The global industrial inspection equipment market, driven by increasing demand for predictive maintenance and operational safety in harsh environments, is experiencing robust growth. According to Grand View Research, the global pipeline inspection services market was valued at USD 1.78 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A critical niche within this sector is high-temperature tank camera systems, which are essential for monitoring and inspecting vessels in industries such as oil & gas, petrochemicals, and power generation. These cameras enable safe, real-time visual assessments in environments exceeding 1,000°F, reducing downtime and preventing catastrophic failures. As regulatory scrutiny and asset integrity requirements tighten, demand for reliable high temp tank camera solutions continues to rise. This growing need has spurred innovation and competition among manufacturers worldwide, leading to advancements in thermal resilience, image clarity, and remote operational capabilities. Based on market presence, technological innovation, and industry reputation, the following are the top 10 high temp tank camera manufacturers shaping the future of industrial inspections.

Top 10 High Temp Tank Camera Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Videotec

Domain Est. 1995

Website: pelco.com

Key Highlights: Videotec cameras are purpose-built for extreme industrial and hazardous conditions, including corrosive saltwater, explosive zones, high heat, freezing cold and ……

#2 Optris

Domain Est. 2004

Website: optris.com

Key Highlights: Optris has been developing and manufacturing affordable innovative infrared measurement devices for non-contact temperature measurement….

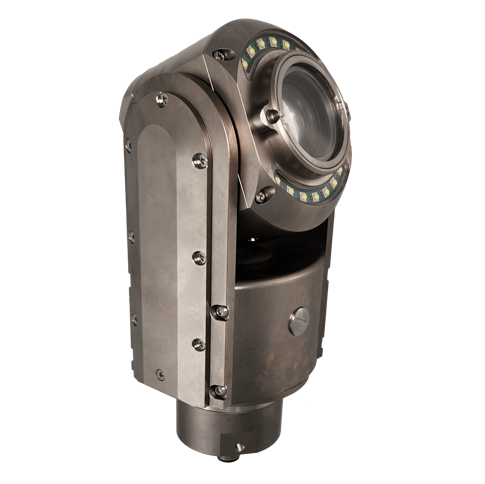

#3 PTZ90HD Inspection System

Domain Est. 2007

Website: aitproducts.com

Key Highlights: Out of stockThe PTZ90HD is the most advanced portable high definition industrial tank and vessel inspection camera with remote control pan, tilt, and zoom….

#4 Bass Electronics

Domain Est. 2009

Website: basscam.com

Key Highlights: Bass Electronics – Home of the Industrial Camera – Cameras for extreme temperature, highly corrosive, explosion proof/flameproof, and high vibration areas….

#5 Handheld Thermal Cameras

Domain Est. 1993

#6 J.M. Canty

Domain Est. 1994

Website: jmcanty.com

Key Highlights: High temperature cameras are used in the glass industry on applications such as molten glass level, gob detection, fiber glass flow, stone & width detection, ……

#7 High

Domain Est. 1999

Website: mirion.com

Key Highlights: High-temperature imaging equipment from Mirion provides a live view into boilers, furnaces, and more, helping you stay one step ahead of costly delays….

