The global fastener market, driven by robust demand from automotive, construction, and industrial machinery sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. Hexagon bolts—known for their reliability, high torque resistance, and widespread compatibility—represent a critical segment within this expanding market. With increasing infrastructure development and the rise of electric vehicles, the demand for high-strength, precision-engineered hexagon bolts has intensified, prompting manufacturers to innovate in materials, coatings, and production efficiency. As competition heats up, a select group of global suppliers have emerged as leaders, combining scale, quality, and technological expertise to capture significant market share. Based on production capacity, geographic reach, product diversity, and industry reputation, the following nine manufacturers stand at the forefront of the hexagon bolt industry.

Top 9 Hexagon Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hex Bolt Suppliers

Domain Est. 2002

Website: industrial-bolts.net

Key Highlights: Find the leading hex bolt suppliers in the United States. These manufacturers offer specialty, corrosion-resistant, durable products for affordable prices….

#2 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#3 Hexagon Industries

Domain Est. 2004

Website: hexagonindustries.com

Key Highlights: Hexagon industries is an ISO certified nationwide manufacturer of stocked and custom bolts and fasteners….

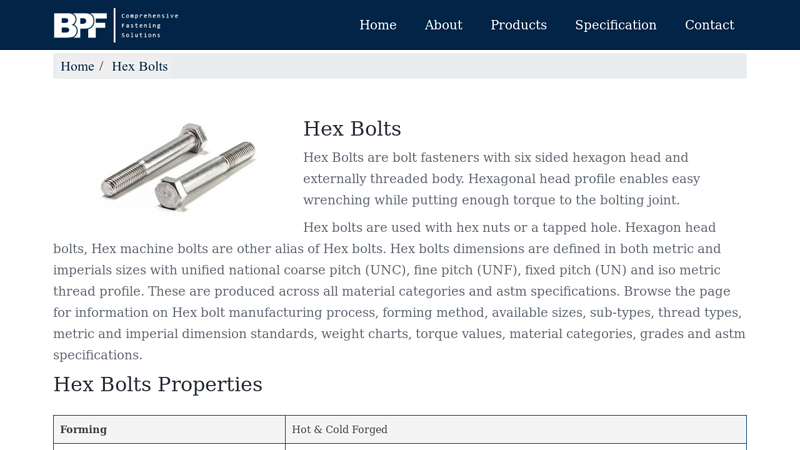

#4 Hex Bolts

Domain Est. 2017

Website: astmbolts.com

Key Highlights: Hex Bolts are bolt fasteners with six sided hexagon head and externally threaded body. Hexagonal head profile enables easy wrenching while putting enough torque ……

#5 Hex Bolts

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Portland Bolt manufactures hex bolts from 1/2′′ diameter through 2-1/2′′ diameter in most ASTM, AASHTO, and SAE specifications….

#6 Bolt Depot

Domain Est. 1999

Website: boltdepot.com

Key Highlights: Metric hex bolts. Bolts with hexagonal heads and machine threads for use with a nut or in a tapped hole. Also known as hex cap screws or machine bolts….

#7 Custom Specialty Hex Head Manufacturing

Domain Est. 2001

Website: masterbolt.com

Key Highlights: Our specialty at Master Bolt is manufacturing custom and standard fasteners for many industries. We can create any bolt, rivet, spike, and other fasteners….

#8 Metric Hex Bolt Dimensions

Domain Est. 2006

Website: atlrod.com

Key Highlights: Metric Hex Bolt Dimensions | Atlanta Rod and Manufacturing | Manufacturing of Bolts, Concrete Embeds, Construction Fasteners, and Stainless Steel Bolts ……

#9 Hex Bolts Dimensions Table

Domain Est. 2017

Website: itafasteners.com

Key Highlights: Shop high quality Hex Bolts from ITA Fasteners at the reasonable price. Available in a range of sizes from M2 to M42 and din 933. Get a quote for Hex Anchor ……

Expert Sourcing Insights for Hexagon Bolts

H2: 2026 Market Trends for Hexagon Bolts

The global hexagon bolts market is poised for steady growth through 2026, driven by expanding industrial activity, infrastructure development, and technological advancements in fastener manufacturing. Several key trends are expected to shape the market landscape in the coming years.

1. Rising Demand from Construction and Infrastructure

Infrastructure expansion, particularly in emerging economies across Asia-Pacific, Africa, and Latin America, is a major driver. Governments are investing heavily in transportation networks, urban development, and energy projects, all of which require vast quantities of high-strength fasteners like hexagon bolts. This sustained demand is expected to bolster market growth through 2026.

2. Growth in Automotive and Industrial Manufacturing

The automotive sector remains a significant consumer of hexagon bolts due to their durability and ease of assembly. With the gradual recovery of global auto production and the rise of electric vehicles (EVs), demand for precision-engineered fasteners is increasing. Additionally, industrial machinery and equipment manufacturing continue to rely on hexagon bolts for structural integrity, supporting steady market expansion.

