The global demand for Intermediate Bulk Container (IBC) tote stands has grown significantly alongside the expanding use of IBCs in sectors such as chemical processing, food and beverage, pharmaceuticals, and agriculture. According to Grand View Research, the global IBC market size was valued at USD 3.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is driven by increasing needs for efficient, safe, and reusable storage and transport solutions. As industries prioritize workplace safety and regulatory compliance, the demand for durable and ergonomic IBC tote stands—essential for stabilizing containers during dispensing and minimizing spill risks—has surged. This rising need has fostered a competitive manufacturing landscape, with innovation in materials, load capacity, and design becoming key differentiators. Based on market presence, product range, and customer reviews, here are the top 7 IBC tote stand manufacturers leading the industry.

Top 7 Ibc Tote Stand Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IBC Tote Stands & Basins

Domain Est. 1998

Website: snydernet.com

Key Highlights: Snyder manufacturers and distributes wide variety of IBC Stands and Containment Basins for industrial, commercial and oilfield applications….

#2 IBC Container Manufacturer

Website: werit.eu

Key Highlights: Rating 4.4 (104) WERIT IBCs are available in 300, 600, 800 and 1000 litre sizes. The range of products also offers various models for a diverse area of applications and ……

#3 GCUBE

Domain Est. 1997

Website: greif.com

Key Highlights: The GCUBE IBC tote is a durable, reusable, and cost-effective cube-shaped stackable container. It is well suited for transporting and storing bulk liquids….

#4 IBC Totes, Tanks, & Water Storage

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsWe sell totes with capacities ranging from 135 gallons to 550 gallons. The Cary Company sells a large variety of IBC totes and tanks that come in a selection of ……

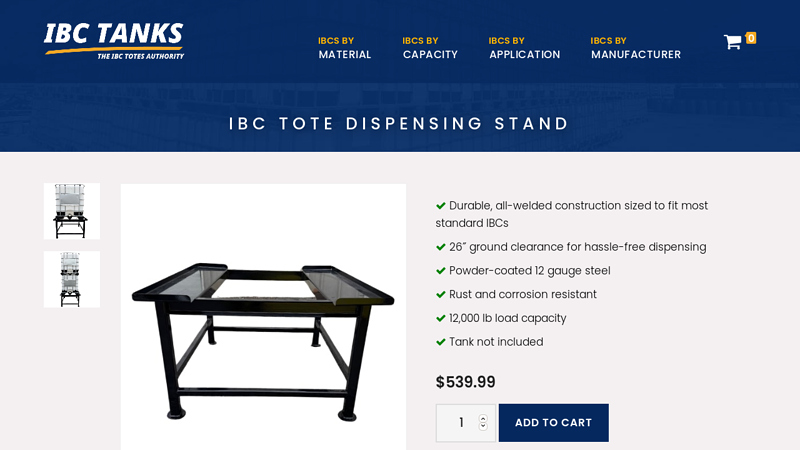

#5 IBC Tote Dispensing Stand

Domain Est. 2003

Website: ibctanks.com

Key Highlights: In stockDurable, all-welded construction sized to fit most standard IBCs · 26″ ground clearance for hassle-free dispensing · Powder-coated 12 gauge steel · Rust and ……

#6 IBC Tote Stand

Domain Est. 2009

Website: denios-us.com

Key Highlights: In stock $250 deliveryIBC Tote Stand – 1 IBC Tote Capacity – Poly Construction – Easy Dispensing – Corrosion Resistant – ✓ Market leader in hazardous storage ✓ Order online now!…

#7 Custom Stainless Steel Tote Bins

Website: totesystems.com

Key Highlights: Custom stainless steel tote bins and IBC containers are ideal for industries that demand robust, adaptable, and hygienic storage solutions….

