The global hose clamp market is experiencing steady expansion, driven by increasing demand from automotive, industrial, and agricultural sectors. According to Grand View Research, the global hose clamp market size was valued at USD 2.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. This growth is fueled by rising vehicle production, stringent safety regulations, and the expanding need for leak-proof sealing solutions across fluid transfer systems. A key segment within this market is hose clamp wire, which forms the foundational material for many clamp types, including screw band, spring, and wire clamps. With manufacturers increasingly focusing on high-tensile, corrosion-resistant alloys to meet performance demands, the supply chain for quality hose clamp wire has become a critical factor in production efficiency and product reliability. As competition intensifies and end-user industries evolve, identifying leading suppliers of hose clamp wire is essential for businesses aiming to maintain a competitive edge. Based on production capacity, material innovation, and global reach, we highlight the top 9 hose clamp wire manufacturers shaping the industry’s future.

Top 9 Hose Clamp Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Murray Corporation: Industrial Clamp Manufacturer

Domain Est. 1996

Website: murraycorp.com

Key Highlights: Murray is a trusted manufacturer of industrial hose clamps, providing custom-designed and manufactured hose clamps to OEMs, Retailers & Distributors….

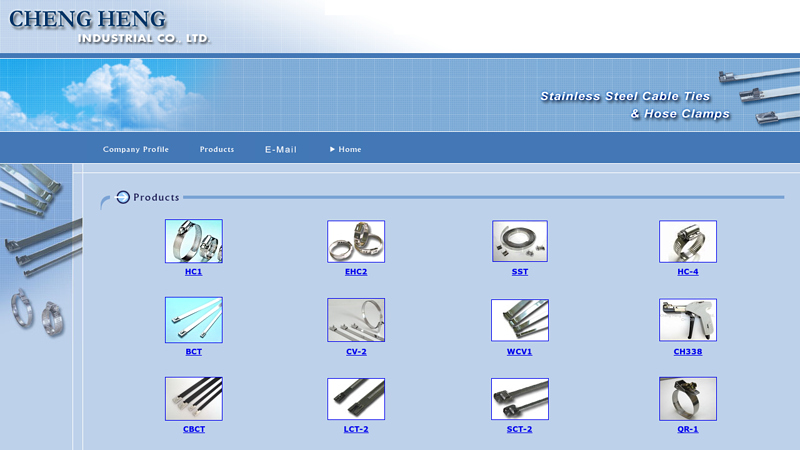

#2 CHENG HENG INDUSTRIAL CO.,LTD.

Domain Est. 1999

Website: hoseclamp.com.tw

Key Highlights: Hose Clip,Hose Clamp Manufacturer,Stainless Steel Cable Tie,Stainless Steel Hose Clamp,Heavy Duty Clamp,Cable Tie Manufacturer,we have devoted in the field ……

#3 Taiwan Hose Clamp, Hose Clip, Wire Puller,Tow Rope Export …

Domain Est. 2001

Website: en.wsclamp.com.tw

Key Highlights: As a leading manufacturer of Wei Shiang Co., Ltd., we provide first-rate Hose Clamps, Storage Boxes, Wire Puller, Tool Cases and General Hardware….

#4 PYI Hose Clamps

Domain Est. 1996

Website: pyiinc.com

Key Highlights: PYI Hose Clamps are manufactured entirely out of 316L Stainless Steel giving them excellent resistance to corrosive chemicals and acids….

#5 Hose Clamps

Domain Est. 1998

Website: fluidpower.com.tw

Key Highlights: Double Bolt Hose Clamp · Double Bolt Clamp Without Saddles · Gripping Claw Double Bolt Hose Clamp · Boss Coupling Clamp · Superior T-Bolt Clamp – Single Nut….

