The plasma cutting equipment market has experienced steady expansion, driven by increased demand for precision cutting solutions in metal fabrication, automotive, and heavy industrial applications. According to Mordor Intelligence, the global plasma cutting machine market was valued at USD 2.85 billion in 2023 and is projected to grow at a CAGR of over 6.2% through 2029. A key driver of this growth is the rising preference for portable, reliable, and cost-effective systems like the Hypertherm 30 (HT30) air plasma cutters, known for their durability and ease of integration. As demand surges, manufacturers globally have stepped up to produce compatible HT30 torches and components—offering alternatives that maintain performance while improving accessibility. Based on market availability, performance benchmarks, and customer feedback, the following analysis identifies the top three Hypertherm 30 air plasma torch manufacturers leading innovation and capture in this expanding segment.

Top 3 Hypertherm 30 Air Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hypertherm

Domain Est. 1995

Website: hypertherm.com

Key Highlights: Hypertherm is the world’s #1 requested plasma brand, trusted by more businesses and metal fabricators than any other….

#2 Compressor/Power Supply equipment for Powermax30 XP

Domain Est. 2003

Website: weldingweb.com

Key Highlights: The soon to be available Powermax30Air from Hypertherm will not cut the same as a Powermax30XP. While both are 30 amp units, the 30 Air has ……

#3 Powermax 30 xp

Domain Est. 2008

Website: plasmaspider.com

Key Highlights: The cut chart on the Powermax 30 xp lacks a little to be desired what is the cut height and pierce height for the Fine cut tips?…

Expert Sourcing Insights for Hypertherm 30 Air

H2: Market Trends for Hypertherm 30 Air in 2026

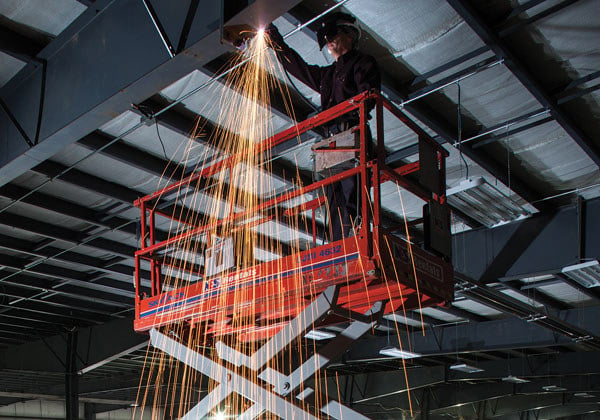

As of 2026, the market for the Hypertherm 30 Air plasma cutting system reflects broader shifts in industrial manufacturing, driven by increased demand for precision, portability, and operational efficiency. The Hypertherm 30 Air, known for its compact design and air-powered plasma cutting capability, continues to hold a strong position in the light to medium-duty metal fabrication sector. Several key trends are shaping its market performance and adoption:

-

Growth in Small and Medium-Sized Enterprises (SMEs):

The rise of agile fabrication shops, metal art studios, and mobile welding/cutting services has fueled demand for affordable, portable cutting solutions. The Hypertherm 30 Air, with its plug-and-play operation and low maintenance requirements, is increasingly adopted by SMEs seeking high-quality plasma cutting without the complexity of high-amperage industrial systems. -

Emphasis on Portability and On-Site Applications:

With construction, maintenance, and repair operations (MRO) increasingly conducted in remote or field locations, portability is a critical factor. The Hypertherm 30 Air’s lightweight design and compatibility with standard air compressors make it ideal for field use, contributing to sustained demand in infrastructure, pipeline, and agricultural equipment repair sectors. -

Integration with Automation and Digital Workflows:

While the Hypertherm 30 Air is primarily a manual cutting tool, 2026 sees growing integration with digital measuring systems and handheld CNC guides. Users are adopting smart accessories and software that enhance cutting accuracy and repeatability, aligning the system with Industry 4.0 trends in smaller-scale operations. -

Competition from Emerging Plasma Technologies:

The market faces pressure from lower-cost plasma cutters manufactured in Asia, particularly in the 20–30 amp range. However, Hypertherm maintains a competitive edge through superior cut quality, consumable longevity, and brand reputation for durability. In 2026, Hypertherm continues to invest in customer education and technical support to reinforce its premium positioning. -

Sustainability and Operational Efficiency:

Manufacturers and end-users are increasingly prioritizing energy efficiency and reduced consumable waste. The Hypertherm 30 Air’s optimized nozzle and electrode designs contribute to longer consumable life and lower operating costs—key selling points in a market focused on reducing total cost of ownership. -

Expansion in Emerging Markets:

In regions such as Southeast Asia, Latin America, and Africa, infrastructure development and local fabrication industries are growing. The Hypertherm 30 Air benefits from distribution partnerships and training programs that support market entry and build brand loyalty in these areas. -

Shift Toward Hybrid Workforce Training:

Vocational training centers and technical schools are incorporating the Hypertherm 30 Air into curricula due to its user-friendly interface and reliability. This trend ensures a steady pipeline of skilled operators, sustaining long-term demand.

