The global wheel hub and bearing market is experiencing steady growth, driven by rising vehicle production and increasing demand for improved vehicle safety and performance. According to a report by Mordor Intelligence, the global wheel hub and bearing market was valued at USD 9.67 billion in 2023 and is projected to reach USD 13.28 billion by 2029, growing at a CAGR of approximately 5.5% during the forecast period. This growth is fueled by the proliferation of advanced driver-assistance systems (ADAS) and the need for durable, precision-engineered components in both passenger and commercial vehicles.

As one of the world’s leading automakers, Honda relies on high-performance wheel bearings to ensure ride quality, noise reduction, and long-term reliability. With OEM and aftermarket demand on the rise, a select group of manufacturers has emerged as key suppliers of wheel bearing systems for Honda vehicles. These companies combine engineering excellence, stringent quality control, and global supply chain capabilities to meet Honda’s exacting standards. Below, we highlight the top seven manufacturers shaping the landscape of Honda wheel bearing production, backed by innovation, market presence, and technical expertise.

Top 7 Honda Wheel Bearing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 44300

Domain Est. 2017

Website: hondapartsconnection.com

Key Highlights: In stock $35.47 deliverySALE: 2023-2025 Honda – Wheel Bearing Genuine OEM Honda® Part # 443003t0j01. Manufacturer Warranty, Fast Shipping. Genuine OEM Parts & Accessories….

#2 OEM 2022

Domain Est. 1998

Website: hondaautomotiveparts.com

Key Highlights: In stock Rating 4.9 (6,390) We offer a wide selection of OEM Honda parts, each manufactured to the same exacting standards that make Honda the most exciting car brand on the mark…

#3 2003

Domain Est. 2015

Website: honda.oempartsonline.com

Key Highlights: All of our parts are genuine OEM parts so we guarantee your Wheel Bearing will perfectly fit your 2003-2008 Honda Pilot vehicle….

#4 Recall Search

Domain Est. 1989

Website: mygarage.honda.com

Key Highlights: See recall details by selecting your product. Enter your year, model, and trim for information about your Honda. Year. Year. Select Year. Model. Model….

#5 DENSO Auto Parts

Domain Est. 2006

Website: densoautoparts.com

Key Highlights: DENSO is a global choice for top automakers, with multiple vehicle models rolling off the assembly line with DENSO auto parts under the hood….

#6 Honda 44300

Domain Est. 2007

Website: hondapartsnow.com

Key Highlights: HondaPartsNow.com offers the great deal for genuine Honda parts, 44300S04008. Bearing Assembly, Front Hub (Ntn Corp.) for $137.73….

#7 44300

Domain Est. 2008

Website: hondapartsonline.net

Key Highlights: When you buy your Wheel Bearing (443003d4a01) for your 2023-2025 Honda CR-V vehicle you will receive a brand new part that fits perfectly….

Expert Sourcing Insights for Honda Wheel Bearing

H2: Projected Market Trends for Honda Wheel Bearings in 2026

As the automotive industry evolves through technological innovation, shifting consumer preferences, and regulatory changes, the market for automotive components such as wheel bearings is expected to undergo significant transformation by 2026. Honda wheel bearings, known for their reliability and integration within Honda’s efficient vehicle platforms, will be influenced by several key trends shaping the global automotive aftermarket and original equipment (OE) supply chain.

-

Growth in Electric Vehicle (EV) Adoption

Honda’s increasing commitment to electrification—evident in its plan to achieve 100% zero-emission vehicle sales by 2040—will directly impact wheel bearing design and demand. By 2026, a rising proportion of Honda EVs like the Prologue and future EV models will require wheel bearings engineered for higher torque loads, reduced noise, and improved sealing to accommodate extended service intervals. These specialized bearings may command premium pricing, driving value growth in the segment. -

Expansion of the Aftermarket Sector

Despite longer lifespans of modern wheel bearings, the growing global fleet of Honda vehicles—including popular models like the CR-V, Civic, and Accord—will sustain strong aftermarket demand. In 2026, emerging markets in Southeast Asia, Latin America, and Africa are expected to contribute significantly to aftermarket sales due to increasing vehicle ownership and maintenance needs. Third-party manufacturers will compete closely with OEM Honda bearings, but brand loyalty and quality assurance will keep Honda’s OE and certified replacement parts in high demand. -

