The global hydraulic table lift market is experiencing robust growth, driven by increasing demand for material handling equipment across industrial and commercial sectors. According to a report by Mordor Intelligence, the Hydraulic Lift Market is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by rising automation in manufacturing, warehousing, and logistics operations, where hydraulic table lifts play a critical role in improving workplace efficiency and ergonomics. Additionally, Grand View Research estimates that the broader material handling equipment market will continue expanding, supported by advancements in hydraulics technology and growing emphasis on worker safety. As industries seek durable, reliable, and high-performance lifting solutions, the need for leading manufacturers in the hydraulic table lift space has never been greater. In this context, we spotlight the top 10 hydraulic table lift manufacturers shaping the future of material handling through innovation, quality, and global reach.

Top 10 Hydraulic Table Lift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Advance Lifts

Domain Est. 1997

Website: advancelifts.com

Key Highlights: Advance Lifts manufactures high-quality loading dock lifts, access platforms and other industrial scissor lift tables. View our wide selection of products ……

#2 Hydraulic Lift Tables & Industrial Scissor Lifts

Domain Est. 1997

Website: liftproducts.com

Key Highlights: Industrial Lift Tables from Lift Products. Shop Mobile, Rotating, Low Profile, Double Scissor, Stainless, Work Bench, High Capacity, and Custom Lift Tables….

#3 Electric Hydraulic Lift Table

Domain Est. 2012

Website: tomahawk-power.com

Key Highlights: In stock $79.99 deliveryWith a 617 lb weight capacity and the ability to raise loads up to 59 inches, this industrial-grade hydraulic lift table is perfect for lifting heavy equipm…

#4 Hydraulic Table Suppliers

Domain Est. 2015

Website: hydraulicliftmanufacturers.com

Key Highlights: Find the top hydraulic table suppliers and manufacturers who offer quick quotes on their easy to operate hydraulic tables of all types and capacities….

#5 Bishamon Lift Tables

Domain Est. 1996

Website: bishamon.com

Key Highlights: Bishamon lift tables play a pivotal role in positioning loads at the perfect height, enhancing overall worker productivity and operational efficiency….

#6 Manual and Powered Lift Tables

Domain Est. 1996

Website: wescomfg.com

Key Highlights: Standard Lexco Lift and Die Tables, Wesco® Lift Tables, Capacities from 200 to 6000 lb, Manual and Powered Lift, Lexco® Hydraulic Lift Tables & Die Handlers….

#7 Hydraulic Lift Tables & Loading Dock Equipment

Domain Est. 1997

Website: pentalift.com

Key Highlights: Explore Pentalift’s hydraulic lift tables and loading dock equipment. Designed for durability and efficiency, our solutions optimize hydraulic lift ……

#8 Hydraulic Lift Tables For Material Handling

Domain Est. 1998

Website: langelift.com

Key Highlights: Lange Lift manufactures high-quality hydraulic lift tables, lift carts, & custom lifts (scissor, electric, and air) that are built to last….

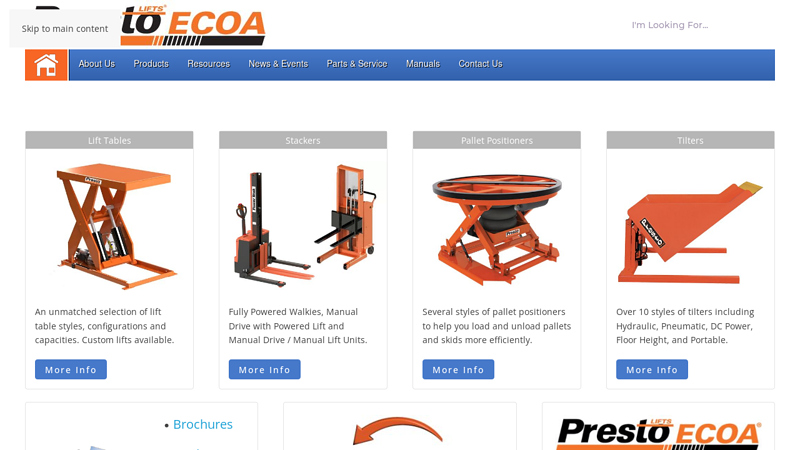

#9 Presto Lifts

Domain Est. 2000

Website: prestolifts.com

Key Highlights: An unmatched selection of lift table styles, configurations and capacities. Custom lifts available. More info…

#10 GARVEE Double Scissor Hydraulic Lift Table Cart

Domain Est. 2022

Website: garvee.com

Key Highlights: Out of stock Rating 5.0 (3) Discover the GARVEE Double Scissor Hydraulic Lift Table Cart, perfect for indoor and outdoor use. With a 500lbs capacity and 48″ height, it’s ideal fo…

Expert Sourcing Insights for Hydraulic Table Lift

H2: 2026 Market Trends for Hydraulic Table Lifts

The global hydraulic table lift market is poised for significant transformation by 2026, driven by industrial automation, growing emphasis on workplace safety, and advancements in material handling technologies. As industries continue to prioritize efficiency and ergonomic design, hydraulic table lifts—essential equipment in manufacturing, warehousing, automotive, and logistics sectors—are expected to witness steady demand and innovation.