In summary, the 2026 market for the Hypertherm 30 Air is characterized by steady demand in niche and mobile applications, supported by Hypertherm’s reputation for quality and ongoing adaptation to evolving user needs. While facing competition on price, the system remains a preferred choice for professionals who prioritize reliability, cut quality, and ease of use.

H2: Common Pitfalls When Sourcing Hypertherm 30 Air – Quality and IP Concerns

When sourcing a Hypertherm 30 Air plasma cutter—especially in the secondary or third-party market—several critical pitfalls related to quality and intellectual property (IP) can compromise performance, safety, and long-term value. Understanding these risks is essential for making informed procurement decisions.

1. Counterfeit or Clone Units (IP Infringement)

- Issue: Numerous third-party manufacturers produce “Hypertherm-style” or “compatible” 30-amp plasma cutters that mimic the original Hypertherm 30 Air design. These clones often infringe on Hypertherm’s patents, trademarks, and proprietary technology.

- Risks:

- Violation of intellectual property rights, especially in regulated industries.

- Lack of official certification or compliance with safety standards (e.g., CE, UL).

- Poor build quality and inconsistent performance.

- Mitigation: Purchase only from authorized Hypertherm distributors or resellers with verifiable documentation. Avoid listings on e-commerce platforms that claim “same as Hypertherm” or “compatible.”

2. Substandard Components Affecting Cut Quality

- Issue: Non-genuine consumables (nozzles, electrodes, swirl rings) or units built with inferior internal components (inverters, cooling fans, PCBs) degrade cutting precision and arc stability.

- Risks:

- Reduced cut speed and poor edge quality.

- Frequent consumable replacement and increased downtime.

- Overheating and premature system failure.

- Mitigation: Ensure consumables are genuine Hypertherm parts (look for part numbers and packaging authenticity). For used units, verify service history and component replacements.

3. Inadequate Ingress Protection (IP Rating)

- Issue: The Hypertherm 30 Air is designed for industrial environments, but counterfeit or poorly maintained units may lack proper IP23 compliance (protection against solid objects and water spray).

- Risks:

- Internal contamination from dust, metal shavings, or moisture.

- Electrical shorts and reduced lifespan.

- Safety hazards in damp or outdoor conditions.

- Mitigation: Confirm the unit meets IP23 rating as per original specifications. Visually inspect seals, vents, and housing integrity—especially for refurbished or used models.

4. Lack of Warranty and Technical Support

- Issue: Cloned or unauthorized resold units typically come without manufacturer warranty or access to technical support.

- Risks:

- No recourse for defective units.

- Difficulty sourcing compatible parts or firmware updates.

- Increased total cost of ownership due to repairs and downtime.

- Mitigation: Source through certified channels that provide valid warranty documentation and post-purchase support.

5. Misrepresentation of Specifications

- Issue: Some sellers exaggerate cutting capacity (e.g., claiming “up to 3/8 inch” when real-world performance is closer to 1/4 inch) or power efficiency.

- Risks:

- Inability to handle required material thickness.

- Overloading circuits or underperforming in production environments.

- Mitigation: Cross-reference claims with official Hypertherm technical datasheets. Verify duty cycle (typically 60% at 25A for Hypertherm 30 Air).

Conclusion

Sourcing a genuine Hypertherm 30 Air plasma cutter ensures reliability, safety, and compliance with IP standards. Avoid the pitfalls of counterfeits, subpar components, and misrepresented specs by purchasing through authorized channels, verifying authenticity, and confirming IP and quality certifications. Protecting IP integrity also supports innovation and long-term equipment performance.

H2: Logistics & Compliance Guide for Hypertherm 30 Air

This guide outlines key logistics and compliance considerations for the international shipment and use of the Hypertherm 30 Air plasma cutting system. Adherence ensures smooth transit, regulatory compliance, and safe operation.

H2: Export Classification & Documentation

- Export Control Classification Number (ECCN): Typically classified under EAR99 (Export Administration Regulations, No License Required for most destinations). Always verify the specific ECCN with Hypertherm or your export compliance officer before shipment, as configurations or end-use may alter classification.

- HS Code (Harmonized System): Commonly 8515.21.00 (Arc-welding apparatus; plasma-arc cutting and welding machines). Confirm the exact code with your freight forwarder or customs broker for the destination country.

- Required Documentation:

- Commercial Invoice (Detailed, including full product description, HS code, value, weight, Harmonized System number)

- Packing List (Itemized, per package, including weights & dimensions)

- Bill of Lading (Ocean) or Air Waybill (Air)

- Certificate of Origin (May be required; specify country of manufacture – USA)

- Export Declaration (e.g., AES Filing in the US via AESDirect)

H2: Packaging & Handling

- Original Packaging: Ship in Hypertherm-provided packaging whenever possible. It is designed for protection during transit.

