The global hydraulic equipment market, including specialized tools like hydraulic toe jacks, is experiencing steady growth driven by rising demand across construction, automotive, and industrial maintenance sectors. According to a 2023 report by Mordor Intelligence, the global hydraulic tools market was valued at USD 2.85 billion and is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This expansion is fueled by increased infrastructure development, stringent safety regulations, and the need for high-efficiency lifting solutions in heavy-duty applications. Hydraulic toe jacks—prized for their low-profile design and ability to lift loads from tight spaces—have become essential in equipment maintenance and machinery installation. With such momentum, identifying reliable manufacturers is critical for quality, safety, and performance. Based on market presence, product innovation, and global distribution, here are the top 8 hydraulic toe jack manufacturers shaping the industry today.

Top 8 Hydraulic Toe Jack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Toe Jacks

Domain Est. 1996

Website: hilmanrollers.com

Key Highlights: Hilman Deluxe Hydraulic Jacks feature a high quality lifting toe that can be adjusted to several heights to accommodate different lift points. Strong lift legs ……

#2 Toe Jacks

Domain Est. 2004

Website: toolwell.com

Key Highlights: 5-day deliveryOur toe jacks offer the highest reliability, ease of use and function employing superior technology, engineering, and manufacturing quality. These hydraulic ……

