The global cordless power tools market is experiencing robust expansion, driven by rising demand across construction, manufacturing, and DIY sectors. According to Grand View Research, the global cordless power tools market size was valued at USD 10.6 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. A key factor fueling this growth is the increasing preference for high-performance, portable tools—particularly high torque cordless drills—offering greater efficiency without the constraints of cords or compressors. Advances in lithium-ion battery technology and motor design have significantly enhanced tool durability and power output, blurring the performance gap between corded and cordless models. With industries shifting toward ergonomic, lightweight, and energy-efficient solutions, manufacturers that prioritize torque innovation, battery life, and smart tool integration are capturing greater market share. In this evolving landscape, we spotlight the top 8 high torque cordless drill manufacturers leading technological advancement and market penetration worldwide.

Top 8 High Torque Cordless Drill Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LXT HAMMER DRILLS & DRIVER

Domain Est. 1995

Website: makitatools.com

Key Highlights: Makita USA: The Leader In Cordless with 18V LXT Lithium-Ion. The best in class for cordless power tool technology. A leader in power tool technology for the ……

#2 Deli Drill, Power Drill Manufacturer/Supplier

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: Cordless drills often have multiple speed settings (gears) and adjustable torque (clutch) settings to prevent overdriving or damaging screws/materials. Forward/ ……

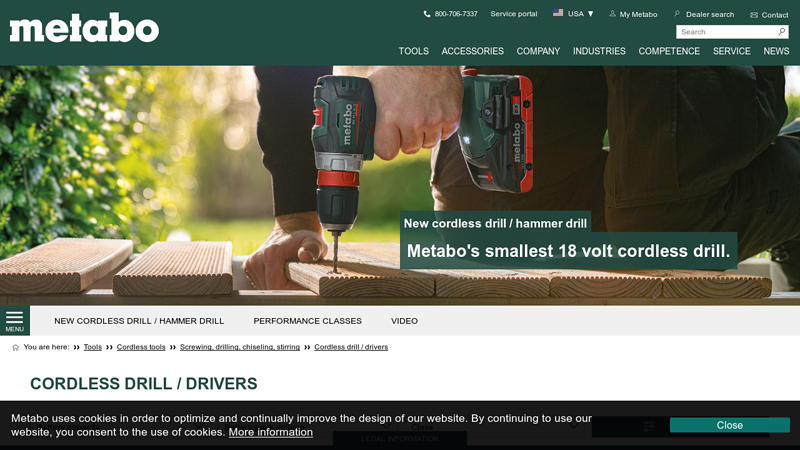

#3 Cordless drill / drivers

Domain Est. 1997

Website: metabo.com

Key Highlights: They have an extremely wide speed range and a high torque of 120 Nm for powerful screwdriving performance and versatile drilling in metal and wood….

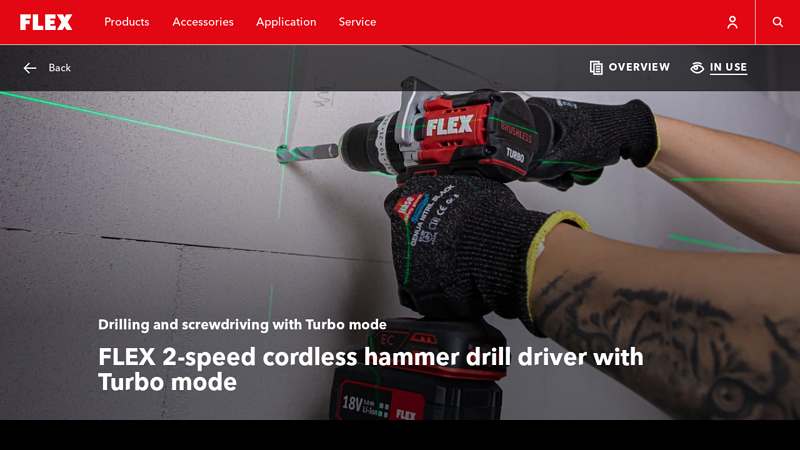

#4 FLEX 2

Domain Est. 1999

Website: flex-tools.com

Key Highlights: The FLEX hammer drill driver with its integrated Turbo mode allows fast and efficient drilling, hammer drilling and screwdriving in various materials….