One major trend shaping the 2026 market is the increased adoption of smart and IoT-integrated hydraulic lifts. Manufacturers are incorporating sensors, remote monitoring systems, and predictive maintenance capabilities into hydraulic table lifts to enhance operational efficiency and reduce downtime. This digital integration allows real-time performance tracking and alerts, aligning with the broader Industry 4.0 movement.

Another key driver is the rising focus on workplace ergonomics and employee safety regulations, especially in North America and Europe. Hydraulic table lifts help reduce manual lifting injuries by enabling smooth vertical transportation of heavy loads. With stricter occupational health and safety standards, companies are investing in compliant lifting solutions, boosting market growth.

Sustainability is also becoming a critical factor. By 2026, there will be a growing demand for energy-efficient and eco-friendly hydraulic systems, including models with low-emission hydraulic fluids and energy recovery mechanisms. Manufacturers are responding by developing greener alternatives and lightweight, durable materials to reduce environmental impact.

Regionally, Asia-Pacific is expected to emerge as a high-growth market due to rapid industrialization, expanding e-commerce infrastructure, and government initiatives supporting manufacturing growth in countries like China, India, and Vietnam. Meanwhile, North America and Europe will maintain strong market shares, led by modernization of legacy systems and the integration of automation.

In conclusion, the 2026 hydraulic table lift market will be defined by technological innovation, regulatory compliance, and regional expansion. Companies that invest in smart, sustainable, and ergonomic solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Hydraulic Table Lifts (Quality & IP)

Sourcing hydraulic table lifts involves navigating several potential challenges that can impact performance, safety, and long-term value. Being aware of these pitfalls helps ensure you select a reliable, high-quality product that meets your operational needs.

Poor Build Quality and Material Selection

Choosing a hydraulic table lift made with substandard materials or poor craftsmanship can lead to premature failure, safety hazards, and increased maintenance costs. Low-quality steel, inadequate welding, or weak hydraulic components may not withstand regular use, especially in industrial environments. Always verify material specifications, load ratings, and manufacturing standards (e.g., ISO, CE) to avoid units prone to deformation, leaks, or structural failure.

Inadequate Load Capacity and Stability

A common mistake is selecting a lift based on minimum load requirements without considering safety margins or dynamic loads. Overloading can compromise stability and lead to tipping or hydraulic system failure. Ensure the lift’s rated capacity exceeds your maximum expected load by a safe margin and confirm that the base design provides sufficient stability for your application.

Lack of IP (Ingress Protection) Rating for Harsh Environments

Failing to consider the IP rating can be a critical oversight, especially in wet, dusty, or washdown environments. Hydraulic lifts without proper IP protection (e.g., IP54 or higher) are vulnerable to water, dust, and chemical ingress, which can damage electrical components, corrode moving parts, and shorten service life. Always match the IP rating to your environment—such as food processing, outdoor use, or manufacturing floors with high particulate levels.

Non-Compliance with Safety and Industry Standards

Some suppliers offer lifts that do not meet regional safety standards (e.g., OSHA, ANSI, or EU Machinery Directive). This can result in legal liability, failed inspections, or workplace accidents. Verify that the lift complies with relevant safety regulations, includes essential features like emergency stop buttons, overload protection, and safety interlocks, and comes with proper certification documentation.

Insufficient After-Sales Support and Spare Parts Availability

Even high-quality lifts require maintenance and occasional repairs. Sourcing from suppliers with poor customer support or limited spare parts availability can lead to extended downtime. Evaluate the supplier’s service network, warranty terms, and responsiveness before purchasing to ensure long-term reliability and support.

Overlooking Customization and Integration Needs

Standard models may not fit specific workspace layouts or workflow requirements. Failing to consider custom stroke lengths, platform sizes, control placements, or integration with existing systems can reduce efficiency. Work with suppliers who offer customization options and technical support to tailor the lift to your exact operational needs.

Logistics & Compliance Guide for Hydraulic Table Lift

This guide outlines essential logistics considerations and compliance requirements for the safe and legal transportation, handling, installation, and operation of Hydraulic Table Lifts.

Transportation & Handling

Ensure proper methods are used during shipping and site delivery to prevent damage and maintain safety.

- Packaging: Verify that the Hydraulic Table Lift is securely packaged in a robust wooden crate or protective enclosure to prevent impact damage during transit.

- Lifting Points: Use only designated lifting points (e.g., lifting eyes or forklift channels) when moving the unit. Never lift by hydraulic lines, controls, or platform edges.