Advancements in Bearing Technology

By 2026, intelligent and condition-monitoring wheel bearings may begin entering high-end Honda models. These integrated systems, featuring sensors to detect wear, temperature, and load anomalies, will support predictive maintenance—especially valuable for fleet operators and autonomous vehicle platforms. While still emerging, this technology will position Honda as a leader in vehicle safety and reliability, increasing the complexity and value of wheel bearing units. -

Supply Chain Resilience and Localization

Ongoing efforts by Honda to regionalize production—particularly in North America and Asia—will influence the sourcing and manufacturing of wheel bearings. Strategic partnerships with suppliers like NTN, NSK, and JTEKT will likely strengthen to ensure supply chain stability amid geopolitical uncertainties and raw material volatility. Localization will reduce lead times and logistics costs, supporting just-in-time manufacturing practices. -

Sustainability and Circular Economy

Environmental regulations and corporate sustainability goals will push Honda and its suppliers toward greener manufacturing processes. By 2026, recyclable materials, energy-efficient production, and remanufactured wheel bearing options may gain traction in the market. Honda’s alignment with circular economy principles could lead to certified refurbished components entering the aftermarket, offering cost-effective and eco-friendly alternatives.

In conclusion, the 2026 market for Honda wheel bearings will be shaped by electrification, technological innovation, regional market dynamics, and sustainability initiatives. OEM and aftermarket stakeholders must adapt to these shifts by investing in R&D, supply chain resilience, and customer education to maintain competitiveness in a rapidly transforming automotive landscape.

Common Pitfalls When Sourcing Honda Wheel Bearings (Quality, IP)

Sourcing genuine and reliable Honda wheel bearings is critical for vehicle safety and performance. However, buyers often encounter several pitfalls related to quality and intellectual property (IP) concerns. Being aware of these issues can help avoid costly mistakes and ensure long-term reliability.

Poor Quality Materials and Construction

Many aftermarket or counterfeit wheel bearings use substandard steel, improper heat treatment, or inadequate lubrication. These compromises lead to premature wear, increased noise, and potential failure under load. Low-quality seals allow moisture and debris to enter, accelerating bearing degradation. Always verify material specifications and manufacturing standards to ensure durability equivalent to OEM parts.