3. Shift Toward High-Performance and Corrosion-Resistant Materials

There is a growing preference for hexagon bolts made from stainless steel, alloy steel, and other corrosion-resistant materials. Industries such as oil & gas, marine, and renewable energy require fasteners that can withstand harsh environments. This trend is pushing manufacturers to innovate with coatings and material compositions to enhance product longevity and performance.

4. Regional Market Dynamics

Asia-Pacific is expected to dominate the hexagon bolts market in 2026, led by China, India, and Southeast Asian countries. These regions are experiencing rapid industrialization and urbanization, fueling construction and manufacturing activities. Meanwhile, North America and Europe will see moderate growth, driven by infrastructure modernization and strict regulatory standards for fastener quality and safety.

5. Sustainability and Supply Chain Optimization

Environmental concerns are influencing the fastener industry, with companies adopting greener manufacturing processes and recyclable materials. Additionally, digitalization and supply chain transparency are becoming critical, especially as companies seek to mitigate disruptions and improve efficiency in procurement and logistics.

6. Competitive Landscape and Innovation

The market is highly competitive, with key players focusing on product differentiation, automation, and R&D. Companies are investing in precision manufacturing technologies such as cold forging and thread rolling to improve bolt quality and reduce waste. Mergers, acquisitions, and strategic partnerships are also expected to increase as firms aim to expand their global footprint.

In conclusion, the 2026 hexagon bolts market will be shaped by infrastructure growth, industrial demand, material innovation, and sustainability initiatives. Manufacturers that adapt to evolving technical requirements and regional dynamics will be well-positioned to capture market share in this resilient and essential segment of the fastener industry.

Common Pitfalls When Sourcing Hexagon Bolts (Quality and Intellectual Property)

Sourcing hexagon bolts may seem straightforward, but overlooking critical quality and intellectual property (IP) aspects can lead to significant issues, including product failure, regulatory non-compliance, and legal disputes. Awareness of these common pitfalls is essential for procurement professionals and engineers.

Poor Material Quality and Non-Compliance with Standards

One of the most frequent issues is receiving hexagon bolts made from substandard or misrepresented materials. Suppliers, particularly in competitive markets, may use inferior steel grades or fail to adhere to specified international standards such as ISO, ASTM, or DIN. This can result in bolts with inadequate tensile strength, poor corrosion resistance, or inconsistent heat treatment—leading to premature failure in critical applications.

Pitfall: Assuming compliance based on supplier claims without verified documentation (e.g., mill test certificates, material certifications).

Mitigation: Require certified test reports (e.g., MTC 3.1 per EN 10204) and conduct third-party material testing when sourcing in high-risk or safety-critical industries.

Inadequate or Inconsistent Thread and Dimensional Accuracy

Dimensional inaccuracy—such as incorrect thread pitch, diameter deviations, or improper head geometry—can prevent proper assembly or reduce clamping force, compromising structural integrity. This is especially problematic when bolts are used in automated assembly lines or precision machinery.

Pitfall: Relying solely on visual inspection or skipping first-article inspections (FAI).

Mitigation: Implement strict incoming quality control (IQC) procedures and use calibrated gauges or coordinate measuring machines (CMM) to verify compliance with specified tolerances (e.g., ISO 4014, ISO 4017).

Misrepresentation of Strength Grade and Mechanical Properties

Suppliers may falsely mark bolts with higher strength grades (e.g., labeling a bolt as Grade 8.8 when it performs at 5.8 levels). Incorrect strength grading poses serious safety risks, especially in automotive, aerospace, or construction sectors.

Pitfall: Accepting supplier labels without mechanical testing.

Mitigation: Conduct destructive testing (e.g., tensile, hardness) on sample batches and verify strength markings against recognized standards.

Lack of Traceability and Documentation

Traceability is critical for quality assurance and regulatory compliance. Without proper batch traceability, identifying the source of defective bolts during a failure investigation becomes nearly impossible.

Pitfall: Accepting shipments without batch/lot numbers or supplier traceability systems.

Mitigation: Enforce traceability requirements in procurement contracts and ensure suppliers maintain documented quality management systems (e.g., ISO 9001).

Intellectual Property (IP) Infringement

Sourcing bolts that replicate patented designs—such as specialized thread forms, anti-theft features, or proprietary coatings—can expose the buyer to IP infringement claims. Even if the supplier is at fault, the end user may face legal action, product recalls, or reputational damage.

Pitfall: Procuring “copy” or “equivalent” bolts without verifying design rights.

Mitigation: Conduct due diligence on bolt designs, especially for non-standard or branded fasteners. Use legally vetted specifications and avoid sourcing from suppliers known for reverse-engineered products.

Inconsistent or Missing Surface Treatments

Surface treatments (e.g., zinc plating, Dacromet, black oxide) affect corrosion resistance and appearance. Poor or inconsistent coating application can lead to premature rusting or hydrogen embrittlement in high-strength bolts.

Pitfall: Assuming all plating is equal without specifying coating thickness or testing for adhesion and salt spray resistance.