#6 Hose Clamps

Domain Est. 1997

Website: rotorclip.com

Key Highlights: Rotor Clip manufactures quality, self-compensating hose clamps to equip low-pressure applications. Our single wire, double wire and constant tension band hose ……

#7 Clamptite Tools

Domain Est. 2003

Website: clamptitetools.com

Key Highlights: Free delivery over $69.96 30-day returnsClampTite quickly replaces ineffective or damaged conventional hose clamps with a temporary or permanent clamping mechanism formed from stai…

#8 Clamps

Domain Est. 2007

Website: prevostusa.com

Key Highlights: Ear clamps are used to attach flexible hoses made from PVC, rubber, and other material. Safe and permanent attachment, quick and easy assembly….

#9 HCL Clamping USA

Domain Est. 2010

Website: hcl-clamping.com

Key Highlights: Buy hose clamps, cable retention, banding and tools for sale. Competitive prices and trade discounts on products like Herbie Clips and Worm Drives….

Expert Sourcing Insights for Hose Clamp Wire

H2: 2026 Market Trends for Hose Clamp Wire

The global hose clamp wire market is expected to witness steady growth by 2026, driven by rising demand across automotive, industrial machinery, HVAC, and agricultural sectors. Key trends shaping the market include advancements in material technology, increasing vehicle production—especially in emerging economies—and a growing emphasis on durability and corrosion resistance in clamp components.

One major trend is the shift toward high-tensile and stainless steel wire, as manufacturers prioritize performance and longevity in harsh operating environments. The automotive industry, a primary consumer of hose clamp wire, continues to adopt lightweight and corrosion-resistant clamps to meet fuel efficiency and emission standards—directly influencing wire quality requirements.