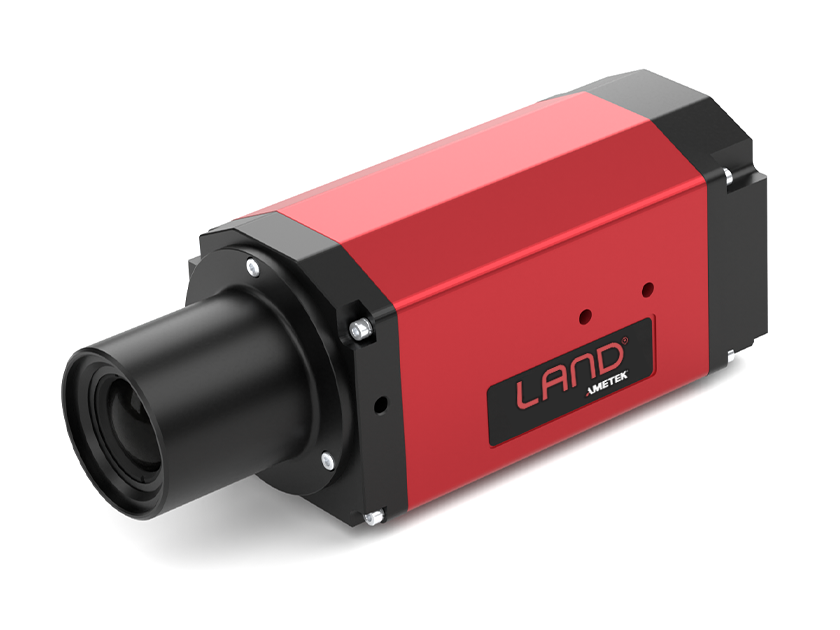

#8 LAND

Domain Est. 2006

Website: ametek-land.com

Key Highlights: A fixed infrared thermal camera for high temperature measurements. High-resolution radiometric thermal imager; Robust housings for harsh conditions; Choice of ……

#9 Tank Inspection Camera

Domain Est. 2009

Website: visioprobe.com

Key Highlights: Made of stainless steel, the camera tank is resistant to radiation and corrosion, offering mechanical stability even at high temperatures. The inspector makes ……

#10 Best Thermal Imaging Cameras

Domain Est. 1986

Website: fluke.com

Key Highlights: Fluke Thermal Cameras. Fluke infrared thermal imaging cameras provide you with high-quality thermal images for industrial inspection….

Expert Sourcing Insights for High Temp Tank Camera

H2: Projected 2026 Market Trends for High-Temperature Tank Cameras

The market for High-Temperature (High-Temp) Tank Cameras is poised for significant evolution by 2026, driven by increasing industrial automation, stringent safety and regulatory demands, and technological advancements. Here’s an analysis of the key trends expected to shape this specialized niche:

-

Accelerated Adoption of Ruggedized Digital & Networked Systems:

- Trend: A major shift away from analog systems towards fully digital, network-integrated cameras (IP-based) offering higher resolution (HD, 4K), superior low-light performance, and enhanced durability.

- Drivers: Demand for clearer imagery for defect detection (corrosion, cracks, weld integrity), seamless integration with plant-wide SCADA/MES systems, remote monitoring capabilities, and easier data storage/retrieval for compliance.

- 2026 Impact: Digital systems will become the standard, enabling predictive maintenance analytics and real-time remote expert consultation.

-

Increased Integration of Advanced Sensing and Analytics:

- Trend: Cameras will increasingly incorporate or be paired with complementary sensors (temperature probes, gas detectors) and leverage edge computing/AI for on-device analytics.

- Drivers: Need for more comprehensive condition monitoring beyond visual inspection, early warning of anomalies (e.g., hot spots, unexpected gas leaks), and reducing human intervention in hazardous zones.

- 2026 Impact: “Smart” inspection systems will provide actionable insights (e.g., automated corrosion detection, predictive failure alerts) directly from the camera feed, significantly improving operational efficiency and safety.

-

Focus on Enhanced Durability and Extreme Environment Performance:

- Trend: Development of cameras capable of withstanding even higher continuous operating temperatures (exceeding 500°C/932°F), greater pressure differentials, and more aggressive chemical environments.

- Drivers: Expansion into more extreme applications (e.g., specialized metallurgy, advanced chemical processing, next-gen energy) and demand for longer inspection intervals and reduced maintenance.

- 2026 Impact: Wider applicability across demanding industries, reduced downtime for camera servicing, and improved reliability in critical applications.

-

Growth in Remote and Automated Inspection Solutions:

- Trend: Increased deployment of robotic crawlers, drones (UAVs), and automated positioning systems integrated with high-temp cameras for internal tank inspections.

- Drivers: Critical need to minimize human entry into confined/ hazardous spaces (improving safety), achieving more consistent and repeatable inspections, and accessing hard-to-reach areas.

- 2026 Impact: Significantly reduced safety risks (confined space entry), faster inspection cycles, and more comprehensive data collection, becoming essential for large-scale storage tanks and complex vessels.

-

Stringent Regulatory Compliance as a Market Driver:

- Trend: Regulations (e.g., OSHA, EPA, API, ISO standards) mandating more frequent, documented, and reliable internal inspections of pressure vessels, storage tanks, and reactors will solidify.