#5 Drill Drivers, Hammer , Magnetic and Right

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Shop heavy duty drilling power tools including drivers, hammer drills, magnetic drills, right angle drills and more….

#6 Ingersoll Rand Cordless & Air Power Tools

Domain Est. 2001

Website: powertools.ingersollrand.com

Key Highlights: Explore Ingersoll Rand power tools, expertly crafted to handle a variety of tasks including drilling, fastening, cutting, grinding, sanding, and much more….

#7 Cordless drills

Domain Est. 2004

Website: festoolusa.com

Key Highlights: With high speed and powerful torque, cordless screwdrivers drill or screw into wood, stone and even metal. You can also work in hard-to-reach places with ……

#8 Cordless drills/drivers

Domain Est. 2008

Website: bosch-professional.com

Key Highlights: Cordless drill/drivers from Bosch are not only powerful, they also set standards in terms of robustness. They impress with their optimum weight and long battery ……

Expert Sourcing Insights for High Torque Cordless Drill

H2: 2026 Market Trends for High Torque Cordless Drills

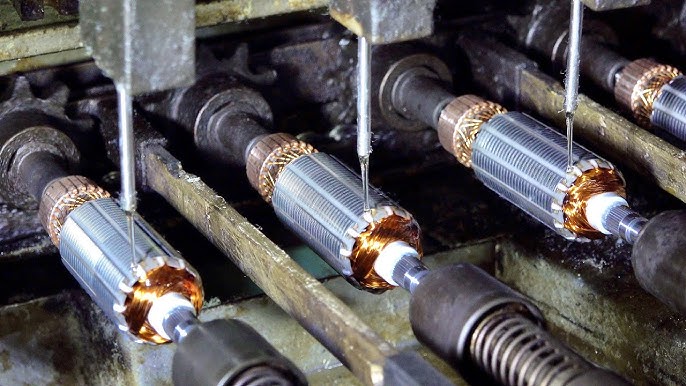

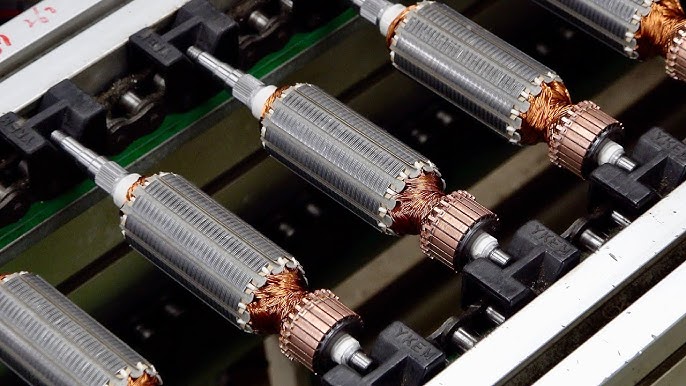

The global market for high torque cordless drills is poised for significant transformation by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications across residential, commercial, and industrial sectors. Key trends shaping the industry include the rise of brushless motor technology, increased demand for higher voltage platforms (particularly 18V, 20V, and 40V+ systems), and a growing emphasis on battery innovation and energy efficiency. As sustainability becomes a core focus, manufacturers are prioritizing longer-lasting lithium-ion batteries with faster charging capabilities, reducing downtime and enhancing productivity.

Another major trend is the integration of smart features such as Bluetooth connectivity, app-based performance tracking, and torque calibration systems. These innovations cater to both professional tradespeople and DIY enthusiasts who seek precision, tool monitoring, and predictive maintenance. Additionally, ergonomics and compact design are becoming differentiators, with brands focusing on lightweight, balanced models that reduce user fatigue during extended use.

