The global hydraulic cylinder market is experiencing robust growth, driven by rising demand across construction, manufacturing, agriculture, and heavy machinery sectors. According to Mordor Intelligence, the market was valued at USD 9.62 billion in 2024 and is projected to reach USD 13.35 billion by 2029, growing at a CAGR of 6.8% during the forecast period. This expansion is fueled by technological advancements in fluid power systems and increasing automation in industrial applications. As key components of hydraulic systems, pistons play a critical role in cylinder performance, durability, and efficiency. With intensifying competition and innovation, a select group of manufacturers has emerged as leaders in piston design, precision engineering, and large-scale production. Based on market presence, product quality, and technological capabilities, the following are the top 10 hydraulic cylinder piston manufacturers shaping the industry’s future.

Top 10 Hydraulic Cylinder Piston Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PHC

Domain Est. 2005

Website: phc-global.com

Key Highlights: PHC | OEM Hydraulic Cylinder Manufacturing | Precision Hydraulic Cylinders is one of the premier manufacturers of cylinders for the material handling and ……

#2 Hydraulic Cylinders Purpose

Domain Est. 2002

Website: aggressivehydraulics.com

Key Highlights: Why Choose Aggressive Hydraulics. We build every cylinder in our U.S. facility with the expertise, equipment, and processes to deliver lasting performance….

#3 Milwaukee Cylinder

Domain Est. 1999

Website: milwaukeecylinder.com

Key Highlights: Milwaukee Cylinder is a premium manufacturer of air cylinders and hydraulic cylinders for standard and custom tie rod cylinder applications….

#4 Mailhot Industries

Domain Est. 2000 | Founded: 1956

Website: mailhotindustries.com

Key Highlights: Mailhot Industries, North American leader in engineering and manufacturing 100% nitrided, hydraulic telescopic and rod cylinders since 1956….