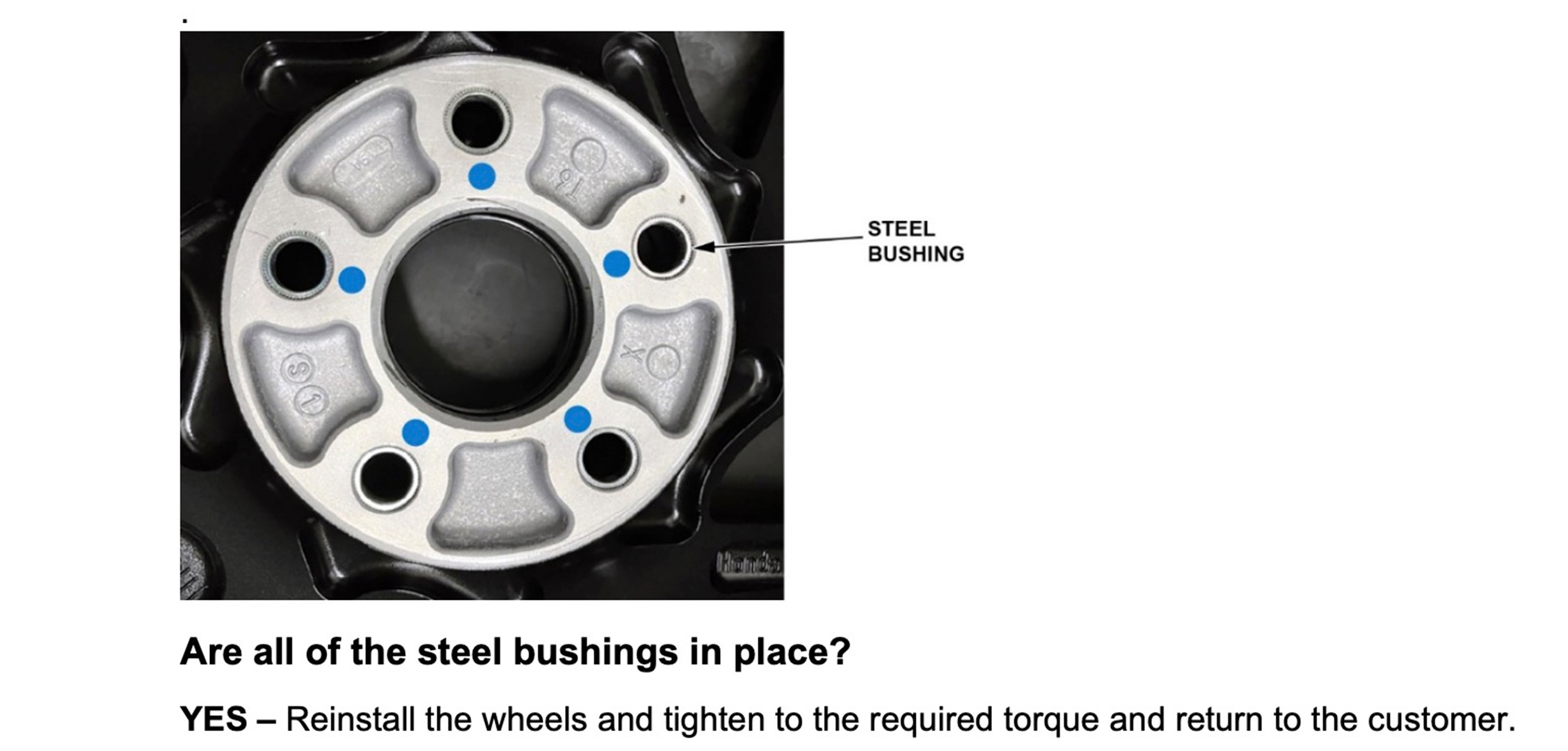

Lack of Genuine OEM Certification

A major pitfall is purchasing bearings labeled as “OEM-quality” without proper certification. Genuine Honda wheel bearings are manufactured to strict tolerances and undergo rigorous testing. Counterfeit or imitation products may mimic packaging but fail to meet these standards. Look for official Honda part numbers, holograms, or distributor certifications to confirm authenticity.

Intellectual Property (IP) Infringement

Sourcing from unauthorized suppliers increases the risk of handling IP-infringing products. Many counterfeit bearings illegally use Honda’s trademarks, logos, and part numbering systems. Distributing or installing such parts can expose businesses to legal liability. Always source through authorized channels or reputable suppliers with documented IP compliance.

Inconsistent Tolerances and Fitment Issues

Non-genuine bearings often have inconsistent dimensional tolerances, leading to improper fitment on Honda hubs and axles. This can result in vibration, uneven wear, or damage to surrounding components. Genuine Honda bearings are engineered for precise fit and alignment—critical for maintaining vehicle dynamics and safety.

Inadequate Packaging and Traceability

Counterfeit or low-quality bearings frequently come in poorly printed, reused, or generic packaging without batch numbers or traceability data. Genuine Honda parts feature tamper-evident packaging with clear labeling and traceable manufacturing information. Lack of traceability makes quality control and recalls difficult.

Misleading Marketing and Branding

Some suppliers use terms like “Honda-compatible” or “direct replacement” to imply OEM equivalence without meeting actual performance standards. These marketing tactics can mislead buyers into thinking they are purchasing high-quality parts. Always cross-reference part numbers with Honda’s official catalogs and verify supplier credentials.

Sourcing from Unverified Suppliers

Purchasing from online marketplaces or third-party vendors without vetting increases exposure to counterfeit or defective products. These suppliers may lack quality control, proper storage, or technical support. Establish relationships with authorized distributors or certified aftermarket brands with proven quality management systems.

By recognizing these common pitfalls—especially those tied to product quality and intellectual property risks—buyers can make informed decisions and ensure the safety, reliability, and legal compliance of the Honda wheel bearings they source.

Logistics & Compliance Guide for Honda Wheel Bearing

This guide outlines the key logistics and compliance considerations for the import, export, distribution, and handling of Honda wheel bearings. Adhering to these standards ensures operational efficiency, regulatory compliance, and product integrity.

Product Classification & HS Code

Honda wheel bearings are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 8708.80.00, which covers “Parts and accessories of the motor vehicles of headings 8701 to 8705: Other parts and accessories of such vehicles: Other.” However, specific models or configurations may fall under subcategories. Always verify the correct code based on the exact product specification and destination country regulations to ensure accurate customs declarations and tariff application.

