The global hydraulic telescoping cylinder market is experiencing steady expansion, driven by rising demand across construction, agriculture, and commercial vehicle sectors. According to Mordor Intelligence, the hydraulic cylinders market—which includes telescoping variants—is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Telescoping cylinders, valued for their compact design and extended stroke length, are increasingly adopted in applications requiring high force in constrained spaces, such as dump trucks, aerial platforms, and material handling equipment. Grand View Research further supports this trend, noting that the expanding automation in industrial machinery and infrastructure development—particularly in Asia-Pacific and North America—are key growth catalysts. As demand intensifies, manufacturers are focusing on durability, precision engineering, and corrosion resistance to meet evolving industry standards. This growing landscape has given rise to a competitive field of innovators, positioning the following nine companies as leading hydraulic telescoping cylinder manufacturers based on market presence, product diversity, and technological advancement.

Top 9 Hydraulic Telescoping Cylinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydraulic Cylinders Purpose

Domain Est. 2002

Website: aggressivehydraulics.com

Key Highlights: Why Choose Aggressive Hydraulics. We build every cylinder in our U.S. facility with the expertise, equipment, and processes to deliver lasting performance….

#2 Telescopic Hydraulic Cylinders

Domain Est. 2014

Website: hydrauliccylindersinc.com

Key Highlights: Hydraulic Cylinders, Inc. is your leading supplier of built-to-last, high-performance telescopic cylinders. From OEM-specific replacement telescoping cylinders ……

#3 HSI Corporation: Custom Hydraulic Cylinders

Domain Est. 1999

Website: hsicorporation.com

Key Highlights: We specialize in multi-stage telescopic cylinders for industries including marine crane, drilling rig, and hydraulic systems manufacturers….

#4 Mailhot Industries

Domain Est. 2000 | Founded: 1956

Website: mailhotindustries.com

Key Highlights: Mailhot Industries, North American leader in engineering and manufacturing 100% nitrided, hydraulic telescopic and rod cylinders since 1956….

#5 Custom Telescopic Hydraulic Cylinders & Components

Domain Est. 2001

Website: texashydraulics.com

Key Highlights: Texas Hydraulics’ Telescopic hydraulic cylinder is designed for applications that require a long stroke and a short length….

#6 Telescopic Hydraulic Cylinders

Domain Est. 2013

Website: baileyhydraulics.com

Key Highlights: Free delivery over $35 45-day returnstelescopic cylinders are designed to achieve longer strokes in tighter spaces to meet demands of various industrial applications. View our sele…

#7 Custom Telescopic Hydraulic Cylinder Manufacturer in USA

Domain Est. 2020

Website: stillwellinc.com

Key Highlights: We work with several international suppliers, specializing in Telescopic Cylinder manufacturing. Choose from a variety of sizes and stages to fit your needs….

#8 Telescopic Hydraulic Cylinders

Domain Est. 2000

Website: phelpsindustries.com

Key Highlights: We specialize in large multiple stage single acting telescopic hydraulic cylinders. We offer a full line of four stage, single acting telescopic cylinders….

#9 Telescopic Cylinders

Domain Est. 2013

Website: empirehyd.com

Key Highlights: Telescopic Cylinders are the largest wall thickness in the industry. And the highest lifting capacity in the industry. We can make what your machine needs….

Expert Sourcing Insights for Hydraulic Telescoping Cylinder

H2: Market Drivers Shaping the Hydraulic Telescoping Cylinder Industry in 2026

The global hydraulic telescoping cylinder market is poised for significant evolution by 2026, driven by a confluence of industrial, technological, and economic factors. Key market drivers influencing growth and direction include rising demand from construction and infrastructure sectors, advancements in mobile and off-highway machinery, and a growing emphasis on equipment efficiency and automation.

One of the primary drivers is the continued expansion of infrastructure development projects globally, particularly in emerging economies across Asia-Pacific, the Middle East, and Africa. Governments are investing heavily in transportation networks, urban development, and energy infrastructure, all of which rely heavily on construction equipment such as excavators, cranes, and dump trucks—machines that extensively use hydraulic telescoping cylinders for lifting, tilting, and extending functions.

Additionally, the agricultural and mining sectors are adopting more sophisticated machinery equipped with advanced hydraulic systems. Telescoping cylinders offer space-saving design and high force output in compact forms, making them ideal for applications where full retraction and extended reach are required. This is especially relevant in dump trucks and aerial work platforms, where performance and reliability are critical.

