The global hydraulic dolly market is experiencing robust growth, driven by rising demand for efficient material handling solutions across construction, manufacturing, and logistics sectors. According to Grand View Research, the global material handling equipment market size was valued at USD 207.4 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030—growth that directly influences the demand for specialized transport equipment like hydraulic dollies. These versatile tools, essential for moving heavy machinery and components with precision and safety, are increasingly adopted in industrial automation and infrastructure development projects. As the industry evolves, innovation in load capacity, maneuverability, and durability has positioned hydraulic dollies as critical assets in modern operations. In this landscape, a select group of manufacturers have emerged as leaders, combining engineering excellence with scalable production to meet expanding global needs. Based on market presence, product range, and technological advancement, the following nine companies represent the forefront of the hydraulic dolly manufacturing sector.

Top 9 Hydraulic Dolly Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hilman Inc.

Domain Est. 1996

Website: hilmanrollers.com

Key Highlights: These versatile rollers are made from durable hardened steel and feature an infinite chain design for easy and reliable heavy load moving. Safely position heavy ……

#2 Vestil Manufacturing Corp.

Domain Est. 1998

Website: vestil.com

Key Highlights: Vestil Manufacturing Corporation is an industry leader in the manufacturing and distributing of industrial material handling equipment….

#3 Shinn Fu America Homepage

Domain Est. 2002

Website: bonecreeper.com

Key Highlights: Shinn Fu Company of America, Inc. (SFA) performs its functions in marketing, sales, service and distributing products throughout North, Central and South ……

#4 Prolift Hydraulic Lift Equipment Homepage

Domain Est. 2011

Website: proliftproducts.com

Key Highlights: Designed after professional grade equipment standards, Pro-Lift is kept under close quality control standards from factory to your home….

#5 Stertil

Domain Est. 1997

Website: stertil-koni.com

Key Highlights: Stertil-Koni is the undisputed #1 leader in advanced, safe and dependable heavy duty vehicle lifting systems. From bus lifts to truck lifts, we do it all….

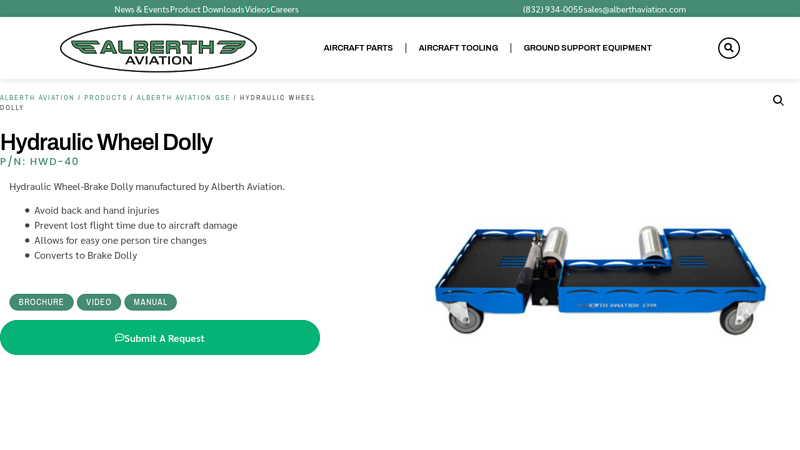

#6 Hydraulic Wheel Dolly

Domain Est. 2004

Website: alberthaviation.com

Key Highlights: Hydraulic Wheel-Brake Dolly · Adjusts for tire widths from 4 to 12 inches · Handles wheel diameters from 25 to 40 inches · Supports wheels up to 350 lbs ……

#7 Heavy Equipment Moving Solutions

Domain Est. 2005

Website: gksweb.com

Key Highlights: Free delivery 30-day returnsGKS provides heavy equipment moving solutions, including machine skates, toe jacks, rotating dollies, and remote-controlled load movers….

#8 Holland Dolly

Domain Est. 2010

Website: hmrsupplies.com

Key Highlights: HMR Supplies offers the standard hydraulic dolly ( Holland Dollie® ), also known as the Coaster Dolly, in 40, 45 and 55 Ton capacity in powered and non-powered ……

#9 Buckingham Power, Coaster, & Crab Steer Dollies

Domain Est. 2011

Website: buckinghamequipment.com

Key Highlights: Buckingham Equipment manufactures top-of-the line hydraulic Power, Coaster, Low Profile, and Crab Steer Dollies….