Import/Export Documentation

Ensure all shipments are accompanied by the following documentation:

– Commercial Invoice (itemized with HS code, value, and country of origin)

– Packing List (detailing weight, dimensions, and quantity per package)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (often required to claim preferential tariffs under trade agreements)

– Export Declaration (if applicable per exporting country regulations)

Maintain digital and physical copies for audit and compliance purposes.

Packaging & Labeling Requirements

Honda wheel bearings must be packaged to prevent damage during transit. Use:

– Corrugated cardboard boxes with internal cushioning (e.g., foam inserts or bubble wrap)

– Desiccant packs to minimize moisture exposure

– Tamper-evident seals where applicable

Labels must include:

– Part number (e.g., 44300-SDA-A01)

– Quantity

– Batch/lot number

– Manufacturer/date code

– “Fragile” and “This Way Up” handling icons

– Compliance marks (e.g., CE, if applicable)

Transportation & Storage Conditions

- Temperature: Store and transport in a climate-controlled environment (15–25°C / 59–77°F recommended)

- Humidity: Maintain relative humidity below 60% to prevent corrosion

- Handling: Avoid dropping or stacking beyond specified weight limits

- Storage: Keep in original packaging, off the floor, and away from direct sunlight or heat sources

- Shelf Life: Bearings have an indefinite shelf life if stored properly, but inspect for rust or seal damage before use

Regulatory Compliance

Ensure compliance with regional and international standards:

– DOT (U.S.): Compliance with Federal Motor Vehicle Safety Standards (FMVSS) where applicable

– ECE Regulations (Europe): Adherence to UNECE safety and component approval standards

– RoHS & REACH (EU): Confirm absence of restricted substances (e.g., lead, cadmium)

– Country-Specific Approvals: Verify local type-approval requirements (e.g., JIS in Japan, CCC in China)

Partner with certified suppliers and obtain all relevant compliance certifications.

Customs Clearance Procedures

- Pre-clear shipments using Advance Cargo Information (ACI) or Importer Security Filing (ISF) where required

- Assign a licensed customs broker in the destination country

- Be prepared for inspections; maintain traceability records (batch numbers, supplier data)

- Address any tariff classification disputes promptly with supporting technical documentation

Sustainability & Environmental Compliance

- Follow WEEE (Waste Electrical and Electronic Equipment) directives if bearings contain electronic sensors (e.g., ABS-integrated units)

- Recycle packaging materials per local regulations

- Document environmental compliance for corporate sustainability reporting

- Use eco-friendly packaging materials when possible

Quality Assurance & Traceability

- Implement a robust tracking system (barcodes or RFID) to trace each bearing to production batch

- Conduct incoming inspections upon receipt to verify part number, quantity, and condition

- Retain supplier Certificates of Conformance (CoC) for minimum 5 years

- Report non-conformances through proper channels per ISO 9001 standards

Risk Management & Contingency Planning

- Identify alternative suppliers and logistics routes to mitigate supply chain disruptions

- Maintain safety stock levels based on lead time and demand variability

- Insure shipments for full replacement value

- Develop recall procedures in case of defective batches, including customer notification and return logistics

By following this guide, stakeholders can ensure that Honda wheel bearings are handled, transported, and distributed in full compliance with global logistics and regulatory standards. Regular audits and staff training are recommended to maintain ongoing compliance.

Conclusion for Sourcing Honda Wheel Bearings

Sourcing Honda wheel bearings requires a strategic approach that balances quality, cost, availability, and reliability. After evaluating various suppliers, OEM (Original Equipment Manufacturer) options remain the benchmark for performance and compatibility, ensuring optimal safety and longevity. However, reputable aftermarket brands such as SKF, Timken, and National offer cost-effective alternatives without significant compromise on quality, provided they meet industry standards and are properly certified.

Key considerations in the sourcing process include vehicle-specific fitment, warranty offerings, supply chain consistency, and total cost of ownership. Establishing relationships with reliable distributors or authorized dealers ensures genuine products and reduces the risk of counterfeit parts. Additionally, factors such as lead times, inventory management, and technical support play a crucial role in efficient sourcing, especially for high-volume operations.

In conclusion, the best sourcing strategy involves a mix of OEM components for critical applications and high-quality aftermarket bearings for cost-sensitive scenarios, all backed by due diligence in supplier evaluation. This balanced approach ensures safety, reliability, and cost-efficiency in maintaining Honda vehicles to the highest standards.