- Drivers: Heightened focus on industrial safety, environmental protection, and asset integrity management globally.

- 2026 Impact: Mandatory use of reliable, verifiable inspection technology (like high-temp cameras) will be a primary growth driver, creating a stable baseline demand and pushing adoption in smaller or previously underserved facilities.

-

Expansion Beyond Traditional Industries:

- Trend: While Oil & Gas, Petrochemicals, and Power Generation remain core markets, growth is expected in emerging sectors like Hydrogen Production/Storage, Advanced Battery Manufacturing (furnaces), and specialized Waste-to-Energy plants.

- Drivers: The rise of new energy technologies and advanced manufacturing processes involving high-temperature processes requiring internal monitoring.

- 2026 Impact: Diversification of the customer base and creation of new application-specific camera requirements, driving innovation.

-

Consolidation and Specialization Among Suppliers:

- Trend: The market may see consolidation as larger industrial automation or inspection technology companies acquire niche high-temp camera specialists. Simultaneously, some suppliers will double down on extreme niche capabilities.

- Drivers: Need for broader solution offerings (cameras + robotics + software) and significant R&D investment required for next-gen technology.

- 2026 Impact: Buyers may see fewer but more capable suppliers offering integrated solutions, alongside highly specialized players for unique requirements.

Conclusion for 2026:

By 2026, the high-temperature tank camera market will be characterized by smarter, more connected, and more automated solutions. Digital integration, AI-powered analytics, and robotics will be key differentiators. The primary drivers will be unrelenting demands for enhanced safety (reducing human entry), stricter regulatory compliance, and the need for predictive maintenance to optimize asset performance and reduce costly downtime. Suppliers who innovate in durability, data intelligence, and integrated inspection systems will lead the market, while adoption will expand into new industrial frontiers like the hydrogen economy.

Common Pitfalls in Sourcing High-Temperature Tank Cameras (Quality & IP Considerations)

Sourcing high-temperature tank cameras involves unique challenges due to the extreme operating environments. Overlooking critical quality and Ingress Protection (IP) factors can lead to premature failure, safety hazards, and costly downtime. Here are key pitfalls to avoid:

Inadequate Temperature Rating Verification

A primary pitfall is assuming the camera’s stated temperature range is sufficient without verifying real-world performance. Suppliers may advertise peak temperature capabilities under ideal lab conditions, but sustained exposure or thermal cycling can degrade components. Always confirm the camera’s continuous operating temperature aligns with your tank’s maximum internal and ambient temperatures, including potential hotspots near heating elements or insulation gaps. Neglecting this can result in sensor damage, lens fogging, or complete system failure.

Misunderstanding IP Rating Requirements

Many buyers focus solely on high IP ratings (e.g., IP66, IP68) without considering how these ratings apply under thermal stress. High temperatures can compromise seals, gaskets, and housing materials, reducing effective protection over time. For example, an IP68-rated camera may resist water immersion at room temperature but fail under steam or thermal expansion at 200°C. Ensure the IP rating is validated across the full operational temperature range and accounts for pressure differentials common in industrial tanks.

Compromising on Build Quality and Materials

To reduce costs, some suppliers use substandard materials such as low-grade stainless steel or non-ceramic lenses that degrade under prolonged heat. Inferior thermal insulation or cooling mechanisms (e.g., passive vs. active air/water purge systems) can also undermine reliability. Always inspect construction details—opt for cameras with 316L stainless steel housings, sapphire or quartz windows, and robust thermal barriers. Poor build quality leads to corrosion, lens cracking, and internal component overheating.

Overlooking Certification and Compliance

High-temp tank cameras used in hazardous or regulated environments (e.g., chemical, petrochemical) must meet specific safety standards such as ATEX, IECEx, or UL. Sourcing cameras without proper certifications is a critical oversight that can violate safety regulations and void insurance. Verify that the camera’s certifications cover both high-temperature operation and the required IP protection in explosive atmospheres.

