The global automotive refinishing market is experiencing robust growth, driven by rising vehicle production, increasing demand for aftermarket customization, and advancements in spray application technologies. According to Grand View Research, the global automotive coatings market was valued at USD 34.8 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030. A key contributor to this expansion is the growing adoption of High Volume Low Pressure (HVLP) spray technology, which offers superior transfer efficiency, reduced overspray, and compliance with environmental regulations. Mordor Intelligence projects steady growth in the industrial and automotive spraying equipment market, with HVLP systems gaining preference among professionals for their precision and eco-friendly performance. As demand surges, a competitive landscape of manufacturers has emerged, innovating in ergonomics, durability, and atomization efficiency. This report identifies the top 10 HVLP auto paint sprayer manufacturers shaping the industry through technological excellence, global reach, and strong customer adoption.

Top 10 Hvlp Auto Paint Sprayer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

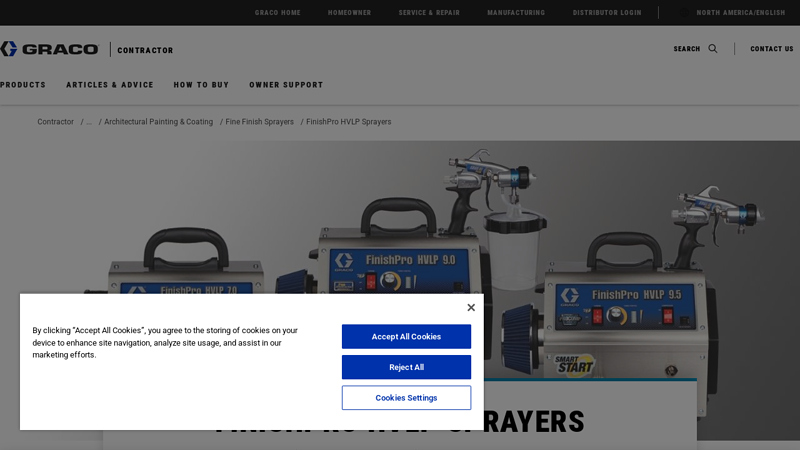

#1 FinishPro HVLP Paint Sprayers

Domain Est. 1994

Website: graco.com

Key Highlights: Graco’s FinishPro HVLP sprayers (High Volume Low Pressure) allow contractors and woodworkers to achieve the highest quality professional ……

#2 hvlp air spray gun

Domain Est. 2024

Website: ranoxspray.com

Key Highlights: As a top HVLP paint gun manufacturer, Ranox delivers innovative hvlp paint spray guns designed for precision and efficiency. Perfect for automotive ……

#3 Apollo Sprayers

Domain Est. 1995

Website: hvlp.com

Key Highlights: Spray Your Way to the Perfect Finish. Apollo Sprayers is the global home of the most advanced High Volume, Low Pressure HVLP paint sprayers….

#4 Fuji Spray

Domain Est. 1996

Website: fujispray.com

Key Highlights: Fuji Spray is a leader in the spray paint industry with its high performance array of products designed for woodworking, automotive body work and spray ……

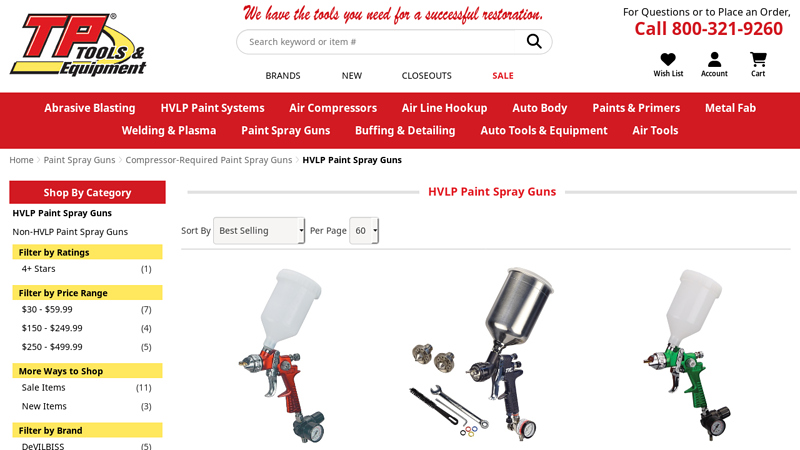

#5 HVLP Paint Spray Guns for Paint Spray Guns

Domain Est. 1999

Website: tptools.com

Key Highlights: $3.95 deliveryTP Tools® by DeVILBISS® Graphite HVLP Paint Spray Gun · $349.00 ; TP Tools® Graphite HVLP Spray Gun & DeVILBISS® High-Efficiency Clearcoat Air Cap Kit · $498.00….

#6 HVLP Paint Sprayer at Paint Sprayers Plus

Domain Est. 2006

Website: paintsprayersplus.com

Key Highlights: Paint Sprayers Plus carries a full line of HVLP paint sprayers, HVLP spray guns, pressure pots, line stripers and many more fine finishing products….

