The global laser marking machine market is witnessing robust expansion, driven by increasing demand for precision, permanence, and high-speed marking across industries such as automotive, electronics, medical devices, and consumer goods. According to a 2023 report by Mordor Intelligence, the market was valued at USD 2.35 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2028. Similarly, Grand View Research estimates a CAGR of 7.2% from 2023 to 2030, citing advancements in fiber laser technology and rising automation as key growth catalysts. Amid this surge, high-speed laser marking machines have become critical for manufacturers seeking efficiency, traceability, and compliance with industry standards. As competition intensifies, a select group of manufacturers has emerged at the forefront—delivering cutting-edge technology, superior speed, and reliable performance. The following list highlights the top nine high-speed laser marking machine manufacturers shaping the future of industrial identification and traceability.

Top 9 High Speed Laser Marking Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

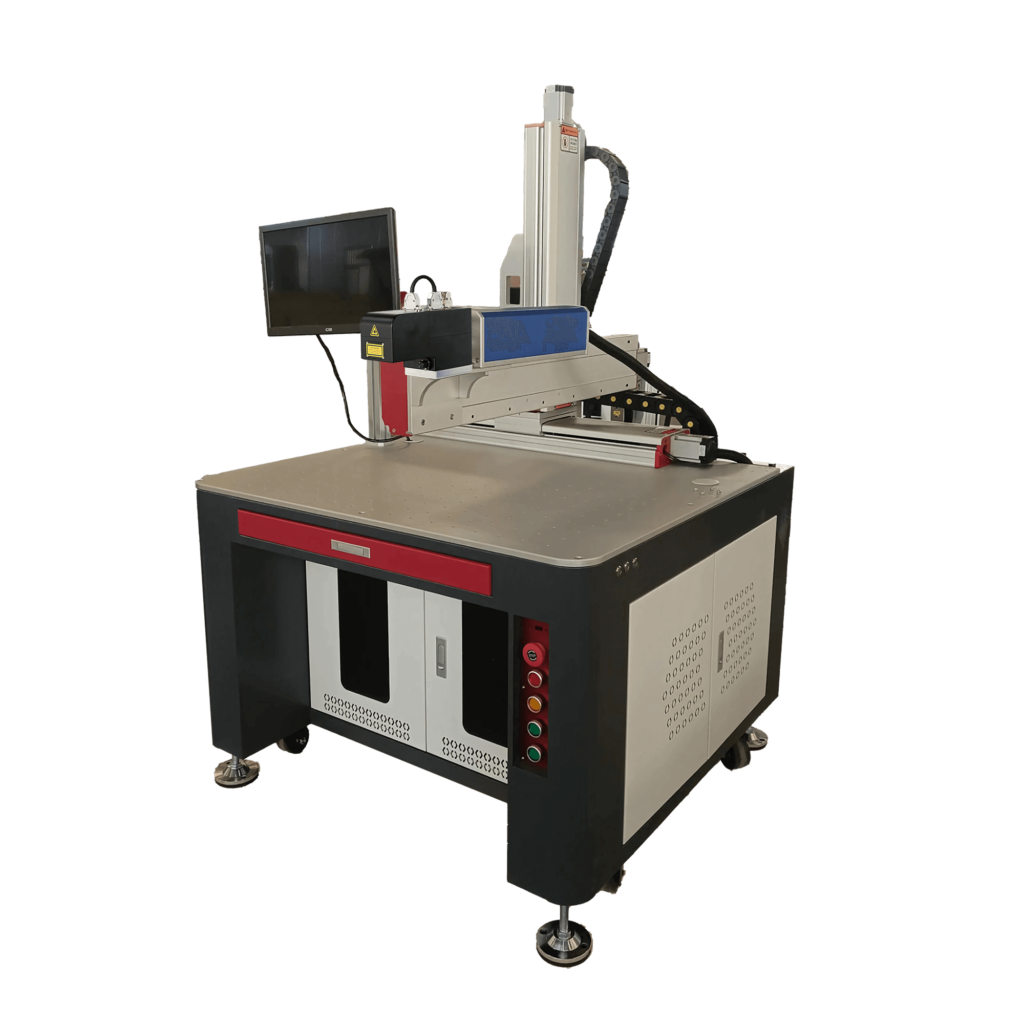

#1 Laser Machines for Marking, Cutting, Cleaning, and Welding

Website: hispeedlaser.com

Key Highlights: Hispeed Laser Technology Ltd. is a laser marking machine manufacturer established to produce and supply laser marking machines and provide laser marking ……