Ignoring Integration and Environmental Factors

Even a high-quality, well-rated camera can fail if environmental factors like vibration, chemical exposure, or rapid temperature cycling are not addressed. Ensure the camera is designed for mechanical stability and chemical resistance beyond just temperature and IP specs. Also, confirm compatibility with existing monitoring systems and purge/cooling infrastructure to maintain internal component temperatures within safe limits.

By carefully evaluating temperature resilience, true IP performance under heat, material integrity, certifications, and environmental integration, you can avoid costly sourcing mistakes and ensure reliable, long-term operation of high-temperature tank cameras.

Logistics & Compliance Guide for High Temp Tank Camera

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient deployment, operation, and maintenance of High Temperature (High Temp) Tank Cameras. Adherence is critical for personnel safety, equipment integrity, regulatory compliance, and operational success.

H2: Transportation & Handling

- Packaging: Utilize the manufacturer-supplied, certified transport case designed for shock, vibration, and temperature extremes. Ensure all components (camera head, cable, controller, connectors, spool) are secured and cushioned. Include desiccant if specified.

- Temperature Control: Maintain ambient temperatures within the camera system’s specified storage/transport range (typically -20°C to +60°C unless otherwise stated) during transit. Avoid prolonged exposure to direct sunlight, freezing conditions, or high-heat environments (e.g., non-climate-controlled trailers). Use insulated containers or active temperature control if necessary.

- Mechanical Protection: Handle the camera head, cable (especially near connectors), and spool with extreme care. Avoid dropping, kinking, crushing, or dragging the cable. Use proper lifting techniques for heavy spools. Protect connectors from contamination and physical damage.

- Hazardous Materials (HazMat): Verify if batteries (especially Li-ion types) or internal components classify the system as HazMat for air or international ground transport (e.g., IATA, ADR, IMDG). If so, package, label, and document according to relevant regulations. Obtain necessary Shipper’s Declaration for Dangerous Goods if required.

- Documentation: Ensure all transport documents (packing lists, certificates of compliance, HazMat declarations if applicable) accompany the shipment. Maintain a chain of custody log.

H2: Site Deployment & Installation

- Permits & Site Access: Obtain all necessary work permits (hot work, confined space entry, radiography exclusion zone if applicable, electrical work) before deployment. Coordinate with site operations for safe access, lockout/tagout (LOTO) of relevant systems, and notification of other personnel.

- Environmental Assessment: Conduct a thorough job site assessment:

- Temperature: Verify the actual tank internal temperature and external ambient conditions are within the camera system’s operational limits (e.g., camera head rating, cable jacket rating, control unit limits). Account for radiant heat.

- Atmosphere: Test for hazardous gases (H2S, CO, O2 deficiency, flammables) before and during entry/near the opening. Ensure adequate ventilation. Use intrinsically safe (IS) rated equipment if required by the classified zone.

- Physical Hazards: Identify trip hazards, fall risks, overhead obstructions, moving equipment, and high-pressure lines. Establish clear exclusion zones.

- Equipment Setup:

- Position the control unit and spool on a stable, level, clean surface, protected from weather, dust, and physical impact.

- Ensure the cable path from spool to tank entry point is smooth, free of sharp edges, and minimizes bending radius (adhere strictly to manufacturer’s minimum bend radius).

- Securely anchor the spool and ensure the cable payout mechanism functions smoothly.

- Perform all connections (camera head to cable, cable to controller) according to manufacturer specifications in a clean environment. Check for debris in connectors.

- Personnel: Only trained and authorized personnel should operate the system. Ensure all personnel wear appropriate PPE (hard hat, safety glasses, gloves, flame-resistant clothing, steel-toe boots, fall protection if needed, gas monitor).

H2: Operational Safety & Procedures

- Pre-Use Inspection: Inspect the entire system (cable, connectors, camera head, spool, controller, cables) for damage, wear, or contamination before each use. Pay special attention to the camera head lens, housing, and cable sheath near the head.

- Intrinsically Safe (IS) Compliance: If operating in a classified hazardous location (e.g., Zone 1, Division 1), the entire system (camera head, cable, controller, power supply, monitor) must be certified for that specific zone and gas group. Verify certification markings (e.g., ATEX, IECEx, UL, CSA) match the site classification. Use only approved IS barriers or power supplies.

