The global stepper motor market is experiencing robust growth, driven by rising automation, increased adoption in robotics, and expanding applications across industrial, healthcare, and precision equipment sectors. According to a 2023 report by Grand View Research, the global stepper motor market was valued at USD 3.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is further fueled by the rising integration of hybrid stepper motors in applications requiring precise motion control, such as 3D printing, CNC machinery, and semiconductor manufacturing. As demand intensifies for compact, high-torque, and energy-efficient motors, hybrid stepper motors—known for their superior resolution, accuracy, and performance—have become a preferred choice across industries. In this competitive landscape, a select group of manufacturers are leading innovation, scalability, and reliability. Based on market presence, product diversity, and technological advancements, here are the top 10 hybrid stepper motor manufacturers shaping the future of motion control.

Top 10 Hybrid Stepper Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oriental Motor U.S.A. Corp.

Domain Est. 1997

Website: orientalmotor.com

Key Highlights: αSTEP Hybrid Step-Servo · AlphaStep Stepper Motors. Stepper Motors · Stepper … 11-26-2025 – Oriental Motor Expands PKP Series with New 0.51” (13 mm) Stepper ……

#2 Lin Engineering

Domain Est. 1998

Website: linengineering.com

Key Highlights: We engineer and manufacture a variety of precision DC motors and motion control components. We have the capability, capacity, and expertise to supply a small ……

#3 Hybrid Stepper Motors

Domain Est. 2011

#4 Hybrid Stepper Motor Manufacturer

Domain Est. 2018

Website: leili-motor.net

Key Highlights: We offer custom hybrid(HB) stepper motors with a wide selection of frame sizes, shaft types, and winding options to suit diverse application needs….

#5 Hybrid Stepper Motor Manufacturer

Domain Est. 2024

Website: gian-transmission.com

Key Highlights: We specialize in the design and manufacture of hybrid type stepper motors in a variety of frame sizes (from 20mm to 110mm), step angles, and options….

#6 Stepper Motors

Domain Est. 1995

Website: kollmorgen.com

Key Highlights: Made in the U.S.A., our advanced hybrid stepper motors incorporate large bearings, high-voltage insulation, large rotor diameters, tight air gap tolerances, and ……

#7 Stepper Motors

Domain Est. 1996

Website: applied-motion.com

Key Highlights: 14-day returnsSince its beginnings, Applied Motion Products has specialized in offering two-phase, hybrid step motors in a variety of frame sizes….

#8 Hybrid Stepper Motors

Domain Est. 1996

Website: portescap.com

Key Highlights: Portescap’s hybrid stepper motor platform offers advanced features that enhance performance, reliability, and precision control by blending key features ……

#9 Hybrid Stepping Motors

Domain Est. 1999

Website: nmbtc.com

Key Highlights: Hybrid stepping motors provide excellent performance in areas of torque, speed, and step resolution. Browse part numbers, request a sample, or buy now….

#10 Hybrid Stepper Motor

Domain Est. 2013

Website: omc-stepperonline.com

Key Highlights: If you are looking for hybrid stepper motor, STEPPERONLINE providing hundreds of hybrid stepper motor at affordable prices….

