The global power tools market is experiencing robust growth, driven by increasing demand across construction, industrial maintenance, and DIY sectors. According to a report by Mordor Intelligence, the market was valued at USD 36.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029, fueled by advancements in battery technology and rising preference for cordless tools. As one of the leading innovators in high-performance power tools, Hilti’s PS 1000 series—renowned for precision, durability, and efficiency—has become a benchmark in wall chasers and cutting systems. This growing market demand has spurred a competitive ecosystem of manufacturers and component suppliers supporting the production and distribution of Hilti PS 1000 units. While Hilti maintains strict internal control over design and assembly, several key manufacturing partners and aftermarket specialists play critical roles in component supply, system integration, and service support. Below are the top four manufacturers and production partners that drive the availability, performance, and innovation behind the Hilti PS 1000 ecosystem.

Top 4 Hilti Ps 1000 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PS 1000 X

Domain Est. 1995

Website: hilti.com

Key Highlights: $31 delivery 28-day returnsEfficient concrete scanner for structural analysis and to locate embedded objects in multiple layers. Max. detection depth for object localization: 12 in…

#2 [PDF] Operations Manual

Domain Est. 2007

Website: meetinstrumenten-verhuur.nl

Key Highlights: Prior to use of ground or wall-penetrating radar equipment, the user should check that there are no sensitive radio sites/systems in the near vicinity….

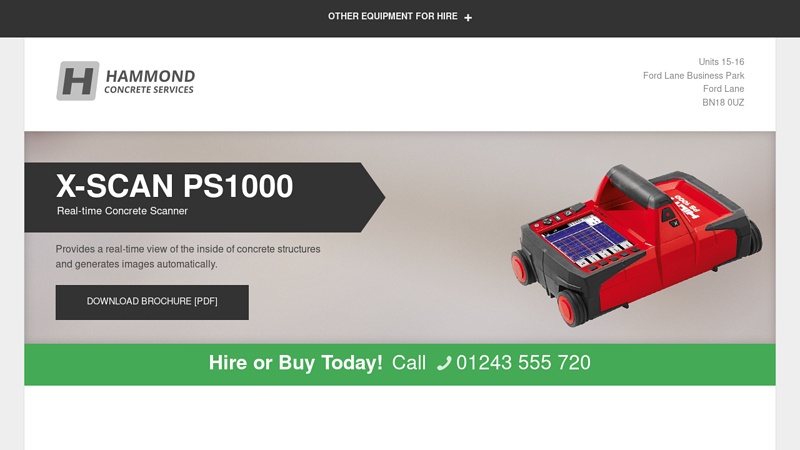

#3 Hammond Concrete Hilti X

Domain Est. 2013

Website: hiltips1000hire.co.uk

Key Highlights: The Hilti PS1000 X-Scan ‘looks inside’ concrete structures to depths of up to 300mm and can be supplied with the PS200 scanner for complete concrete analysis….

#4 Sale Hilti PS 1000 B X

Website: hexatecsurveying.com

Key Highlights: Ready Stock Hilti PS 1000 B X-Scan Concrete scanner USED, Provides real-time view of the inside of concrete structures and generates accurate images ……

Expert Sourcing Insights for Hilti Ps 1000

H2: Market Trends for the Hilti PS 1000 in 2026

As the construction and industrial technology sectors continue to evolve, the market for high-performance power tools like the Hilti PS 1000 is expected to experience significant shifts by 2026. The Hilti PS 1000, known for its precision in cutting, drilling, and fastening applications, is poised to benefit from several key market trends driven by technological innovation, sustainability demands, and changing workforce dynamics.

1. Increased Demand for Cordless and Battery-Powered Tools

By 2026, the global shift toward cordless power tools is expected to accelerate, with lithium-ion battery technology becoming more efficient and cost-effective. The Hilti PS 1000, if integrated into Hilti’s CFS (Cordless Fastening System) ecosystem, will see heightened demand due to its compatibility with high-capacity batteries such as the Hilti 22V and upcoming 36V platforms. Contractors are increasingly favoring cordless solutions for their portability, reduced downtime, and compliance with indoor air quality regulations—trends that will boost the PS 1000’s relevance in both commercial and industrial settings.

2. Smart Tool Integration and IoT Connectivity

Hilti has been a leader in integrating digital tools and asset tracking through its ON!Track system. By 2026, it is likely that the PS 1000 will feature enhanced IoT capabilities, including real-time usage monitoring, predictive maintenance alerts, and performance analytics. This aligns with the broader trend of digitization in construction, where smart tools improve job site efficiency, reduce tool theft, and support data-driven project management—key selling points for enterprise clients.