Expert Sourcing Insights for Ibc Tote Stand

H2: 2026 Market Trends for IBC Tote Stands

The global market for Intermediate Bulk Container (IBC) tote stands is poised for significant evolution by 2026, driven by industrial automation, sustainability initiatives, and increasing demand across key sectors such as chemicals, food and beverage, pharmaceuticals, and agriculture. As companies prioritize operational efficiency, worker safety, and compliance with regulatory standards, IBC tote stands—used to elevate and stabilize IBCs during dispensing, mixing, and storage—are becoming critical components in material handling systems.

One of the most prominent trends shaping the 2026 IBC tote stand market is the growing emphasis on ergonomic design and workplace safety. With rising awareness of occupational health, industries are investing in stands that reduce physical strain during handling and minimize the risk of spills and leaks. Height-adjustable, anti-slip, and corrosion-resistant models are gaining traction, particularly in facilities adopting lean manufacturing principles.

Another key trend is the integration of smart technologies. By 2026, an increasing number of IBC tote stands are expected to feature IoT-enabled sensors for real-time monitoring of load weight, tilt angle, and structural integrity. This data integration supports predictive maintenance, inventory management, and process automation, especially in smart factories and Industry 4.0 environments.

Sustainability is also reshaping product development. Manufacturers are shifting toward recyclable materials like powder-coated steel and stainless steel, reducing the environmental footprint of tote stands. Additionally, modular and stackable designs are gaining popularity due to their space-saving attributes and reusability, aligning with circular economy goals.

Regionally, North America and Europe are expected to lead market growth due to stringent safety regulations and high industrial automation rates. Meanwhile, the Asia-Pacific region is projected to witness the fastest growth, fueled by expanding manufacturing bases in China, India, and Southeast Asia, along with rising investments in chemical and food processing infrastructure.

Lastly, customization is emerging as a competitive differentiator. End users are demanding tailored solutions that match specific container sizes, load capacities, and operational environments. This has prompted manufacturers to offer configurable stand systems and value-added services like on-site installation and compliance certification.

In summary, the 2026 IBC tote stand market will be defined by innovation in safety, digitization, sustainability, and customization. Companies that adapt to these trends will be well-positioned to meet evolving industrial demands and capture growing market opportunities.

Common Pitfalls When Sourcing IBC Tote Stands: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for IBC Tote Stands

Overview

This guide outlines the essential logistics considerations and compliance requirements for the safe handling, transportation, storage, and use of Intermediate Bulk Container (IBC) Tote Stands. IBC Tote Stands provide structural support and elevation for IBCs, facilitating secure dispensing, improved ergonomics, and workplace safety. Adhering to these guidelines ensures regulatory compliance and operational efficiency.

Regulatory Compliance Requirements

OSHA Standards (U.S.)

- 29 CFR 1910.176 – Material Handling and Storage: Requires secure storage and handling of containers to prevent tipping or collapse.

- 29 CFR 1910.144 – Safety Color Code: Encourage use of yellow or high-visibility colors on stands for hazard identification.

- 29 CFR 1910.23 – Guarding Floor and Wall Openings: If the stand creates elevated work platforms, guardrails may be required.

ANSI/ISEA Standards

- ANSI/ISEA Z358.1: If used in environments requiring emergency eyewash stations, ensure stands do not obstruct access.

- ANSI MH26.1 – Designation of Industrial Lift Trucks: Ensure forklift operations around stands comply with load capacity and clearance specifications.

International Standards (ISO & EU)

- ISO 1496-3: Pertains to the design and testing of freight containers; while not directly applicable, general principles of structural integrity apply.

- EU Machinery Directive 2006/42/EC: If the stand incorporates moving parts or is used as part of a processing system, CE marking may be required.

- EN 1004 – Mobile Access Towers: Relevant if the stand doubles as a work platform; compliance with stability and guardrail provisions is mandatory.

Load Capacity & Structural Integrity

Maximum Load Rating

- Clearly label each IBC Tote Stand with its maximum weight capacity (e.g., 4,000 lbs / 1,814 kg).

