The global hydrostatic testing equipment market is experiencing robust growth, driven by increasing regulatory demands for pipeline and pressure vessel safety across oil & gas, water infrastructure, and industrial manufacturing sectors. According to a report by Mordor Intelligence, the hydrostatic testing equipment market was valued at USD 1.35 billion in 2023 and is projected to grow at a CAGR of over 5.8% during the forecast period 2024–2029. This expansion is fueled by rising investments in energy infrastructure, especially in emerging economies, alongside stricter safety compliance standards mandating regular equipment validation. With aging pipeline networks and the development of new LNG and water transmission projects, the demand for reliable, high-performance hydro testers has never been more critical. In this evolving landscape, leading manufacturers are differentiating themselves through technological innovation, automation, and enhanced data logging capabilities. Based on market presence, product range, global reach, and customer reviews, the following list highlights the top 10 hydro testers manufacturers shaping the industry’s future.

Top 10 Hydro Testers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydrostatic Testers & Hose Testers

Domain Est. 1998

Website: hydraulictechnology.com

Key Highlights: Hydraulic Technology Inc. has been manufacturing hydrostatic test equipment to the US Military, aerospace and industrial sectors for over 30 years….

#2 to Webtec

Domain Est. 1995

Website: webtec.com

Key Highlights: We are specialist manufacturers of hydraulic measurement and control products helping to improve the productivity of heavy machinery….

#3 Hydro, Inc.

Domain Est. 1996

Website: hydroinc.com

Key Highlights: As the largest independent pump repairer with over 50 years of expertise, Hydro, Inc. delivers repair, condition monitoring, and worldwide service center ……

#4 RICE Hydro, Inc.

Domain Est. 1996

Website: ricehydro.com

Key Highlights: Fire Hose Testers. Trust us with all your fire hose testing needs, offering exceptional quality and superior design in hose testing equipment: Fire Departments, ……

#5 Hydro

Domain Est. 1997

Website: hydro-test.com

Key Highlights: Hydro-Test Products is a leading manufacturer of advanced cylinder testing equipment, offering a wide range of automated and manual solutions for various ……

#6 Hydro Instruments

Domain Est. 1998

Website: hydroinstruments.com

Key Highlights: Hydro Instruments is the top manufacturer for gas chlorinators, chlorination systems, liquid analyzers, and other equipment. Visit our website to learn more…

#7 General Pump

Domain Est. 1998

Website: gpequip.com

Key Highlights: For over 50 years, we have been providing top quality hydrostatic test pumps. Home of the Hydro-Test Hydrostatic Tester!…

#8 Hydrotesters

Domain Est. 2000

Website: pemusa.com

Key Highlights: Plastics Extrusion Machinery LLC (PEM) offers both submersible and non-submersible style hydrostatic testing machines (hydrotesters)….

#9 High and Low Pressure Hydrostatic Testing Machines

Domain Est. 2000

Website: extinval.com

Key Highlights: At Extinval, we provide hydrostatic testing machines that ensure the safety and performance of pressure equipment, such as fire extinguishers, hoses, ……

#10 Hydrostatic testing: fast and accurate

Domain Est. 2007

Website: fivesgroup.com

Key Highlights: Fives offers Taylor-Wilson hydrostatic pipe testers to accommodate any length variation, as well as tube and pipe testing with diameters from less than 25 mm ……

Expert Sourcing Insights for Hydro Testers

H2: Projected 2026 Market Trends for Hydro Testers

The global hydro tester market is poised for significant evolution by 2026, driven by increasing industrial safety regulations, infrastructure development, and technological innovation. Hydro testers—devices used to verify the integrity and strength of pressure vessels, pipelines, and other containment systems through hydrostatic testing—are becoming more sophisticated and integral across key sectors such as oil and gas, water supply, construction, and manufacturing.

