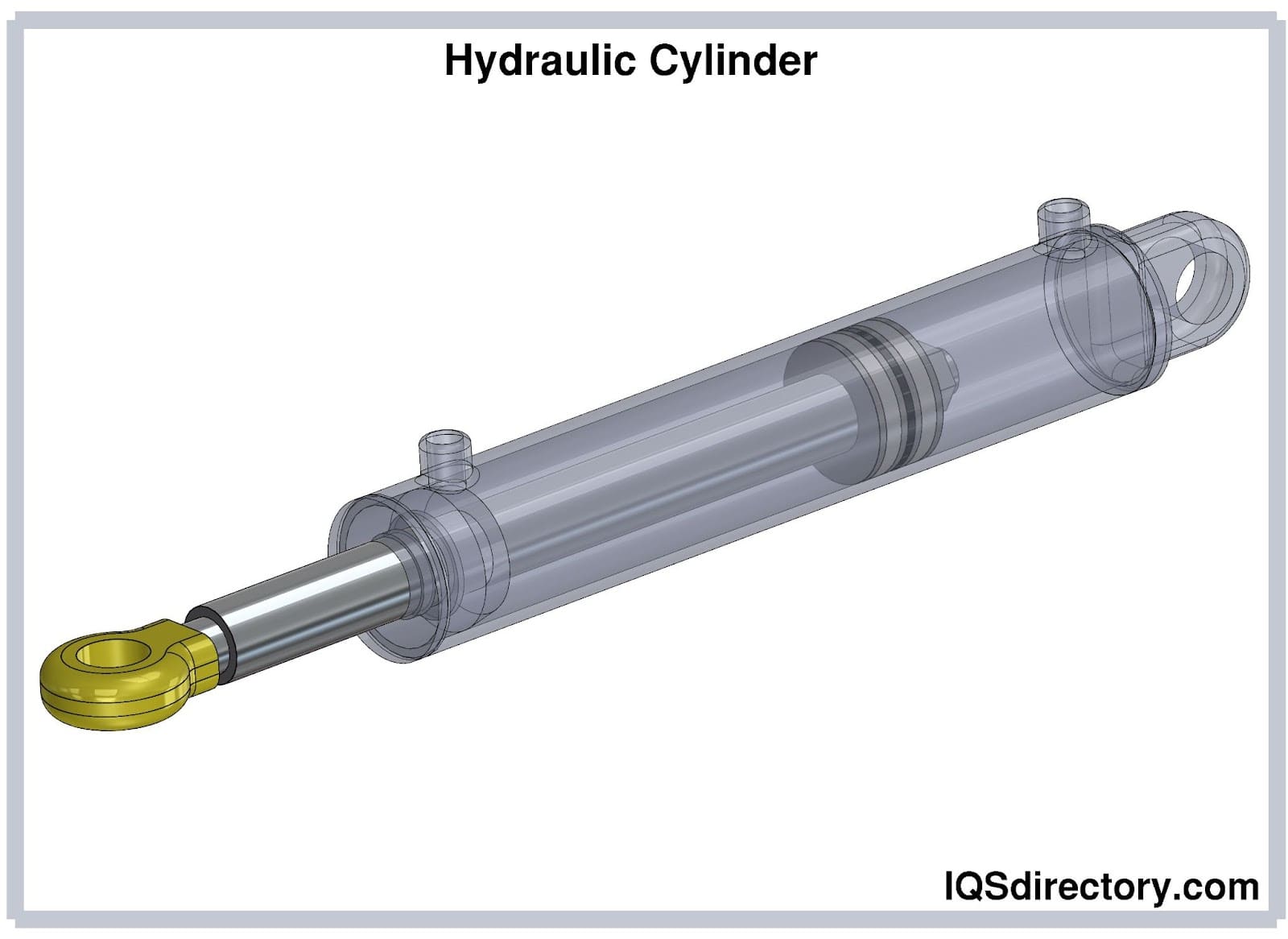

The global hydraulic cylinder market is experiencing robust growth, driven by rising demand across construction, manufacturing, agriculture, and material handling industries. According to Grand View Research, the market was valued at USD 8.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. This expansion is fueled by increasing automation, infrastructure development, and the need for high-performance fluid power systems in heavy machinery. Mordor Intelligence further supports this trend, forecasting continued growth due to advancements in mobile hydraulics and the integration of smart hydraulic systems in industrial equipment. As demand rises, several manufacturers have emerged as leaders through innovation, global reach, and reliable performance. Below is a data-driven overview of the top 10 hydraulic cylinder manufacturers shaping the future of fluid power technology.

