The demand for hurricane-resistant sliding glass doors has surged in recent years, driven by increasing storm intensity and stricter building codes in coastal regions. According to Grand View Research, the global impact-resistant windows and doors market was valued at USD 6.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by rising infrastructure investments in hurricane-prone areas and a growing emphasis on energy efficiency and safety. As homeowners and developers seek durable, code-compliant solutions, manufacturers specializing in hurricane-rated sliding glass doors are expanding their product portfolios with advanced materials like laminated glass, reinforced frames, and rigorous ASTM-certified designs. In this competitive landscape, innovation, certification breadth, and regional market presence are key differentiators—factors that shape our data-driven selection of the top 10 hurricane sliding glass door manufacturers leading the industry today.

Top 10 Hurricane Sliding Glass Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Top Brands for Hurricane Impact Windows & Doors

Domain Est. 1999

Website: windowprofessionals.com

Key Highlights: CGI Windows & Doors is the premier manufacturer of hurricane impact resistant windows and doors. Produced to the most exacting industry standards, ……

#2 Plaza Door

Domain Est. 2019

Website: plazadoorcompany.com

Key Highlights: Plazadoor Corp. is the manufacturer of custom sliding glass doors known as Plaza Doors. These doors have been continually tested, modified and improved….

#3 Therma

Domain Est. 1995

Website: thermatru.com

Key Highlights: The Therma-Tru retractable screen door allows fresh air and natural light inside while keeping debris and insects out….

#4 Coastal Impact Windows & Doors

Domain Est. 1996

Website: andersenwindows.com

Key Highlights: Our hurricane strength windows and patio doors are designed, engineered and manufactured to withstand severe coastal weather conditions….

#5 CGI Windows

Domain Est. 1997

Website: cgiwindows.com

Key Highlights: CGI Windows & Doors manufactures impact resistant hurricane windows and doors, made from commercial-grade, impact-resistant glass….

#6 Hurricane Guard Sliding Patio Doors

Domain Est. 2000

Website: cws.cc

Key Highlights: Designed with strong frame and impact-resistant laminated glass, these gliding doors are built to face hurricane winds in the High Velocity Hurricane Zone….

#7

Domain Est. 2002

Website: pgtwindows.com

Key Highlights: Choose from a variety of custom window styles, including traditional single hung windows, casement windows, architectural shapes and more….

#8 Hurricane Impact Folding & Sliding Glass Doors

Domain Est. 2002

Website: nanawall.com

Key Highlights: NanaWall hurricane-rated folding glass doors use impact-resistant glass to withstand extreme weather, high winds, and flying debris for residential and ……

#9 hurricane proof sliding glass doors st croix

Domain Est. 2004

Website: egsinternationalllc.com

Key Highlights: These are all the blog posts and articles archived under the category hurricane proof sliding glass doors st croix….

#10 Sliding Doors

Domain Est. 2013

Website: hurricanewindowsofmiami.com

Key Highlights: In stockSliding Doors in a variety of sizes. We offer professional installation and permit services. Best Prices for Hurricane Impact Doors in Miami Florida….

Expert Sourcing Insights for Hurricane Sliding Glass Doors

2026 Market Trends for Hurricane Sliding Glass Doors

As the demand for resilient, energy-efficient, and aesthetically pleasing building materials continues to grow, the market for hurricane sliding glass doors is poised for significant evolution by 2026. Driven by climate change, stricter building codes, and shifting consumer preferences, several key trends are expected to shape the industry.

1. Increased Demand in Coastal and High-Risk Regions

With the frequency and intensity of hurricanes on the rise—particularly along the Gulf Coast, Southeastern U.S., and Caribbean—homeowners and developers are increasingly prioritizing storm-resistant construction. By 2026, demand for certified hurricane sliding glass doors is expected to surge in states like Florida, Texas, Louisiana, and the Carolinas. Insurance incentives and compliance with updated building codes (such as Florida’s Building Code and Miami-Dade County NOA approvals) will further drive adoption.