Expert Sourcing Insights for Hybrid Stepper Motor

H2: 2026 Market Trends for Hybrid Stepper Motors

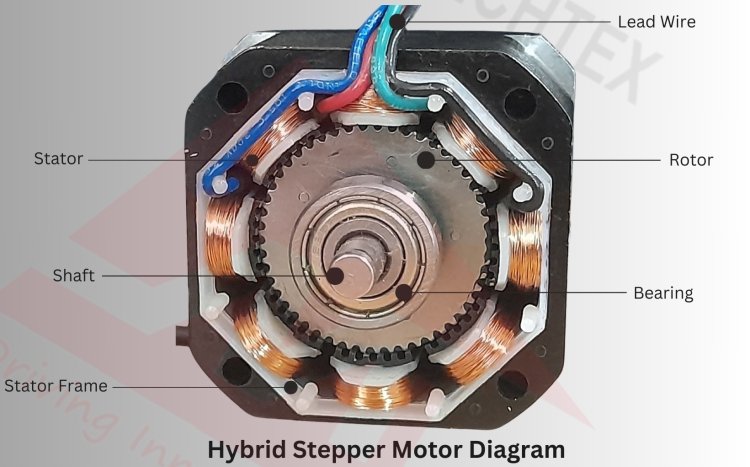

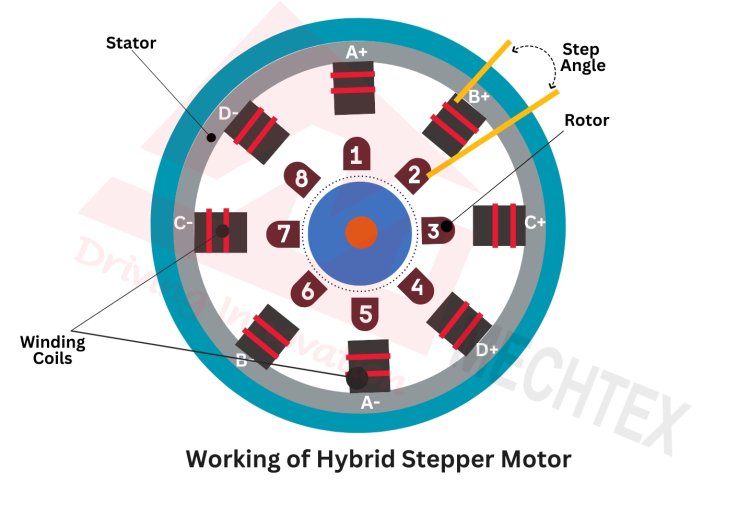

The global hybrid stepper motor market is poised for significant transformation by 2026, driven by technological advancements, rising automation across industries, and increasing demand for precision control systems. Hybrid stepper motors, which combine the best features of permanent magnet and variable reluctance stepper motors, continue to gain traction due to their high torque, accuracy, and reliability in open-loop control systems. Key trends shaping the market in 2026 include:

1. Growth in Industrial Automation and Robotics

The expansion of Industry 4.0 initiatives is accelerating the adoption of hybrid stepper motors in automated manufacturing, material handling, and robotics. These motors are critical in applications requiring precise positioning, such as CNC machines, pick-and-place robots, and automated guided vehicles (AGVs). The integration of smart sensors and IoT-enabled motor controls is enhancing their functionality, making them more attractive for next-generation industrial systems.

2. Rising Demand in Automotive and Electric Vehicles (EVs)

Hybrid stepper motors are increasingly used in automotive applications, including electronic throttle control, HVAC actuators, and advanced driver-assistance systems (ADAS). With the global push toward electric and autonomous vehicles, demand for compact, efficient, and reliable motors is growing. By 2026, the automotive sector is expected to be one of the fastest-growing end-use markets for hybrid stepper motors.

3. Miniaturization and High-Efficiency Designs

Manufacturers are focusing on developing smaller, lighter, and more energy-efficient hybrid stepper motors to meet the needs of compact electronic devices and portable medical equipment. Advances in magnetic materials, coil design, and thermal management are enabling higher performance in reduced footprints, which is particularly beneficial for applications in consumer electronics and medical robotics.

4. Expansion in Medical and Healthcare Applications

The medical device industry is increasingly adopting hybrid stepper motors for use in infusion pumps, lab automation equipment, surgical robots, and imaging systems. Their ability to deliver precise, repeatable motion with minimal maintenance makes them ideal for life-critical applications. Regulatory approvals and increased healthcare spending, especially in emerging economies, are expected to drive market growth in this segment by 2026.

5. Regional Market Shifts and Supply Chain Optimization

Asia-Pacific, led by China, Japan, and South Korea, remains the dominant region in both production and consumption of hybrid stepper motors. However, due to geopolitical tensions and supply chain disruptions, there is a growing trend toward regionalization and nearshoring in North America and Europe. This shift is encouraging local manufacturing investments and partnerships to ensure supply stability.

6. Integration with Smart Technologies and Digital Control

By 2026, hybrid stepper motors are increasingly being paired with advanced driver electronics, closed-loop control systems, and digital communication protocols (such as CANopen and EtherCAT). This integration enables real-time monitoring, predictive maintenance, and improved system efficiency—key requirements in smart factories and connected devices.