- Temperature Monitoring: Continuously monitor the camera head temperature via the control unit display if equipped. Adhere strictly to the maximum exposure time at peak temperature as specified by the manufacturer. Implement a strict cooldown protocol after withdrawal.

- Cable Management: Pay out and retrieve cable slowly and steadily. Never force the camera head or cable. Monitor for kinks or snags. Do not exceed the maximum cable length or pull tension specified. Use cable guides if necessary.

- Emergency Procedures: Establish clear, documented procedures for:

- Camera head/cable snag or jam.

- Loss of video signal or control.

- Detection of hazardous gas or unsafe conditions.

- Fire or other immediate danger.

- Include rapid retrieval protocols and emergency power cutoff.

H2: Maintenance, Calibration & Record Keeping

- Post-Use Procedures: After withdrawal, allow the camera head to cool to ambient temperature before cleaning or disconnecting. Clean the camera head, lens, and cable meticulously according to the manufacturer’s instructions using approved cleaners. Inspect thoroughly for damage (cracks, burns, abrasions).

- Scheduled Maintenance: Perform preventive maintenance (lubrication of spool, connector cleaning, cable inspection, controller function checks) as per the manufacturer’s schedule. Replace worn or damaged parts immediately with genuine manufacturer components.

- Calibration: Calibrate depth measurement systems (if equipped) and any integrated sensors (e.g., temperature probes) at intervals specified by the manufacturer or required by company policy/regulation. Maintain calibration certificates.

- Record Keeping: Maintain detailed logs for:

- Equipment deployment (date, location, tank ID, operator, purpose).

- Pre-use and post-use inspection results.

- Maintenance and repair history (parts replaced, dates, technician).

- Calibration dates and results.

- Any incidents or near misses.

- Storage conditions (if applicable).

H2: Regulatory & Compliance

- Manufacturer Specifications: Strictly adhere to all operational, environmental, and safety specifications provided in the official High Temp Tank Camera manual. This is the primary compliance document.

- Hazardous Location Certification: Ensure the system’s certification (ATEX, IECEx, UL, CSA, etc.) is valid, appropriate for the specific site’s hazardous area classification (Zone/Division, Gas Group, Temperature Class), and not expired. Keep certification documents readily available.

- Electrical Safety: Comply with relevant electrical safety standards (e.g., NEC, CEC, IEC 60364) for power supply, grounding, and operation in industrial environments. Ensure control units are properly grounded.

- Data Management: Comply with company policies and any relevant regulations (e.g., environmental monitoring, integrity management programs like API 510/570/653) regarding the storage, security, and retention of inspection video and data.

- Training Records: Maintain records demonstrating that all operators and maintenance personnel have received and understood specific training on the safe and correct use of the High Temp Tank Camera system.

- Local Regulations: Be aware of and comply with any additional local, state/provincial, or national regulations governing industrial operations, hazardous materials, or confined space work applicable to the deployment site.

Conclusion: Sourcing a High-Temperature Tank Camera

After a thorough evaluation of available options and technical requirements, sourcing a high-temperature tank camera is a critical step in ensuring reliable monitoring and operational safety in extreme industrial environments. These specialized cameras must withstand prolonged exposure to intense heat, chemical exposure, and potentially hazardous conditions while delivering clear, real-time visual data.

Key considerations such as thermal resistance (typically up to 500°C or higher with proper shielding), durability, image quality, cooling mechanisms (air- or water-cooled housings), and ease of integration with existing control systems have guided the selection process. Additionally, vendor reliability, compliance with safety standards (e.g., ATEX, IECEx for explosive atmospheres), and after-sales support are essential for long-term performance.

Based on the analysis, the recommended approach is to source a high-temperature camera system from a reputable supplier offering proven technology in similar industrial applications—such as those used in cement kilns, metal processing, or petrochemical reactors. Customizable options with remote monitoring capabilities and predictive maintenance features further enhance operational efficiency and safety.

In conclusion, investing in a robust, high-temperature tank camera system not only improves process visibility and troubleshooting capabilities but also contributes significantly to preventive maintenance, worker safety, and overall plant reliability. Careful vendor selection and system specification will ensure long-term value and performance in demanding thermal environments.