Top 10 Hydraulic Cylinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydraulic Cylinder Manufacturer

Domain Est. 1999

Website: cylval.com

Key Highlights: Cylinders & Valves, Inc. offers a wide variety of standard and custom hydraulic cylinders, pneumatic cylinders, replacement parts, and cylinder repair….

#2 Custom Hydraulic Cylinder Manufacturing

Domain Est. 2001

Website: texashydraulics.com

Key Highlights: We are a leading manufacturer of custom welded hydraulic cylinders in the United States and we maintain our place as a leader in the industry….

#3 Hydraulic Cylinders Purpose

Domain Est. 2002

Website: aggressivehydraulics.com

Key Highlights: Custom Hydraulic Cylinders. Our Purpose-Built™ hydraulic cylinders are engineered for high performance in demanding applications. Welded Hydraulic Cylinders….

#4 Hydraulic Cylinders

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker manufactures a diverse range of standard and special tie rod, roundline and ‘mill’ type cylinders to suit all types of industrial cylinder applications….

#5 Milwaukee Cylinder

Domain Est. 1999

Website: milwaukeecylinder.com

Key Highlights: Milwaukee Cylinder is a premium manufacturer of air cylinders and hydraulic cylinders for standard and custom tie rod cylinder applications….

#6 Ligon Hydraulics

Domain Est. 2022

Website: ligonhyd.com

Key Highlights: Ligon Hydraulics is the leader in hydraulic cylinder solutions. Ligon makes welded/threaded, multi-stage, bolted-head, pneumatic & piggyback cylinders….

#7 Energy Mfg. Co.

Domain Est. 1996

Website: energymfg.com

Key Highlights: Energy Mfg. Co. specializes in providing custom hydraulic cylinders, valves, and Williams pumps, tanks, and valves for demanding applications….

#8 Hercules Sealing Products

Domain Est. 2006

Website: herculesus.com

Key Highlights: Hercules Sealing Products is a leading supplier of aftermarket hydraulic seals, seal kits, hydraulic cylinders, and cylinder repair parts….

#9

Domain Est. 2012

Website: hpsinternational.com

Key Highlights: HPS production plants can design and manufacture all types of hydraulic cylinders, up to the maximum dimensions of 1 000 mm bore and 11 000 mm stroke….

#10 Hydraulic Cylinders, Valves, Pumps and Components from Bailey …

Domain Est. 2013

Website: baileyhydraulics.com

Key Highlights: Free delivery over $35 45-day returns…

Expert Sourcing Insights for Hydraulic Cylinder

H2: 2026 Market Trends for Hydraulic Cylinders

The global hydraulic cylinder market is poised for significant transformation by 2026, driven by technological advancements, evolving industrial demands, and shifts in key end-user sectors. Several trends are expected to shape the industry landscape over the next few years.

-

Increased Demand from Construction and Infrastructure Sectors

Rising infrastructure development, particularly in emerging economies across Asia-Pacific, Africa, and Latin America, will be a major growth driver. Governments investing in transportation networks, urban development, and energy projects are boosting demand for heavy machinery—equipment that heavily relies on hydraulic cylinders. The continued focus on smart cities and sustainable infrastructure will further amplify this trend. -

Adoption of Smart and IoT-Enabled Hydraulic Systems

By 2026, integration of the Internet of Things (IoT) and Industry 4.0 technologies into hydraulic systems is expected to accelerate. Smart hydraulic cylinders equipped with sensors for real-time monitoring of pressure, temperature, and wear will gain traction. This enables predictive maintenance, improves operational efficiency, and reduces downtime—key priorities for industries such as manufacturing, mining, and agriculture. -

Growth in Mobile and Off-Highway Applications

The off-highway vehicle segment—including excavators, loaders, agricultural tractors, and forestry equipment—will remain the largest end-user of hydraulic cylinders. As automation and electrification advance in these machines, demand for high-performance, compact, and energy-efficient hydraulic solutions will rise. OEMs are increasingly focusing on lightweight and corrosion-resistant cylinder designs to meet durability and fuel-efficiency standards. -

Shift Toward Sustainable and Energy-Efficient Solutions

Environmental regulations and the push for carbon neutrality are prompting manufacturers to develop energy-efficient hydraulic systems. Trends include the use of electro-hydraulic actuators, regenerative circuits, and hybrid systems that reduce energy consumption. Additionally, increased focus on recyclable materials and leak-proof designs supports sustainability goals. -

