The global market for high-quality blank apparel—encompassing undecorated t-shirts, hoodies, and other garments used widely in print-on-demand and private-label fashion—has experienced robust growth, driven by the rise of e-commerce, customization trends, and the expansion of direct-to-consumer (DTC) brands. According to a 2023 report by Mordor Intelligence, the global blank apparel market was valued at USD 45.7 billion and is projected to grow at a CAGR of 5.8% through 2028. This growth is further supported by increasing demand for sustainable and ethically produced base garments, particularly in North America and Europe. As brands prioritize supply chain transparency and material quality, the selection of reliable high-quality blanks manufacturers has become a strategic imperative. In this evolving landscape, manufacturers that combine premium fabric sourcing, consistent production standards, and environmental responsibility are emerging as key partners for retailers and decorators alike. Below, we highlight the top 10 high-quality blanks manufacturers shaping the industry through innovation, scalability, and commitment to excellence.

Top 10 High Quality Blanks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Clothing Manufacturers

Domain Est. 2016

Website: createfashionbrand.com

Key Highlights: Shop Blanks High-quality, ready-to-brand apparel Made in Portugal in our clothing manufacturer for startups for premium garments….

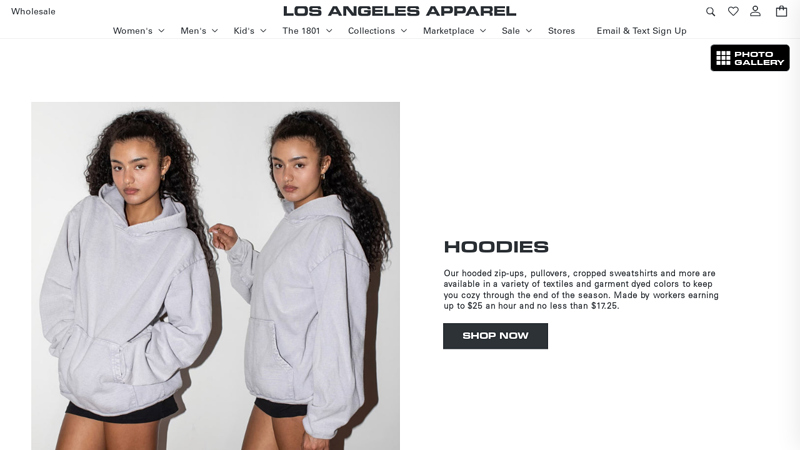

#2 Los Angeles Apparel

Domain Est. 2016

Website: losangelesapparel.net

Key Highlights: Free delivery over $125Los Angeles Apparel is a basics apparel manufacturer and distributor founded by Dov Charney, a long-standing leader in American garment manufacturing….

#3 Buy Wholesale Clothing & Blank Apparel in Bulk

Domain Est. 2000

Website: theadairgroup.com

Key Highlights: 3-day delivery · Free 30-day returnsWe are a leading supplier of wholesale apparel. We offer the lowest prices on the internet on blank t-shirts, hoodies, tie dye, and more….

#4 Bulk Apparel Wholesale Blank T-shirts and Hoodies

Domain Est. 2005

Website: bulkapparel.com

Key Highlights: Free delivery over $79At BulkApparel find Wholesale Blank Hoodies, Gildan T-shirts in Bulk and Wholesale Crewneck Sweatshirts, Independent Trading Apparel at the lowest prices ……

#5 US Blanks

Domain Est. 2008 | Founded: 2007

Website: usblanks.net

Key Highlights: Free delivery 30-day returnsUS Blanks, established in 2007 in Los Angeles, creates high-quality, locally-made knitwear in classic silhouettes. At US Blanks we prioritize sustainabi…

#6 Wholesale Clothing Distributors

Domain Est. 2011

Website: bellacanvas.com

Key Highlights: Wholesale blank tee shirts perfect for custom printing. T- Shirts, tanks, polo shirts, hoodies, fleece, tri blend, and Heathers in all popular colors….

#7 Luxury Blank Apparel Supplier

Domain Est. 2020

Website: westcoastblends.com

Key Highlights: We utilize premium heavyweight materials and natural blends with an elevated hand feel. Our garments are made with 100% luxury-grade first quality yarns….

#8 Organic Blank

Domain Est. 2022

Website: organicblank.com

Key Highlights: Organic Blank offers sustainable, 100% organic cotton t-shirts and customizable apparel. Committed to eco-friendly practices, we provide high-quality products ……

#9 Luxury Wholesale Blanks

Domain Est. 2023

Website: asherlablanks.com

Key Highlights: To ensure the highest quality, we’ve created an in-house luxury blanks program that produces top-of-the-line, long-lasting blanks right here in LA….

#10 ASBX Blanks

Website: asbx.pt

Key Highlights: Explore our Luxury Blank Line, with the paramount quality of any top Brand and the vastest range in the market. ASBX Blanks are analytically made….

