The global hinge market is experiencing robust growth, driven by increasing demand in construction, industrial, and architectural applications. According to Grand View Research, the global hinges market size was valued at USD 21.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising infrastructure development and the growing preference for durable, heavy-duty hardware solutions—such as metal utility barn doors—in commercial, agricultural, and residential settings. With the North American and European markets leading in industrial construction and farm building investments, demand for high-performance hinges capable of supporting heavy metal barn doors has surged. Manufacturers specializing in heavy-duty, corrosion-resistant hinges are positioning themselves to meet these evolving needs, particularly in utility buildings where reliability and longevity are critical. In this competitive landscape, selecting the right hinge from top-tier manufacturers is essential for ensuring structural integrity, smooth operation, and long-term durability.

Top 9 Hinges For Metal Utility Barn Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hinge Manufacturers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Easily locate hinge manufacturers and suppliers listed on this site that provide many industrial hinge types in stock, substantial production volume, ……

#2 Crown Industrial

Domain Est. 1998

Website: crown-industrial.com

Key Highlights: From unique high end residential to large heavy duty industrial applications; we design, engineer, manufacture, and install to meet the needs of our clients….

#3 Hinges and Hardware

Domain Est. 2003

Website: evermark-lnl.com

Key Highlights: Evermark is a premier manufacturer of hinges and hardware. Products include hinges and hardware for exterior doors, interior doors, barn doors, and….

#4 Swinging Door Hardware

Domain Est. 2000

Website: rwhardware.com

Key Highlights: Decorative and heavy duty strap hinge hardware for swinging doors comes in various thicknesses, usually 1/4″, 5/16″, 3/8″, or 1/2″ for doors weighing between ……

#5 Onward Hardware

Domain Est. 2001

Website: onwardhardware.com

Key Highlights: Find one of the widest range of builder’s hardware and related products such as cabinet and furniture hinges, as well as window and door hardware….

#6 Type of Hinges, Door Hinge Resource, Hinge Types

Domain Est. 2004

Website: hingeoutlet.com

Key Highlights: Looking for a door hinge guide to help guide you in the right direction when purchasing your door hinges? We’ve provided you with a comprehensive guide….

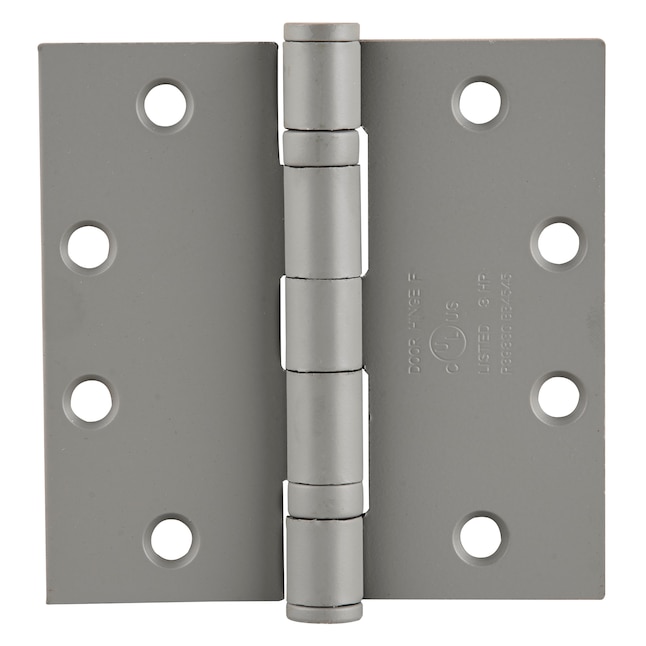

#7 Commercial Door Hinges

Domain Est. 2006

Website: stanleyhinges.com

Key Highlights: Stanley Hinges provide high quality commercial door hinges including stainless steel, butt, spring, cabinet & continuous hinges. Buy online today….

#8 Hinges

Domain Est. 2016

Website: systemequine.com

Key Highlights: Heavy Duty Madison Adjustable Strap Hinge 24″ Black. $125.00. Adjustable barn door hinge built to withstand daily heavy use. Add to wishlist · Add to cart….

#9 Shop Exterior Barn Door Hardware

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryShop a wide selection of premium exterior barn door hardware at Do it Best. Browse rails, brackets, and more, and get same day pick-up or home delivery….