The construction and renovation boom in emerging economies, coupled with infrastructure development in North America and Europe, is fueling demand. At the same time, the tools-as-a-service (TaaS) model is gaining traction, especially among contractors who prefer leasing high-end cordless drills rather than purchasing them outright.

By 2026, competition among key players such as DeWalt, Milwaukee, Makita, Bosch, and emerging Chinese brands is expected to intensify, leading to more innovation, competitive pricing, and expanded product ecosystems. Overall, the high torque cordless drill market will continue evolving toward smarter, more efficient, and user-centric solutions, solidifying its role as an indispensable tool across multiple industries.

Common Pitfalls When Sourcing High Torque Cordless Drills (Quality & IP Considerations)

Sourcing high torque cordless drills—especially for professional or industrial applications—requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to poor performance, safety hazards, and increased long-term costs. Below are common pitfalls to avoid:

Overlooking Build Quality and Component Materials

Many buyers focus solely on torque specifications while ignoring the construction quality. Low-cost drills often use inferior materials such as plastic gears, weak chuck mechanisms, or substandard motors. These components wear quickly under high torque loads, leading to tool failure. Always inspect the drill’s housing, gearbox, and motor specifications. Opt for models with metal gears and robust housings designed for durability.

Assuming Higher Torque Equals Better Performance

While high torque is critical for demanding applications, excessive torque without proper control can damage fasteners or workpieces. Drills lacking adjustable torque settings or clutch mechanisms increase the risk of over-tightening. Ensure the model offers variable speed triggers and multiple torque settings to match the application, improving both precision and tool longevity.

Ignoring IP Rating for Harsh Environments

Ingress Protection (IP) ratings indicate a tool’s resistance to dust and water. A common mistake is selecting a drill without verifying its IP rating for the intended environment. For instance, using a non-IP-rated drill on a wet or dusty job site can lead to motor corrosion or electrical failure. Always match the IP rating to the work environment—e.g., IP54 or higher for outdoor or construction sites with exposure to dust and moisture.

Prioritizing Brand Name Over Real-World Testing

Recognized brands often command higher prices, but not all deliver consistent quality. Some rebranded or lesser-known models may offer comparable or superior performance. Avoid assuming brand reputation equals reliability. Instead, review independent performance tests, user feedback, and warranty terms before making a decision.

Neglecting Battery and Charger Compatibility

High torque drills consume more power, making battery life and charging speed crucial. A common oversight is sourcing drills with incompatible or proprietary battery systems, limiting flexibility and increasing downtime. Ensure the battery platform is scalable and shared across other tools in your inventory. Also, verify whether fast chargers are included or available.

Skipping Warranty and After-Sales Support Evaluation

Low-cost drills may come with limited or difficult-to-claim warranties. In industrial settings, quick repair turnaround and access to spare parts are essential. Failing to assess the manufacturer’s service network and support can result in extended downtime. Choose suppliers or brands with proven after-sales service and readily available spare components.

Underestimating Vibration and Ergonomics

High torque tools often generate significant vibration, leading to user fatigue and long-term health issues. Drills without effective anti-vibration systems or ergonomic designs compromise safety and productivity. Evaluate grip comfort, weight distribution, and built-in vibration dampening features before procurement.

By addressing these common pitfalls—particularly around material quality, IP ratings, and real-world usability—you can ensure the sourced high torque cordless drills deliver reliable, safe, and efficient performance in demanding applications.