Expert Sourcing Insights for Hydraulic Dolly

H2: 2026 Market Trends for Hydraulic Dollies

The hydraulic dolly market is poised for steady growth and technological evolution by 2026, driven by increasing automation, labor efficiency demands, and advancements in material handling across key industries. Here’s an analysis of the dominant trends shaping the market:

1. Rising Demand for Ergonomic and Labor-Saving Solutions:

With persistent labor shortages and heightened focus on workplace safety, industries are investing heavily in equipment that reduces physical strain and injury risks. Hydraulic dollies, which enable safe lifting and maneuvering of heavy loads with minimal manual effort, are seeing increased adoption in manufacturing, warehousing, and construction. This trend will accelerate through 2026 as companies prioritize worker well-being and compliance with OSHA and similar regulations.

2. Integration with Smart Technologies and IoT:

By 2026, expect a surge in “smart” hydraulic dollies equipped with sensors, load monitoring systems, and wireless connectivity. These enhancements allow real-time tracking of load weight, usage patterns, and maintenance needs. Integration with warehouse management systems (WMS) and fleet management software will optimize logistics operations, improving inventory accuracy and operational efficiency.

3. Growth in E-Commerce and Logistics Infrastructure:

The continued expansion of e-commerce fuels demand for efficient warehouse and distribution center operations. Hydraulic dollies play a crucial role in intra-facility transport, especially for heavy or bulky items. As logistics networks expand globally—including last-mile distribution hubs—flexible and reliable material handling tools like hydraulic dollies will be essential, driving market growth.

4. Emphasis on Customization and Application-Specific Designs:

Manufacturers are increasingly offering customizable hydraulic dollies tailored to specific sectors—such as automotive, aerospace, and energy—where unique load profiles and operating environments exist. Features like adjustable height, swivel casters, ruggedized frames, and non-marking wheels are becoming standard offerings, allowing businesses to optimize performance and safety.

5. Sustainability and Energy Efficiency Considerations:

While hydraulic systems are inherently robust, there is growing interest in energy-efficient designs and eco-friendly hydraulic fluids. Some manufacturers are exploring hybrid or electric-hydraulic systems to reduce environmental impact and maintenance costs. Though not yet mainstream, sustainability will become a differentiating factor by 2026.

6. Regional Market Expansion:

Asia-Pacific, particularly China and India, is expected to lead market growth due to rapid industrialization, infrastructure development, and government initiatives promoting manufacturing (e.g., “Make in India”). North America and Europe will maintain strong demand, driven by warehouse automation and modernization of aging industrial facilities.

7. Competitive Landscape and Innovation:

The market will see increased competition among established players (e.g., Liftomatic, Rotom, DJ Products) and emerging manufacturers, especially from Asia. Innovation in materials (e.g., lightweight alloys), durability, and ease of maintenance will be key differentiators. Rental and service-as-a-solution models may also gain traction, offering flexibility to end-users.

Conclusion:

By 2026, the hydraulic dolly market will be characterized by smarter, safer, and more specialized equipment. Driven by automation trends, labor dynamics, and logistical demands, the sector will evolve beyond basic load-moving tools into integrated components of intelligent material handling ecosystems. Companies that invest in innovation, customization, and digital integration will be best positioned to capture market share in this growing niche.

Common Pitfalls When Sourcing Hydraulic Dollies (Quality, IP)

Sourcing hydraulic dollies—especially from international suppliers—can lead to significant issues if due diligence isn’t performed. Two major areas where problems frequently arise are product quality and intellectual property (IP) risks. Being aware of these pitfalls helps avoid costly delays, safety hazards, and legal complications.

Poor Build Quality and Material Deficiencies

One of the most common pitfalls in sourcing hydraulic dollies is receiving units that fail to meet durability, safety, or performance standards. This often stems from:

- Substandard Materials: Suppliers may use low-grade steel, inferior hydraulic seals, or undersized cylinders to cut costs, leading to premature wear or catastrophic failure under load.

- Inadequate Welding and Fabrication: Poor welding practices compromise structural integrity, increasing the risk of collapse during operation.

- Lack of Quality Control: Many manufacturers skip essential testing procedures such as pressure testing hydraulic systems or load testing the frame, resulting in unreliable performance.

- Non-Compliance with Safety Standards: Imported dollies may not conform to regional safety regulations (e.g., OSHA in the US, CE in Europe), exposing buyers to liability and compliance risks.

To mitigate these risks, conduct factory audits, request third-party inspection reports (e.g., SGS, BV), and insist on sample testing under real-world conditions.

Intellectual Property (IP) Infringement Risks

Another critical pitfall involves sourcing hydraulic dollies that infringe on existing patents, trademarks, or design rights—especially when dealing with low-cost suppliers in regions with weaker IP enforcement.

