The global hydraulic floor spring market is experiencing steady growth, driven by rising demand for automated and energy-efficient building solutions in commercial and industrial infrastructure. According to Grand View Research, the global door control equipment market—which includes floor springs—was valued at USD 2.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by increasing construction activities, stringent safety regulations, and the proliferation of smart building technologies, particularly across North America, Europe, and the Asia Pacific. With hydraulic floor springs playing a critical role in ensuring door durability, accessibility, and controlled closing mechanisms, demand for high-performance and reliable products continues to rise. As competition intensifies, a select group of manufacturers has emerged as leaders through innovation, quality compliance, and global distribution networks. Based on market presence, product performance, and industry reputation, we present the top 10 hydraulic floor spring manufacturers shaping this evolving landscape.

Top 10 Hydraulic Floor Spring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Heavy Duty Floor Spring Suppliers, Manufacturers, Factory

Domain Est. 2021

Website: heinda-cn.com

Key Highlights: HEINDA is one of the most professional heavy duty floor spring manufacturers and suppliers in China. If you’re going to wholesale bulk high quality heavy ……

#2 Graco Inc.

Domain Est. 1994

Website: graco.com

Key Highlights: Graco designs and manufactures thousands of fluid handling products and solutions for the industries we pursue around the world….

#3 Floor Spring

Domain Est. 2002

Website: dnd.com.tw

Key Highlights: D&D Builders Hardware Co., a premier Taiwanese manufacturer, specializes in high-quality hardware solutions, including Floor Spring, door closers, exit devices, ……

#4 Ozone India

Domain Est. 2010

Website: ozone.in

Key Highlights: Floor Spring · Door Closers for Glass · Glass Door Rail · Hydraulic Door Hinges · Pivot Hinge · Central Pivot Hinge · Partition Door Hinges · Glass Door Handles….

#5 Hydraulic Floor Spring Manufacturer For Frameless Glass Door

Domain Est. 2017

Website: aoyuhardware.com

Key Highlights: Enhance your doors with premium hydraulic floor springs crafted by a trusted manufacturer….

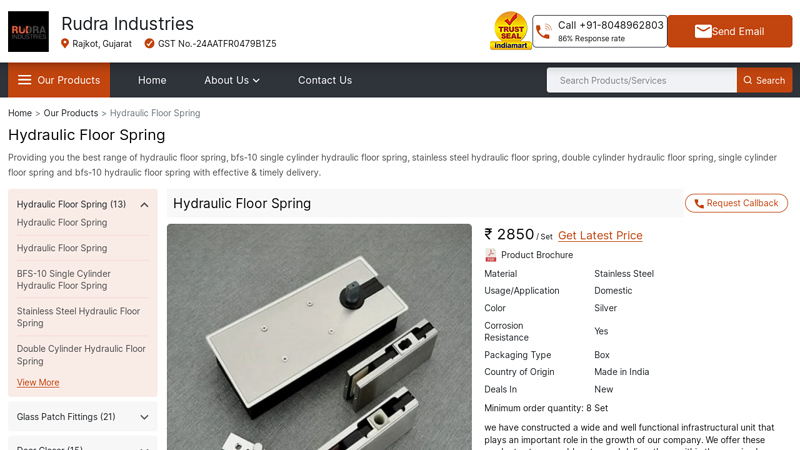

#6 Hydraulic Floor Spring

Domain Est. 2020

Website: rudrafloorspring.com

Key Highlights: Manufacturer of Hydraulic Floor Spring – BFS-10 Single Cylinder Hydraulic Floor Spring … Hydraulic Floor Spring offered by Rudra Industries, Rajkot, Gujarat….

#7 High Quality Hydraulic Floor Spring Door Closer

Domain Est. 2006

Website: allwinhardware.com

Key Highlights: Rating 5.0 · Review by jasonDescription. Engineered for smooth and stable operation, this hydraulic floor spring closer provides precise control for heavy glass or metal doors…

#8 FLOOR SPRINGS

Domain Est. 2007

Website: kadson.co.in

Key Highlights: This floor springs are easy to install and simple to operate and are favourable to use with any types of the glass doors. The complete solution related to the ……

#9 Floor Springs

Domain Est. 2012

Website: fortress-hardware.com

Key Highlights: Floor hinge, the mechanical door closing device used for glass doors along with hydraulic patch fitting. You can find a wide range of floor springs to meet ……

#10 Floor Spring

Domain Est. 2018

Website: jianlaihk.com

Key Highlights: Jianlai has excellent production system and complete quality control system to make sure our floor spring high quality. Jianlai tests every floor spring….