2. Advancements in Impact-Resistant Technology

Manufacturers are investing heavily in next-generation materials and engineering. By 2026, expect widespread use of laminated glass with enhanced interlayers (e.g., SentryGlas or DuPont Butacite), stronger aluminum or fiberglass frames, and improved sealing systems. These innovations will deliver higher performance in wind pressure, water intrusion, and debris impact resistance—meeting or exceeding ASTM E1886 and E1996 standards.

3. Integration of Smart Home Features

Smart technology integration is a growing trend. Hurricane sliding glass doors in 2026 will increasingly feature built-in sensors for wind, rain, and break-in detection, automatic locking mechanisms, and mobile app connectivity. These features not only enhance security and convenience but also provide real-time monitoring during storms.

4. Energy Efficiency and Sustainability

As green building standards (such as ENERGY STAR and LEED) gain traction, manufacturers will focus on improving thermal performance. Features like Low-E coatings, thermally broken frames, and better insulation will make hurricane-rated doors more energy-efficient. Additionally, increased use of recycled materials and sustainable manufacturing processes will appeal to environmentally conscious consumers.

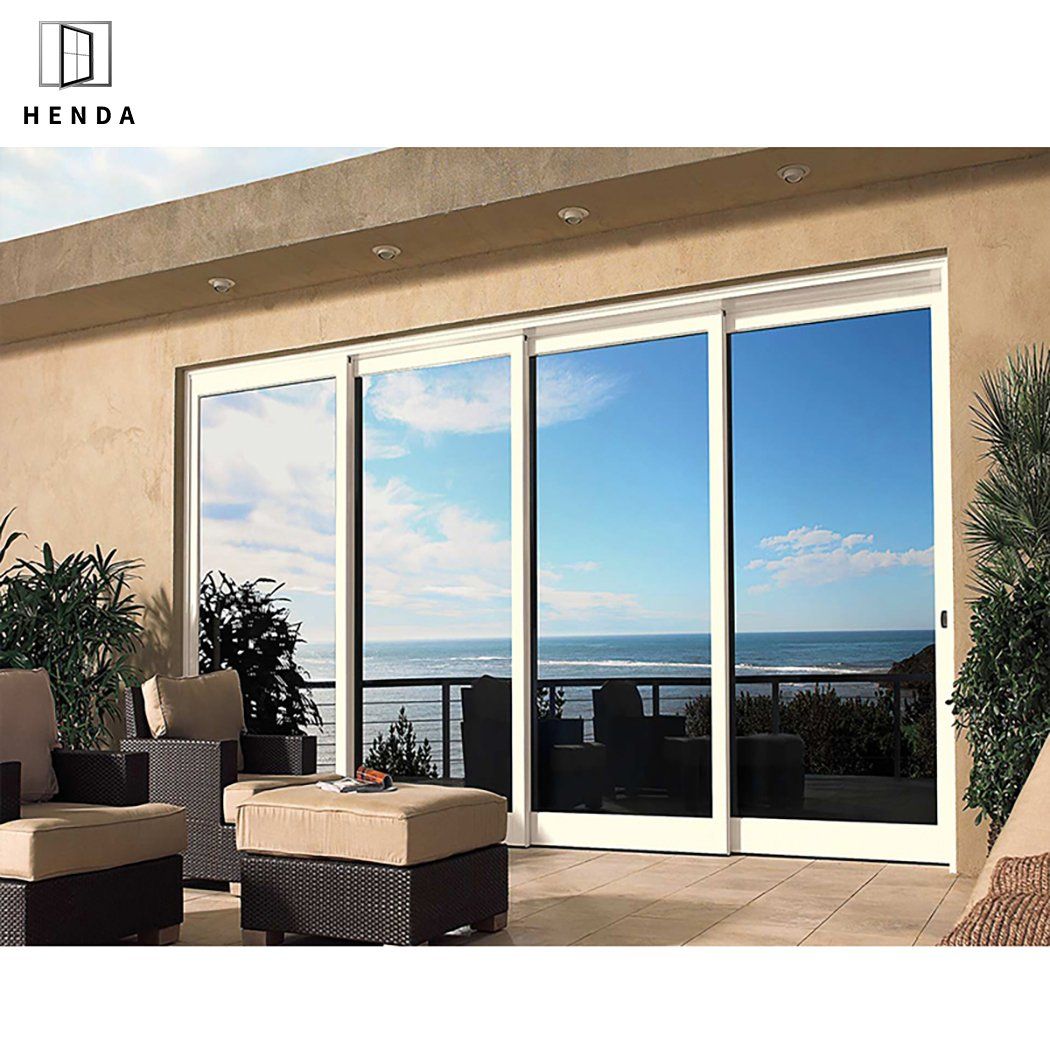

5. Expansion of Design and Customization Options

Gone are the days when storm protection meant sacrificing aesthetics. By 2026, consumers will expect hurricane sliding glass doors in a variety of styles, finishes, colors, and configurations—including multi-panel, corner, and floor-to-ceiling designs. Custom sizing and integration with outdoor living spaces (e.g., lanais, patios) will become standard offerings.

6. Growth in Replacement and Retrofit Markets

Beyond new construction, the retrofit market will expand as older homes upgrade to meet code requirements or improve safety. Modular and easy-install systems will gain popularity, allowing homeowners to replace standard sliding doors with hurricane-rated versions without major structural changes.

7. Competitive Pricing and Market Expansion

As production scales and technology matures, prices for hurricane sliding glass doors are expected to stabilize or decrease slightly by 2026. This affordability, combined with federal and state resilience grants, will make these products accessible to a broader market, including mid-tier housing developments.

Conclusion

By 2026, the hurricane sliding glass door market will reflect a convergence of safety, sustainability, technology, and design. With climate resilience becoming a necessity rather than a luxury, these doors will play a crucial role in modern construction—particularly in regions vulnerable to extreme weather. Manufacturers who innovate across performance, aesthetics, and smart functionality will lead the market forward.

