The global hydroponic systems market is experiencing robust growth, driven by rising demand for sustainable agriculture, urban farming, and efficient use of limited arable land. According to a 2023 report by Mordor Intelligence, the market was valued at USD 1.27 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.4% from 2024 to 2029. Similarly, Grand View Research estimates that the hydroponics market size reached USD 1.3 billion in 2023 and is expected to expand at a CAGR of 12.1% through 2030, fueled by advancements in controlled environment agriculture and increasing adoption in both commercial and residential sectors. This surge in demand has led to a proliferation of hydroponic system kit manufacturers offering scalable, user-friendly solutions for beginners and commercial growers alike. As the industry evolves, a select group of manufacturers are leading innovation, reliability, and market reach—shaping the future of soilless cultivation.

Top 10 Hydroponic System Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About

Website: greenfuturehydro.com

Key Highlights: We are a global manufacturer of sustainable hydroponic systems, dedicated to promoting greener and smarter agriculture worldwide. Our advanced systems ……

#2 CropKing Inc

Domain Est. 1998

Website: cropking.com

Key Highlights: We’ve manufactured and sold greenhouse structures, hydroponic growing systems, growing supplies, and education materials. … has over 30 years of experience in ……

#3 Nutrients

Domain Est. 1998

Website: generalhydroponics.com

Key Highlights: Providing superior results in both soil and hydroponic gardens, our hydroponic nutrient products offer total nutrition as a mineral-based plant food….

#4 Nutraponics: Buy Hydroponic Tower Systems

Domain Est. 2008

Website: nutraponics.com

Key Highlights: Free delivery 30-day returnsBuy premium indoor hydroponic tower systems. Grow fresh vegetables year-round. Free shipping, 60-day returns. Shop now! Nutraponics….

#5 EZ GRO Garden

Domain Est. 2010

Website: ezgrogarden.com

Key Highlights: We produce vertical gardening kits that are simple to use and provide serious results. Our kits are unique because they include virtually everything you need….

#6 Grow Generation

Domain Est. 2014

Website: growgeneration.com

Key Highlights: 7-day returnsExplore GrowGeneration, the largest hydroponics store in the U.S., offering grow lights, nutrients, tents & more. Shop online or find a store near you….

#7 Hydroponic Growing Systems

Domain Est. 2016

Website: growrillahydroponics.com

Key Highlights: 14-day returnsGrowrilla Hydroponics is a 100% Italian brand of hydroponic growing systems, designed and manufactured in Italy by growers for growers….

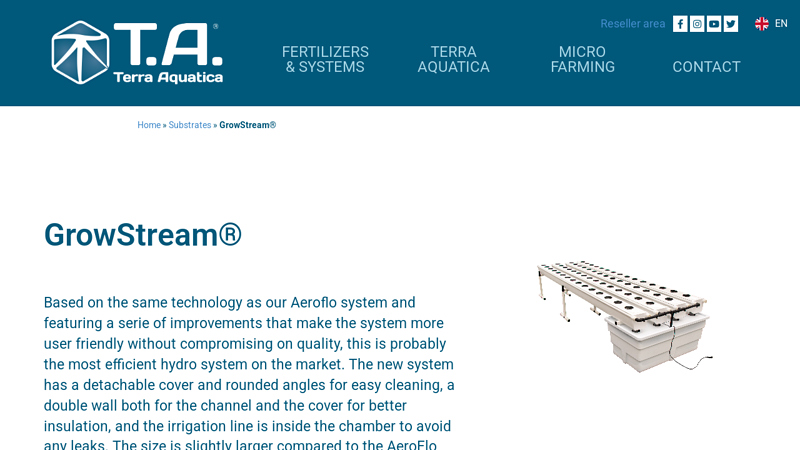

#8 GrowStream®

Domain Est. 2017

Website: terraaquatica.com

Key Highlights: It is the only hydroponic system on the market adapted to growing large plants and not only lettuces or herbs. Ranging from 10 to 120 plants per unit….

#9 FarmBox Foods

Domain Est. 2017

Website: farmboxfoods.com

Key Highlights: Our company develops hydroponic container farms — sustainable, eco-friendly methods that promote locally-grown food and year-long harvests….

#10 Hydroponics Europe

Domain Est. 2019

Website: hydroponicseuro.com

Key Highlights: 60-day returnsHydroponics Europe is a Netherlands based supplier of Hydroponic supplies and the official distributor of Masterblend Hydroponic Fertilizer in Europe….

Expert Sourcing Insights for Hydroponic System Kit

H2: Projected 2026 Market Trends for Hydroponic System Kits

The hydroponic system kit market is poised for significant growth and transformation by 2026, driven by advancements in technology, rising consumer interest in sustainable agriculture, and supportive government policies. Several key trends are expected to shape the landscape of this industry over the coming years.