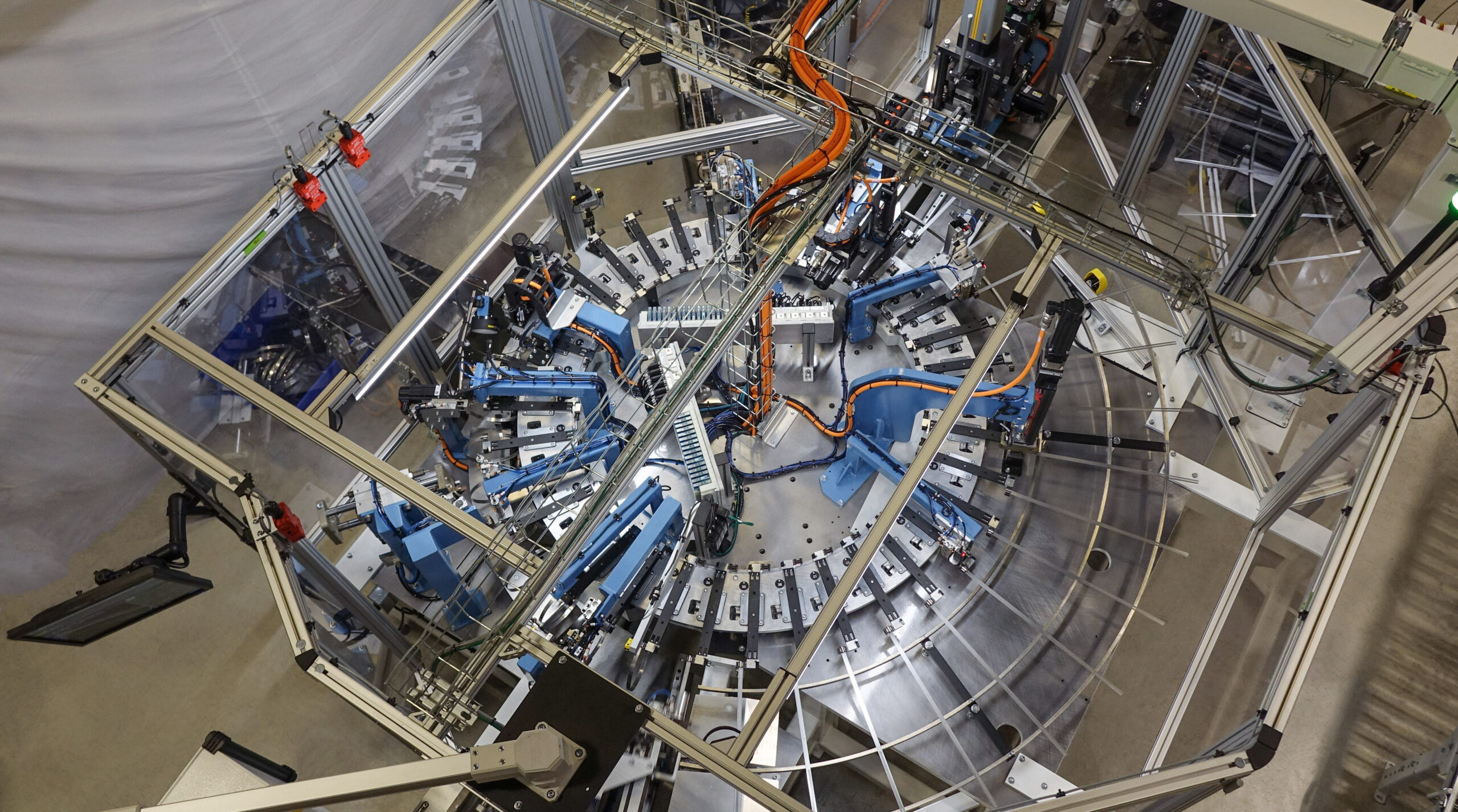

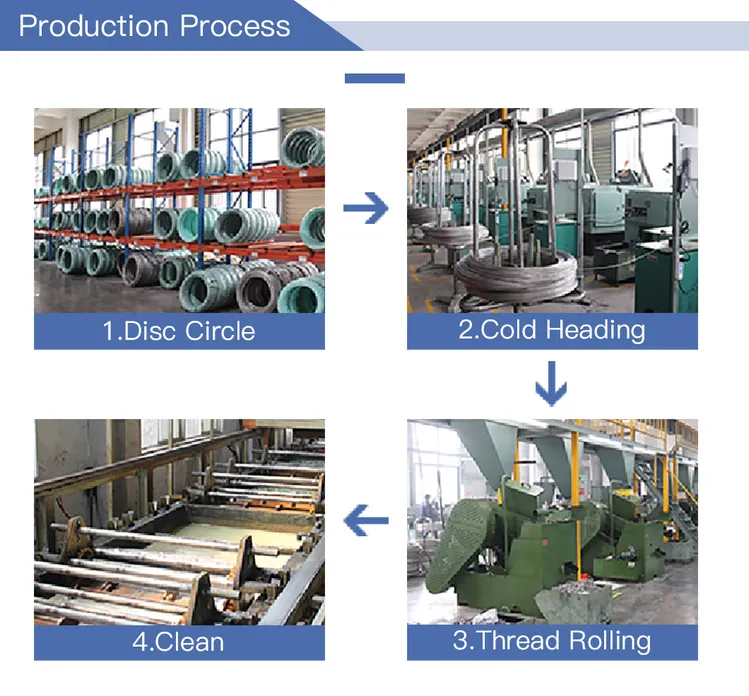

Additionally, automation in manufacturing processes is enabling more precise wire forming and tighter tolerances in clamp production. This trend is expected to boost demand for uniform, high-quality wire with consistent mechanical properties.

Geographically, Asia-Pacific remains the dominant region due to rapid industrialization and robust automotive production in countries like China, India, and Vietnam. North America and Europe are also seeing steady demand, supported by aftermarket services and stringent safety regulations.

Sustainability is emerging as a key consideration, with manufacturers exploring recyclable materials and energy-efficient production methods. By 2026, companies that integrate eco-friendly practices and innovate in wire coating technologies—such as zinc-aluminum alloy coatings for enhanced rust protection—are likely to gain a competitive edge.

In summary, the 2026 hose clamp wire market will be shaped by material innovation, automation, regional industrial growth, and sustainability, positioning high-performance wire solutions at the forefront of industry development.