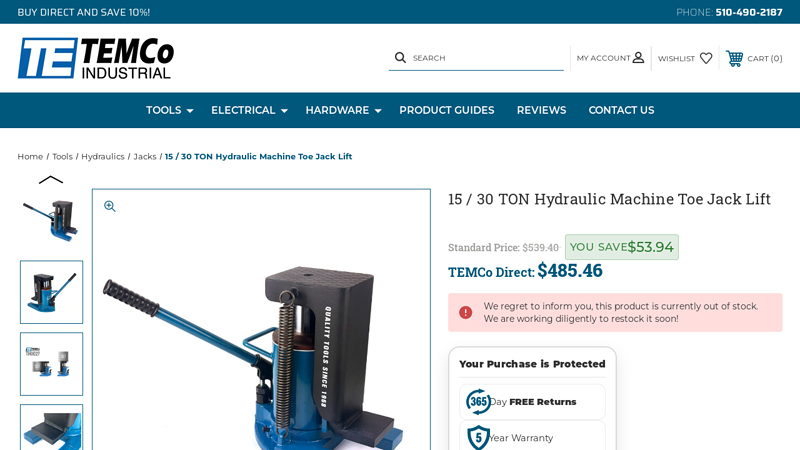

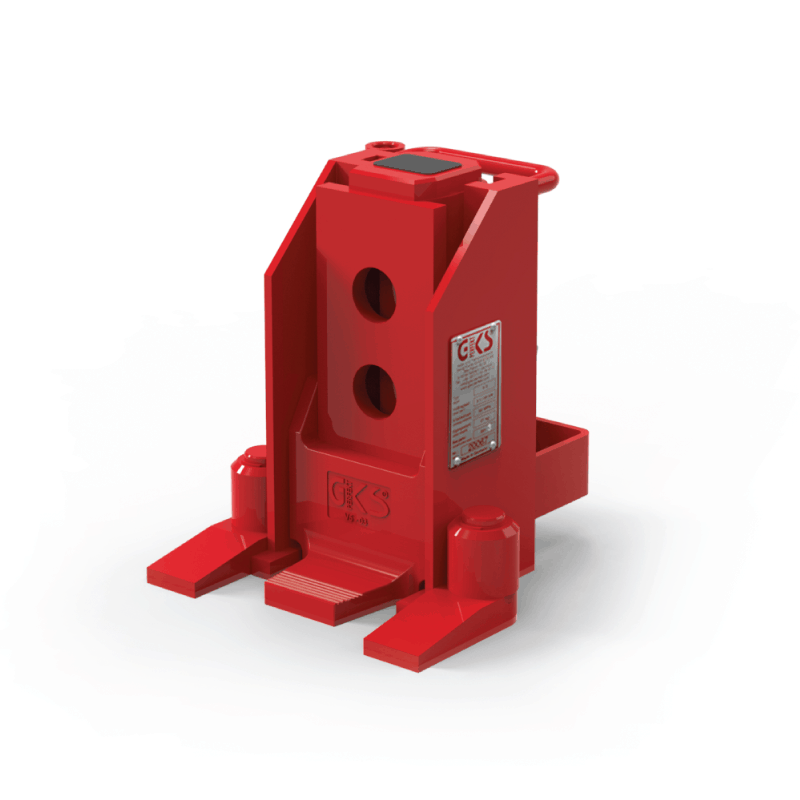

#3 15 / 30 TON Hydraulic Machine Toe Jack Lift

Domain Est. 2012

Website: temcoindustrial.com

Key Highlights: Lowest Minimum Jacking Clearance at Only 1.125 inches. Compact design for field use on construction sites and maintenance jobs. In-stock, ready to ship. 5 Year ……

#4 EAGLE Made in Japan

Domain Est. 2020

Website: toe-jack.com

Key Highlights: EAGLE products such as toe jacks and machine skates (or rollers) for carrying heavy machineries are tools used when installing industrial machines or changing ……

#5 TJH10A

Domain Est. 1995

Website: enerpac.com

Key Highlights: Self-contained models for maximum versatility. Low toe heights fit in tight clearances. The lowest handle effort for easy operation….

#6 Zinko Hydraulic Jack

Domain Est. 2000

Website: zinkojack.com

Key Highlights: 30-day returnsSingle Speed Air Pump, operating at up to 10,000 psi. Operate on shop air to drive a variety of single acting rams, presses and hydraulic pullers….

#7 Hydraulic Toe Jack

Domain Est. 2002

Website: hts-direct.com

Key Highlights: The hydraulic toe jack is far more flexible than its older counterpart. It still includes and uses all the benefits of hydraulic mechanics….

#8 Lifting Jacks

Domain Est. 2018

Website: liftingequipmentstore.us

Key Highlights: $26.50 deliveryOur range of hydraulic, mechanical, and air jacks is designed to handle a variety of lifting challenges, ensuring efficient and safe operations….

Expert Sourcing Insights for Hydraulic Toe Jack

H2: 2026 Market Trends for Hydraulic Toe Jacks

The global hydraulic toe jack market is poised for steady growth and transformation by 2026, driven by industrial automation, infrastructure development, and the increasing demand for efficient material handling equipment. Key trends shaping the market include technological advancements, regional expansion, sustainability initiatives, and evolving end-user requirements across industries such as automotive, construction, logistics, and manufacturing.

-

Technological Innovation and Smart Integration

By 2026, hydraulic toe jacks are expected to incorporate smart technologies such as digital load indicators, wireless connectivity, and IoT-enabled monitoring systems. These enhancements will allow users to track usage, monitor safety parameters in real time, and schedule preventive maintenance. Manufacturers are focusing on lightweight yet durable materials like high-strength alloys and composites to improve portability and corrosion resistance. -

Growing Demand in Automotive and Industrial Maintenance

The automotive repair and maintenance sector remains a primary consumer of hydraulic toe jacks. With the rise in vehicle ownership and the expansion of service centers globally, demand for reliable and compact lifting tools will continue to grow. Hydraulic toe jacks, known for their low-profile design and high lifting capacity, are especially favored in tight under-vehicle spaces. -

Expansion in Emerging Markets

Regions such as Asia-Pacific (particularly India, China, and Southeast Asia), Latin America, and parts of Africa are witnessing rapid industrialization and infrastructure development. This growth is fueling demand for material handling and maintenance equipment, including hydraulic toe jacks. Local manufacturing and cost-effective production are making these tools more accessible in price-sensitive markets. -

Focus on Safety and Ergonomics

Regulatory standards and workplace safety norms are becoming stricter worldwide. In response, manufacturers are redesigning hydraulic toe jacks with improved safety features such as overload protection, non-slip pads, and ergonomic handles. These features not only enhance user safety but also reduce operator fatigue during repetitive tasks. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing product design and production processes. By 2026, leading manufacturers are expected to adopt greener manufacturing practices, including the use of recyclable materials and environmentally safe hydraulic fluids. This shift aligns with broader ESG (Environmental, Social, and Governance) goals and appeals to eco-conscious buyers. -

E-Commerce and Digital Distribution Channels

The rise of B2B and B2C e-commerce platforms is transforming how hydraulic toe jacks are marketed and sold. Online marketplaces offer wider product visibility, competitive pricing, and faster delivery, especially beneficial for small businesses and independent mechanics. Manufacturers are investing in digital marketing and direct-to-consumer channels to capture a larger market share. -

Customization and Niche Applications

There is an increasing trend towards specialized hydraulic toe jacks tailored for specific applications—such as heavy-duty models for industrial machinery or compact versions for aerospace maintenance. Customization in load capacity, stroke length, and mounting options allows manufacturers to cater to niche segments and differentiate their offerings.