Technological innovation is another major catalyst. By 2026, manufacturers are increasingly integrating smart hydraulics with IoT-enabled sensors and predictive maintenance capabilities. These advancements allow for real-time monitoring of cylinder performance, reducing downtime and improving operational efficiency. The push toward energy-efficient and lightweight hydraulic systems is also leading to the development of aluminum-bodied and composite telescoping cylinders, particularly in mobile applications where weight reduction translates directly into fuel savings.

Furthermore, the global shift toward electrification and sustainability is influencing hydraulic system design. While electric actuators are gaining traction in some applications, hydraulic telescoping cylinders remain dominant in high-load scenarios. Hybrid hydraulic-electric systems are emerging as a compromise, offering the power density of hydraulics with the precision and efficiency of electric controls.

In summary, the 2026 market for hydraulic telescoping cylinders will be shaped by robust infrastructure growth, technological integration, and demand for high-performance, reliable motion control solutions across construction, mining, agriculture, and transportation industries. Companies that innovate in materials, digital integration, and energy efficiency are likely to capture greater market share in this evolving landscape.

Common Pitfalls When Sourcing Hydraulic Telescoping Cylinders (Quality and Intellectual Property)

Sourcing hydraulic telescoping cylinders involves significant risks related to both product quality and intellectual property (IP) protection. Failing to address these pitfalls can lead to equipment failure, safety hazards, legal disputes, and financial losses. Below are key challenges to avoid:

Poor Manufacturing Quality and Material Deficiencies

One of the most frequent issues is receiving cylinders made with substandard materials or poor craftsmanship. This includes the use of low-grade steel, improper surface treatments (such as insufficient chrome plating), and inadequate welding practices. These deficiencies can result in premature wear, internal leakage, buckling under load, or catastrophic failure during operation. Buyers must verify supplier certifications (e.g., ISO 9001), request material test reports (MTRs), and conduct third-party inspections to ensure adherence to industry standards.

Inaccurate Load and Stroke Specifications

Telescoping cylinders are highly application-specific, and sourcing units that do not meet exact stroke length, load capacity, or retraction requirements can render them unusable. Miscommunication or lack of technical clarity with suppliers—especially in offshore sourcing—often leads to mismatched performance. It is essential to provide detailed technical drawings, performance requirements, and operating conditions to avoid functional incompatibility.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability for critical components, including hydraulic tubes, seals, and piston rods. Sourcing from vendors who cannot supply batch numbers, certification documents, or manufacturing logs increases the risk of counterfeit or non-compliant parts. This absence of documentation also complicates warranty claims and regulatory compliance, especially in industries like construction or mining.

Intellectual Property Infringement Risks

When sourcing from regions with weak IP enforcement, there is a heightened risk of purchasing cylinders that replicate patented designs or proprietary technology without authorization. Using such components may expose the buyer to legal liability, especially if the original IP holder initiates litigation. Conducting due diligence on supplier legitimacy, verifying design ownership, and including IP indemnification clauses in contracts are critical preventive measures.

Inadequate Testing and Quality Assurance Processes

Some suppliers claim compliance with international standards (e.g., ISO 10100 or NFPA) but lack robust in-house testing procedures. Cylinders may not undergo pressure cycling, leakage tests, or endurance evaluations before shipment. Insist on witnessing factory acceptance tests (FAT) or reviewing test reports to confirm performance and reliability.

Supply Chain Transparency and Counterfeit Components

Global supply chains can obscure the origin of components, increasing the risk of counterfeit seals, valves, or hydraulic fittings being integrated into the cylinder assembly. These components may fail prematurely under pressure or temperature extremes. Ensure suppliers disclose sub-tier vendors and implement strict component sourcing policies.

By proactively addressing these quality and IP-related pitfalls, buyers can secure reliable, compliant, and legally sound hydraulic telescoping cylinders for their applications.