Expert Sourcing Insights for Hinges For Metal Utility Barn Doors

H2: Projected Market Trends for Hinges for Metal Utility Barn Doors in 2026

The market for hinges designed specifically for metal utility barn doors is poised for notable evolution by 2026, shaped by advancements in materials, rising demand in residential and agricultural sectors, and increasing emphasis on durability and ease of installation. This analysis outlines key trends expected to influence the hinges segment for metal utility barn doors in the coming years.

1. Growth in DIY and Home Improvement Markets

The continued expansion of the DIY (Do-It-Yourself) home improvement sector is expected to significantly boost demand for heavy-duty hinges. Consumers are increasingly opting for metal utility barn doors as space-saving and aesthetically pleasing alternatives in garages, sheds, and utility rooms. Hinges that offer easy installation, adjustability, and compatibility with standard metal door profiles will see higher adoption.

2. Demand for Durable, Corrosion-Resistant Materials

By 2026, hinges made from stainless steel, powder-coated carbon steel, and aluminum alloys are expected to dominate the market. These materials offer superior resistance to rust and wear—critical for metal barn doors exposed to harsh weather, moisture, and industrial environments. Galvanized and zinc-plated finishes will also be in demand for outdoor and agricultural applications.

3. Rise in Smart and Motorized Barn Door Systems

While still niche, the integration of smart technology into barn door mechanisms is gaining traction. Motorized sliding systems for heavy metal doors will drive demand for high-load-capacity hinges compatible with automated tracks. Hinge manufacturers may begin offering smart-enabled components that support remote operation and load-sensing capabilities.

4. Sustainability and Recyclability Focus

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable production practices. Hinges made from recyclable metals with low-emission manufacturing processes will gain market favor. Certifications such as Energy Star or Cradle-to-Cradle may become differentiators in the commercial and institutional sectors.

5. Regional Market Expansion

North America and Europe will remain leading markets due to high construction activity and retrofitting of older agricultural buildings. However, emerging markets in Latin America and Southeast Asia are expected to show above-average growth, driven by infrastructure development and modernization of rural storage facilities.

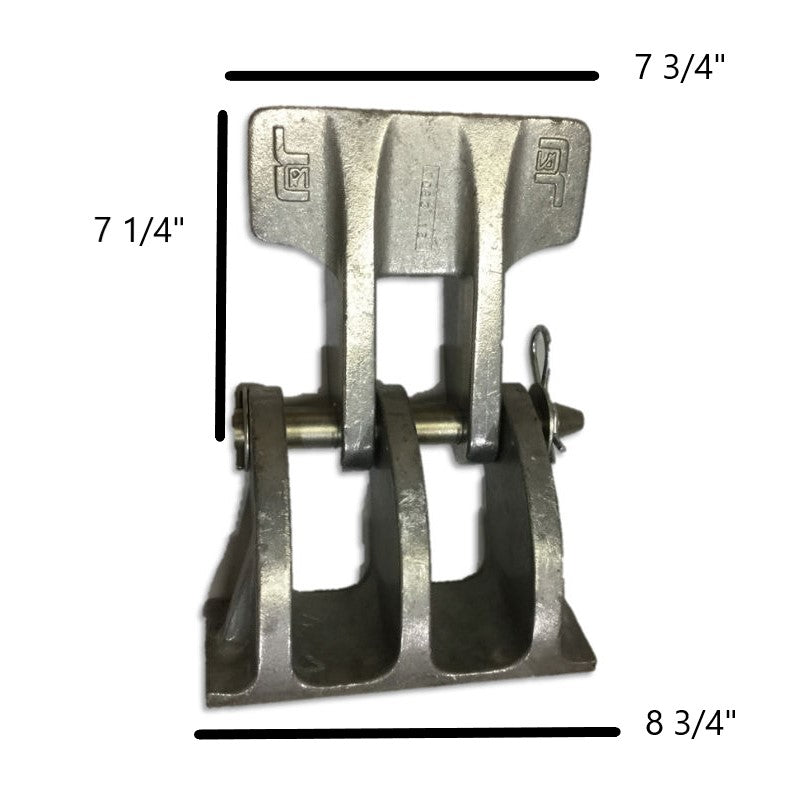

6. Customization and Load Capacity Innovation

As metal barn doors grow larger and heavier (especially in commercial and industrial applications), hinge designs will need to support higher weight loads—upwards of 500 lbs. Customizable hinge systems with adjustable rollers, pivot points, and mounting configurations will become more prevalent to meet diverse architectural needs.

7. E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms will play a pivotal role in hinge distribution by 2026. Manufacturers and suppliers offering detailed product specs, installation guides, and compatibility tools online will capture a larger share of the market. Subscription models for maintenance and replacement parts may also emerge.