#7 HVLP Gravity feed spray gun

Domain Est. 2012

Website: renaissance-company.com

Key Highlights: In stock Rating 4.4 (21) 3 days ago · HVLP Gravity feed spray gun ; Product details · Brand new spray gun never used it. Was going to use it for spraying frames on a vehicle….

#8 Maxi

Domain Est. 2016

Website: maxi-miser.com

Key Highlights: Benefits of Apollo HVLP Electric Paint Systems · Huge Paint Savings · Clean, Dry Air · Plug and Spray · Best Transfer Efficiency · Portable · No Paint Booth Needed….

#9 Fuji Spray Auto

Domain Est. 2019

Website: fujisprayauto.com

Key Highlights: Fuji Spray Auto offers automotive paint guns, auto paint sprayers, and HVLP spray guns for precision finishes. Shop Fuji spray gun parts and paint kits ……

#10 Sames

Website: sames.com

Key Highlights: We provide advanced coating & dispensing solutions that meet the strict quality and durability standards of the automotive industry, ensuring perfect finishes ……

Expert Sourcing Insights for Hvlp Auto Paint Sprayer

H2: 2026 Market Trends for HVLP Auto Paint Sprayers

The market for High Volume Low Pressure (HVLP) auto paint sprayers is poised for significant evolution by 2026, driven by technological innovation, environmental regulations, and shifting consumer and industrial demands. Key trends shaping the industry include:

1. Increased Demand for Eco-Friendly and Low-VOC Solutions

Environmental regulations, particularly in North America and Europe, are tightening restrictions on volatile organic compound (VOC) emissions. HVLP sprayers, known for their high transfer efficiency (typically 65–85%), are gaining favor over conventional high-pressure systems due to reduced overspray and paint waste. By 2026, manufacturers are expected to prioritize sprayers designed specifically for water-based and low-VOC coatings, aligning with sustainability goals and compliance standards such as the U.S. EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP).

2. Technological Advancements in Spray Efficiency and Ergonomics

Innovation in motor design, turbine technology, and nozzle engineering will enhance the performance of HVLP systems. Expect lightweight, cordless, and battery-powered HVLP sprayers with improved airflow consistency and reduced noise levels. Smart features such as adjustable pressure controls, automatic fluid regulation, and integration with mobile apps for performance tracking are anticipated to enter the mainstream by 2026, particularly in professional and semi-professional segments.

3. Growth in Refinish and Customization Markets

The automotive refinish and customization industry is expanding, fueled by rising consumer interest in vehicle personalization and the growth of electric vehicle (EV) body repair centers. HVLP sprayers are preferred in these applications due to their precision and finish quality. By 2026, demand is projected to rise in both independent body shops and dealership service centers, especially in emerging markets like India, Southeast Asia, and Latin America.

4. Expansion of DIY and Home Workshop Segments

The proliferation of home garages and enthusiast-driven automotive projects is boosting demand for affordable, user-friendly HVLP systems. Manufacturers are responding with entry-level models that balance cost, performance, and ease of use. Online tutorials and social media content on car painting are further driving adoption among DIY users, a trend expected to accelerate through 2026.

5. Competitive Landscape and Market Consolidation

The HVLP sprayer market is witnessing increased competition between established brands (e.g., Fuji, SATA, Iwata) and emerging players offering budget-friendly alternatives. By 2026, strategic partnerships, mergers, and R&D investments are likely to consolidate the market, with a focus on innovation, distribution networks, and after-sales support.

6. Integration with Digital and IoT Platforms

Future HVLP systems may incorporate IoT-enabled diagnostics and connectivity, allowing for remote monitoring of equipment health, usage analytics, and predictive maintenance—particularly valuable for large-scale repair operations and fleet maintenance centers.

In summary, by 2026, the HVLP auto paint sprayer market will be shaped by environmental compliance, technological sophistication, and diversification across professional and consumer segments. Companies that invest in sustainable design, digital integration, and user-centric innovation are expected to lead the market.

Common Pitfalls When Sourcing HVLP Auto Paint Sprayers (Quality & IP)

When sourcing HVLP (High Volume, Low Pressure) auto paint sprayers, especially from overseas or less-regulated markets, buyers often encounter critical issues related to product quality and intellectual property (IP). Being aware of these pitfalls can help avoid costly mistakes, operational inefficiencies, and legal risks.

Poor Build Quality and Material Substitution

Many low-cost HVLP sprayers are constructed with substandard materials—such as cheap plastics, inferior nozzles, and low-grade seals—that degrade quickly under regular use. This leads to inconsistent spray patterns, clogging, air leaks, and premature failure. Buyers may receive units that look identical to reputable brands but lack the durability and precision engineering essential for professional auto painting.

Inaccurate Spray Performance and Overspray

HVLP systems are designed to minimize overspray and maximize transfer efficiency. However, counterfeit or poorly engineered units often fail to maintain true low-pressure delivery, resulting in excessive overspray, wasted paint, and poor finish quality. This undermines one of the primary advantages of HVLP technology and increases both material costs and environmental impact.