- Forklift Handling: When using a forklift, ensure adequate load capacity and that forks are fully inserted under reinforced channels. Keep the lift level during transport.

- Ground Conditions: Ensure delivery and installation areas have firm, level surfaces capable of supporting the lift’s weight plus its load.

- Climate Protection: Protect the unit from prolonged exposure to rain, snow, or extreme temperatures during transit and storage.

Import & Export Regulations

Comply with international trade laws when shipping Hydraulic Table Lifts across borders.

- HS Code Classification: Confirm the correct Harmonized System (HS) code for Hydraulic Table Lifts (e.g., 8428.10 or 8428.90, depending on design) to determine tariffs and import duties.

- Documentation: Prepare accurate commercial invoice, packing list, bill of lading, and certificate of origin. Include technical specifications such as weight, dimensions, lifting capacity, and hydraulic system details.

- CE Marking (EU): For shipments to the European Union, ensure the lift bears CE marking, indicating compliance with EU Machinery Directive (2006/42/EC) and relevant EN standards (e.g., EN 1570-1 for safety of lifting tables).

- US Compliance (FCC/OSHA): For the United States, confirm adherence to OSHA 29 CFR 1910 for workplace safety. Electrical components must comply with FCC regulations if they emit radio frequency energy.

- Country-Specific Approvals: Check local requirements; some countries may require additional certifications (e.g., UKCA in Great Britain, CCC in China).

Installation & Site Requirements

Proper setup is critical for operational safety and regulatory compliance.

- Clearance: Provide adequate overhead, side, and rear clearance as specified by the manufacturer to prevent entrapment or collision.

- Floor Load Capacity: Ensure the installation floor can support the combined weight of the lift and its maximum load. Reinforce if necessary.

- Power Supply: Match electrical supply (voltage, phase, frequency) to the lift’s requirements. Use a dedicated circuit with proper grounding.

- Hydraulic Fluid: Use only manufacturer-recommended hydraulic fluid. Check for leaks and proper fluid levels before initial operation.

- Anchoring: Secure the lift to the floor if recommended by the manufacturer, especially in seismic zones or high-traffic areas.

Safety & Operational Compliance

Adhere to safety standards to protect personnel and ensure equipment longevity.

- Operator Training: Train all users on safe operation, emergency procedures, and load limitations. Maintain training records.

- Guarding & Safety Devices: Ensure all safety features (e.g., emergency stop buttons, overload protection, guardrails, and interlocks) are functional and not bypassed.

- Load Limits: Never exceed the maximum rated load capacity. Distribute loads evenly across the platform.

- Maintenance Schedule: Follow the manufacturer’s preventive maintenance plan, including inspections of hydraulic hoses, cylinders, valves, and structural components.

- Inspection & Documentation: Conduct periodic inspections (e.g., monthly visual checks, annual thorough examinations) and keep records as required by local regulations (e.g., LOLER in the UK).

Environmental & Disposal Compliance

Manage environmental impact throughout the product lifecycle.

- Hydraulic Fluid Disposal: Dispose of used hydraulic oil as hazardous waste in accordance with local environmental regulations (e.g., EPA rules in the US).

- End-of-Life Recycling: Recycle metal components and properly handle electronic control units per WEEE directives (EU) or equivalent local e-waste laws.

- Spill Prevention: Use drip trays during maintenance and have spill kits available to contain hydraulic fluid leaks.

Regulatory Standards & Certifications

Ensure the Hydraulic Table Lift meets all applicable industry and regional standards.

- Machinery Directive (EU): Comply with 2006/42/EC, including risk assessment, technical file, and CE declaration of conformity.

- ANSI/ITSDF B56.7 (USA): Follow safety standards for low-lift and powered industrial trucks, where applicable.

- ISO 3691-6: Adhere to international standards for operator-controlled industrial trucks, including safety aspects.

- EMC Directive (EU): Ensure electrical systems comply with electromagnetic compatibility requirements (2014/30/EU).

- Pressure Equipment Directive (PED): If hydraulic components exceed pressure thresholds, compliance with 2014/68/EU may be required.

By following this guide, businesses can ensure the safe, compliant, and efficient use of Hydraulic Table Lifts across their logistics and operational workflows.

Conclusion for Sourcing Hydraulic Table Lift

In conclusion, sourcing a hydraulic table lift requires a careful evaluation of operational needs, safety standards, load capacity, lift height, power source, build quality, and supplier reliability. Selecting the right hydraulic table lift enhances workplace efficiency, improves ergonomics, reduces the risk of injury, and supports smooth material handling processes. It is essential to choose a reputable supplier offering durable, compliant equipment with proper after-sales service and warranty support. By aligning the technical specifications with specific application requirements and considering long-term maintenance and total cost of ownership, organizations can make a strategic investment that ensures safety, productivity, and operational excellence.