#2 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now become the flagship of Chinese national laser ……

#3 Laserax

Website: laserax.com

Key Highlights: For over 10 years, we have produced laser marking and laser cleaning machines … Ranging from 20W to 500W, they can mark at high speed and operate in a large ……

#4 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: At Telesis Technologies, we’re dedicated to creating the perfect laser marking system for you, with integrated software solutions and custom machines….

#5 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#6 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: These compact and easy to operate 10W and 20W fiber lasers offer high-speed marking of complex codes on metal, plastic, and many other substrates. Read more….

#7 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#8 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: The best RF laser engraving machine. Integrated camera with a speed of up to 2000 mm/s. Laser engraving photo to precise detail is so easy….

#9 Laser cutting and engraving machine

Website: troteclaser.com

Key Highlights: Fastest laser engraver on the market ✓ Engrave and cut acrylic, wood, leather etc. ✓ Work area of 1016 x 610 mm. Check it out now!…

Expert Sourcing Insights for High Speed Laser Marking Machine

2026 Market Trends for High Speed Laser Marking Machines

The global market for High Speed Laser Marking Machines (HSLMMs) is poised for significant transformation by 2026, driven by technological advancements, evolving industrial demands, and broader macroeconomic trends. Key developments shaping the landscape include:

1. Dominance of Fiber Laser Technology Accelerates:

By 2026, fiber lasers will solidify their position as the preferred technology for high-speed applications. Their superior beam quality, exceptional reliability (with lifespans exceeding 100,000 hours), low maintenance requirements, and high electrical efficiency (often >30%) make them ideal for continuous, high-throughput production lines. The gap between fiber and older technologies like CO2 or lamp-pumped lasers will widen, particularly in demanding sectors like automotive and electronics.

2. Integration of Smart Manufacturing & Industry 4.0:

HSLMMs will become deeply embedded components of smart factories. Expect widespread adoption of machines equipped with IoT connectivity, enabling real-time monitoring of performance, predictive maintenance alerts, and seamless data integration with MES (Manufacturing Execution Systems) and ERP platforms. This shift will focus on maximizing Overall Equipment Effectiveness (OEE) and enabling traceability throughout the supply chain.

3. Surge in Demand for Ultra-High-Speed and Precision:

Industries like consumer electronics, electric vehicles (EVs), and medical devices will demand even faster marking speeds (exceeding 7,000 mm/s) combined with micron-level precision. This will drive innovation in galvanometer scanner technology (faster scanning heads, advanced servo control) and beam delivery systems to handle complex 2D/3D marking on miniaturized components and high-volume production.

4. Growth Driven by Traceability and Serialization Regulations:

Stringent regulations (e.g., UDI in healthcare, anti-counterfeiting mandates in pharmaceuticals and aerospace) will be a primary growth catalyst. HSLMMs are essential for creating permanent, tamper-proof Data Matrix codes, QR codes, and alphanumeric serial numbers on diverse materials, ensuring compliance and enabling end-to-end product tracking.

5. Expansion into New Materials and Applications:

While metals remain dominant, demand for high-speed marking on challenging materials will grow. This includes advanced polymers, composites (e.g., CFRP in aerospace/automotive), ceramics, and coated surfaces. Machine manufacturers will develop specialized wavelengths (e.g., green, UV lasers) and optimized pulse parameters to achieve high-quality marks on these materials without damage.

6. Increased Focus on Automation and Robotic Integration:

HSLMMs will be increasingly deployed as end-effectors on robotic arms or integrated into complex automated assembly lines. This requires compact, lightweight designs, robust communication protocols (like EtherCAT), and user-friendly programming interfaces to facilitate rapid deployment and reconfiguration in dynamic production environments.