Logistics & Compliance Guide for High Torque Cordless Drill

Product Classification & Documentation

Ensure accurate product classification for international shipping and customs clearance. The High Torque Cordless Drill should be classified under the Harmonized System (HS) code 8467.21.00 (Hand-held mechanical appliances with self-contained electric motor). Maintain the following documentation:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Product Specifications Sheet

– Safety and Compliance Certifications (e.g., UL, CE, RoHS)

Packaging & Labeling Requirements

Use durable, shock-resistant packaging to protect the drill and accessories during transit. Each unit must include:

– Tamper-evident packaging for batteries

– Clearly visible labels with:

– Product name and model number

– Voltage and battery chemistry (e.g., 20V Li-ion)

– Manufacturer and distributor information

– CE, FCC, and UL marks (where applicable)

– Battery safety warnings in compliance with IATA/IMDG regulations

Battery Shipping Regulations

Lithium-ion batteries are subject to strict international shipping rules:

– Comply with IATA Dangerous Goods Regulations (DGR) for air freight

– Batteries must be shipped at ≤30% state of charge

– Packages must display UN3480 marking and Class 9 lithium battery hazard label

– Include a Shipper’s Declaration for Dangerous Goods when required

– Ground transport must follow 49 CFR (U.S.) or ADR (Europe) guidelines

Import & Export Compliance

Verify all import/export requirements based on destination country:

– Obtain required import licenses or permits

– Confirm compliance with local electrical safety standards (e.g., UKCA for the UK, KC for South Korea)

– Register products with regulatory bodies where needed (e.g., FCC ID in the U.S.)

– Maintain records for audit purposes per customs regulations (typically 5–7 years)

Environmental & Safety Compliance

Adhere to environmental directives and safety standards:

– Comply with EU RoHS (Restriction of Hazardous Substances) and REACH regulations

– Follow WEEE (Waste Electrical and Electronic Equipment) guidelines for end-of-life disposal

– Ensure product meets relevant safety standards such as:

– UL 62841-1 and UL 62841-2-2 (North America)

– IEC 62841-1 and IEC 62841-2-2 (International)

– Provide multilingual user manuals with proper safety instructions

Customs Clearance & Duties

Facilitate smooth customs processing:

– Provide accurate Harmonized System (HS) codes and country of origin

– Declare correct product value to determine applicable tariffs

– Use an experienced customs broker for high-volume shipments

– Monitor changes in trade agreements or tariffs affecting drill components

Quality Control & Traceability

Implement quality assurance procedures:

– Conduct pre-shipment inspections to verify compliance with specifications

– Assign unique serial numbers or batch codes for traceability

– Maintain records of testing, certifications, and supplier compliance

– Establish a recall protocol in case of non-compliance or safety issues

Storage & Handling

Follow best practices for warehousing and distribution:

– Store batteries in fire-resistant containers at controlled temperatures (10–25°C)

– Avoid stacking packages beyond recommended limits

– Train staff in hazardous material handling procedures

– Use inventory management systems to track shelf life and compliance status

Regulatory Updates & Continuous Monitoring

Stay current with global compliance requirements:

– Subscribe to regulatory update services (e.g., ECC, iCompliance)

– Conduct annual compliance audits

– Review changes in battery regulations, safety standards, and import policies

– Update technical documentation and labeling as needed

By following this guide, distributors and importers can ensure safe, legal, and efficient logistics for the High Torque Cordless Drill across global markets.

In conclusion, sourcing a high-torque cordless drill requires careful consideration of power, battery life, build quality, brand reliability, and specific application needs. High-torque models from reputable manufacturers such as DeWalt, Makita, Milwaukee, and Bosch offer a balance of performance, durability, and ergonomic design suitable for both professional and heavy-duty DIY use. Advances in lithium-ion battery technology have significantly improved runtime and charging efficiency, making cordless drills more versatile than ever. When selecting a model, prioritize torque settings, motor type (brushless motors are preferred), battery voltage (18V–20V for most heavy tasks), and compatibility with existing tool ecosystems. Additionally, purchasing from authorized suppliers ensures genuine products, warranties, and good after-sales support. Ultimately, investing in a high-quality, high-torque cordless drill enhances productivity, precision, and convenience across a wide range of drilling and fastening applications.