Common Pitfalls Sourcing Hose Clamp Wire (Quality, IP)

Sourcing hose clamp wire, especially when specific quality standards and Intellectual Property (IP) considerations are involved, presents several potential pitfalls. Overlooking these can lead to product failure, compliance issues, legal disputes, and reputational damage. Below are key challenges to be aware of:

Inadequate Material Quality and Specifications

One of the most frequent issues is receiving hose clamp wire that does not meet required material specifications. Suppliers may substitute lower-grade alloys (e.g., using non-stainless steel or substandard grades like 304 instead of 316), leading to reduced corrosion resistance, tensile strength, or durability. This is especially critical in automotive, marine, or industrial applications where performance under stress and exposure to harsh environments is expected.

Lack of Traceability and Certification

Many suppliers fail to provide proper material test reports (MTRs), mill certifications, or traceability documentation. Without these, it’s impossible to verify the chemical composition and mechanical properties of the wire. This absence increases the risk of non-compliance with industry standards (e.g., ASTM, ISO) and can result in rejected shipments or field failures.

Inconsistent Dimensional Tolerances

Poor process control at the supplier level often results in inconsistent wire diameter, ovality, or surface finish. Even minor deviations can affect the performance of the final hose clamp—impacting clamping force, ease of assembly, or sealing integrity. Tight tolerances are essential for automated manufacturing lines, where variability causes downtime or defective products.

Intellectual Property (IP) Risks and Reverse Engineering

Sourcing from regions with weak IP enforcement increases the risk of design theft or unauthorized replication. If your hose clamp design includes proprietary features (e.g., specialized threading, crimping profiles, or multi-layer construction), suppliers may reverse engineer the product and sell it to competitors. This undermines market exclusivity and can lead to costly litigation.

Hidden Tooling and Setup Costs

Some suppliers quote low per-unit prices but hide significant upfront tooling, setup, or minimum order quantity (MOQ) costs. These can make small-batch sourcing prohibitively expensive. Additionally, tooling ownership may not be clearly transferred, creating dependency on the supplier and limiting production flexibility.

Supply Chain and Lead Time Unreliability

Unpredictable lead times, lack of production transparency, and poor communication are common with overseas suppliers. This can disrupt inventory planning and production schedules. Relying on a single supplier without contingency planning increases vulnerability to disruptions due to logistics, political instability, or quality issues.

Non-Compliance with Environmental and Safety Regulations

Hose clamp wire used in regulated industries (e.g., automotive, aerospace, medical) must comply with standards such as RoHS, REACH, or FDA. Some suppliers may not adhere to these regulations or provide false compliance documentation, exposing the buyer to liability and market access restrictions.

Inadequate Quality Control Processes

Suppliers may lack robust incoming inspection, in-process checks, or final quality audits. Without third-party inspections or on-site audits, defects like surface cracks, decarburization, or improper heat treatment may go undetected until after integration into final products.

Mitigating these pitfalls requires thorough due diligence, clear contractual agreements, regular audits, and strong IP protection strategies such as NDAs and registered designs. Working with reputable suppliers who offer transparency, certification, and compliance assurance is essential for reliable and secure sourcing.

Logistics & Compliance Guide for Hose Clamp Wire

Overview

Hose clamp wire is a critical component in various industrial, automotive, and manufacturing applications. Ensuring its proper logistics handling and compliance with international and domestic regulations is essential for safe, efficient, and legal distribution. This guide outlines best practices for transporting, storing, and complying with regulatory standards for hose clamp wire.

Packaging and Handling

Proper packaging prevents damage during transit and ensures product integrity.

– Coiled or Spooled Forms: Hose clamp wire is typically shipped in coils or on spools. Use protective end caps and banding to prevent uncoiling.

– Palletization: Secure coils on wooden or plastic pallets using stretch wrap or strapping. Ensure even weight distribution to avoid tipping.