Expert Sourcing Insights for High Quality Blanks

H2: Market Trends for High-Quality Blanks in 2026

As we approach 2026, the market for high-quality blanks—unfinished garments such as t-shirts, hoodies, and other apparel items used primarily in the custom apparel and print-on-demand industries—is expected to undergo significant transformation driven by technological advancements, shifting consumer preferences, and evolving supply chain dynamics.

-

Rising Demand for Sustainable Materials

A dominant trend shaping the high-quality blanks market in 2026 is the increasing consumer and regulatory emphasis on sustainability. Buyers are favoring blanks made from organic cotton, recycled polyester, and other eco-friendly fabrics. Leading manufacturers such as Bella+Canvas, Stanley/Stella, and American Apparel are investing heavily in closed-loop production systems and low-impact dyes. Certifications like GOTS (Global Organic Textile Standard) and OEKO-TEX are becoming key differentiators, with retailers and print providers prioritizing suppliers who meet these standards. -

Growth of Direct-to-Garment (DTG) and On-Demand Production

The expansion of digital printing technologies, particularly direct-to-garment (DTG) printing, continues to fuel demand for high-thread-count, consistent-quality blanks optimized for printing. In 2026, the integration of AI-driven color matching and fabric pre-treatment systems is enhancing print quality, driving preference for purpose-designed blanks. The rise of on-demand and made-to-order models reduces overproduction and inventory waste, aligning with sustainability goals and increasing reliance on reliable, high-performance blanks. -

Regionalization of Supply Chains

Following disruptions from global events in the early 2020s, many brands and manufacturers are reshoring or nearshoring production. In 2026, North American and European producers are gaining market share due to shorter lead times, better compliance with labor and environmental regulations, and reduced carbon footprints. This shift is boosting regional blank manufacturers who can offer premium quality with faster turnaround. -

Premiumization and Brand Collaboration

Consumers are increasingly willing to pay a premium for high-quality basics, especially when tied to strong brand narratives or customization. In 2026, we see more collaborations between blank suppliers and lifestyle or streetwear brands, offering co-branded blank lines that appeal to niche markets. This trend elevates the perceived value of blanks beyond mere commodities, positioning them as foundational elements of brand identity. -

Technological Integration in Fabric Innovation

Smart textiles and performance fabrics—once limited to athletic wear—are entering the mainstream blank market. High-quality blanks now feature moisture-wicking, anti-odor, and UV-protective properties, appealing to both fashion and functional apparel sectors. In 2026, innovations in biodegradable synthetics and temperature-regulating fabrics are setting new benchmarks for quality and versatility. -

E-Commerce and B2B Platform Expansion

The B2B ecosystem for high-quality blanks is becoming more digitized. In 2026, platforms like SPOKE, JOOR, and custom marketplaces from major blank suppliers offer enhanced visualization tools, 3D fabric sampling, and bulk ordering with integrated logistics. These platforms streamline procurement for print shops and brands, increasing efficiency and transparency across the supply chain.

Conclusion

By 2026, the high-quality blanks market is characterized by sustainability, technological integration, and regional resilience. Success will depend on a supplier’s ability to innovate in materials, respond to eco-conscious demand, and support evolving production models. As customization and personalization remain central to apparel retail, high-quality blanks will continue to serve as the essential canvas for creative expression and brand differentiation.

Common Pitfalls in Sourcing High-Quality Blanks: Quality and Intellectual Property Issues

Sourcing high-quality blanks—whether for apparel, accessories, or manufactured components—requires careful vetting to avoid costly mistakes. Two major areas where companies often encounter problems are product quality and intellectual property (IP) risks. Overlooking these can lead to reputational damage, legal liability, and financial loss.

Quality Inconsistencies and Misrepresentation

One of the most frequent pitfalls is receiving blanks that do not meet the promised quality standards. Suppliers may provide impressive samples but deliver substandard bulk orders. Issues include inconsistent fabric weight, poor stitching, shrinkage after washing, color variation, or use of inferior materials. These discrepancies often arise from lax quality control, subcontracting to unapproved factories, or miscommunication about specifications. Without clear quality benchmarks and third-party inspections, brands risk customer dissatisfaction and increased returns.

Intellectual Property Infringement Risks

Sourcing blanks, especially from overseas manufacturers, carries significant IP risks. Some suppliers may offer “branded” blanks or designs that mimic well-known trademarks, logos, or patented features—posing a threat of unintentional infringement. Using such items can expose the buyer to cease-and-desist letters, product seizures, or lawsuits. Additionally, custom-designed blanks may involve unclear ownership of artwork or molds, leading to disputes over rights and usage. Failing to secure proper IP clearances or written agreements with suppliers increases legal exposure and undermines brand integrity.