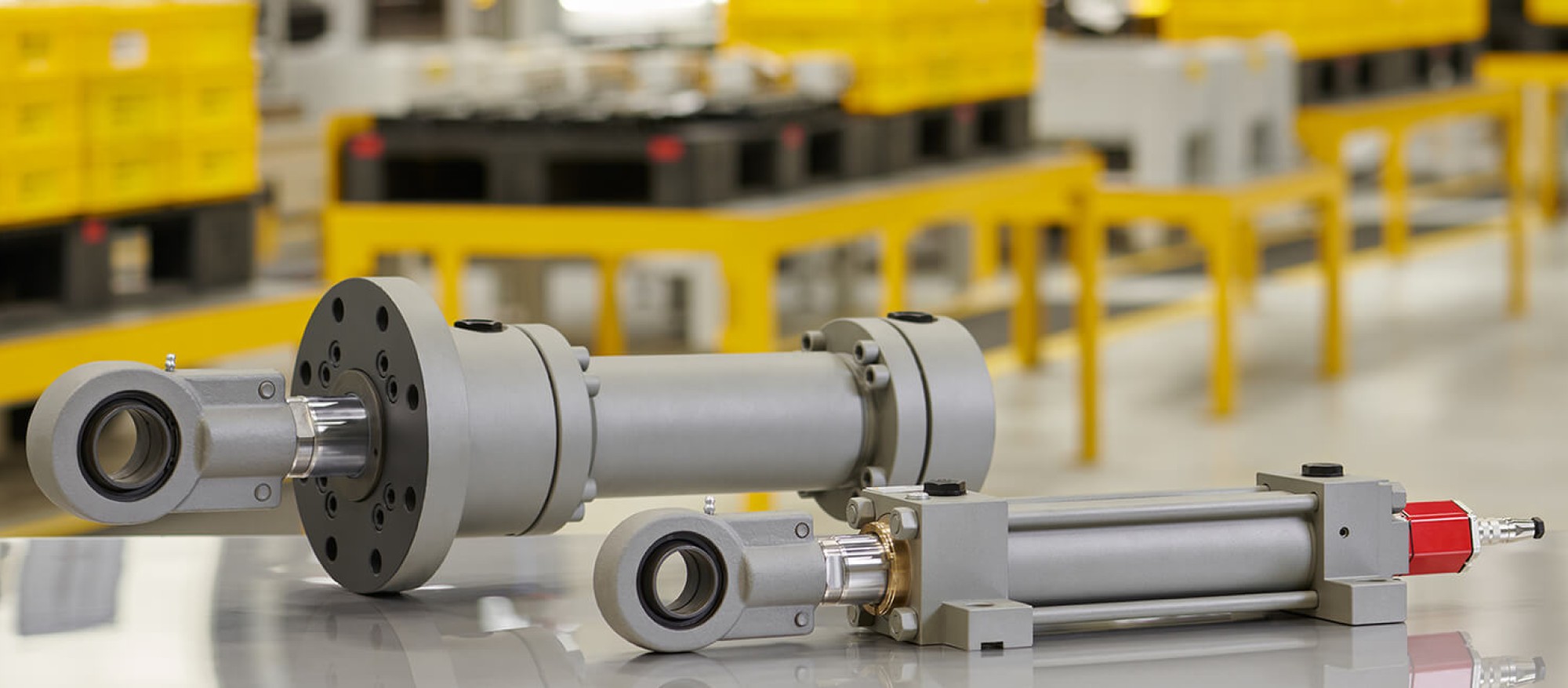

#5 Ligon Hydraulics

Domain Est. 2022

Website: ligonhyd.com

Key Highlights: Ligon Hydraulics is the leader in hydraulic cylinder solutions. Ligon makes welded/threaded, multi-stage, bolted-head, pneumatic & piggyback cylinders….

#6 Hydraulic Actuator Division

Domain Est. 1995

Website: parker.com

Key Highlights: At Parker Hydraulic Actuator Division, we proudly manufacture cylinders, actuators, piston accumulators, and compact hydraulic power units in the U.S. With ……

#7 Energy Mfg. Co.

Domain Est. 1996

Website: energymfg.com

Key Highlights: Energy Mfg. Co. specializes in providing custom hydraulic cylinders, valves, and Williams pumps, tanks, and valves for demanding applications….

#8 Hercules Sealing Products

Domain Est. 2006

Website: herculesus.com

Key Highlights: Hercules Sealing Products is a leading supplier of aftermarket hydraulic seals, seal kits, hydraulic cylinders, and cylinder repair parts….

#9

Domain Est. 2012

Website: hpsinternational.com

Key Highlights: HPS production plants can design and manufacture all types of hydraulic cylinders, up to the maximum dimensions of 1 000 mm bore and 11 000 mm stroke….

#10 Hydraulic Cylinders, Valves, Pumps and Components from Bailey …

Domain Est. 2013

Website: baileyhydraulics.com

Key Highlights: Free delivery over $35 45-day returns…

Expert Sourcing Insights for Hydraulic Cylinder Piston

H2: 2026 Market Trends for Hydraulic Cylinder Pistons

The global market for hydraulic cylinder pistons is poised for significant evolution by 2026, driven by advancements in industrial automation, growing demand from construction and manufacturing sectors, and a shift toward energy-efficient and smart hydraulic systems. Key trends shaping the market include:

-

Increased Demand from Heavy Industries

The construction, mining, agriculture, and material handling industries continue to be primary drivers of hydraulic cylinder piston demand. With global infrastructure development accelerating—especially in Asia-Pacific and Africa—equipment such as excavators, loaders, and cranes will require high-performance hydraulic components. This sustained demand is projected to boost the hydraulic piston market through 2026. -

Adoption of Lightweight and High-Strength Materials

Manufacturers are shifting toward advanced materials such as high-grade alloy steels, stainless steel, and composite coatings to enhance durability, reduce weight, and improve corrosion resistance. These innovations contribute to longer service life and lower maintenance costs, appealing to OEMs and end-users alike. -

Rise of Smart and IoT-Enabled Hydraulics

Integration of sensors and IoT technology into hydraulic systems allows for real-time monitoring of piston performance, pressure, temperature, and wear. By 2026, smart hydraulic cylinders featuring predictive maintenance capabilities are expected to gain traction, especially in industrial automation and mobile machinery applications. -

Focus on Energy Efficiency and Sustainability

Stricter environmental regulations are pushing manufacturers to develop energy-efficient hydraulic solutions. Optimized piston designs that reduce internal leakage and friction contribute to improved system efficiency. Additionally, the use of biodegradable hydraulic fluids is influencing seal and surface treatment choices for pistons. -

Growth in Customization and Modular Designs

End-users are increasingly seeking customized hydraulic pistons tailored to specific applications. Modular designs that allow for easy maintenance and replacement are becoming popular, particularly in off-highway vehicles and industrial machinery. -