Regional Market Shifts and Localization

While North America and Europe remain strong markets due to advanced manufacturing and automation, the Asia-Pacific region is expected to witness the highest growth rate. China, India, and Southeast Asian countries are expanding industrial and construction activities. Localization of production to reduce logistics costs and comply with regional trade policies will be a strategic focus for global hydraulic cylinder manufacturers. -

Impact of Electrification and Alternative Actuation Technologies

Although hydraulic systems will continue to dominate in high-force applications, the rise of electric linear actuators poses a competitive challenge in light- and medium-duty applications. However, hydraulic cylinders will maintain an edge in sectors requiring high power density, ruggedness, and reliability—such as mining and heavy construction. -

Consolidation and Innovation Among Key Players

Market consolidation through mergers, acquisitions, and partnerships is expected to increase as companies seek to expand their technological capabilities and geographic reach. Leading players like Bosch Rexroth, Parker Hannifin, and HYDAC are investing heavily in R&D to develop next-generation cylinders with enhanced performance, digital integration, and modular designs.

In conclusion, the hydraulic cylinder market in 2026 will be shaped by digitalization, sustainability, and growing industrial automation. While facing competition from alternative actuation methods, hydraulic cylinders will remain indispensable in high-force applications, with innovation ensuring their relevance in modern industrial ecosystems.

Common Pitfalls Sourcing Hydraulic Cylinders (Quality, IP)

Sourcing hydraulic cylinders involves several critical considerations, particularly regarding quality assurance and Ingress Protection (IP) ratings. Overlooking these aspects can lead to system failures, safety hazards, and increased lifecycle costs. Below are common pitfalls to avoid:

Poor Quality Materials and Construction

One of the most frequent issues when sourcing hydraulic cylinders is compromising on material quality to reduce upfront costs. Low-grade steel, substandard seals, and poor surface finishes on rods can lead to premature wear, pitting, and leakage. Cheaply manufactured cylinders often exhibit inconsistent tolerances, leading to misalignment, increased friction, and reduced efficiency. Always verify material specifications, manufacturing standards (e.g., ISO 6020/2), and request test reports or certifications from suppliers.

Inadequate Ingress Protection (IP) Rating

The IP rating indicates a cylinder’s resistance to dust and moisture ingress. A common mistake is selecting a cylinder with an IP rating insufficient for the operating environment. For example, using an IP54-rated cylinder in a washdown or outdoor application exposes internal components to water and contaminants, risking seal failure and internal corrosion. Always match the IP rating to the environment—IP65 or higher is typically required for harsh or wet conditions.

Ignoring Duty Cycle and Load Requirements

Selecting a cylinder based solely on size or cost without evaluating the actual duty cycle and load demands can result in premature failure. Overloading or rapid cycling beyond design limits causes stress on components like the piston rod and gland, leading to bending, buckling, or seal extrusion. Ensure the cylinder is rated for the expected stroke length, operating pressure, and frequency of use.

Lack of Compliance with Industry Standards

Sourcing cylinders that do not conform to recognized international standards (such as ISO, NFPA, or DIN) increases the risk of incompatibility and safety issues. Non-compliant cylinders may lack proper documentation, testing, or traceability, making maintenance and troubleshooting difficult. Always confirm that the cylinder meets relevant regulatory and safety standards for your region and application.

Insufficient Supplier Vetting

Relying on unverified or low-cost suppliers without assessing their quality control processes, production capabilities, or after-sales support can result in inconsistent product quality. Poor supplier communication and lack of technical support may delay projects and increase downtime. Conduct due diligence by reviewing supplier certifications (e.g., ISO 9001), requesting samples, and evaluating customer references.

Overlooking Environmental and Operating Conditions

Failure to account for ambient temperature, exposure to chemicals, vibration, or outdoor weathering can compromise cylinder performance. For instance, standard seals may degrade when exposed to UV radiation or aggressive fluids. Specify appropriate materials and seal types (e.g., polyurethane, Viton) and protective coatings (e.g., chrome plating, paint finishes) based on the operating environment.

Incomplete Documentation and Traceability

Cylinders lacking proper documentation—such as test certificates, material traceability, or assembly records—can hinder maintenance, compliance audits, and warranty claims. Always insist on comprehensive documentation, including pressure test results and conformity declarations, especially in regulated industries like oil & gas or marine.

Avoiding these pitfalls requires thorough specification, due diligence in supplier selection, and a clear understanding of application requirements. Investing time upfront ensures reliable, long-term performance and reduces total cost of ownership.

Logistics & Compliance Guide for Hydraulic Cylinders

Overview and Importance

Hydraulic cylinders are critical components in various industrial, construction, and mobile machinery applications. Due to their weight, size, and material composition, transporting and complying with international and domestic regulations for hydraulic cylinders requires careful planning. Proper logistics and adherence to compliance standards ensure safety, avoid delays, and prevent fines.

