The global market for garden and irrigation equipment, including high-pressure water hose nozzles, is experiencing steady expansion driven by rising residential landscaping demand, urban greening initiatives, and increased agricultural automation. According to Mordor Intelligence, the garden tools and equipment market was valued at USD 28.5 billion in 2023 and is projected to grow at a CAGR of 4.8% through 2029, with irrigation accessories representing a key growth segment. Similarly, Grand View Research highlights that the global irrigation equipment market size reached USD 11.3 billion in 2022 and is expected to expand at a CAGR of 7.5% from 2023 to 2030, fueled by the need for water-efficient tools such as high-pressure nozzles. As demand for precision water control intensifies across residential, commercial, and agricultural applications, manufacturers specializing in high-performance nozzles are scaling innovation in durability, pressure regulation, and ergonomic design. The following list highlights the top 10 manufacturers leading this evolution in high-pressure water hose nozzle technology.

Top 10 Highest Pressure Water Hose Nozzle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Reliable Sprinkler

Domain Est. 1995

Website: reliablesprinkler.com

Key Highlights: Reliable Automatic Sprinkler Co., Inc. is a manufacturer and distributor of fire protection products, specializing in fire sprinklers, valves, and system ……

#2 Spray Nozzles & Spray Systems

Domain Est. 1995

Website: bete.com

Key Highlights: BETE designs and manufactures spray nozzles, spray injectors, tank washers, and spray systems for industrial applications worldwide….

#3 Water Jetting Equipment

Domain Est. 2001

Website: alljetting.com

Key Highlights: Water Blasting Nozzle Manufacturer. All Jetting Technologies Inc manufactures quality sapphire nozzles for high pressure and ultra high-pressure water jetting ……

#4 1.5 Inch High Pressure Fire Hose Nozzle

Domain Est. 2012

Website: absolutewaterpumps.com

Key Highlights: Free delivery 30-day returnsThe AMT Red Lexan Fire Hose Nozzle is designed for water service applications that require high pressure and/or commercial and industrial applications….

#5 High Pressure, Heavy Duty, Professional Hose Nozzles

Domain Est. 1995

Website: gilmour.com

Key Highlights: Find your heavy duty hose nozzle with the gardening and yard care experts at Gilmour. Shop the industry leader’s selection of professional hose nozzles ……

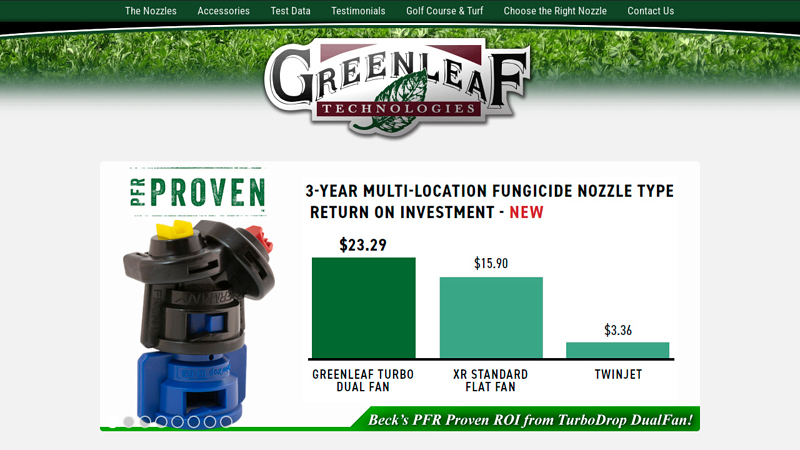

#6 Greenleaf Technologies

Domain Est. 1996

Website: greenleaftech.com

Key Highlights: Compare the low pressure, medium pressure and high pressure nozzles from Greenleaf and find the one right for your application….

#7 to Alemite

Domain Est. 1996

Website: skf.com

Key Highlights: High-Pressure Model 6320 · High-Volume Model 3572 · High-Volume Model 6438 · Model … Air/Water Hoses · Fuel Hoses · Grease Hoses · Hose Reel Hose Stops · Oil ……

#8 Heavy Duty Hose Nozzle

Domain Est. 1998

Website: superklean.com

Key Highlights: SuperKlean manufactures our Standard heavy duty water guns or commercial hose nozzles in lighter materials that tend to be rugged but offer a lower weight….