7. Sustainability and Energy Efficiency Regulations

Global emphasis on energy conservation and sustainability is pushing manufacturers to develop eco-friendly motor solutions. Hybrid stepper motors with lower power consumption and reduced electromagnetic interference (EMI) are gaining preference, especially in Europe and North America, where regulatory standards are stringent.

In conclusion, the hybrid stepper motor market in 2026 will be characterized by innovation, diversification of applications, and deeper integration with digital ecosystems. Companies that invest in R&D, sustainability, and strategic regional expansion are likely to capture significant market share in this evolving landscape.

Common Pitfalls Sourcing Hybrid Stepper Motors (Quality, IP)

Sourcing hybrid stepper motors involves more than just matching voltage and step angle. Overlooking critical quality and intellectual property (IP) aspects can lead to performance issues, reliability failures, and legal risks. Below are common pitfalls to avoid:

Inadequate Quality Control and Consistency

Many suppliers, especially low-cost manufacturers, lack robust quality assurance processes. This results in motors with inconsistent torque, step accuracy, or electrical characteristics, leading to field failures or integration challenges. Always verify certifications (e.g., ISO 9001), request test reports, and consider third-party inspections.

Misrepresentation of IP Ratings

Suppliers may claim high IP (Ingress Protection) ratings (e.g., IP65) without proper testing or sealing. A motor labeled IP65 should resist dust and low-pressure water jets, but some lack proper gaskets, sealed bearings, or encapsulated windings. Verify IP claims with test documentation or independent validation to avoid premature failure in harsh environments.

Counterfeit or Reverse-Engineered Designs

Some manufacturers replicate well-known motor designs without licensing, resulting in motors that appear identical but use inferior materials or construction. These clones often fail under prolonged use and may infringe on patents. Source from reputable suppliers and verify trademarks and design patents to avoid IP violations and substandard performance.

Poor Thermal and Insulation Performance

Low-quality motors may use substandard insulation materials or inadequate varnish, leading to early winding failure under thermal stress. Check insulation class (e.g., Class B, F) and ensure thermal performance matches your application’s duty cycle and ambient conditions.

Inaccurate or Incomplete Datasheets

Exaggerated performance data—such as holding torque, speed-torque curves, or step accuracy—is common. Relying solely on published specs without validation can result in motor selection errors. Request real-world test data and conduct application-specific testing before full-scale procurement.

Lack of Traceability and Documentation

Reputable suppliers provide batch traceability, material certifications, and RoHS/REACH compliance documents. Absence of these increases supply chain risks, especially in regulated industries. Ensure documentation is available to support quality audits and compliance requirements.

Logistics & Compliance Guide for Hybrid Stepper Motors

This guide outlines key logistics considerations and compliance requirements for the safe, efficient, and legal handling, transportation, import/export, and use of hybrid stepper motors across global supply chains.

Regulatory Compliance

Hybrid stepper motors must comply with various international, regional, and national regulations to ensure safety, environmental protection, and market access. Key compliance areas include:

-

RoHS (Restriction of Hazardous Substances): Ensure motors comply with EU Directive 2011/65/EU, restricting substances like lead, mercury, cadmium, and certain flame retardants. Provide RoHS compliance documentation (e.g., DoC, material declarations).

-

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Confirm compliance with EU Regulation (EC) No 1907/2006. Declare substances of very high concern (SVHC) if present above threshold levels.

-

CE Marking: Affix CE marking to indicate conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Includes compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

-

UL/CSA Certification: For North American markets, motors should be certified by recognized bodies such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) to meet safety standards like UL 1004.

-

IEC Standards: Adhere to relevant International Electrotechnical Commission standards such as IEC 60034 for rotating electrical machines.

-

Eco-design (ErP Directive): Ensure motors comply with energy-related products regulations if applicable, particularly for integrated drive systems.

-

Country-Specific Approvals: Check for additional requirements in target markets (e.g., CCC in China, PSE in Japan, KC in South Korea).

Packaging & Handling

Proper packaging and handling are essential to prevent mechanical damage, contamination, and moisture ingress during storage and transport.

-

Anti-Static Protection: Use static-dissipative or conductive packaging (e.g., shielded bags, foam) to protect motors with sensitive electronics or encoder components.