7. Sustainability and Energy Efficiency as Key Differentiators:

Environmental concerns will influence purchasing decisions. Manufacturers will emphasize the energy efficiency of HSLMMs (especially fiber lasers), reduced waste (non-contact, no consumables), and longer component lifespans. “Green” certifications and lower total cost of ownership (TCO) calculations will become important competitive factors.

8. Regional Market Dynamics:

Asia-Pacific (particularly China, India, Southeast Asia) will remain the largest and fastest-growing market, driven by manufacturing expansion, electronics production, and infrastructure development. North America and Europe will see steady growth, fueled by automation in traditional industries, advanced manufacturing initiatives, and strict regulatory compliance needs.

9. Competitive Landscape Evolution:

The market will see consolidation among component suppliers (e.g., laser sources, scanners) and increased competition from established industrial automation players entering the space. Differentiation will come through software capabilities (advanced marking software, AI-powered optimization), application expertise, and comprehensive service/support networks.

10. Rise of Hybrid and Adaptive Solutions:

While not mainstream by 2026, early adoption of hybrid systems (e.g., combining different laser types or laser + other processes) and adaptive marking (using sensors for real-time adjustment based on material variations) will emerge, particularly in high-value niche applications demanding ultimate flexibility and quality control.

In conclusion, the 2026 HSLMM market will be characterized by faster, smarter, more connected, and more versatile machines, driven by the relentless pursuit of efficiency, traceability, and automation across global manufacturing.

Common Pitfalls When Sourcing High Speed Laser Marking Machines

Sourcing a high-speed laser marking machine can significantly enhance production efficiency and product traceability. However, several critical pitfalls—particularly around quality and intellectual property (IP)—can undermine your investment if not carefully addressed.

Quality-Related Pitfalls

Overlooking Build and Component Quality

Many suppliers offer machines at competitive prices but cut corners on core components. Low-quality lasers, galvanometers, and cooling systems may initially appear functional but degrade rapidly under continuous high-speed operation, leading to frequent downtime and higher total cost of ownership.

Inadequate Performance Validation

Relying solely on manufacturer claims without independent testing is risky. High-speed performance must be validated under real-world conditions—marking speed, accuracy, and repeatability should be tested with your specific materials and mark types. Without on-site demonstrations or third-party verification, you may receive a machine that fails to meet production requirements.

Insufficient After-Sales Support and Service

Even high-quality machines require maintenance and technical support. Sourcing from suppliers without local service networks or clear maintenance protocols can result in extended downtimes. Poor documentation and untrained support staff further compound operational challenges.

Mismatched Specifications for Production Needs

Selecting a machine based only on speed specifications, without considering integration requirements (e.g., software compatibility, automation interfaces, or footprint), can lead to bottlenecks. Ensure the machine aligns with your production line’s cycle time, material handling, and environmental conditions.

Intellectual Property (IP) Risks

Use of Counterfeit or Reverse-Engineered Lasers

Some low-cost suppliers use counterfeit or illegally reverse-engineered laser sources (e.g., mimicking IPG or SPI lasers). These units often lack proper certification, offer inconsistent performance, and expose your company to legal liability for IP infringement, especially in regulated industries or export markets.

Proprietary Software and Licensing Issues

The control software is a core part of the machine. Hidden licensing fees, restrictive usage rights, or lack of access to source code can limit your ability to upgrade, integrate, or troubleshoot. Ensure software licensing terms are transparent and allow for long-term use and modification if needed.

Lack of IP Ownership Clarity

When customizing marking solutions or developing proprietary workflows, clarify who owns the resulting IP. Some suppliers may claim ownership over software modifications or process-specific configurations, limiting your freedom to replicate or scale the solution.

Non-Compliance with International Standards

Machines using infringing components may fail to meet safety or regulatory standards (e.g., FDA, CE, or RoHS). This can result in shipment rejections, customs delays, or legal action—especially if the machine incorporates patented technology without authorization.

To avoid these pitfalls, conduct thorough due diligence: verify component authenticity, request performance data under real conditions, review software licenses, and partner with reputable suppliers who respect IP and offer robust technical support.