To mitigate these risks, businesses should conduct thorough due diligence on suppliers, require detailed specifications, perform regular quality audits, and ensure all designs and materials are legally compliant and properly licensed.

Logistics & Compliance Guide for High Quality Blanks

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to High Quality Blanks (HQB)—pre-manufactured components or substrates used in industries such as automotive, aerospace, medical devices, and precision engineering.

Supply Chain Management

Ensure a reliable and traceable supply chain by sourcing High Quality Blanks from certified suppliers with documented quality management systems (e.g., ISO 9001). Maintain clear supplier agreements that define material specifications, tolerances, surface finish requirements, and delivery schedules. Implement vendor performance monitoring and conduct regular audits to verify compliance with technical and logistical standards.

Packaging and Handling

High Quality Blanks must be packaged to prevent contamination, corrosion, and physical damage during transit and storage. Use anti-static, moisture-resistant, or vacuum-sealed packaging as appropriate for the material type (e.g., aluminum, titanium, specialty alloys). Clearly label packages with part numbers, batch/lot codes, material grade, heat treatment status, and handling instructions (e.g., “Fragile,” “This Side Up”). Employ clean handling procedures in controlled environments to avoid surface blemishes or particulate contamination.

Transportation Requirements

Transport HQBs via carriers experienced in handling high-precision industrial components. Use climate-controlled or cushioned transport when necessary to avoid thermal shock or vibration damage. Provide shipping documentation that includes packing lists, material certifications (e.g., Mill Test Reports), and export compliance details where applicable. Ensure proper insurance coverage for high-value shipments.

Import/Export Compliance

When shipping internationally, comply with relevant trade regulations such as:

– Export Control Classification Numbers (ECCN) under the Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR), if applicable.

– Accurate Harmonized System (HS) codes for customs declarations.

– Required export licenses or authorizations based on destination, end-use, and material specifications.

– Adherence to sanctions lists (e.g., OFAC, EU Consolidated List).

Maintain records of export transactions for a minimum of five years as per most regulatory frameworks.

Material Traceability & Documentation

Each batch of High Quality Blanks must be fully traceable from raw material source to final delivery. Required documentation includes:

– Material Test Reports (MTRs) or Certificates of Conformance (CoC)

– Heat treatment records

– Dimensional inspection reports

– Non-destructive testing (NDT) results (if applicable)

– Lot and batch traceability logs

Digital traceability systems (e.g., ERP or MES platforms) are recommended to streamline compliance and audit readiness.

Regulatory Standards & Certifications

Ensure all High Quality Blanks comply with industry-specific standards such as:

– AS9100 for aerospace components

– ISO 13485 for medical device applications

– IATF 16949 for automotive supply chains

– ASTM, AMS, or DIN material specifications

Regular internal audits and third-party assessments should validate ongoing compliance with these standards.

Storage Conditions

Store High Quality Blanks in a controlled environment with regulated temperature and humidity levels to prevent oxidation or dimensional instability. Segregate materials by alloy, grade, and certification status. Implement a First-In, First-Out (FIFO) inventory system to minimize aging-related risks and ensure traceability.

Quality Inspections & Receiving Procedures

Upon receipt, conduct incoming inspections to verify:

– Package integrity

– Conformance to purchase order specifications

– Completeness of documentation

– Dimensional and material verification (via sampling or 100% inspection, as per quality plan)

Document all inspection results and quarantine non-conforming items for disposition in accordance with quality procedures.

Environmental, Health & Safety (EHS) Compliance

Adhere to EHS regulations for handling metal blanks, including safe lifting practices, proper waste disposal of packaging materials, and worker protection from sharp edges or metal dust. Comply with OSHA (or local equivalent) standards and maintain Safety Data Sheets (SDS) for any treated or coated blanks.

Record Retention & Audit Preparedness

Maintain comprehensive records of logistics activities, compliance documentation, quality inspections, and supplier communications for a minimum of 10 years—especially for regulated industries. Prepare for internal and external audits by organizing documentation systematically and ensuring staff are trained on compliance responsibilities.

By adhering to this guide, organizations can ensure the secure, compliant, and efficient movement of High Quality Blanks through the supply chain while meeting the highest standards of quality and regulatory performance.

In conclusion, sourcing high-quality blanks is a critical step in ensuring the success and reliability of final manufactured products. It requires a strategic approach that includes thorough supplier vetting, strict quality control standards, material traceability, and consistent communication. Prioritizing suppliers with proven track records, certifications, and advanced manufacturing capabilities helps mitigate risks related to performance, compliance, and lead times. Additionally, fostering long-term partnerships and conducting regular audits can further enhance supply chain resilience. By investing time and resources into selecting the right blanks, companies can achieve superior product consistency, reduce waste, and maintain a competitive edge in their respective markets.