In conclusion, the hydraulic toe jack market in 2026 will be characterized by innovation, regional diversification, and a strong emphasis on safety and sustainability. Companies that invest in R&D, expand into emerging economies, and adapt to digital sales models are likely to gain a competitive advantage in this evolving landscape.

Common Pitfalls When Sourcing Hydraulic Toe Jacks: Quality and Intellectual Property Concerns

Sourcing hydraulic toe jacks, especially from international or unfamiliar suppliers, can expose buyers to several risks related to product quality and intellectual property (IP). Being aware of these pitfalls helps ensure you procure reliable, safe, and legally compliant equipment.

Quality-Related Pitfalls

1. Substandard Materials and Construction

Many low-cost suppliers use inferior steel, weak welds, or inadequate hydraulic seals to cut production costs. This leads to reduced load capacity, premature failure under stress, and potential safety hazards such as sudden collapse or oil leakage.

2. Inaccurate Load Ratings

Some manufacturers exaggerate or misrepresent the lifting capacity of their toe jacks. Without proper third-party certification (e.g., CE, ISO), the stated load rating may not reflect real-world performance, risking equipment and personnel safety.

3. Lack of Quality Control and Testing

Suppliers with weak quality management systems may skip critical testing phases like pressure testing, cycle testing, or stress evaluation. This results in inconsistent product performance and higher rates of field failure.

4. Poor Surface Finishes and Corrosion Resistance

Inadequate coating or plating exposes metal components to rust and corrosion, especially in industrial or outdoor environments. This reduces the lifespan of the jack and compromises structural integrity over time.

5. Inconsistent Dimensions and Fit

Off-spec manufacturing can lead to dimensional inaccuracies, making the toe jack incompatible with existing equipment or fixtures. This is particularly problematic in automated or precision-dependent applications.

Intellectual Property (IP) Pitfalls

1. Counterfeit or Copycat Products

Some suppliers replicate branded hydraulic toe jacks without authorization, mimicking design, logos, and packaging. These counterfeit products often lack quality assurance and may expose the buyer to legal liability.

2. Unauthorized Use of Patented Designs

Many toe jack mechanisms (e.g., quick-lift systems, release valves) are protected by patents. Sourcing from suppliers who infringe on these patents can lead to IP disputes, shipment seizures, or reputational damage.

3. Lack of Design Originality

Suppliers offering “generic” models may use designs stolen from established manufacturers. Even if not overtly labeled as a brand, the functional similarities can still infringe on utility or design patents.

4. Weak Supplier Transparency

Unreliable suppliers may withhold information about design origins, manufacturing processes, or IP ownership. This opacity increases the risk of unintentionally sourcing infringing products.

5. Legal and Customs Risks

Importing IP-infringing products can lead to customs detentions, fines, or lawsuits—especially in regions with strong IP enforcement like the EU or U.S. Buyers may be held liable even if infringement was unintentional.

Mitigation Strategies

To avoid these pitfalls:

– Request product certifications and test reports.

– Conduct factory audits or third-party inspections.

– Verify supplier IP compliance and request design ownership documentation.

– Work with reputable suppliers and avoid unusually low bids.

– Consult legal counsel when sourcing from high-risk regions.

By focusing on both quality assurance and IP integrity, buyers can ensure safer, more reliable, and legally sound procurement of hydraulic toe jacks.