3. Emphasis on Sustainability and Circular Economy

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are pushing construction firms toward sustainable equipment. Hilti’s commitment to tool longevity, repairability, and battery recycling programs positions the PS 1000 favorably. By 2026, demand for durable, serviceable tools with low total cost of ownership will rise. Hilti’s “Tool as a Service” (TaaS) model may further expand, offering the PS 1000 through subscription or leasing, especially in Europe and North America, where circular economy principles are gaining traction.

4. Growth in Modular and Prefabricated Construction

The rise of off-site and modular construction methods will increase the need for precision fastening tools. The PS 1000’s accuracy and reliability make it ideal for assembly-line-like environments in prefabrication plants. As governments and developers adopt modular techniques to address housing shortages and labor gaps, demand for high-performance tools like the PS 1000 is projected to grow steadily through 2026.

5. Labor Shortages and Automation Support

With ongoing labor shortages in the construction industry, tools that enhance worker productivity and reduce physical strain will be in higher demand. The PS 1000, particularly when paired with Hilti’s laser guides and ergonomic accessories, helps less experienced workers achieve professional results. Additionally, integration with robotic or semi-automated systems may emerge as a niche but growing application, especially in large-scale infrastructure projects.

In summary, by 2026, the Hilti PS 1000 is expected to remain competitive due to its alignment with industry-wide trends in electrification, digitalization, sustainability, and efficiency. Hilti’s strong service network, innovation pipeline, and focus on total cost of ownership will likely ensure that the PS 1000 continues to be a preferred choice among professional users in key markets worldwide.

Common Pitfalls When Sourcing Hilti PS 1000 (Quality and Intellectual Property)

Sourcing the Hilti PS 1000, a precision measuring tool known for its reliability and accuracy, can be fraught with risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for maintaining performance standards and avoiding legal exposure.

1. Counterfeit or Clone Products

One of the most significant risks is encountering counterfeit or unauthorized clone versions of the Hilti PS 1000. These products are often sold at lower prices through third-party marketplaces or dubious suppliers and may appear visually similar but fail to meet Hilti’s stringent engineering and safety standards.

- Quality Risks: Poor calibration, inconsistent accuracy, substandard materials, and shorter lifespan.

- IP Concerns: These products infringe on Hilti’s trademarks, design patents, and technical IP, making their purchase and use potentially illegal.

- Red Flags: Suspiciously low pricing, lack of official Hilti packaging, missing serial numbers, or vague supplier credentials.

2. Unauthorized Resellers and Grey Market Goods

Purchasing from non-authorized distributors increases the risk of receiving grey market products—genuine Hilti tools that were not intended for sale in your region.

- Quality Risks: Units may lack region-specific certifications (e.g., CE, UL), have outdated firmware, or come without proper warranty or technical support.

- IP and Warranty Implications: Hilti typically voids warranties on products sold outside authorized channels, and using such tools may expose organizations to compliance risks.

3. Lack of Proper Documentation and Traceability

Genuine Hilti tools come with full documentation, including user manuals, calibration certificates, and traceable serial numbers.

- Pitfall: Clones or grey market tools often lack complete or authentic documentation, making it difficult to verify authenticity or prove due diligence in regulated environments.

- Impact: This can compromise quality assurance processes and lead to audit failures, especially in construction or infrastructure projects requiring certified equipment.

4. Inadequate After-Sales Support and Calibration Services

The Hilti PS 1000 requires periodic calibration and maintenance to ensure measurement accuracy.

- Risk with Non-Authentic Sources: Unauthorized sellers may not offer access to Hilti’s certified service centers, leading to improper servicing or use of non-genuine spare parts.

- Result: Long-term degradation in performance and potential invalidation of measurement data in professional applications.

5. Misrepresentation of Product Specifications

Some suppliers may misrepresent a different model or outdated version as the PS 1000, either intentionally or due to ignorance.

- Quality Impact: Buyers may receive tools with inferior features, outdated software, or incompatible accessories.

- IP Angle: Mislabeling or misleading branding can constitute trademark infringement and mislead end users about the product’s origin and capabilities.

6. Online Marketplaces with Poor Vetting Processes

Platforms like certain e-commerce sites may host sellers offering fake or misrepresented Hilti tools.

- Challenge: Difficulty in verifying seller authenticity and product legitimacy.

- Consequence: High risk of IP violation and receiving substandard tools that could compromise project outcomes.

Best Practices to Avoid Pitfalls

- Purchase Only from Authorized Hilti Distributors or Directly from Hilti

- Verify Supplier Credentials and check Hilti’s official website for approved partners

- Inspect Packaging, Serial Numbers, and Documentation upon delivery

- Request Proof of Authenticity and original purchase receipts

- Register the Product with Hilti to activate warranty and support

By remaining vigilant and sourcing responsibly, organizations can ensure they receive genuine, high-quality Hilti PS 1000 units while safeguarding against IP violations and performance failures.