Logistics & Compliance Guide for Hydraulic Telescoping Cylinders

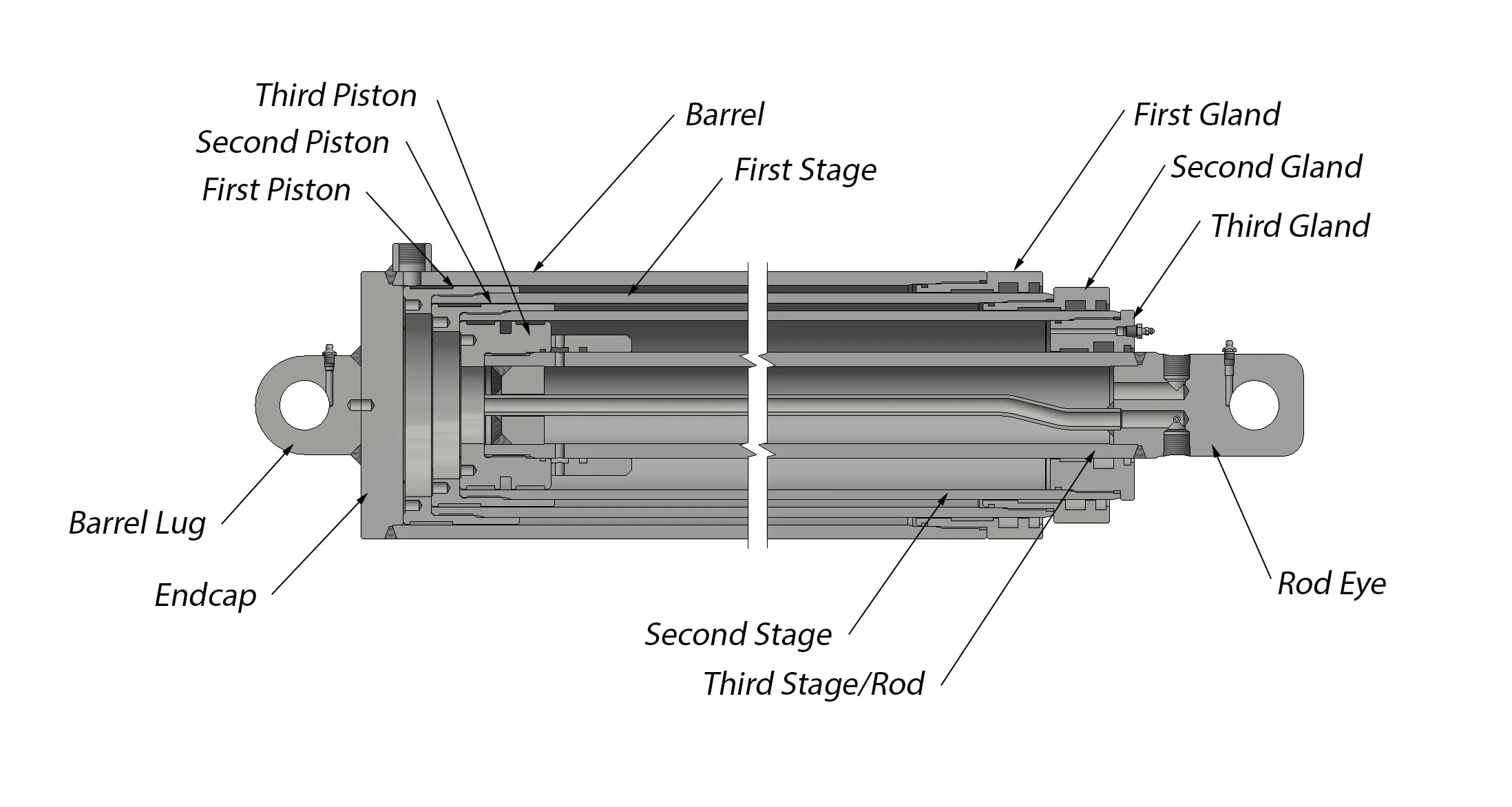

Product Overview and Classification

Hydraulic telescoping cylinders are multi-stage cylinders designed to provide extended stroke lengths within a compact retracted size, commonly used in dump trucks, cranes, aerial platforms, and agricultural machinery. Proper logistics and compliance management are essential due to their size, weight, and industrial application.

Harmonized System (HS) Code Classification

Correct HS code classification ensures accurate customs clearance and duty assessment:

– Typical HS Code: 8412.21.00 (Hydraulic cylinders, linear acting)

– Confirm code with local customs authority, as variations may apply by country.

– Provide detailed technical specifications (bore, stroke, stages, pressure rating) to support classification.