-

Increased Urban Farming Adoption: With urbanization accelerating globally, space-efficient farming solutions like hydroponic system kits are gaining traction among city dwellers. By 2026, urban households, community gardens, and commercial vertical farms are anticipated to adopt pre-packaged hydroponic kits at a faster rate, especially in densely populated regions such as North America, Europe, and parts of Asia-Pacific.

-

Smart Technology Integration: Hydroponic kits are evolving into smart, IoT-enabled systems. By 2026, the market will see wider integration of sensors, automated nutrient dosing, mobile app controls, and AI-driven analytics. These features will allow users to monitor pH levels, temperature, and nutrient concentrations remotely, improving yield efficiency and reducing human error.

-

Expansion of E-commerce and Direct-to-Consumer Sales: Online platforms will continue to be a dominant channel for hydroponic kit distribution. Brands are expected to invest in subscription models, offering refill nutrients, seeds, and replacement parts, thereby creating recurring revenue streams. Enhanced digital marketing and educational content will further drive consumer engagement.

-

Focus on Sustainability and Circular Design: Environmental consciousness will influence product development. By 2026, leading manufacturers will prioritize recyclable materials, energy-efficient LED lighting, and water-saving designs. Kits using modular or upgradable components will appeal to eco-conscious consumers and reduce electronic waste.

-

Growth in Educational and DIY Markets: Hydroponic kits are increasingly used in schools, STEM programs, and home education. The DIY segment will expand with customizable kits that cater to hobbyists and tech-savvy users. This trend will be supported by online tutorials, forums, and augmented reality (AR) assembly guides.

-

Regional Market Diversification: While North America and Europe remain dominant markets, regions like Southeast Asia, the Middle East, and Africa are expected to witness rapid growth due to food security concerns and government-backed agricultural modernization initiatives. Localized kits designed for regional crops and climates will emerge.

-

Consolidation and Innovation Among Key Players: The competitive landscape will likely see consolidation, with major agri-tech companies acquiring niche hydroponic startups. Simultaneously, innovation in compact, low-cost entry-level kits will open the market to first-time users, further democratizing access to indoor farming.

In conclusion, by 2026, the hydroponic system kit market will be characterized by technological sophistication, environmental responsibility, and broader consumer accessibility, positioning it as a cornerstone of the future of sustainable food production.

Common Pitfalls When Sourcing a Hydroponic System Kit (Quality & Intellectual Property)

Sourcing a hydroponic system kit involves more than just finding the lowest price. Overlooking quality and intellectual property (IP) considerations can lead to operational failures, legal risks, and reputational damage. Here are the key pitfalls to avoid:

Poor Build Quality and Material Durability

Many low-cost hydroponic kits, especially those from less reputable suppliers, use substandard materials such as thin, UV-sensitive plastics or corrosion-prone metals. These degrade quickly under constant exposure to water, nutrients, and light, leading to leaks, structural failures, and contamination. Always verify material specifications—look for food-grade, UV-stabilized plastics and rust-resistant components like stainless steel or coated hardware.

Inaccurate or Incomplete System Design

Some kits are poorly engineered, resulting in inefficient water flow, inadequate aeration, or improper root zone support. This compromises plant health and yield. Ensure the design follows proven hydroponic principles (e.g., proper NFT slope, sufficient pump capacity, and reservoir volume). Request detailed schematics and user manuals before purchase.

Lack of Certification and Safety Standards

Reputable hydroponic systems should comply with relevant safety and environmental standards (e.g., CE, RoHS, or NSF certifications). Kits lacking these may use harmful chemicals in plastics or unsafe electrical components (e.g., substandard water pumps), posing health and fire hazards. Verify compliance documentation to mitigate risk.

Counterfeit or IP-Infringing Products

A significant risk when sourcing, especially from online marketplaces or unknown manufacturers, is purchasing kits that copy patented designs or branded systems. Using such products exposes buyers to legal liability for IP infringement. Always investigate the supplier’s legitimacy and confirm whether the product design is licensed or original. Avoid kits that closely mimic well-known brands without authorization.

Inadequate Technical Support and Documentation

Low-quality suppliers often provide minimal or inaccurate assembly instructions, troubleshooting guides, or customer support. This can lead to incorrect setup, system failure, and increased downtime. Prioritize suppliers who offer comprehensive documentation, multilingual support, and accessible technical assistance.

Hidden Costs from Poor Quality

While a kit may appear cost-effective upfront, poor quality often leads to frequent replacements, maintenance, and crop loss. These hidden costs far exceed the initial savings. Conduct a total cost of ownership analysis, considering durability, reliability, and support.

Mitigation Strategies

- Request Samples: Test the kit’s materials and performance before bulk ordering.

- Audit Suppliers: Evaluate manufacturing processes and quality control measures.