Mitigation: Define coating requirements clearly in technical specifications (e.g., ASTM B633, ISO 4042) and request test reports for corrosion performance.

Overlooking Supplier Qualification and Audit Failures

Choosing suppliers based solely on price increases the risk of encountering the above issues. Unqualified suppliers may lack the process controls, equipment, or expertise to produce consistent, high-quality bolts.

Pitfall: Skipping supplier audits or relying on outdated certifications.

Mitigation: Perform regular on-site audits, assess supplier quality systems, and monitor performance through key quality metrics.

By recognizing and addressing these common pitfalls, organizations can ensure reliable, compliant, and legally safe sourcing of hexagon bolts.

Logistics & Compliance Guide for Hexagon Bolts

This guide outlines the essential logistics and compliance considerations for the procurement, transportation, storage, and use of hexagon bolts in industrial and construction applications.

Product Classification and Standards Compliance

Hexagon bolts must conform to international, national, or industry-specific standards to ensure reliability and interoperability. Common standards include:

– ISO 4014/4017: International standards for hexagon head bolts with full or partial thread.

– ASTM A325/A490: U.S. standards for structural bolts used in steel construction.

– DIN 931/933: German standards widely used in Europe.

– BS EN 14399: European standard for preloaded high-strength structural bolts.

Ensure all bolts are certified and supplied with documentation (e.g., test certificates, material certifications) verifying compliance with the relevant standard. Non-compliant fasteners can lead to structural failure and legal liability.

Material and Finish Requirements

Compliance also depends on material composition and surface treatment:

– Materials: Typically carbon steel, alloy steel, stainless steel (e.g., A2/A4), or other corrosion-resistant alloys.

– Finishes: Zinc plating, hot-dip galvanizing, Dacromet, or plain, depending on environmental exposure.

Verify that material and finish meet project specifications and environmental regulations (e.g., RoHS, REACH for hazardous substances).

Packaging and Labeling

Proper packaging ensures product integrity during transit and supports traceability:

– Bolts should be packaged in moisture-resistant materials (e.g., sealed plastic bags inside sturdy cartons).

– Labels must include:

– Product description (e.g., M10 x 50, 8.8, ISO 4014)

– Material grade

– Finish type

– Manufacturer or supplier name

– Batch/lot number

– Compliance markings (e.g., ISO, ASTM)

Clear labeling supports inventory management and regulatory audits.

Storage and Handling

Improper storage can compromise bolt integrity:

– Store in a dry, temperature-controlled environment to prevent rust and degradation.

– Keep off the ground using pallets and avoid exposure to corrosive chemicals.

– Segregate different grades, sizes, and finishes to prevent mix-ups.

– Follow FIFO (First-In, First-Out) inventory practices.

Transport and Shipping

Logistics requirements vary by region and shipment size:

– Use secure, weather-protected transport methods.

– For international shipments, comply with Incoterms (e.g., FOB, CIF) clearly defined in purchase agreements.

– Declare accurate Harmonized System (HS) codes (e.g., 7318.15 for steel bolts) for customs clearance.

– Include Safety Data Sheets (SDS) if required, especially for coated or chemically treated bolts.

Regulatory and Safety Compliance

Hexagon bolts used in critical applications (e.g., construction, aerospace, automotive) are subject to strict regulations:

– Traceability: Maintain records of supplier, batch number, and certification for full traceability.

– Quality Audits: Conduct incoming inspections per ISO 9001 or customer-specific quality plans.

– Export Controls: Verify if bolts fall under export control regimes (e.g., ITAR, EAR), particularly for military or aerospace use.

Documentation and Recordkeeping

Retain the following for compliance and audit purposes:

– Purchase orders and contracts

– Certificates of Conformance (CoC) or Mill Test Certificates (MTC)

– Inspection reports

– Shipping and customs documents

– Storage and handling logs

Environmental and Sustainability Considerations

- Recycle packaging materials where possible.

- Use bolts made from recycled content when available and compliant.

- Comply with local waste disposal regulations for defective or excess inventory.

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient handling of hexagon bolts throughout the supply chain.

Conclusion for Sourcing Hexagon Bolts

Sourcing hexagon bolts requires a strategic approach that balances quality, cost, reliability, and compliance with industry standards. After evaluating suppliers, material specifications, production capabilities, and delivery timelines, it is clear that selecting the right vendor involves more than just competitive pricing. Key factors such as adherence to international standards (e.g., ISO, DIN, ASTM), material traceability, and consistent quality control processes are critical to ensuring performance and safety in end applications.

Establishing long-term partnerships with reputable suppliers who offer technical support, scalability, and responsive service can significantly reduce procurement risks and enhance supply chain resilience. Additionally, considering sustainability practices and logistical efficiency further contributes to a responsible and cost-effective sourcing strategy.

In conclusion, a well-structured sourcing plan for hexagon bolts—grounded in thorough supplier assessment, clear specifications, and ongoing performance monitoring—ensures reliability, compliance, and operational efficiency across projects and industries.