Logistics & Compliance Guide for High Speed Laser Marking Machine

This guide outlines key logistics considerations and compliance requirements for the safe, efficient, and legal transport, installation, and operation of a High Speed Laser Marking Machine.

Shipping & Transportation

Ensure the laser marking machine is securely packed in its original manufacturer-designed crate or a robust, custom-fitted container. Use shock-absorbing materials to protect sensitive optical and mechanical components. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Coordinate with certified freight carriers experienced in handling precision industrial equipment, and verify that temperature and humidity controls are maintained during transit, especially for long-distance or international shipments.

Import/Export Regulations

Verify all applicable import and export regulations based on the origin and destination countries. Obtain necessary export licenses if required under dual-use or strategic technology controls (e.g., under EAR in the U.S. or EU Dual-Use Regulation). Ensure compliance with customs documentation, including a detailed commercial invoice, packing list, and certificate of origin. Classify the machine correctly using the appropriate HS (Harmonized System) code—typically under 8456.10 or 8515.21, depending on configuration and power.

Safety Compliance (Laser Classification)

Confirm the laser marking machine complies with international laser safety standards, primarily IEC 60825-1 (or ANSI Z136.1 in the U.S.). The device must be correctly classified (typically Class 1, 3B, or 4) and labeled with the appropriate warning labels, including laser aperture indicators and safety interlock information. Class 3B and Class 4 lasers require additional engineering and administrative controls, such as interlocked enclosures and key-controlled operation.

Electrical & EMC Standards

Ensure the machine meets regional electrical safety and electromagnetic compatibility (EMC) requirements. In the European Union, compliance with the Machinery Directive (2006/42/EC) and EMC Directive (2014/30/EU) is mandatory, requiring CE marking. In the U.S., adherence to UL/CSA standards (e.g., UL 1977, UL 61010-1) is typically required. Verify voltage compatibility (e.g., 200–240 V, 50/60 Hz) and ensure proper grounding and circuit protection are in place at the installation site.

Installation & Workplace Safety

Install the laser marking machine in a controlled environment with adequate ventilation, especially if marking materials generate fumes or particulates. Implement appropriate local exhaust ventilation (LEV) or fume extraction systems compliant with OSHA (U.S.) or similar occupational health standards. Establish a designated laser-controlled area with safety barriers, warning signs, and emergency stop mechanisms. Provide laser safety training for all operators and maintenance personnel.

Environmental & Waste Management

Adhere to local and international environmental regulations regarding the disposal of consumables (e.g., filters, coolant) and waste materials generated during laser marking (e.g., ablated particles, contaminated air filters). Follow guidelines under REACH (EU) or TSCA (U.S.) for restricted substances. Ensure proper segregation and disposal of hazardous waste according to applicable environmental protection laws.

Documentation & Traceability

Maintain comprehensive documentation, including the user manual, CE/UL certification documents, laser safety report, conformity declarations, and maintenance logs. Keep records of operator training and safety audits. Ensure traceability of the machine’s serial number and compliance certificates for regulatory inspections or warranty claims.

After-Sales & Service Compliance

Verify that service technicians are certified and trained according to manufacturer specifications and local safety regulations. Remote diagnostics and software updates must comply with data protection laws (e.g., GDPR). Spare parts used in repairs should meet original equipment specifications and relevant safety standards.

In conclusion, sourcing a high-speed laser marking machine requires a comprehensive evaluation of technical specifications, production requirements, budget constraints, and long-term operational goals. Key factors such as marking speed, laser type (fiber, CO2, or UV), beam quality, software compatibility, and integration capabilities with existing production lines must be carefully assessed. Additionally, reliability, after-sales support, warranty, and supplier reputation play a crucial role in ensuring sustained performance and minimal downtime.

Investing in a high-speed laser marking machine offers significant advantages, including improved throughput, precise and permanent markings, reduced maintenance, and compliance with industry standards. By selecting a machine that aligns with your application—whether for manufacturing, automotive, electronics, or medical devices—you can enhance product traceability, boost efficiency, and maintain a competitive edge.

Ultimately, a well-informed sourcing decision that balances performance, cost, and support will lead to a robust, scalable marking solution that delivers long-term value and supports future growth.