- Verify IP Status: Consult legal experts to confirm designs do not infringe existing patents.

- Choose Reputable Brands or Certified Distributors: Reduce risk through established supply chains.

By focusing on quality assurance and respecting intellectual property, buyers can ensure reliable, legal, and efficient hydroponic operations.

Logistics & Compliance Guide for Hydroponic System Kit

Overview

This guide outlines the essential logistics and compliance considerations for the distribution, import, export, and sale of a Hydroponic System Kit. Adherence to these guidelines ensures efficient operations, legal compliance, and customer satisfaction across domestic and international markets.

Product Classification & Tariff Codes

Hydroponic System Kits are typically classified under the Harmonized System (HS) Code 8436.80 – “Parts and accessories for agricultural, horticultural, or forestry machinery.” However, classification may vary by country and kit composition.

– Confirm exact HS code with local customs authorities.

– Kits containing electrical components (e.g., pumps, timers) may require additional sub-categorization.

– Provide a detailed Bill of Materials (BOM) to customs brokers for accurate classification.

Packaging & Shipping Requirements

- Packaging: Use durable, recyclable materials to prevent damage during transit. Clearly label boxes with product name, weight, dimensions, and handling instructions (e.g., “Fragile,” “This Side Up”).

- Kit Contents: Include all components (grow trays, reservoirs, pumps, tubing, instructions) in a single, sealed package unless shipping in bulk.

- Shipping:

- Use carriers experienced in handling consumer goods and e-commerce logistics.

- Offer tracking and insurance options.

- For international shipments, comply with IATA and IMDG regulations if batteries or hazardous components are included (rare for standard kits).

Import & Export Compliance

- Export Controls: Most hydroponic kits are not subject to export restrictions. However, verify if any components (e.g., high-pressure pumps, specialized sensors) are regulated under dual-use or technology control lists.

- Import Regulations:

- Check destination country’s import duties, taxes (e.g., VAT, GST), and product safety standards.

- Some countries may require conformity assessments (e.g., CE marking for EU, FCC for electronic parts in the U.S.).

- Prohibited or restricted materials (e.g., certain plastics, lead-based fittings) must be avoided.

Regulatory & Safety Standards

- Electrical Components:

- Pumps and timers must comply with local electrical safety standards (e.g., UL/ETL in U.S., CE in EU, RCM in Australia).

- Include voltage and power specifications on labels and manuals.

- Materials Safety:

- All materials in contact with water or plants must be food-grade and non-toxic (e.g., FDA-compliant plastics).

- Avoid BPA, phthalates, and other regulated substances.

- Labeling:

- Include manufacturer details, model number, warning labels, and multilingual instructions where applicable.

- For EU markets, comply with GPSR (General Product Safety Regulation).

Environmental & Sustainability Compliance

- WEEE (EU): If the kit includes electronic components, ensure compliance with Waste Electrical and Electronic Equipment directives. Provide take-back or recycling information.

- RoHS (EU/UK): Restrict use of hazardous substances (lead, mercury, cadmium, etc.) in electrical and electronic parts.

- Packaging Waste: Comply with local packaging waste regulations (e.g., Germany’s VerpackG, France’s AGEC Law) by joining producer responsibility organizations if required.

Documentation Requirements

Maintain and provide the following documents:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Safety and Compliance Certificates (CE, UL, RoHS, etc.)

– User Manual (translated as needed)

– Warranty and Return Policy

Labeling & Language Requirements

- Include safety warnings in the official language(s) of the destination country.

- User manuals must be available in local languages for EU, Canada, and other regulated markets.

- QR codes linking to digital manuals and support can reduce print costs and improve accessibility.

Returns & Reverse Logistics

- Establish a clear return policy compliant with local consumer laws (e.g., 14-day return window in EU).

- Design packaging to support reuse or easy recycling.

- Provide prepaid return labels where legally required or as a customer service benefit.

Conclusion

Successfully managing the logistics and compliance of a Hydroponic System Kit requires attention to classification, safety standards, documentation, and regional regulations. By proactively addressing these elements, businesses can minimize delays, avoid penalties, and deliver a reliable product to customers worldwide. Regularly review regulatory updates and consult with legal and logistics experts when expanding into new markets.

In conclusion, sourcing a hydroponic system kit requires careful consideration of several key factors, including system type, scalability, budget, ease of use, and intended application—whether for personal use, commercial production, or educational purposes. Evaluating reputable suppliers, comparing product quality and customer support, and ensuring compatibility with local growing conditions are essential steps in making an informed decision. Investing in a reliable hydroponic kit not only promotes efficient resource use and higher crop yields but also supports sustainable agriculture practices. By selecting the right system from a trustworthy source, growers can establish a successful soil-free cultivation setup that meets their immediate needs and supports long-term growth and innovation in modern farming.