-

Moisture Protection: Include desiccant packs and moisture barrier bags (MBB) when shipping to humid environments or for long-term storage. Label with moisture sensitivity level (MSL) if applicable.

-

Mechanical Protection: Secure motors in rigid packaging with cushioning materials (e.g., foam inserts, bubble wrap) to prevent shock, vibration, and impact damage.

-

Labeling: Clearly label packages with:

- Product name and model number

- Quantity

- Handling instructions (e.g., “Fragile,” “Do Not Stack,” “This Side Up”)

-

Electrostatic discharge (ESD) warning symbols if needed

-

Storage Conditions: Store in a clean, dry, temperature-controlled environment (typically 5°C to 40°C, 20%–70% non-condensing humidity). Avoid exposure to dust, corrosive gases, and direct sunlight.

Transportation & Shipping

Ensure safe and compliant shipment of hybrid stepper motors via air, sea, or ground.

-

Hazard Classification: Hybrid stepper motors are generally non-hazardous. However, motors with integrated batteries or specific coatings may require hazard classification under IATA, IMDG, or ADR regulations.

-

Export Controls: Verify if motors fall under dual-use or strategic export control lists (e.g., EU Dual-Use Regulation, U.S. EAR). High-precision or high-torque models may require export licenses.

-

Documentation: Prepare accurate shipping documents including:

- Commercial invoice

- Packing list

- Certificate of Origin

- RoHS/REACH compliance statements

- Test reports or certifications (e.g., UL, CE)

-

Export license (if required)

-

Customs Classification: Use correct HS (Harmonized System) codes for tariff classification. Common codes include 8501.31 (motors of an output not exceeding 750 W) or 8501.32 (motors exceeding 750 W). Confirm with local customs authorities.

-

Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP) in sales contracts to avoid disputes over shipping costs and risks.

Import & Customs Clearance

Facilitate smooth customs entry into destination countries.

-

Duties & Taxes: Calculate applicable import duties, VAT, and customs fees based on HS code, country of origin, and trade agreements (e.g., USMCA, RCEP, EU preferential tariffs).

-

Local Representation: Appoint a licensed customs broker or agent in the destination country to handle clearance procedures.

-

Product Inspection: Be prepared for potential customs inspections, especially for first-time imports or high-value shipments. Provide technical specifications and test reports if requested.

-

Labeling Requirements: Ensure product labels meet local language and regulatory requirements (e.g., CE marking, safety warnings in local language).

End-of-Life & Environmental Responsibility

Support sustainable practices in line with environmental regulations.

-

WEEE Compliance (EU): Register with national WEEE authorities and provide take-back or recycling options for end-of-life motors.

-

Recyclability: Design motors for disassembly and recycling. Provide material composition data to support recycling efforts.

-

Proper Disposal: Advise customers to dispose of motors through certified electronic waste (e-waste) handlers to prevent environmental contamination.

Summary

Compliance and efficient logistics are critical for the successful distribution of hybrid stepper motors. Adhering to regulatory standards, using appropriate packaging, managing documentation, and understanding import/export requirements ensure product safety, legal market access, and customer satisfaction. Regular audits and updates to compliance protocols are recommended to keep pace with evolving global regulations.

Conclusion for Sourcing Hybrid Stepper Motors:

In conclusion, sourcing hybrid stepper motors requires a careful evaluation of technical specifications, application requirements, quality standards, and supplier reliability. Hybrid stepper motors offer an optimal balance of precision, torque, and step resolution, making them ideal for applications in automation, robotics, medical devices, and CNC machinery. When selecting a supplier, it is essential to consider factors such as motor performance consistency, certifications (e.g., ISO, RoHS), lead times, pricing, and after-sales support.

Engaging with reputable manufacturers or authorized distributors ensures genuine products with reliable performance and compliance. Additionally, establishing long-term partnerships can lead to better pricing, customized solutions, and technical support. Conducting pilot testing and requesting samples prior to bulk procurement helps verify compatibility and performance under real operating conditions.

Ultimately, a strategic sourcing approach that aligns technical needs with supplier capabilities will ensure the successful integration of hybrid stepper motors into your systems, enhancing overall efficiency, accuracy, and product reliability.