Common Pitfalls When Sourcing Hurricane Sliding Glass Doors (Quality and Impact Protection)

Sourcing hurricane sliding glass doors requires careful attention to ensure both structural integrity and compliance with safety standards. Overlooking key factors can lead to compromised protection, costly repairs, or non-compliance with building codes. Here are the most common pitfalls to avoid:

Inadequate Impact-Resistant Certification

One of the most critical mistakes is selecting doors that lack proper certification for impact resistance. Always verify that the doors meet rigorous standards such as ASTM E1886 and E1996, and are certified by recognized agencies like Miami-Dade County or the Florida Building Code (FBC). Products without third-party certification may appear sturdy but fail under actual hurricane conditions.

Poor Material Quality and Frame Construction

Low-quality aluminum or vinyl frames may warp, corrode, or fail under high wind loads. Similarly, subpar glass—even if labeled “impact-resistant”—can shatter or delaminate if not made with proper laminated layers. Prioritize doors with heavy-gauge frames and glass tested to withstand debris impact and cyclic pressure.

Misalignment with Regional Building Codes

Hurricane requirements vary significantly by region, especially in High-Velocity Hurricane Zones (HVHZ). Sourcing doors without confirming local code compliance can result in failed inspections or insurance issues. Always match the door’s design pressure (DP) rating to the specific wind load requirements of the installation site.

Inadequate Sealing and Water Infiltration Protection

Even impact-rated doors can fail during storms if they lack effective weatherstripping and drainage systems. Poor seals allow water intrusion during heavy rain and wind-driven storms. Look for doors with multi-point locking systems and integrated weather gaskets designed to prevent air and water infiltration.

Overlooking Installation Requirements

The performance of a hurricane door depends heavily on proper installation. Using unqualified contractors or incorrect anchoring methods compromises the entire system. Ensure that installation follows the manufacturer’s specifications and is performed by professionals certified for impact-resistant products.

Choosing Based on Price Alone

While cost is a factor, the cheapest option often cuts corners on materials, testing, and engineering. Investing in a higher-quality, code-compliant door reduces long-term risks and potential damage costs. Consider lifecycle value, insurance discounts, and safety over initial price.

Ignoring Aesthetics and Operational Functionality

Some impact-resistant doors have bulky frames or limited design options, affecting curb appeal and usability. However, modern options offer sleek profiles and smooth operation. Balance safety with functionality—ensure the door glides easily, locks securely, and complements the building’s design.