#9 X Jet Pressure Washing

Domain Est. 2005

Website: xjetnozzle.com

Key Highlights: Our DS Twist nozzle is the traditional use nozzle that will draw chemicals from a tank located beside the pressure washer however it offers adjustability other ……

#10 FANHAO Professional Heavy Duty Garden Hose Nozzle, 100 …

Domain Est. 2016

Website: dutyfreeglobal.com

Key Highlights: In stock Rating 4.7 (52) 3 days ago · UPGRADED ALL METAL HOSE NOZZLE: Metal construction is virtually indestructible. The premium FANHAO water nozzle is extra heavy duty made fro…

Expert Sourcing Insights for Highest Pressure Water Hose Nozzle

H2: Emerging Market Trends for Highest Pressure Water Hose Nozzles (2026)

As we approach 2026, the market for highest pressure water hose nozzles is undergoing significant transformation, driven by technological innovation, sustainability demands, and evolving consumer and industrial needs. Below are the key trends shaping this specialized segment of the outdoor power equipment and cleaning tools industry.

-

Increased Demand in Industrial and Commercial Applications

The 2026 market is seeing a surge in demand for high-pressure water hose nozzles from sectors such as construction, automotive detailing, agriculture, and municipal sanitation. These industries are adopting high-pressure nozzles for efficient cleaning of heavy machinery, infrastructure, and large-scale facilities. The push for faster, water-efficient cleaning solutions is driving procurement of nozzles capable of withstanding pressures exceeding 4,000 PSI. -

Advancements in Material Science and Durability

Manufacturers are investing in advanced materials such as reinforced polymers, aerospace-grade aluminum, and ceramic-coated tips to enhance nozzle durability under extreme pressure. These materials reduce wear and corrosion, extending product life and reducing maintenance costs—critical factors for commercial users. By 2026, nozzles made with composite materials are expected to dominate premium market segments. -

Smart Nozzle Technology Integration

A defining trend is the integration of smart technologies into high-pressure nozzles. Sensors and IoT-enabled controls allow users to monitor water pressure, flow rate, temperature, and nozzle wear in real time. Mobile app connectivity enables remote adjustments and predictive maintenance alerts. This trend is particularly strong in industrial applications where operational efficiency and equipment longevity are paramount. -

Focus on Water Conservation and Efficiency

With growing environmental regulations and water scarcity concerns, especially in regions like the American Southwest and parts of Europe, manufacturers are designing nozzles with optimized flow dynamics. Variable pressure settings and precision spray patterns help reduce water consumption by up to 30% without sacrificing cleaning performance. Regulatory incentives and certifications (e.g., EPA WaterSense) are influencing purchasing decisions. -

Expansion of E-commerce and Direct-to-Consumer Sales

The 2026 market is witnessing a shift in distribution channels. Online platforms such as Amazon, Home Depot, and specialized industrial suppliers are becoming primary sales avenues. Enhanced product visualization (3D models, AR previews), detailed performance metrics, and customer reviews are driving consumer confidence in high-end nozzles without in-person testing. -

Rise in DIY and Residential Power Cleaning

Homeowners are increasingly adopting professional-grade pressure washing for home maintenance, landscaping, and vehicle cleaning. This trend is fueled by affordable electric pressure washers and the availability of modular, high-pressure nozzles that are easy to attach and adjust. In 2026, residential users are expected to account for over 40% of total nozzle sales. -

Customization and Modular Design

Modularity is a key differentiator. Consumers and professionals alike are seeking nozzle systems that offer interchangeable tips (fan, rotary, pinpoint) for different tasks. Brands are responding with customizable kits and quick-connect mechanisms, enhancing versatility and value proposition. -

Sustainability and Circular Economy Initiatives

Leading manufacturers are introducing take-back programs, recyclable packaging, and repairable nozzle designs. By 2026, environmental, social, and governance (ESG) criteria are becoming important in procurement decisions, especially among municipal and corporate buyers.