– Labeling: Clearly label each package with product specifications, batch/lot number, net weight, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

– Moisture Protection: Use moisture-resistant wrapping or desiccants if shipping to humid environments to prevent corrosion.

Storage Conditions

Optimal storage preserves wire quality and prevents degradation.

– Environment: Store in a dry, temperature-controlled indoor facility. Relative humidity should be below 60% to reduce oxidation.

– Ventilation: Ensure adequate airflow to prevent condensation.

– Racking: Store coils vertically on racks or shelves to avoid deformation. Do not stack heavy items on top of wire coils.

– Separation: Keep away from corrosive chemicals, acids, and salts to prevent contamination.

Transportation Requirements

Adherence to transportation regulations ensures safety and compliance across modes.

– Domestic (e.g., U.S. DOT): Classify hose clamp wire as non-hazardous material. Follow FMCSA guidelines for load securement.

– International (e.g., IMDG, IATA): Generally exempt from hazardous goods regulations when uncoated and non-reactive. Confirm classification under HS Code 7326.20 (other articles of steel).

– Maritime & Air Freight: Use ISPM 15-compliant wooden pallets if applicable. Declare accurate weight and dimensions for freight calculation.

– Customs Documentation: Provide commercial invoice, packing list, and bill of lading. Include country of origin and material composition.

Regulatory Compliance

Meet global standards for materials, safety, and trade.

– REACH (EU): Ensure no restricted substances (e.g., lead, cadmium) exceed allowable thresholds. Provide SVHC (Substances of Very High Concern) documentation if requested.

– RoHS (EU & China): Comply if wire is used in electrical/electronic equipment. Confirm lead-free composition and test for restricted materials.

– Conflict Minerals (U.S. SEC Rule 13p-1): Disclose if tin, tungsten, tantalum, or gold (3TG) are present and sourced from conflict-affected regions.

– EPA & OSHA (U.S.): Follow workplace safety guidelines for handling wire (e.g., cut-resistant gloves). No special emissions reporting required for standard steel wire.

Documentation and Traceability

Maintain records for audit and compliance purposes.

– Mill Test Certificates (MTC): Provide EN 10204 3.1 or 3.2 certificates verifying material composition and mechanical properties.

– Batch Traceability: Implement a system to track production batches from raw material to final shipment.

– Import/Export Licenses: Not typically required for standard steel wire, but verify with local authorities based on destination country.

Environmental and Disposal Considerations

Promote sustainability and safe end-of-life handling.

– Recyclability: Steel wire is 100% recyclable. Encourage customers to return scrap for recycling.

– Waste Disposal: Follow local regulations for metal waste. Do not incinerate coated wires without checking for hazardous fumes.

– Carbon Footprint: Optimize logistics routes and use recyclable packaging to reduce environmental impact.

Summary

Effective logistics and compliance for hose clamp wire require attention to packaging, storage, transportation, and regulatory standards. By following this guide, manufacturers and distributors can ensure product quality, regulatory adherence, and efficient supply chain operations globally. Regular audits and updates to compliance protocols are recommended to respond to evolving regulations.

Conclusion for Sourcing Hose Clamp Wire:

Sourcing hose clamp wire requires a strategic approach that balances quality, cost, and supply chain reliability. Based on the evaluation of potential suppliers, material specifications, and production requirements, it is evident that selecting a supplier with proven expertise in steel wire manufacturing—particularly for precision applications like hose clamps—is crucial. Key considerations such as tensile strength, corrosion resistance, dimensional accuracy, and compliance with industry standards (e.g., ASTM, ISO) must be prioritized to ensure product performance and durability.

Establishing long-term partnerships with suppliers who offer consistent quality, scalability, and technical support will enhance operational efficiency and reduce risk. Additionally, conducting regular audits, material testing, and maintaining contingency plans can further safeguard supply continuity. In summary, a well-structured sourcing strategy focused on qualified global or regional suppliers, supported by strong quality assurance protocols, will enable reliable access to high-performance hose clamp wire, ultimately contributing to the overall quality and competitiveness of the final product.