Expert Sourcing Insights for Hydraulic Floor Spring

H2: 2026 Market Trends for Hydraulic Floor Springs

The global hydraulic floor spring market is projected to undergo significant transformation by 2026, driven by advancements in building automation, increasing demand for energy-efficient infrastructure, and rising construction activities in emerging economies. Hydraulic floor springs, essential components in commercial and public building entrances, are evolving to meet higher performance, safety, and aesthetic standards. Below are key market trends expected to shape the industry by 2026:

-

Growth in Commercial and Institutional Construction

Expansion in office complexes, healthcare facilities, educational institutions, and transportation hubs—especially in Asia-Pacific and Latin America—is boosting demand for high-quality door control systems. Hydraulic floor springs are preferred for their durability and sleek design, particularly in frameless glass doors, which are gaining popularity in modern architecture. -

Emphasis on Safety and Accessibility Compliance

Stricter building codes and regulations related to fire safety, accessibility (e.g., ADA in the U.S.), and energy efficiency are compelling building owners to invest in certified hydraulic floor springs with controlled closing speed, soft stop features, and anti-pinch technology. This trend is particularly strong in North America and Europe. -

Integration with Smart Building Systems

The rise of smart buildings is pushing manufacturers to develop intelligent floor springs integrated with sensors and IoT platforms. By 2026, expect increased adoption of hydraulic floor springs with monitoring capabilities such as usage tracking, maintenance alerts, and remote diagnostics—enhancing facility management and reducing operational costs. -

Sustainability and Eco-Friendly Materials

Environmental concerns are driving demand for recyclable materials and energy-efficient production methods. Leading manufacturers are adopting eco-conscious practices, including using lead-free brass, recyclable aluminum alloys, and low-emission hydraulic fluids—aligning with green building certifications like LEED and BREEAM. -

Innovation in Design and Customization

Architects and designers are seeking customizable, minimalist solutions that blend seamlessly with modern interiors. As a result, hydraulic floor springs are being redesigned for slimmer profiles, improved corrosion resistance (e.g., stainless steel variants), and finishes that match various architectural styles. -

Regional Market Expansion

While Europe remains a dominant market due to stringent safety standards and mature construction sectors, Asia-Pacific is expected to register the highest CAGR. Rapid urbanization in countries like India, Vietnam, and Indonesia, coupled with government investments in infrastructure, will fuel market growth. -

Competitive Landscape and Mergers & Acquisitions

The market is witnessing consolidation, with major players acquiring niche innovators to expand product portfolios. Companies such as Dorma (now Dormakaba), TS Architectural, and GEZE are investing heavily in R&D to maintain technological leadership and expand their global footprint. -

Supply Chain Resilience and Localization

Post-pandemic disruptions have prompted manufacturers to localize production and diversify supply chains. By 2026, regional manufacturing hubs in Southeast Asia and Eastern Europe are expected to reduce dependency on single-source suppliers and improve delivery timelines.

In conclusion, the hydraulic floor spring market in 2026 will be characterized by innovation, regulation-driven demand, and integration into smarter, greener buildings. Stakeholders who prioritize technological advancement, compliance, and sustainability are poised to lead in this evolving landscape.

Common Pitfalls When Sourcing Hydraulic Floor Springs (Quality, IP)

Sourcing hydraulic floor springs—especially for commercial or high-traffic applications—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, safety hazards, or non-compliance. Here are common pitfalls to avoid:

Overlooking Build Quality and Material Standards

Many buyers focus on price and overlook the mechanical integrity of the floor spring. Low-cost models often use inferior metals (e.g., zinc alloys instead of brass or stainless steel), which corrode quickly or deform under stress. Poor internal hydraulic seals degrade over time, leading to inconsistent door closing, fluid leaks, or complete failure. Always verify material specifications and request third-party test reports for durability and cycle life.

Ignoring IP (Ingress Protection) Ratings

Hydraulic floor springs are often installed in environments exposed to water, dust, or debris (e.g., entrances, restrooms, outdoor areas). Failing to check IP ratings is a major pitfall. A low IP rating (e.g., IP40) offers minimal protection against dust and no water resistance, making the unit prone to internal contamination. For wet or high-dust environments, aim for at least IP65 (dust-tight and protected against water jets). Without adequate IP protection, moisture and debris can compromise hydraulic performance and lead to rust or mechanical jamming.

Assuming All Floor Springs Are Interchangeable

Not all hydraulic floor springs are compatible with every door type, size, or weight. Selecting a unit without verifying load capacity, door width, and swing direction can result in poor performance or excessive wear. Additionally, retrofitting without checking dimensions or mounting requirements can lead to installation issues or structural damage.

Skipping Certification and Compliance Checks

In many regions, fire-rated or safety-critical doors require floor springs that meet specific standards (e.g., EN 1154, CE marking, UL certification). Sourcing non-compliant products risks failing inspections, voiding fire safety certifications, or creating liability issues in the event of injury.