Expansion in Aftermarket and Remanufacturing

The aftermarket segment for hydraulic cylinder pistons is growing due to cost considerations and sustainability goals. Remanufactured pistons offer a cost-effective and environmentally friendly alternative, supported by improved refurbishment technologies and quality standards. -

Regional Market Shifts

While North America and Europe maintain strong demand due to industrial automation and aging infrastructure renewal, the Asia-Pacific region—led by China, India, and Southeast Asia—is expected to witness the highest growth. Government investments in smart cities and transportation infrastructure will drive hydraulic component demand. -

Impact of Supply Chain Diversification

Post-pandemic supply chain challenges have prompted companies to diversify sourcing and production. By 2026, regional manufacturing hubs and localized supply chains are expected to reduce lead times and improve resilience, especially for critical components like hydraulic pistons.

In conclusion, the hydraulic cylinder piston market in 2026 will be shaped by innovation, digitalization, and sustainability. Companies that invest in advanced materials, smart technologies, and efficient production methods are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Hydraulic Cylinder Pistons (Quality & IP)

Sourcing hydraulic cylinder pistons involves more than just finding the lowest price. Overlooking critical quality and intellectual property (IP) factors can lead to performance failures, safety hazards, legal liabilities, and increased total cost of ownership. Here are key pitfalls to avoid:

Poor Material Quality and Specifications

Selecting pistons made from substandard materials or failing to verify compliance with required specifications can result in premature wear, deformation, or catastrophic failure under pressure. Always ensure pistons are manufactured from appropriate grades of steel or aluminum alloys (e.g., CK45, 42CrMo) with proper heat treatment, surface finish, and hardness ratings that match the application’s demands.

Inadequate Surface Finish and Coating

The piston’s surface finish directly impacts seal performance and longevity. A rough or improperly coated surface increases friction, accelerates seal wear, and may cause leakage. Avoid suppliers who do not guarantee precise surface finishes (typically Ra < 0.4 µm) or fail to apply anti-corrosion coatings like hard chrome plating or HVOF when required.

Tolerance and Dimensional Inaccuracy

Hydraulic pistons must meet tight dimensional tolerances to ensure proper fit within the cylinder bore and alignment with seals and rods. Poor machining leads to binding, uneven wear, and reduced efficiency. Always request certified dimensional reports and ensure the supplier adheres to international standards such as ISO 3309 or DIN/ISO 6020.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including material test reports (MTRs), heat numbers, and inspection certificates. Sourcing from vendors who cannot supply this documentation increases the risk of receiving non-compliant or counterfeit parts, making it difficult to resolve quality issues or meet regulatory requirements.

Ignoring Intellectual Property Rights

Many hydraulic cylinder designs, including integrated piston features, are protected by patents or copyrights. Sourcing generic or reverse-engineered pistons without verifying IP clearance can expose your company to legal action, product recalls, or import bans. Always confirm that the design does not infringe on existing patents, especially when replacing OEM components.

Choosing Suppliers Without Quality Certifications

Working with manufacturers lacking recognized quality management certifications (e.g., ISO 9001, IATF 16949) increases the risk of inconsistent quality and unreliable processes. Certified suppliers are more likely to have robust quality control systems in place, reducing the chance of defective batches.

Overlooking Compatibility with Seals and Fluids

Pistons must be compatible with the hydraulic fluid type (e.g., mineral oil, water-glycol, biodegradable) and the elastomer materials used in seals. Incompatible combinations can cause swelling, degradation, or seal failure. Verify chemical and thermal compatibility with your system’s operating conditions.

Skipping Prototype Testing and Qualification

Rushing into mass procurement without testing sample pistons under real-world conditions can lead to field failures. Always conduct thorough bench and field testing to validate performance, leakage, and durability before full-scale sourcing.

Avoiding these pitfalls ensures reliable hydraulic system performance, reduces downtime, and protects your organization from legal and operational risks.

Logistics & Compliance Guide for Hydraulic Cylinder Pistons

Product Classification and Harmonized System (HS) Code

Hydraulic cylinder pistons are typically classified under the broader category of hydraulic components or parts for machinery. The most applicable Harmonized System (HS) code is 8412.90, which covers “Other hydraulic cylinders” and associated parts. However, if the piston is imported separately (not as part of a complete cylinder), it may fall under 8487 (“Parts suitable for use solely or principally with the machines of headings 8401 to 8479”). Final classification should be verified with customs authorities in the destination country, as interpretations may vary.