-

Regulatory and Safety Drivers

By 2026, stringent safety and compliance standards—especially in North America, Europe, and parts of Asia-Pacific—are expected to mandate more frequent and reliable hydrostatic testing. Regulatory bodies such as OSHA (U.S.), ISO, and API are tightening inspection protocols, pushing industries to adopt advanced hydro testers. This regulatory push is a primary growth catalyst, particularly in aging infrastructure markets where pipeline integrity is a growing concern. -

Growth in Energy and Infrastructure Sectors

The continued expansion of energy infrastructure—including LNG terminals, cross-border pipelines, and offshore drilling—will increase demand for hydro testers. Emerging markets in Southeast Asia, the Middle East, and Africa are investing heavily in water and gas distribution networks, where hydrostatic testing is a critical phase in commissioning. By 2026, these regions are expected to become high-growth markets for hydro testers. -

Technological Advancements

The hydro tester market is shifting toward smart, digital, and automated solutions. By 2026, expect widespread adoption of: - IoT-enabled hydro testers with real-time pressure monitoring and remote data logging

- Integration with cloud-based platforms for compliance documentation and predictive maintenance

-

Portable, battery-operated units with digital readouts and automated shut-off features

These innovations enhance accuracy, reduce human error, and improve operational efficiency—making them attractive to both large enterprises and field service contractors. -

Rise of Rental and Service Models

An increasing number of end-users are opting for rental or service-based models instead of capital purchases. This trend is especially visible in project-based industries like construction and pipeline installation. By 2026, the hydro testing service market is expected to grow faster than equipment sales, with companies offering bundled solutions that include equipment, calibration, and certified technicians. -

Sustainability and Environmental Compliance

Environmental awareness is influencing hydro testing practices. Closed-loop hydro testers that recycle test water and minimize waste are gaining traction. By 2026, eco-friendly testing solutions are expected to become a competitive differentiator, particularly in regions with strict environmental regulations. -

Market Consolidation and Competition

The hydro tester market is witnessing consolidation, with key players acquiring niche technology providers to expand their digital testing portfolios. Companies like TQC, Superior Energy, and Gardner Denver are investing in R&D to offer integrated testing systems. Meanwhile, regional manufacturers in China and India are increasing their footprint through cost-competitive offerings. -

Skills Gap and Training Demand

As hydro testers become more complex, there is a growing need for skilled technicians. By 2026, training programs and certification courses for hydrostatic testing are expected to expand globally, supported by equipment manufacturers and industry associations.

Conclusion

By 2026, the hydro tester market will be characterized by smart, connected, and compliant testing solutions driven by safety mandates, infrastructure growth, and digital transformation. Companies that innovate in automation, data integration, and sustainability will lead the market, while service-based models and emerging geographies offer new revenue opportunities.

Common Pitfalls Sourcing Hydro Testers (Quality, IP)

Sourcing hydro testers involves critical considerations beyond price and availability. Overlooking quality and intellectual property (IP) aspects can lead to significant operational, legal, and safety risks. Here are the key pitfalls to avoid:

Quality-Related Pitfalls

1. Inadequate Pressure Rating Verification

Relying solely on manufacturer claims without independent validation of the hydro tester’s maximum pressure rating is dangerous. Using equipment beyond its true capacity risks catastrophic failure, endangering personnel and facilities. Always demand certified test reports (e.g., ASME, PED) and verify traceability to recognized standards.

2. Poor Material and Construction Quality

Low-cost testers may use substandard materials (e.g., inferior stainless steel, weak seals) or poor welding practices. This leads to premature leaks, corrosion, or structural failure under pressure. Inspect build quality meticulously and request material certifications (e.g., MTRs) to ensure compatibility with test media and environmental conditions.

3. Lack of Calibration and Accuracy

Hydro testers with uncalibrated or inaccurate pressure gauges and sensors provide false data, compromising test validity. Ensure the supplier provides recent calibration certificates (e.g., NIST-traceable) and specifies accuracy tolerances. Verify recalibration intervals and service support.

4. Non-Compliance with Safety Standards

Sourcing testers that don’t meet regional safety standards (e.g., ASME B31.3, API 570, ISO 14692, local pressure equipment directives) creates legal and operational liabilities. Confirm certifications (CE, UKCA, CRN) and ensure safety features like burst discs, pressure relief valves, and emergency stops are correctly implemented.