In conclusion, the 2026 market for highest pressure water hose nozzles is marked by innovation, efficiency, and adaptability. Companies that invest in smart features, sustainable materials, and user-centric design are best positioned to capture growing demand across industrial, commercial, and residential sectors.

Common Pitfalls When Sourcing the Highest Pressure Water Hose Nozzle (Quality & IP)

Sourcing a high-pressure water hose nozzle demands careful attention to both performance specifications and intellectual property (IP) considerations. Overlooking key pitfalls can lead to equipment failure, safety hazards, legal issues, and significant financial losses. Below are the most common pitfalls to avoid:

1. Overlooking Material Quality and Build Standards

Many suppliers advertise “high-pressure” nozzles without disclosing material composition or manufacturing standards. Using inferior materials like low-grade plastics or unhardened metals leads to premature cracking, erosion, or catastrophic failure under pressure. Always verify the use of industrial-grade materials such as stainless steel, brass with anti-corrosion plating, or reinforced polymers rated for the intended PSI/Bar range.

2. Inadequate Pressure and Flow Rate Verification

Suppliers may exaggerate maximum pressure ratings (e.g., claiming 4000 PSI without certification). Relying on unverified specs risks using nozzles beyond safe operating limits. Ensure nozzles come with independent pressure testing documentation and are compliant with recognized standards such as ISO 18459 or ANSI B1.20.1 for thread compatibility and pressure integrity.

3. Ignoring Nozzle Tip Design and Wear Resistance

High-pressure applications accelerate tip erosion, especially in abrasive environments. Nozzles with soft or poorly designed tips degrade quickly, reducing efficiency and creating inconsistent spray patterns. Opt for nozzles with replaceable ceramic, tungsten carbide, or hardened stainless steel tips, and confirm wear resistance specifications.

4. Neglecting IP and Patent Infringement Risks

Sourcing from manufacturers that replicate patented nozzle designs (e.g., specific swirl chambers, trigger mechanisms, or quick-connect systems) exposes buyers to intellectual property litigation. Always request proof of IP ownership or licensing, and conduct basic patent searches to avoid inadvertently purchasing counterfeit or infringing products.

5. Poor Sealing and Connection Integrity

High-pressure systems are vulnerable to leaks at connection points. Nozzles with substandard O-rings, improper thread tolerances, or incompatible fittings (e.g., M22 vs. G1/4) compromise safety and performance. Confirm that seals are made from high-quality elastomers (e.g., Viton or EPDM) and that connection types match your hose and pump specifications.

6. Lack of Certifications and Compliance Documentation

Reputable high-pressure nozzles should carry certifications such as CE, UL, or WRAS (for potable water use), indicating compliance with safety and environmental regulations. Absence of such certifications may signal non-compliance with international standards, increasing liability risks.

7. Inadequate Supplier Due Diligence

Choosing suppliers based solely on price or fast delivery—especially from unverified online marketplaces—increases the risk of receiving counterfeit or substandard products. Evaluate suppliers based on track record, manufacturing transparency, warranty terms, and customer support for technical and safety issues.

8. Overlooking Ergonomics and Safety Features

High-pressure nozzles require user safety mechanisms like dead-man triggers, pressure relief valves, or anti-kink designs. Ignoring ergonomic design can lead to operator fatigue or injury. Ensure nozzles include necessary safety features and are designed for prolonged, safe use.

By addressing these pitfalls, buyers can ensure reliable performance, regulatory compliance, and legal safety when sourcing the highest pressure water hose nozzles.

H2: Logistics & Compliance Guide for Highest Pressure Water Hose Nozzle

This guide outlines the critical logistics and compliance considerations for the safe, legal, and efficient handling, transportation, storage, and use of Highest Pressure Water Hose Nozzles (HPWHNs). These specialized tools operate at extreme pressures (typically > 3,000 psi / 207 bar, often exceeding 10,000 psi / 689 bar) and pose significant risks if mishandled.

H3: Regulatory Compliance & Safety Standards

Adherence to international, national, and industry-specific regulations is paramount.