Export Controls and Regulatory Compliance

Hydraulic telescoping cylinders may be subject to export regulations depending on destination and end-use:

– Check for dual-use or military applications under regulations such as:

– EAR (Export Administration Regulations) – U.S. Department of Commerce

– ITAR (International Traffic in Arms Regulations) – if integrated into defense systems

– Screen end-users and destinations against denied party lists (e.g., BIS, EU, UN sanctions).

– Obtain export licenses when required.

Packaging and Handling Requirements

Proper packaging ensures product integrity during transit:

– Use wooden crates or reinforced pallets with corner protectors for large cylinders.

– Seal ports with protective caps and apply anti-corrosion coating (VCI paper or oil).

– Secure cylinders to prevent movement; use cushioning material (foam, bubble wrap) to protect rods and seals.

– Label packages with “Fragile,” “This Side Up,” and handling instructions.

Transportation Modes and Considerations

Choose transportation based on size, weight, and delivery urgency:

– Road Freight: Preferred for regional shipments; ensure load securement and route planning for oversized cargo.

– Sea Freight: Suitable for heavy or large-volume shipments; use FCL (Full Container Load) for protection.

– Air Freight: Use only for urgent, lightweight units; verify dimensional and weight limits.

– Consider crating dimensions and weight when quoting freight costs.

Import Documentation Requirements

Prepare complete documentation for customs clearance:

– Commercial Invoice (with detailed description, value, and INCOTERMS)

– Packing List (itemizing units, weight, dimensions)

– Bill of Lading or Air Waybill

– Certificate of Origin (required for preferential tariffs)

– Export Certificate or License (if applicable)

– Technical Datasheets (to support HS code classification)

Safety and Environmental Compliance

Adhere to health, safety, and environmental standards:

– Comply with REACH (EU) and RoHS directives for material content.

– Ensure manufacturing meets ISO 4413 (Hydraulic fluid power – General rules) and ISO 6020/2 (Mounting dimensions).

– Disclose use of hazardous substances if present (e.g., hydraulic oil residues).

– Provide Safety Data Sheets (SDS) if shipped with hydraulic fluid.

Customs Duties and Tariff Mitigation

Minimize duty costs through proper planning:

– Leverage free trade agreements (e.g., USMCA, EU-South Korea FTA) with valid Certificates of Origin.

– Use tariff engineering strategies (e.g., shipping unassembled components if beneficial).

– Verify duty rates in destination country’s tariff schedule.

Installation and End-Use Compliance

Ensure end-user compliance with local standards:

– Confirm cylinder integration meets machinery safety directives (e.g., EU 2006/42/EC).

– Provide installation guidelines and maintenance documentation.

– Advise users to comply with local pressure equipment regulations (e.g., ASME BPVC, PED).

Recordkeeping and Audit Trail

Maintain documentation for regulatory audits:

– Retain export records for minimum 5 years (as per U.S. EAR and many international standards).

– Archive invoices, licenses, shipping documents, and compliance certifications.

– Implement a traceability system for serial-numbered units.

Summary and Best Practices

- Classify accurately using HS codes and technical specs.

- Verify export controls and obtain required licenses.

- Use robust packaging and clear labeling.

- Prepare complete import documentation.

- Stay updated on international trade regulations and sanctions.

- Partner with experienced freight forwarders and customs brokers.

Conclusion for Sourcing Hydraulic Telescoping Cylinders:

Sourcing hydraulic telescoping cylinders requires a comprehensive evaluation of technical specifications, application requirements, supplier reliability, and total cost of ownership. These specialized cylinders are critical in applications requiring extended strokes within compact spaces, such as dump trucks, cranes, and agricultural machinery. To ensure optimal performance and longevity, it is essential to select cylinders that match the required load capacity, stroke length, operating pressure, and environmental conditions.

Prioritizing suppliers with proven engineering expertise, quality certifications (such as ISO 9001), and robust testing procedures helps mitigate risks related to failure and downtime. Additionally, considering factors such as material durability, sealing technology, and customization capabilities can significantly enhance system efficiency and reduce maintenance needs.

In conclusion, a strategic sourcing approach—balancing performance, reliability, cost, and after-sales support—ensures the successful integration of hydraulic telescoping cylinders into demanding applications, ultimately supporting improved operational efficiency and equipment uptime.