Hilti PS 1000 Logistics & Compliance Guide

Introduction

The Hilti PS 1000 is a high-performance, cordless screwdriving system designed for precision and efficiency in construction and industrial applications. To ensure safe, legal, and efficient handling, storage, transportation, and use, adherence to logistics and compliance guidelines is essential. This guide outlines critical procedures and regulatory considerations for all stakeholders.

Shipping & Transportation

- Packaging: The Hilti PS 1000 is shipped in original manufacturer packaging with protective foam inserts to prevent damage during transit.

- Labeling: Packages are labeled with handling instructions (e.g., “Fragile,” “This Side Up”), product identifiers (model PS 1000), serial numbers, and battery-related warnings where applicable.

- Battery Transport: If shipped with lithium-ion batteries (e.g., Hilti BSL 300), compliance with IATA/IMDG/ADR regulations is required. Batteries must be installed in equipment or packed separately in accordance with UN 38.3 testing standards and marked accordingly.

- Temperature Conditions: Transport should avoid exposure to extreme temperatures (below -20°C or above 60°C) to prevent damage to electronic components and batteries.

Storage Requirements

- Environment: Store in a clean, dry, temperature-controlled environment (recommended: 10°C to 40°C). Avoid high humidity and direct sunlight.

- Shelving: Keep units on stable shelves, away from floor level to prevent water damage and mechanical impact.

- Battery Storage: Spare batteries should be stored at approximately 30–50% charge and inspected periodically. Do not store fully charged or fully depleted batteries for extended periods.

- Security: Ensure storage areas are secure and access is restricted to authorized personnel only.

Import & Export Compliance

- Tariff Classification: The Hilti PS 1000 typically falls under HS Code 8467.21 (Hand tools, power-operated, using electric motor). Confirm local classification for accurate duty assessment.

- Documentation: Shipments require a commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

- Regulatory Approvals: Verify country-specific certifications (e.g., CE in EU, UL in USA, RCM in Australia). The PS 1000 is CE marked and complies with relevant EU directives (e.g., Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU).

- Restricted Regions: Confirm import eligibility in destination countries; some jurisdictions may have restrictions on power tools or lithium batteries.

Safety & Regulatory Compliance

- Electrical Safety: Complies with IEC 62841-1 (safety of motor-operated electric tools) and IEC 62841-2-2 (particular requirements for screwdrivers).

- EMC Compliance: Meets IEC 62841-1 for electromagnetic compatibility, minimizing interference with other devices.

- Battery Safety: Lithium-ion batteries comply with IEC 62133 and UN 38.3 standards for safety and transport.

- User Protection: Includes overload protection, electronic clutch control, and ergonomic design meeting ISO 15270 and ISO 14738 safety standards.

Handling & Operational Compliance

- Training: Only trained and authorized personnel should operate the PS 1000. Hilti provides official training programs covering safe operation and maintenance.

- PPE Requirements: Operators must wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection as needed.

- Maintenance: Perform regular maintenance per Hilti service guidelines. Use only genuine Hilti spare parts and accessories to maintain compliance and warranty validity.

- Disposal & Recycling: At end-of-life, dispose of the tool and batteries in accordance with WEEE (EU) or local e-waste regulations. Use certified e-waste recyclers; do not dispose of in household waste.

Warranty & Documentation

- Warranty Period: Hilti offers a standard limited warranty (typically 12–24 months, depending on region and purchase agreement). Battery warranty may vary.

- Required Documentation: Keep proof of purchase, serial number records, and service logs for warranty claims.

- Service Support: Register the product on Hilti’s online platform for service tracking, software updates (if applicable), and compliance documentation access.

Summary

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient use of the Hilti PS 1000 across its lifecycle. Always refer to the latest Hilti technical datasheets, user manuals, and local regulatory requirements for updates and region-specific directives.

In conclusion, sourcing the Hilti PS 1000 cable placement system requires a strategic approach that balances authenticity, cost-efficiency, and reliability. As a specialized tool designed for precision and durability in demanding construction environments, it is essential to procure the Hilti PS 1000 through authorized distributors or directly from Hilti to ensure product authenticity, access to warranty support, and compliance with safety standards. While alternative sourcing options such as third-party suppliers or used equipment may offer short-term cost savings, they carry risks related to product integrity and after-sales service. Establishing a relationship with an official Hilti representative not only guarantees genuine equipment but also provides technical support, training, and maintenance services that enhance the tool’s long-term performance. Therefore, for optimal results and compliance with industry best practices, sourcing the Hilti PS 1000 through official channels is the most reliable and sustainable choice.

![[PDF] Operations Manual](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-operations-manual-131.jpg)