Lack of Compliance with Safety and Emissions Standards

Reputable HVLP sprayers comply with regional safety and environmental regulations (e.g., EPA, CE). Sourced units, particularly from unverified suppliers, may not meet these standards. Using non-compliant equipment can expose users to regulatory fines, health hazards from improper vapor control, and liability issues in commercial settings.

Intellectual Property Infringement

A significant number of low-cost HVLP sprayers are counterfeit or “knock-off” versions of well-known brands (e.g., Fuji, Devilbiss, SATA). These products often mimic logos, design features, and model names, infringing on trademarks and design patents. Sourcing such products—even unknowingly—can expose businesses to legal consequences, including seizure of goods, lawsuits, and reputational damage.

Inadequate or Missing Technical Support and Spare Parts

Genuine HVLP sprayers come with access to technical support, service manuals, and a supply of replacement parts. Counterfeit or off-brand units frequently lack these resources, making maintenance difficult and downtime costly. Users may find it impossible to source compatible nozzles, seals, or fluid tips, rendering the sprayer unusable after minor wear.

Misleading Specifications and Performance Claims

Some suppliers exaggerate key performance metrics—such as air consumption, atomization quality, and fluid delivery rates—making their products appear comparable to high-end models. In reality, the actual performance falls far short, leading to dissatisfaction and rework. Independent testing or verified reviews are essential to validate claims.

Supply Chain and Warranty Risks

Sourcing from unknown manufacturers or third-party platforms often means limited or nonexistent warranties. Even when warranties are offered, enforcement can be difficult due to lack of local service centers or unresponsive suppliers. This increases the total cost of ownership and creates operational uncertainty.

To mitigate these risks, buyers should prioritize verified suppliers, request product certifications, conduct performance testing, and consult legal counsel when sourcing equipment that may involve IP concerns. Investing in genuine, high-quality HVLP systems ultimately ensures better results, compliance, and long-term value.

Logistics & Compliance Guide for HVLP Auto Paint Sprayer

Product Classification & Documentation

Ensure accurate product classification using the Harmonized System (HS) code, typically falling under 8424.89 for spraying machinery. Maintain up-to-date commercial invoices, packing lists, and certificates of origin to facilitate customs clearance. Include detailed technical specifications such as spray pressure, airflow rate, and compliance certifications on all documentation.

Shipping & Handling Requirements

Package HVLP sprayers in durable, shock-resistant containers with internal cushioning to prevent damage during transit. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include the model number and serial number on exterior labels. Use carriers experienced in handling industrial equipment and provide tracking for all shipments.

Regulatory Compliance

HVLP sprayers must comply with regional safety and emissions standards. In the U.S., verify conformity with EPA and OSHA requirements, particularly concerning spray booth ventilation and worker protection. In the EU, ensure compliance with CE marking directives including the Machinery Directive (2006/42/EC) and Electromagnetic Compatibility (EMC) Directive. Provide multilingual user manuals and safety data sheets (SDS) where applicable.

Import/Export Controls

Check for export restrictions or licensing requirements, especially when shipping to countries with strict environmental regulations. Battery-powered models may be subject to UN38.3 testing requirements if lithium batteries are included. Declare dual-use potential if applicable, and confirm that the product does not contain restricted substances under RoHS or REACH regulations.

Customs Clearance & Duties

Prepare for customs inspections by having all compliance documentation readily available. Accurately declare the value, country of manufacture, and intended use of the sprayer to avoid delays. Research applicable tariff rates and import duties based on the destination country, and consider utilizing a customs broker for complex shipments.

Environmental & Disposal Compliance

Inform end-users of proper maintenance and disposal procedures for worn components such as nozzles and filters. Recommend recycling programs for metal and plastic parts in accordance with local waste management laws. Highlight energy efficiency features of the HVLP system to support sustainability reporting.

Warranty & After-Sales Support

Clearly define warranty terms in shipment documentation, including coverage period, conditions, and return procedures. Provide contact information for technical support and authorized service centers. Maintain inventory of spare parts at strategic distribution hubs to minimize downtime for customers.

In conclusion, sourcing an HVLP (High Volume Low Pressure) auto paint sprayer requires careful consideration of several key factors to ensure optimal performance, durability, and value. It is essential to evaluate the sprayer’s technical specifications—such as airflow rate, nozzle size, material capacity, and transfer efficiency—to match your specific automotive painting needs. Sourcing from reputable manufacturers or suppliers who provide warranty support, genuine parts, and technical assistance ensures reliability and long-term satisfaction. Additionally, balancing cost with quality is critical; while budget-friendly options may be tempting, investing in a high-quality HVLP system improves finish quality, reduces paint waste, and complies with environmental regulations due to lower overspray and VOC emissions. Whether sourcing locally or internationally, verifying certifications, reading user reviews, and comparing after-sales service can significantly impact your decision. Ultimately, selecting the right HVLP auto paint sprayer enhances productivity, delivers professional-grade results, and supports a more efficient and sustainable painting process.