Relying Solely on Supplier Claims Without Verification

Some suppliers exaggerate performance claims or provide inaccurate IP and quality ratings. Always request documentation such as test reports, material certifications, and independent lab results. Whenever possible, obtain samples for real-world testing before large-scale procurement.

Avoiding these pitfalls ensures reliable operation, longer service life, and compliance with safety and environmental standards.

Logistics & Compliance Guide for Hydraulic Floor Spring

Product Overview

The Hydraulic Floor Spring is a heavy-duty door-closing mechanism installed in the floor to control the opening and closing of doors, commonly used in commercial and institutional buildings. It ensures smooth operation, safety, and compliance with accessibility and fire safety standards.

Packaging Requirements

- Protective Packaging: Each unit must be enclosed in a rigid cardboard or wooden crate to prevent impact damage during transit.

- Internal Cushioning: Use foam inserts or bubble wrap to secure moving parts and prevent internal abrasion.

- Moisture Protection: Include desiccant packs and vacuum-seal or wrap in moisture-resistant plastic for humid climates or sea freight.

- Labeling: Clearly label packages with product name, model number, weight, handling instructions (e.g., “Fragile,” “This Side Up”), and barcodes for inventory tracking.

Transportation & Handling

- Mode of Transport: Suitable for road, sea, and air freight. For air cargo, ensure compliance with IATA regulations—no leakage or pressurized components.

- Palletization: Secure units on standard wooden or plastic pallets using stretch wrap or strapping. Max load height: 1.8 meters.

- Stacking Limits: Do not stack more than two loaded pallets high during storage or transport to prevent crushing.

- Handling Equipment: Use forklifts or pallet jacks for movement; avoid dragging or dropping packages.

Storage Conditions

- Environment: Store indoors in a dry, temperature-controlled environment (5°C to 35°C). Avoid direct sunlight and extreme humidity.

- Shelf Life: Up to 24 months when stored properly. Inspect seals and hydraulic fluid before installation after long storage.

- Orientation: Store vertically if possible, or flat with protective spacers between units to prevent deformation.

Import/Export Compliance

- HS Code: Typically classified under 8302.41 (Fittings for doors, windows, etc., of base metal). Confirm with local customs authority.

- Documentation: Provide commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

- Regulatory Approvals: Ensure compliance with destination country standards (e.g., CE marking for EU, UL/cUL for North America).

- Restricted Substances: Confirm no use of substances restricted under RoHS, REACH, or Prop 65. Provide material safety data sheet (MSDS) upon request.

Safety & Installation Compliance

- Fire Safety: Units installed in fire-rated doors must meet fire door certification standards (e.g., EN 1154, BS EN 1154).

- Accessibility: Comply with ADA (U.S.) or EN 16005 (EU) for controlled door closing force and opening ease.

- Installation Standards: Must be installed by qualified personnel per manufacturer’s guidelines to ensure operational safety and warranty validity.

Warranty & Returns

- Warranty Period: Standard 2-year limited warranty covering manufacturing defects.

- Return Process: Contact distributor or supplier for return authorization (RA). Returns require original packaging and proof of purchase.

- Non-Compliance Handling: Defective or non-compliant units will be replaced or refunded per warranty terms.

Environmental & Disposal Guidelines

- Recyclability: Components are primarily steel and aluminum—fully recyclable.

- Hydraulic Fluid: Dispose of leaking units as hazardous waste per local environmental regulations (e.g., EPA, EU WEEE).

- End-of-Life: Return to manufacturer or certified e-waste handler for proper disassembly and fluid recovery.

Contact & Support

For logistics inquiries, compliance documentation, or technical support, contact:

Customer Service: [email protected]

Technical Support: [email protected]

Phone: +1 (800) 555-0199 (Mon–Fri, 9:00 AM – 5:00 PM EST)

In conclusion, sourcing hydraulic floor springs requires careful consideration of quality, durability, compatibility, and supplier reliability. These critical components play a vital role in door functionality, safety, and longevity, especially in high-traffic commercial and public buildings. It is essential to partner with reputable manufacturers or suppliers who provide certified products that meet industry standards such as ANSI, CE, or DIN. Evaluating factors such as load capacity, closing force adjustability, fire and smoke ratings, and warranty support ensures optimal performance and compliance with safety regulations. Additionally, cost-effectiveness should not compromise quality, as investing in high-performance hydraulic floor springs reduces long-term maintenance and replacement costs. Conducting thorough market research, obtaining product samples, and verifying certifications will help in making informed procurement decisions, ultimately ensuring safety, efficiency, and reliability in door systems.