Logistics & Compliance Guide for Hydraulic Toe Jack

Product Overview

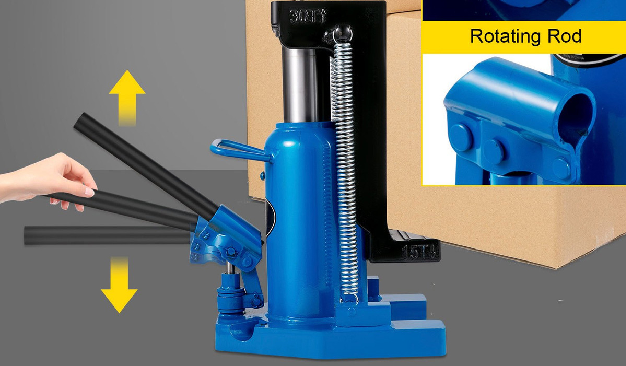

Hydraulic Toe Jacks are heavy-duty lifting tools designed to raise loads from tight spaces using a low-profile toe plate and hydraulic mechanism. Commonly used in automotive, industrial, and construction settings, these jacks require careful handling, proper packaging, and adherence to regulatory standards during transportation and storage.

Packaging Requirements

- Protective Packaging: Each Hydraulic Toe Jack must be securely packaged in a rigid corrugated cardboard box with internal foam or molded inserts to prevent movement and damage during transit.

- Moisture Protection: Include desiccant packs to prevent rust, especially in humid environments or maritime shipping.

- Labeling: Clearly label the outer packaging with “Fragile,” “This Side Up,” and the product name and model number. Include weight and center of gravity indicators if applicable.

Transportation Guidelines

- Stacking: Limit stacking to no more than two layers high when palletized to avoid crushing lower units.

- Palletization: Secure units on standard wooden or plastic pallets using stretch wrap or banding. Ensure even weight distribution.

- Mode-Specific Handling:

- Air Freight: Comply with IATA regulations; ensure no hydraulic fluid leaks and secure internal mechanisms.

- Sea Freight: Use moisture-resistant wrapping and consider VCI (Vapor Corrosion Inhibitor) bags for long voyages.

- Road Transport: Protect from extreme temperatures and secure loads to prevent shifting.

Import/Export Compliance

- HS Code: Typically classified under HS Code 8425.42 (Hydraulic jacks). Confirm with local customs authority for accuracy.

- Documentation: Provide commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

- Regulatory Approvals: Verify compliance with destination country standards (e.g., CE marking for EU, ANSI/ASME for U.S., PSE for Japan).

- Restricted Substances: Ensure compliance with RoHS, REACH, and other regional chemical regulations. Hydraulic fluid must meet environmental and safety standards.

Safety & Regulatory Standards

- Load Capacity Labeling: Each jack must have a permanent, legible rating plate indicating maximum load capacity, model number, and manufacturer information.

- Certification Marks: Display applicable safety certifications (e.g., CE, GS, ANSI/ASME B30.1).

- User Manual: Include multilingual safety instructions and operating guidelines in packaging.

Storage Conditions

- Environment: Store in a dry, temperature-controlled warehouse (5°C to 40°C) away from direct sunlight and corrosive substances.

- Orientation: Store upright to prevent hydraulic fluid leakage and seal degradation.

- Shelf Life: Inspect seals and fluid levels before dispatch if stored over 12 months.

Environmental & Disposal Compliance

- Hydraulic Fluid: Use biodegradable or environmentally safe fluids where possible. Dispose of used jacks per local e-waste or hazardous material regulations.

- Recycling: Encourage end-of-life recycling of metal components. Provide disposal guidelines in product documentation.

Incident Reporting & Recalls

- Non-Conformance Reporting: Establish a process for reporting damaged shipments or compliance issues to suppliers and authorities.

- Recall Preparedness: Maintain traceability (batch/serial numbers) and have a recall plan aligned with consumer safety regulations in target markets.

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact:

Compliance Officer

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Hydraulic Toe Jacks

In conclusion, sourcing hydraulic toe jacks requires a careful evaluation of quality, reliability, supplier reputation, and total cost of ownership. These specialized tools are essential in various industrial, automotive, and construction applications due to their ability to lift heavy loads in confined spaces. To ensure optimal performance and safety, it is crucial to select jacks that meet international standards (such as ISO or ANSI) and are constructed from durable, high-strength materials.

Prioritizing suppliers with proven track records, certifications, and responsive customer support helps mitigate risks related to equipment failure and downtime. Additionally, considering factors such as load capacity, lift height, warranty, and after-sales service contributes to long-term operational efficiency.

Ultimately, a well-informed sourcing strategy—balancing cost, quality, and supplier reliability—will ensure the acquisition of hydraulic toe jacks that enhance productivity, maintain workplace safety, and deliver a strong return on investment.