- Securing: Ensure the unit and accessories are tightly secured within the packaging to prevent movement. Use void fill (e.g., foam, air pillows) as needed.

- Labeling:

- Clearly label “FRAGILE” and “THIS SIDE UP”.

- Include handling labels per IATA/IMDG regulations if applicable (e.g., “Battery, Wet, Non-spillable” if battery-equipped).

- Display accurate shipping labels with full consignee/consignor details.

- Weight & Dimensions: Provide accurate gross weight and external dimensions (L x W x H) for each package to the carrier.

H2: Battery Shipping Compliance (If Applicable)

- Lithium Battery: The Hypertherm 30 Air contains a non-spillable, valve-regulated lead-acid (VRLA) battery. While not lithium, VRLA batteries have specific regulations.

- IATA DGR / IMDG Code: Classify under UN2794 (Lead-acid batteries, wet, filled with acid, electric storage) or UN2796 (Batteries, wet, filled with alkali, electric storage) depending on electrolyte. VRLA batteries often qualify for Special Provision 238 (SP 238) allowing transport as “Not Restricted” under certain conditions (e.g., fully charged, contained within equipment, protected from short circuits).

- Packaging: Battery must be securely installed in the equipment or separately packed in non-conductive inner packaging preventing short circuits. Outer packaging must be strong enough to withstand handling.

- Marking: If shipped under SP 238 (“Not Restricted”), mark packages: “BATTERY, WET, NON-SPILLABLE, WITH EQUIPMENT”. Include the UN number and proper shipping name if not using SP 238.

- Documentation: Declare batteries on the Air Waybill/Bill of Lading and Commercial Invoice. Include “Not Restricted, IATA DGR Special Provision A123 (or applicable SP)” on the AWB if applicable. Consult your carrier for specific declaration requirements.

H2: Import Requirements (Destination Country)

- Duties & Taxes: Import duties, VAT, and other taxes are the responsibility of the consignee. Rates vary significantly by country. The commercial invoice value is used for calculation.

- Conformity Markings: The Hypertherm 30 Air bears relevant safety certifications (e.g., CE, UKCA, RCM). Verify if additional local certification or registration is required for import or sale (e.g., INMETRO in Brazil, KC in Korea). The end-user is responsible for compliance with local electrical codes.

- Local Regulations: Be aware of any import restrictions or permits required in the destination country for industrial equipment.

H2: Carrier Selection & Shipping

- Mode: Air freight is common for speed. Ocean freight may be economical for large volumes.

- Carrier Requirements: Select a carrier experienced in shipping industrial equipment and batteries. Provide them with the correct classification (UN number, proper shipping name, class) and documentation.

- Insurance: Ship with adequate cargo insurance covering the full replacement value.

H2: End-User Compliance & Safety

- Safety Standards: The Hypertherm 30 Air is designed to meet relevant international safety standards (e.g., IEC/EN 60974-1, -7). The end-user must operate it according to the provided Safety Manual and local regulations.

- Electrical Requirements: Ensure the end-user has the correct power supply (voltage, phase, frequency) as specified in the manual.

- Ventilation: Adequate ventilation is required during plasma cutting to remove fumes and gases.

- Personal Protective Equipment (PPE): End-users must wear appropriate PPE (e.g., welding helmet, gloves, protective clothing, hearing protection).

Important: This guide provides general information. Always consult:

1. The latest Hypertherm product documentation and compliance certificates.

2. Your organization’s export/import compliance officer.

3. A licensed freight forwarder and customs broker.

4. The relevant authorities in the destination country.

Regulations change frequently; verify requirements immediately before shipment.

Conclusion for Sourcing Hypertherm 30 Air Plasma Cutters

Sourcing the Hypertherm Powermax 30 AIR plasma cutter presents a reliable and efficient solution for operators requiring a portable, easy-to-use, and high-performance cutting system for thin to medium-thickness metals. Its integrated air compressor design eliminates the need for external gas supplies, making it an ideal choice for job shops, maintenance teams, and field service applications where mobility and simplicity are essential.

The Powermax 30 AIR delivers clean, precision cuts on conductive materials up to 10 mm (3/8 in) with a rated cutting speed, while maintaining rugged durability in demanding environments. Backed by Hypertherm’s reputation for superior build quality, advanced plasma technology, and excellent customer support, this system ensures long-term reliability and lower operating costs through consumable efficiency and reduced maintenance.

Procuring the Hypertherm Powermax 30 AIR offers a strong return on investment through increased productivity, minimal downtime, and consistent cut quality. It is a recommended solution for businesses seeking a versatile and dependable air plasma system that combines performance, portability, and ease of use. Consider partnering with authorized Hypertherm distributors to ensure genuine products, warranty coverage, and access to technical support and training.