- Include the weight of the IBC, contents, and any additional accessories (pumps, hoses).

- Never exceed the manufacturer-specified load limit.

Material & Construction Standards

- Use galvanized steel or stainless steel for corrosion resistance, especially in chemical or outdoor environments.

- Welds must be continuous and certified to structural integrity standards.

- Stands must resist deformation under dynamic loads (e.g., during forklift movement).

Transportation & Handling

Load Securing During Transit

- Use straps or chains to secure the IBC to the stand during transport.

- Confirm that the combined IBC/stand unit fits within standard truck or container dimensions.

- Avoid overhang beyond pallet edges to prevent damage during handling.

Forklift & Pallet Jack Compatibility

- Ensure fork openings are standard (typically 40” x 48” or 48” x 48”) and clearly marked.

- Maintain a low center of gravity to reduce tipping risks.

- Train operators on safe lifting techniques and load balance checks.

Storage & Facility Requirements

Floor Load Capacity

- Verify that warehouse or facility flooring can support the total weight of the loaded stand (IBC + stand + contents).

- Use load-distribution plates if floor strength is marginal.

Spacing and Access

- Maintain a minimum 36-inch clearance around stands for safe access and emergency egress.

- Store away from high-traffic zones and emergency equipment.

- Avoid stacking unless specifically designed and certified for multi-level use.

Spill Containment Compliance

- Pair IBC Tote Stands with secondary containment systems (e.g., spill decks) when storing hazardous liquids.

- Ensure containment capacity meets or exceeds 110% of the largest IBC, per EPA Spill Prevention, Control, and Countermeasure (SPCC) Rule (40 CFR 112).

- Use stands with grated platforms to allow drainage into containment sumps.

Inspection, Maintenance & Documentation

Routine Inspection Checklist

- Check for rust, cracks, bent legs, or damaged welds monthly.

- Inspect forklift impact damage and load deformation.

- Verify leg levelers and anti-slip feet are functional.

Maintenance Protocol

- Replace damaged components immediately; do not attempt field welding unless qualified.

- Reapply protective coatings as needed to prevent corrosion.

- Keep maintenance logs for audit and compliance purposes.

Training & Documentation

- Train personnel on proper use, weight limits, and emergency procedures.

- Retain manufacturer specifications, load test certifications, and inspection records for at least three years.

Environmental & Disposal Considerations

End-of-Life Disposal

- Recycle steel components through certified scrap metal recyclers.

- Decontaminate stands exposed to hazardous materials per local environmental regulations (e.g., RCRA guidelines).

- Document disposal in facility waste management logs.

Conclusion

Proper logistics planning and compliance adherence are critical for the safe and legal use of IBC Tote Stands. By following these guidelines, organizations can enhance operational safety, meet regulatory requirements, and extend equipment lifespan. Always consult the manufacturer’s instructions and applicable local, state, and federal regulations for site-specific compliance.

Conclusion for Sourcing IBC Tote Stands

After evaluating various suppliers, materials, design options, and cost considerations, sourcing IBC tote stands requires a strategic approach that balances durability, safety, compliance, and long-term value. Selecting the right stand—typically made from galvanized steel or stainless steel—ensures stable, safe storage and efficient dispensing of bulk liquids while meeting industry safety standards such as OSHA and EPA secondary containment requirements.

Key factors in the sourcing decision include load capacity, corrosion resistance, ease of access for maintenance and spill containment, and compatibility with the specific IBC tote model in use. It is also essential to consider supplier reliability, lead times, and after-sales support, especially when integrating tote stands into large-scale or automated operations.

Ultimately, investing in high-quality, properly sourced IBC tote stands enhances workplace safety, prolongs equipment life, and improves operational efficiency. By prioritizing certified suppliers and standards-compliant products, organizations can ensure reliable performance and regulatory compliance in their liquid storage and handling processes.