In summary, the 2026 market for hinges for metal utility barn doors will be defined by innovation in materials, increased automation readiness, and responsiveness to evolving consumer and environmental demands. Companies that prioritize durability, ease of use, and sustainability will be best positioned for growth in this specialized niche.

Common Pitfalls When Sourcing Hinges for Metal Utility Barn Doors (Quality and IP Considerations)

Logistics & Compliance Guide for Hinges for Metal Utility Barn Doors

Overview

Hinges for metal utility barn doors are essential hardware components used to ensure durable and functional door operation in industrial, agricultural, and commercial settings. Due to their mechanical function and potential safety implications, proper logistics handling and compliance with regulatory standards are critical throughout the supply chain—from manufacturing to end-use.

International Shipping & Logistics

Packaging Requirements

- Hinges must be packaged in moisture-resistant, durable materials (e.g., corrugated cardboard with plastic lining or sealed polybags) to prevent rust and physical damage during transit.

- Bulk shipments should be palletized and secured with stretch wrap or strapping to prevent shifting.

- Each package must include clear labeling indicating contents, weight, handling instructions (e.g., “Fragile,” “Do Not Stack”), and country of origin.

Transportation Modes

- Suitable for air, sea, and ground freight depending on order size and destination.

- Sea freight is cost-effective for large-volume shipments; air freight is recommended for urgent or time-sensitive orders.

- Ground transport within regions (e.g., North America, EU) should comply with local weight and dimension regulations.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (required for tariff determination)

- Harmonized System (HS) Code: Typically 8302.41 (staples, hinges, and similar articles of iron or steel) – verify based on material composition and design.

Regulatory Compliance

Material & Safety Standards

- Must comply with ISO 9001 for quality management systems if supplied by certified manufacturers.

- In the U.S., hinges should meet ASTM A153/A153M for zinc coating requirements (if galvanized) to prevent corrosion.

- EU compliance: Adherence to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) if applicable to plating or coatings.

Product Certification

- No specific product certification is universally required for hinges unless part of a safety-critical system. However, some industrial or construction applications may require third-party testing.

- CE marking is not mandatory for standalone hinges but may be required when sold as part of a door assembly in the European Economic Area (EEA).

Environmental & Duty Considerations

- Duty rates vary by destination country and hinge material (e.g., stainless steel vs. carbon steel). Use the correct HS code to determine applicable tariffs.

- Ensure environmentally responsible disposal of packaging materials in compliance with local waste regulations (e.g., EPA guidelines in the U.S., WEEE in the EU).

Storage & Handling

Warehouse Guidelines

- Store in dry, temperature-controlled environments to prevent oxidation or corrosion.

- Keep off concrete floors using pallets or shelving to avoid moisture absorption.

- Implement FIFO (First In, First Out) inventory rotation to minimize long-term storage risks.

Handling Precautions

- Use appropriate lifting equipment for bulk loads to prevent worker injury.

- Avoid dropping or impact loading, which may deform hinge barrels or pivot points.

End-User Compliance & Installation

Installation Standards

- Follow manufacturer’s torque specifications for mounting screws/bolts.

- Ensure proper alignment and weight capacity match door specifications (e.g., heavy-duty hinges for doors over 100 lbs).

- Recommend use of locknuts or thread-locking compounds in high-vibration environments.

Maintenance & Safety

- Inspect hinges regularly for wear, corrosion, or misalignment.

- Lubricate pivot points periodically with manufacturer-recommended grease or oil.

- Replace damaged or worn hinges immediately to avoid door failure.

Conclusion

Proper logistics planning and compliance adherence ensure the safe, efficient delivery and use of hinges for metal utility barn doors. By following international shipping standards, regulatory requirements, and best practices in storage and installation, suppliers and end users can maintain product integrity and operational safety. Always consult local regulations and industry standards for region-specific compliance needs.

In conclusion, sourcing hinges for metal utility barn doors requires careful consideration of durability, weight capacity, material compatibility, and environmental resistance. Given the heavy-duty nature of metal barn doors, it is essential to select industrial-strength hinges—such as continuous (piano) hinges or heavy-duty pivot hinges—constructed from materials like stainless steel or galvanized steel to prevent corrosion and ensure long-term performance. Proper measurements, door weight assessment, and alignment during installation are critical to optimal function and longevity. Additionally, sourcing from reputable suppliers who offer warranties and product support can provide assurance of quality. By prioritizing strength, reliability, and suitability for the intended environment, you can ensure a secure and smooth-operating barn door solution that meets both functional and safety requirements.