer demand for intelligent home systems.

-

Focus on Energy Efficiency and Sustainability: Regulatory standards and consumer preferences are pushing OEMs to develop eco-friendly ice makers. Solenoid valves with low power consumption, leak-proof designs, and longer service life are in high demand. In regions such as Europe and North America, compliance with energy efficiency directives (e.g., ENERGY STAR, Ecodesign) is driving innovation in solenoid technology.

-

Material and Design Innovations: To improve durability and prevent contamination, manufacturers are adopting advanced materials such as lead-free brass, PPS (polyphenylene sulfide), and high-performance thermoplastics. These materials reduce corrosion and scaling, especially in areas with hard water, thereby extending product lifespan and reducing maintenance costs.

-

Supply Chain Resilience and Localization: Post-pandemic disruptions have prompted companies to reevaluate supply chains. By 2026, there is a noticeable shift toward regional manufacturing and inventory localization, especially in North America and Southeast Asia, to mitigate risks and reduce lead times for solenoid components.

-

Growth in Industrial and Medical Applications: Beyond household and commercial refrigeration, ice maker solenoids are finding new applications in medical cooling systems, laboratory equipment, and industrial processes requiring precise temperature control. This diversification is opening new revenue streams and contributing to market expansion.

In conclusion, the 2026 ice maker solenoid market is marked by technological advancement, sustainability efforts, and expanding application scope. Manufacturers who invest in smart integration, energy efficiency, and supply chain agility are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Ice Maker Solenoids (Quality & IP Protection)

When sourcing ice maker solenoid valves for production, maintenance, or replacement, overlooking critical quality and Ingress Protection (IP) rating factors can lead to premature failure, safety hazards, and costly downtime. Here are common pitfalls to avoid:

Choosing Low-Quality Materials and Construction

Many low-cost solenoids use subpar materials such as brass with high lead content, inferior seals, or weak coil windings. These compromise longevity and reliability, especially in environments with frequent cycling or fluctuating water quality. Poorly constructed solenoids are prone to internal corrosion, coil burnout, and valve seat leakage—leading to inconsistent ice production or complete failure.

Ignoring IP Rating Requirements

The Ingress Protection (IP) rating indicates a solenoid’s resistance to dust and moisture. In refrigeration and ice-making environments, condensation, splashing water, and high humidity are common. Sourcing a solenoid with an inadequate IP rating (e.g., IP65 or lower when IP67/IP68 is needed) exposes the coil to moisture ingress, risking short circuits, electrical faults, or corrosion. Always match the IP rating to the operating environment—particularly for units installed in walk-in freezers or outdoor-facing appliances.

Assuming All Solenoids Are Interchangeable

Even if solenoids appear physically similar, variations in voltage (AC vs. DC), pressure ratings, flow rates, and connection types can lead to improper operation. Using a solenoid not rated for the system’s water pressure or temperature range may result in leaks, reduced efficiency, or catastrophic failure. Always verify electrical specifications and fluid compatibility before substitution.

Overlooking Certification and Compliance

Reputable ice maker solenoids should meet industry standards such as UL, CSA, or NSF for food safety and electrical safety. Sourcing non-certified parts may violate equipment warranties, fail inspections, or pose health risks due to non-potable materials leaching into water lines.

Prioritizing Price Over Long-Term Reliability

While cost is a factor, opting for the cheapest available solenoid often leads to higher total cost of ownership due to frequent replacements and service calls. Investing in a high-quality, appropriately rated solenoid from a trusted supplier ensures better performance, durability, and compliance with safety standards.

By carefully evaluating material quality, IP protection, specifications, certifications, and total lifecycle costs, you can avoid these common sourcing pitfalls and ensure reliable, safe operation of ice-making systems.

Logistics & Compliance Guide for Ice Maker Solenoid

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for the ice maker solenoid to ensure accurate customs classification. Typically, solenoids fall under HS Code 8505.20 (Electromagnetic actuators) or 8481.80 (Valves and similar appliances for pipes, tanks, etc.). Confirm with local customs authorities, as classifications may vary by country and specific product design (e.g., voltage, application). Proper classification affects import duties, taxes, and eligibility for trade agreements.

Regulatory Compliance Requirements

Ensure the solenoid meets relevant international and regional safety and electromagnetic compatibility (EMC) standards. Key certifications include:

– CE Marking (Europe): Compliance with the Low Voltage Directive (LVD) and EMC Directive.

– UL/CSA (North America): Certification to UL 60730 or CSA C22.2 for safety in household appliances.

– RoHS & REACH (EU): Restriction of hazardous substances and chemical safety compliance.

– UKCA (UK): Required for sales in the United Kingdom post-Brexit.

Maintain up-to-date technical documentation and test reports to support compliance claims.

Packaging and Labeling Standards

Use packaging that protects the solenoid from moisture, vibration, and physical damage during transit. Label each unit or package with:

– Product name and model number

– Manufacturer details and country of origin

– Compliance marks (e.g., CE, UL)

– Voltage and electrical specifications

– Handling symbols (e.g., “Fragile,” “This Side Up”)

Ensure labels are durable and legible, adhering to destination country language requirements (e.g., French in Quebec, bilingual labels in Canada).

Import and Export Documentation

Prepare essential shipping and customs documents:

– Commercial Invoice (with value, quantity, HS code)

– Packing List (itemized contents per shipment)

– Bill of Lading or Air Waybill

– Certificate of Origin (required for preferential tariff treatment under trade agreements)

– Compliance Certificates (CE, UL, RoHS, etc.)

Verify export control regulations; while solenoids are generally not controlled, dual-use considerations may apply in certain jurisdictions.

Transportation and Handling Procedures

Ship via reliable freight carriers experienced in handling electronic components. Use anti-static packaging where applicable and avoid extreme temperatures during storage and transport. For air freight, comply with IATA regulations for lithium batteries if the solenoid is part of an assembly containing such components. Monitor shipment tracking and insurance coverage, especially for high-value or time-sensitive deliveries.

Environmental and Disposal Regulations

Ensure the solenoid’s end-of-life disposal aligns with environmental directives such as WEEE (Waste Electrical and Electronic Equipment) in the EU. Provide disposal guidance to customers and consider take-back programs where required. Avoid materials banned under regional environmental laws and document substance declarations for transparency.

Recordkeeping and Audit Readiness

Maintain comprehensive records of compliance certifications, test reports, shipping documents, and supplier declarations for a minimum of 5–10 years, depending on jurisdiction. Conduct periodic internal audits to verify ongoing compliance with logistics and regulatory standards, especially when product specifications or regulations change.

Conclusion for Sourcing Ice Maker Solenoid

After thorough evaluation of the technical specifications, supplier reliability, cost-effectiveness, and availability, sourcing the ice maker solenoid should be finalized with a qualified supplier that offers consistent quality, compliance with industry standards (such as UL or CE certification), and responsive after-sales support. It is recommended to establish long-term procurement agreements with one or two trusted vendors to ensure supply chain stability, minimize downtime in production, and maintain product performance and reliability. Additionally, implementing ongoing quality control measures and periodic supplier audits will further mitigate risks and support continuous improvement in ice maker manufacturing operations.