- Patent Violations: Some suppliers replicate patented features (e.g., unique lifting mechanisms, locking systems, or modular designs) without licensing, exposing the buyer to legal action if the product is imported or sold in protected markets.

- Counterfeit or Knock-off Products: Suppliers may present their dollies as original designs when they are close copies of branded models, leading to brand reputation damage and legal exposure.

- Lack of IP Documentation: Suppliers often fail to provide proof of IP ownership or design freedom-to-operate, making it difficult to verify legitimacy.

To protect against IP risks, conduct patent landscape searches, require suppliers to sign IP indemnity clauses in contracts, and work with legal counsel to assess infringement risks before mass production or importation.

Addressing these quality and IP pitfalls early in the sourcing process ensures safer, compliant, and legally secure procurement of hydraulic dollies.

Logistics & Compliance Guide for Hydraulic Dolly

Product Overview

A hydraulic dolly is a heavy-duty material handling device used to lift, move, and position heavy loads with precision. It operates using hydraulic power to raise and lower its platform, allowing for smooth transportation across industrial environments such as warehouses, manufacturing facilities, and construction sites. Understanding proper logistics handling and compliance requirements is essential for safe and legal operation.

Transportation and Shipping Requirements

Hydraulic dollies must be securely packaged to prevent damage during transit. When shipping, ensure the unit is drained of excess hydraulic fluid (if required by carrier regulations), and all movable parts are immobilized. Use skids or crates for stability, and follow standard freight classifications (e.g., NMFC codes in North America). International shipments may require compliance with IATA, IMDG, or ADR regulations if hydraulic fluid is classified as hazardous.

Import and Export Regulations

When importing or exporting hydraulic dollies, verify country-specific customs documentation, including commercial invoices, packing lists, and certificates of origin. Check for applicable tariffs and ensure the product meets relevant safety and emissions standards in the destination country. Units with electric or powered components may require additional certifications (e.g., CE, UKCA, or UL listing).

Safety and Operational Compliance

Operators must comply with OSHA (in the U.S.) or equivalent workplace safety regulations. This includes proper training, use of personal protective equipment (PPE), and adherence to load capacity limits specified by the manufacturer. Hydraulic dollies should be routinely inspected for leaks, structural integrity, and functional controls. Maintenance records must be kept to demonstrate compliance during safety audits.

Environmental and Fluid Handling Regulations

Hydraulic systems may use fluids subject to environmental regulations. Spills must be contained and cleaned according to local EPA or equivalent guidelines. Used hydraulic fluid should be disposed of as hazardous waste where applicable, following proper recycling or disposal protocols. Facilities using hydraulic dollies should have Spill Prevention, Control, and Countermeasure (SPCC) plans if storing large volumes of fluid.

Certification and Standards

Ensure the hydraulic dolly meets recognized industry standards such as ANSI/ITSDF B56.1 (for industrial trucks) or ISO 5057 (for platform trucks). CE marking is required for sale within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Documentation should include a Declaration of Conformity and user manuals in the local language.

Storage and Handling Precautions

Store hydraulic dollies in a dry, level area protected from extreme temperatures and corrosive environments. Relieve hydraulic pressure before prolonged storage, and inspect seals and hoses periodically. When not in use, lower the platform to prevent accidental release of pressure and ensure stability.

Training and Documentation

Employers must provide documented training for all personnel using hydraulic dollies. Training should cover load limits, proper coupling techniques (if used with other equipment), emergency procedures, and inspection routines. Maintain training logs and equipment maintenance records for regulatory compliance and liability protection.

Maintenance and Inspection Schedule

Follow the manufacturer’s recommended maintenance schedule, including fluid checks, hose inspections, and structural evaluations. Document all inspections and repairs. Non-compliance with maintenance protocols can void warranties and result in regulatory penalties or workplace incidents.

Emergency and Incident Reporting

In the event of an accident or equipment failure involving a hydraulic dolly, follow internal incident reporting procedures and notify relevant authorities if injuries or environmental contamination occur. Preserve evidence and conduct a root cause analysis to prevent recurrence.

Conclusion for Sourcing Hydraulic Dolly

After thorough evaluation of suppliers, product specifications, pricing, and after-sales support, it is concluded that sourcing hydraulic dollies is a strategic decision to enhance operational efficiency, reduce manual handling risks, and improve workplace safety. The selected supplier offers reliable, high-quality hydraulic dollies that meet required load capacities, durability standards, and industry compliance. Competitive pricing, timely delivery, and comprehensive warranty support further strengthen the sourcing decision. Implementing these hydraulic dollies across relevant departments will contribute to increased productivity and reduced physical strain on personnel. Moving forward, consistent supplier engagement and regular performance reviews will ensure long-term value and operational success.