- Pressure Equipment Directive (PED) 2014/68/EU (Europe):

- HPWHNs fall under Category II, III, or IV due to high pressure and potential hazard.

- Requirement: Must bear the CE mark. Manufacturer must perform conformity assessment (involving notified body for higher categories), issue an EU Declaration of Conformity, and maintain technical documentation.

- Key Standards: EN ISO 13849-1 (Safety of machinery – Safety-related parts of control systems), EN 60204-1 (Safety of machinery – Electrical equipment of machines).

- ASME Boiler and Pressure Vessel Code (BPVC) – Section VIII, Division 1 or 3 (USA/Canada/Global):

- Governs the design, fabrication, inspection, testing, and certification of pressure vessels and components.

- Requirement: HPWHN components (especially the nozzle body/housing) may require ASME U or U2 stamp certification if designed as pressure-retaining parts. Manufacturer must provide Manufacturer’s Data Report (MDR).

- OSHA (Occupational Safety and Health Administration) – 29 CFR 1910 (USA):

- General Duty Clause: Requires employers to provide a workplace free from recognized hazards.

- Specific Standards: 1910.132 (Personal Protective Equipment), 1910.147 (Lockout/Tagout), 1910.242 (Hand and portable powered tools and other hand-held equipment), 1910.106 (Flammable Liquids – if used near).

- Requirement: Implement a Comprehensive Safety Program including hazard assessments, PPE, training, and safe work procedures.

- ANSI B30.7 – Hoisting and Hauling Equipment (USA – Specific to Waterjetting):

- Provides safety standards for high-pressure waterjetting equipment, including nozzles, hoses, fittings, and operations.

- Requirement: Follow design, inspection, maintenance, and operational guidelines. Mandates use of dead-man controls, pressure relief valves, and proper guarding.

- Other Regional Regulations:

- Canada: CSA B56.11 (Safety Standard for High-Pressure Water Jetting), provincial OHS regulations.

- Australia/New Zealand: AS/NZS 4600 (Structural steelwork), relevant state OHS/WHS Acts, potentially AS 4024 (Safety of machinery).

- Global: Check local national standards (e.g., JIS in Japan, GB in China) and environmental regulations (e.g., water discharge permits, noise ordinances).

H3: Critical Safety Protocols

Failure to follow strict safety protocols can result in fatal injuries from high-pressure injection, lacerations, or equipment failure.

- Personal Protective Equipment (PPE): MANDATORY.

- Impact-Resistant: Full-face shield (ANSI Z87.1+), heavy-duty gloves (cut/puncture resistant, ANSI/ISEA 105 Cut Level 5+), apron or full-body suit (abrasion/cut resistant, ANSI/ISEA 107 Class 3 for visibility).

- Hearing Protection: Ear muffs or plugs (NRR 25+ dB).

- Foot Protection: Steel-toed, puncture-resistant boots (ASTM F2413).

- Respiratory Protection: If generating hazardous dust (e.g., lead paint, silica) – NIOSH-approved respirator (e.g., N95, P100, or supplied air).

- Operator Training & Certification:

- Comprehensive training on specific HPWHN model, system operation, hazards (esp. fluid injection), emergency shutdown, lockout/tagout (LOTO), and PPE use.

- Certification programs exist (e.g., WJTA-PCI Certified Waterjetting Technician).

- System Integrity & Inspection:

- Pre-Use Inspection: Check nozzle tip for cracks, erosion, or blockages. Inspect hose for kinks, abrasion, cuts, bulges. Verify fittings are tight and undamaged. Check safety interlocks and dead-man controls.

- Regular Maintenance: Follow manufacturer’s schedule for nozzle replacement, hose rotation/replacement, and system servicing. Keep detailed logs.

- Pressure Testing: Conduct hydrostatic testing of hoses and critical fittings per manufacturer specs and regulatory requirements (e.g., ANSI B30.7: 1.5x working pressure for 5 min).

- Operational Procedures:

- Never Point at People or Animals: Treat the nozzle as a loaded firearm.

- Use Dead-Man Controls: The trigger must require constant pressure to release water; releasing pressure instantly stops flow.