By avoiding these common pitfalls, buyers can source hurricane sliding glass doors that provide reliable protection, meet regulatory standards, and deliver lasting performance in storm-prone areas.

Logistics & Compliance Guide for Hurricane Sliding Glass Doors

Product Overview

Hurricane sliding glass doors are engineered to withstand extreme wind loads and impact from wind-borne debris, making them essential for coastal and high-wind regions. These doors combine robust construction—featuring reinforced frames, impact-resistant glazing, and secure locking mechanisms—with sleek, space-saving sliding functionality. Proper logistics and compliance management are crucial to ensure product integrity, regulatory adherence, and successful installation.

Regulatory Compliance Requirements

All hurricane sliding glass doors must comply with regional building codes and national safety standards. Key compliance benchmarks include:

– Miami-Dade County Product Approval (NOA): Required for products installed in High-Velocity Hurricane Zones (HVHZ).

– ASTM E1886 and E1996: Standards for testing performance against windborne debris and cyclic wind pressure.

– Florida Building Code (FBC): Mandates specific design pressures (DP) based on geographic location and building height.

– Energy Efficiency: Products must meet ENERGY STAR® and local requirements, including U-factor and Solar Heat Gain Coefficient (SHGC) ratings.

– NFRC Certification: Ensures accurate energy performance labeling.

– ADA Compliance: Where applicable, doors must meet accessibility standards for operability and clear opening width.

Shipping & Handling Procedures

To maintain product integrity during transit:

– Packaging: Doors must be shipped in robust, labeled crates or skids with corner protectors and protective film on glass surfaces.

– Loading/Unloading: Use forklifts or pallet jacks; never drag or drop units. Employ proper lifting straps to avoid frame deformation.

– Orientation: Store and transport doors vertically; never lay flat unless designed for horizontal shipping.

– Weather Protection: Keep units under cover and protected from moisture. Avoid prolonged exposure to direct sunlight or rain.

Inventory & Storage Guidelines

- Store doors in a dry, level indoor environment with ventilation to prevent condensation.

- Maintain vertical storage with adequate spacing between units to prevent scratching.

- Limit stack height to manufacturer specifications (typically no more than 3 units).

- Inspect upon receipt for shipping damage and document issues immediately with photos and carrier reports.

Installation & Field Compliance

- Only certified, licensed contractors should install hurricane-rated doors.

- Follow manufacturer’s installation manual strictly, including anchoring, flashing, and sealing procedures.

- Verify site-specific design pressure (DP) ratings match project requirements.

- Conduct post-installation inspections to ensure proper operation, weather-tightness, and compliance with building official requirements.

- Submit final compliance documentation, including product certification, test reports, and Notice of Acceptance (NOA), to the local authority having jurisdiction (AHJ).

Documentation & Recordkeeping

Maintain a complete compliance dossier for each project, including:

– Product cut sheets and engineering drawings

– Third-party test reports (ASTM, AAMA)

– Miami-Dade NOA or equivalent approval

– Installation certification and inspection reports

– Warranty information and maintenance guidelines

Maintenance & Long-Term Compliance

- Schedule routine inspections for track cleanliness, seal integrity, and hardware function.

- Replace damaged components with manufacturer-approved parts to maintain code compliance.

- Retain service records to support warranty claims and future compliance audits.

Adhering to this logistics and compliance guide ensures hurricane sliding glass doors perform safely and effectively throughout their lifecycle, meeting both regulatory demands and customer expectations.

In conclusion, sourcing hurricane-rated sliding glass doors requires careful consideration of several key factors including compliance with local building codes, structural performance under high wind and impact conditions, energy efficiency, and long-term durability. It is essential to work with reputable manufacturers and suppliers who provide certified products tested to meet strict standards such as those set by ASTM, Miami-Dade County, or other relevant regulatory bodies. Additionally, proper installation by qualified professionals is crucial to ensure the doors perform as intended during severe weather events. By prioritizing safety, quality, and compliance, property owners and builders can make informed decisions that enhance protection, increase property value, and provide peace of mind in hurricane-prone regions.