5. Insufficient Documentation and Traceability

Poor documentation (missing manuals, schematics, or material records) complicates maintenance, compliance audits, and incident investigations. Demand complete technical files, including design calculations, test records, and as-built drawings for full traceability.

IP-Related Pitfalls

1. Infringement of Patented Technology

Using hydro testers that incorporate patented components (e.g., proprietary pump designs, control systems) without authorization exposes your organization to infringement lawsuits. Conduct due diligence on the supplier’s IP ownership and request indemnification clauses in contracts.

2. Unclear Software and Control System Licensing

Modern hydro testers rely on embedded software for automation and data logging. Sourcing units with unlicensed or poorly documented software risks legal action and limits customization. Verify software licensing terms, source code access (if needed), and update rights.

3. Lack of IP Protection in Contracts

Failing to define IP ownership in procurement agreements can lead to disputes, especially for custom-designed testers. Ensure contracts explicitly state that any modifications or bespoke features developed for your use are owned by your organization or properly licensed.

4. Counterfeit or Clone Equipment

Purchasing from unauthorized distributors may result in counterfeit testers that mimic reputable brands but lack IP legitimacy and quality controls. This risks safety failures and voids warranties. Source only from authorized channels and verify authenticity through serial numbers and supplier credentials.

5. Data Ownership and Security Risks

Test data generated by smart hydro testers may contain sensitive operational or proprietary information. Ensure agreements clarify data ownership and include provisions for cybersecurity (e.g., encryption, access controls) to prevent IP theft or unauthorized data use.

Avoiding these pitfalls requires rigorous supplier vetting, clear contractual terms, and adherence to technical and legal standards—ensuring reliable, safe, and legally compliant hydro testing operations.

H2: Logistics & Compliance Guide for Hydro Testers

This guide outlines the essential logistics and compliance procedures for personnel involved in hydrostatic testing operations (Hydro Testers). Adherence to these protocols ensures safety, regulatory compliance, equipment integrity, and operational efficiency.

H2: 1. Pre-Testing Planning & Logistics

1.1 Site Assessment & Preparation

– Conduct a thorough site inspection to evaluate accessibility, environmental conditions, and safety hazards.

– Ensure the test area is clear of unauthorized personnel and designated with visible warning signage (e.g., “Danger – High Pressure Testing in Progress”).

– Confirm availability of emergency response equipment (e.g., first aid kits, fire extinguishers, communication devices).

1.2 Equipment Transport & Handling

– Use appropriate lifting and handling equipment (e.g., forklifts, cranes) to move test components; follow load capacity guidelines.

– Secure all high-pressure hoses, pumps, valves, and fittings during transit to prevent damage.

– Inspect all equipment for wear, corrosion, or defects before deployment.

1.3 Personnel & Documentation

– Ensure all Hydro Testers are certified, trained, and familiar with the test plan and emergency procedures.

– Verify that required permits (e.g., work permits, environmental clearances) are obtained prior to testing.

– Maintain a checklist of all equipment, calibration certificates, and test specifications.

H2: 2. Regulatory & Safety Compliance

2.1 Regulatory Standards

– Comply with relevant regulations, including:

– OSHA 29 CFR 1910 (General Industry Standards)

– ASME B31.3 (Process Piping) or B31.4/B31.8 (Pipeline Systems)

– API 570 (Piping Inspection, Repair, Alteration, and Rerating)

– Local environmental and pressure testing regulations

– Follow manufacturer specifications and client requirements.

2.2 Pressure Testing Procedures

– Use calibrated pressure gauges and relief valves (certified within the last 12 months).

– Conduct tests at the specified pressure (typically 1.5x the maximum allowable working pressure) for the required duration.

– Perform testing in incremental stages with hold periods to monitor for leaks or deformation.

– Never exceed the test pressure limit or bypass safety devices.

2.3 Environmental Compliance

– Use biodegradable or non-toxic test medium (e.g., water with corrosion inhibitor) when discharging into the environment.

– Capture and dispose of test water according to local wastewater regulations.