- Secure Work Area: Establish a clear hazard zone. Use barriers and warning signs. Ensure bystanders are excluded.

- Lockout/Tagout (LOTO): Isolate energy sources (hydraulic, electrical, water pressure) before any maintenance, nozzle changes, or unclogging.

- Hose Management: Use hose reels or guides to prevent whipping. Never step on or kink the high-pressure hose. Keep excess hose coiled loosely.

- Emergency Stop: Know the location and operation of the system’s emergency stop button.

H3: Logistics & Supply Chain Management

Efficient and safe handling throughout the supply chain is crucial.

- Packaging & Labeling:

- Robust Packaging: Use strong, crush-resistant boxes with ample internal cushioning (foam, molded inserts). Protect nozzle orifice and threads.

- Hazard Labeling: Clearly label as “HIGH PRESSURE COMPONENT – HANDLE WITH CARE.” Include manufacturer, model, max pressure rating, and weight.

- Regulatory Labels: Include CE mark, ASME stamp (if applicable), and any required transport hazard labels (though nozzles themselves are usually not classified as dangerous goods for transport).

- Transportation:

- Ground/Air/Sea: Generally transported as standard freight. Ensure packages are secured to prevent movement and damage during transit. Avoid extreme temperatures.

- Hazardous Materials (HazMat): HPWHNs themselves are not typically HazMat. However, the complete system (pump, accumulator) might contain hydraulic oil or other fluids requiring HazMat classification. Consult SDS and regulations (e.g., IATA, IMDG, 49 CFR) for the entire system.

- Warehousing & Storage:

- Environment: Store in a clean, dry, temperature-controlled environment. Avoid direct sunlight, moisture, and corrosive atmospheres.

- Handling: Use appropriate tools (trolleys) for heavy items. Store vertically or on racks to prevent damage. Protect nozzle tips from impact.

- Inventory Management: Implement FIFO (First-In, First-Out) for consumable parts like nozzle tips. Track calibration and maintenance dates.

- Import/Export:

- Documentation: Ensure accurate commercial invoices, packing lists, and certificates of origin.

- Compliance: Verify import regulations for the destination country (e.g., CE conformity for EU, NRTL listing for Canada/USA). ASME certification may be required for components.

- Customs: Declare accurately. Be prepared for potential inspection. Tariff codes (HS Codes) typically fall under 8424.89 (Other mechanical appliances for projecting, dispersing or spraying liquids).

H3: Environmental & Disposal Considerations

- Waste Stream Management: Waterjetting generates wastewater (slurry) containing removed material (paint, rust, contaminants) and potentially additives. NEVER discharge untreated wastewater to storm drains or soil.

- Compliance: Obtain necessary permits for wastewater discharge. Use filtration systems (e.g., clarifiers, filter presses). Dispose of sludge as hazardous or non-hazardous waste per local regulations and waste analysis.

- Spill Containment: Have spill kits readily available for hydraulic fluid or chemical additives used in the system.

- End-of-Life Disposal: Recycle metal components (nozzle body, fittings) through metal recyclers. Dispose of worn ceramic/sapphire inserts according to local regulations (often non-hazardous).

Conclusion: Managing HPWHNs requires rigorous adherence to safety standards (PED, ASME, OSHA, ANSI), comprehensive operator training, strict operational protocols, and careful logistics planning. Prioritize safety above all else – the consequences of failure at these pressures are severe. Always consult the specific manufacturer’s instructions and the regulations applicable in your jurisdiction.

In conclusion, sourcing the highest pressure water hose nozzle requires careful consideration of several key factors including maximum PSI rating, build material (such as brass or stainless steel for durability), nozzle type (adjustable, zero-degree tip, or turbo nozzle), and compatibility with your existing hose and pressure washer system. Safety, reliability, and brand reputation should not be overlooked, as high-pressure nozzles demand robust construction to handle intense operating conditions. Ultimately, selecting a nozzle from a reputable manufacturer that meets or exceeds your pressure and performance requirements will ensure optimal cleaning efficiency, longevity, and user safety. Conducting thorough research, reading customer reviews, and verifying product specifications will lead to a well-informed decision and the best value in the long run.