Export Control and Regulatory Compliance

Hydraulic cylinder pistons are generally not subject to strict export controls such as ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations), as they are considered standard industrial components. However, if the pistons are designed for military or aerospace applications, a review of export control regulations is necessary. Always confirm the end-use and end-user to ensure compliance with dual-use regulations under the EAR, particularly if destined for embargoed countries or restricted entities.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. Pistons should be:

– Protected against corrosion using VCI (Vapor Corrosion Inhibitor) paper or rust preventative coatings.

– Secured in sturdy corrugated boxes or wooden crates with cushioning materials to prevent movement.

– Labeled with product identification, batch/lot numbers, handling instructions (e.g., “Fragile,” “Do Not Stack”), and orientation arrows.

– Stored and transported in dry, temperature-controlled environments to avoid moisture exposure.

Transportation and Shipping Considerations

Hydraulic cylinder pistons can be shipped via air, ocean, or ground freight depending on urgency and volume. Key considerations include:

– Weight and Dimensions: Pistons vary in size; ensure accurate measurements for freight classification and load planning.

– Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP) to allocate costs and risks.

– Documentation: Include commercial invoice, packing list, bill of lading (or air waybill), and certificate of origin.

– Hazard Status: Pistons are non-hazardous, but ensure cleaning residues (e.g., oils) do not classify the shipment as dangerous goods.

Import Regulations and Duties

Import requirements depend on the destination country. Common steps include:

– Verifying HS code alignment with local customs tariff schedules.

– Paying applicable import duties and value-added taxes (VAT or GST).

– Complying with local standards (e.g., CE marking in the EU, CCC in China if part of a larger regulated system).

– Providing conformity documentation if required by market regulations.

Quality and Industry Standards

Pistons should conform to relevant industry standards to ensure compatibility and safety, such as:

– ISO 6020-1 / ISO 6020-2 – Dimensions and performance standards for hydraulic cylinders.

– ISO 3309 – Specifications for piston rods (often related to piston assemblies).

– SAE J514 – Applicable in North America for hydraulic tube and port connections.

Certification or test reports may be required by customers or customs for high-specification applications.

Traceability and Documentation Retention

Maintain full traceability of materials and manufacturing processes. Retain documentation such as:

– Material certifications (e.g., steel grade, heat treatment).

– Inspection and test reports.

– Batch/serial number records.

Retention period should align with industry standards—typically 5–10 years for industrial components.

Environmental and Disposal Compliance

Hydraulic cylinder pistons are primarily made of steel or aluminum and are recyclable. Ensure:

– Cleaning processes comply with environmental regulations (e.g., proper disposal of degreasing solvents).

– Packaging materials are recyclable and meet local environmental directives (e.g., EU Packaging Waste Directive).

– End-of-life recycling guidance is available for customers where required.

Summary and Best Practices

To ensure smooth logistics and compliance:

– Confirm HS classification early in the shipping process.

– Use protective packaging and clear labeling.

– Maintain accurate and complete shipping documentation.

– Verify destination-specific import requirements.

– Adhere to relevant quality and safety standards.

– Implement traceability systems for quality control and regulatory audits.

Conclusion for Sourcing Hydraulic Cylinder Pistons

Sourcing hydraulic cylinder pistons requires a strategic approach that balances quality, cost, durability, and supplier reliability. High-performance pistons are critical components in hydraulic systems, directly affecting efficiency, safety, and operational longevity. Therefore, selecting the right supplier and material specifications—such as forged steel, aluminum alloy, or coated variants for corrosion resistance—is essential to ensure optimal performance under specific operating conditions.

Key considerations in the sourcing process include material quality, manufacturing precision, compliance with industry standards (such as ISO or DIN), and the supplier’s track record for consistency and after-sales support. Engaging with suppliers who offer customization options, rigorous quality control, and timely delivery can significantly reduce downtime and maintenance costs.

Additionally, evaluating total cost of ownership—rather than unit price alone—helps in making informed decisions that support long-term reliability and system performance. Building strong relationships with trusted manufacturers or distributors, preferably with local support for faster service, further enhances supply chain resilience.

In conclusion, a well-executed sourcing strategy for hydraulic cylinder pistons not only ensures system reliability and efficiency but also contributes to reduced operational risks and improved equipment lifecycle management. Prioritizing quality and partnership over short-term savings is key to sustainable success in industrial and mobile hydraulic applications.