Classification and Harmonized System (HS) Code

Hydraulic cylinders are typically classified under the Harmonized System (HS) for customs purposes. The most common HS code is:

8412.21.00 – Hydraulic cylinders, other than rotary.

Note: Specific codes may vary slightly by country. Always verify with local customs authorities or a licensed customs broker before shipment.

Packaging and Handling Requirements

- Use wooden crates or reinforced cardboard boxes with internal bracing to protect rod ends, seals, and piston rods.

- Cap all ports to prevent contamination and damage during transit.

- Apply protective coatings or rust inhibitors on exposed metal surfaces, especially for sea freight.

- Secure cylinders to prevent movement within containers or vehicles.

- Include handling labels (e.g., “Fragile,” “This Side Up”) and weight markers.

Transportation Modes and Considerations

- Road Transport: Ideal for regional distribution. Ensure load is secured and compliant with weight and dimension regulations (e.g., ADR in Europe).

- Sea Freight: Most cost-effective for international shipments. Use containerized shipping (20’ or 40’ containers) and consider moisture protection (desiccants, VCI paper).

- Air Freight: Recommended for urgent or high-value shipments. Subject to strict dimensional and weight limitations; may incur higher costs.

- Rail: Suitable for long-distance overland transport in regions with developed rail infrastructure.

International Shipping Documentation

Essential documents include:

– Commercial Invoice (detailing value, quantity, terms of sale)

– Packing List (itemizing contents, weights, dimensions)

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (if required by trade agreement)

– Export Declaration (per country-specific requirements)

– Material Safety Data Sheet (MSDS), if containing hydraulic fluid or lubricants

Regulatory Compliance

- REACH and RoHS (EU): Ensure materials used (e.g., seals, coatings) comply with chemical restrictions.

- EPA and DOT (USA): Adhere to transportation safety standards; cylinders containing fluids may be subject to hazardous material regulations.

- Customs Valuation: Declare accurate transaction value to avoid penalties or delays.

- Import Duties and Taxes: Calculate applicable tariffs, VAT, or GST based on destination country and HS code.

Special Handling for Pressurized or Fluid-Filled Units

- Hydraulic cylinders shipped with trapped air or residual fluid may be subject to dangerous goods regulations.

- If filled with hydraulic oil, classify under UN3082, ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S. (hydraulic fluid), and comply with IMDG Code (sea) or IATA DGR (air).

- Empty and properly drained cylinders are preferred for international shipping to minimize regulatory burden.

Storage and Inventory Management

- Store in a dry, temperature-controlled environment to prevent corrosion.

- Keep vertical or properly supported to avoid bending of piston rods.

- Implement FIFO (First In, First Out) inventory rotation to ensure product integrity.

Return Logistics and Reverse Supply Chain

- Establish clear processes for defective or damaged units.

- Include return authorization (RMA) procedures and proper packaging instructions.

- Ensure returned cylinders are cleaned and drained before shipment to comply with environmental regulations.

Best Practices Summary

- Verify HS code and import requirements early in the shipping process.

- Invest in robust packaging tailored to transport mode.

- Maintain accurate and complete documentation.

- Train staff on handling, labeling, and compliance protocols.

- Partner with experienced freight forwarders familiar with industrial machinery.

Adhering to this guide ensures efficient, compliant logistics operations for hydraulic cylinders across global supply chains.

Conclusion for Sourcing Hydraulic Cylinder Suppliers

Successfully sourcing hydraulic cylinder suppliers requires a strategic and comprehensive approach that balances quality, reliability, cost-efficiency, and long-term partnership potential. After evaluating various suppliers based on critical factors such as manufacturing capabilities, quality certifications (e.g., ISO 9001), material standards, lead times, customization options, and after-sales support, it becomes evident that selecting the right supplier is crucial to ensuring optimal system performance and operational efficiency.

Suppliers from both established industrial regions and emerging manufacturing hubs offer competitive advantages, but due diligence is essential to mitigate risks related to quality inconsistency, communication barriers, and logistical challenges. Onshoring, nearshoring, or global sourcing should be assessed based on specific project demands, volume requirements, and supply chain resilience goals.

In conclusion, the ideal hydraulic cylinder supplier should not only meet current technical and commercial needs but also demonstrate a commitment to innovation, continuous improvement, and responsive service. Building strong, transparent relationships with a select group of qualified suppliers will enhance supply chain stability, reduce downtime, and support long-term business growth in industries ranging from construction and manufacturing to agriculture and heavy machinery.