– Prevent contamination of soil or water sources through secondary containment or spill kits.

H2: 3. On-Site Execution & Monitoring

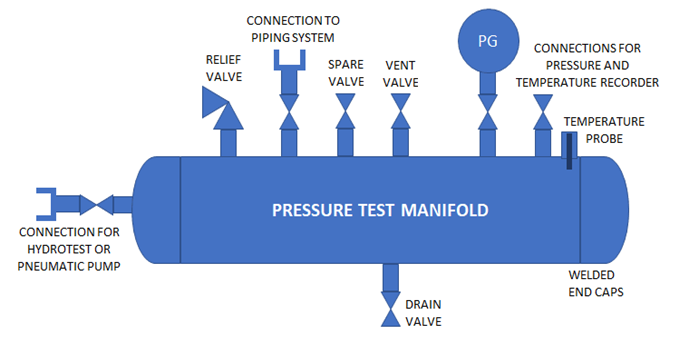

3.1 Test Setup

– Isolate the test section from live systems using blinds, spades, or double block and bleed valves.

– Vent all air from the system before pressurization to prevent pressure surges.

– Connect data loggers or recording devices if required for verification.

3.2 Real-Time Monitoring

– Assign a qualified observer to monitor pressure gauges, hoses, and test integrity continuously.

– Maintain constant communication between team members using radios or hand signals.

– Halt testing immediately if leaks, unusual noises, or pressure fluctuations occur.

3.3 Emergency Response

– Establish an emergency shutdown (ESD) procedure and ensure all personnel know how to activate it.

– Evacuate the test zone if a rupture or uncontrolled release occurs.

– Report incidents to supervisors and regulatory bodies as required.

H2: 4. Post-Test Procedures

4.1 Depressurization & Drainage

– Slowly and safely release pressure through controlled venting.

– Drain test medium completely and inspect for residual water or contaminants.

– Open vents and drains to ensure the system is fully depressurized before disassembly.

4.2 Documentation & Reporting

– Complete a Hydro Test Report including:

– Date, location, and equipment tested

– Test pressure, duration, and results

– Names of personnel and certifications

– Calibration records for instruments used

– Submit reports to the client and regulatory authorities as required.

4.3 Equipment Maintenance

– Clean, dry, and store all testing equipment properly.

– Schedule recalibration and inspection of pressure gauges, pumps, and hoses per manufacturer guidelines.

– Log all maintenance activities in the equipment history file.

H2: 5. Continuous Improvement & Training

- Conduct post-test debriefings to identify areas for improvement.

- Provide refresher training on safety, compliance, and new regulations annually.

- Stay updated on industry best practices and technological advancements in hydro testing.

H2: Summary

Hydrostatic testing is a high-risk operation that demands strict logistical coordination and compliance with safety and environmental standards. By following this guide, Hydro Testers can perform their duties safely, efficiently, and in full regulatory compliance.

Note: Always consult project-specific procedures and engineering specifications before initiating any hydro test.

Conclusion for Sourcing Hydro Testers

Sourcing hydro testers is a critical step in ensuring the safety, reliability, and compliance of pressure vessels, pipelines, and other components subjected to high-pressure environments. A well-structured sourcing strategy emphasizes not only cost-effectiveness but also equipment quality, technical specifications, safety certifications, and after-sales support. By evaluating suppliers based on reliability, service capabilities, adherence to international standards (such as ASME, ISO, or API), and proven track records, organizations can mitigate risks associated with equipment failure and ensure consistent performance.

Additionally, considering factors such as portability, pressure range, pump type, and compatibility with testing media enhances operational efficiency across different project requirements. Investing in hydro testers from reputable manufacturers or suppliers ultimately supports long-term operational safety, regulatory compliance, and reduced downtime.

In conclusion, effective sourcing of hydro testers involves a balanced approach that prioritizes quality, safety, and supplier reliability over initial cost savings. This ensures that testing procedures remain accurate, compliant, and integral to maintaining the integrity of pressurized systems across industries such as oil and gas, manufacturing, and construction.