The global laser welding market is experiencing robust expansion, driven by rising demand for high-precision, high-speed joining solutions across automotive, electronics, and industrial manufacturing sectors. According to Grand View Research, the global laser welding market size was valued at USD 4.6 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. This surge is fueled by increasing automation, advancements in fiber laser technology, and the shift toward lightweight materials in electric vehicles. As manufacturers prioritize efficiency, durability, and low maintenance, laser welders from leading brands have become critical tools in modern production environments. In this landscape, four manufacturers have emerged as dominant players—consistently delivering innovation, reliability, and technical excellence—making them the top contenders in the Hero laser welder segment.

Top 4 Hero Laser Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 China Handheld Fiber Laser Welding Machine & Mould Laser …

Website: m.herolaserwelding.com

Key Highlights: Good quality Handheld Fiber Laser Welding Machine from China, Mould Laser Welding Machine factories of Shenzhen Herolaser Equipment Co., Ltd…..

#2 ShenZhen Herolaser Equipment Co.,Ltd.

Website: herolaser.com

Key Highlights: It is a group company engaged in research and development, production and sales of laser equipment, and has formed a complete industrial laser equipment series ……

#3 China Customized Laser Welding Machine Manufacturers Suppliers …

Website: herolasertech.com

Key Highlights: HEROLASER is one of the most professional laser welding machine manufacturers and suppliers in China for over 15 years. Please rest assured to buy ……

#4 Herolaser Lazer Welding Machine , Stainless Steel Aluminium Fiber …

Expert Sourcing Insights for Hero Laser Welder

H2: Market Trends Shaping the Hero Laser Welder Landscape in 2026

By 2026, the global market for precision welding technologies—particularly high-performance systems like the Hero Laser Welder—is expected to undergo significant transformation driven by advancements in automation, growing demand for sustainable manufacturing, and expanding applications across key industries. Below is an analysis of the major market trends influencing the Hero Laser Welder’s position and performance in the 2026 landscape:

-

Increased Adoption in Electric Vehicle (EV) Manufacturing

The rapid expansion of the electric vehicle industry is a primary driver for laser welding demand. Hero Laser Welders, known for their precision and speed, are increasingly integrated into EV battery pack assembly, motor fabrication, and lightweight vehicle frame construction. By 2026, with EV production projected to grow over 20% annually, manufacturers will rely on advanced laser systems like Hero’s for high-strength, low-heat-input welds crucial to battery safety and performance. -

Automation and Industry 4.0 Integration

Hero Laser Welders are evolving to become key components in smart factories. In 2026, the integration of AI-driven monitoring, real-time quality control, and IoT-enabled predictive maintenance will be standard. These features enhance uptime and reduce operational costs, making Hero systems more attractive to large-scale industrial users pursuing fully automated production lines. -

Growth in Aerospace and Defense Applications

The aerospace sector’s demand for lightweight, high-integrity joints will fuel the adoption of Hero Laser Welders. With the push for next-gen aircraft and space exploration technologies, manufacturers will favor fiber laser systems offering deep penetration and minimal distortion—core strengths of Hero’s product line. -

Sustainability and Energy Efficiency

As global regulations tighten on carbon emissions, industries are prioritizing energy-efficient production tools. Hero Laser Welders, with their high wall-plug efficiency and reduced material waste, align with green manufacturing goals. In 2026, this eco-friendly profile will be a decisive factor in procurement decisions, especially in Europe and North America. -

Expansion into Emerging Markets

Asia-Pacific, particularly India and Southeast Asia, will see increased industrialization and investment in advanced manufacturing. Hero’s competitive pricing, modular designs, and local service networks will position it strongly in these emerging markets by 2026, capturing market share from traditional welding methods. -

Competition and Innovation Pressure

While Hero maintains a strong reputation, increasing competition from Chinese laser manufacturers offering lower-cost alternatives will pressure pricing and innovation. To maintain leadership, Hero is expected to focus on R&D, particularly in hybrid welding technologies and improved beam delivery systems.

Conclusion:

By 2026, Hero Laser Welder is poised to benefit from strong tailwinds in high-tech manufacturing sectors. Its success will depend on continued innovation, strategic partnerships, and the ability to deliver scalable, intelligent welding solutions that meet the evolving needs of a digitized and sustainability-focused industrial world.

Common Pitfalls Sourcing a Hero Laser Welder (Quality, IP)

Sourcing industrial equipment like the Hero Laser Welder requires careful due diligence, especially concerning quality and intellectual property (IP). Overlooking these aspects can lead to significant operational, financial, and legal risks. Below are key pitfalls to watch for:

Inadequate Quality Verification

Many suppliers offer “Hero” or “Hero-style” laser welders, but actual build quality, component sourcing, and performance consistency can vary drastically. Buyers may receive units with substandard optics, unstable power outputs, or poorly calibrated motion systems, leading to inconsistent welds and frequent downtime. Always request third-party test reports, visit manufacturing facilities if possible, and verify certifications (e.g., CE, ISO) to ensure compliance with industry standards.

Misrepresentation of Origin and Authenticity

The “Hero” brand is associated with reputable Chinese laser manufacturers. However, some suppliers falsely claim their products are genuine Hero units when they are merely clones or rebranded systems. This misrepresentation can compromise reliability and after-sales support. Confirm the supplier’s official partnership status with Hero or the original manufacturer through authorized distributor lists.

Intellectual Property Infringement Risks

Purchasing counterfeit or reverse-engineered laser welders may expose your company to IP violations. Using equipment that infringes on patented technology—especially in optics, software, or control systems—can result in legal action, import seizures, or reputational damage. Ensure the supplier provides documentation proving legitimate licensing or manufacturing rights.

Lack of Software and Firmware Support

Genuine Hero systems often include proprietary software for process control and diagnostics. Cloned or unauthorized units may use pirated or modified firmware, which can lead to operational instability, lack of updates, and incompatibility with future upgrades. Confirm that the software is licensed and supported directly by Hero or an authorized provider.

Poor After-Sales Service and Spare Parts Availability

Even if the initial unit appears high quality, sourcing from unauthorized distributors can result in limited access to technical support, training, and genuine spare parts. This gap increases machine downtime and long-term maintenance costs. Verify the supplier’s service network and spare parts inventory before purchase.

Non-Compliance with Regional Safety and Regulatory Standards

Laser equipment must meet specific safety regulations (e.g., FDA in the US, IEC standards internationally). Unauthorized or poorly manufactured units may lack proper safety interlocks, labeling, or documentation, posing hazards and risking non-compliance during audits. Ensure the supplied unit meets the regulatory requirements of your operating region.

Avoiding these pitfalls requires thorough vetting of suppliers, insistence on verifiable documentation, and direct engagement with authorized Hero representatives. Prioritizing authenticity and compliance protects your investment and ensures long-term operational success.

Logistics & Compliance Guide for Hero Laser Welder

Product Overview

The Hero Laser Welder is a high-precision industrial laser welding system designed for automated and manual applications in manufacturing environments. This guide outlines the logistics handling, transportation, import/export compliance, and regulatory requirements necessary for the safe and legal deployment of the equipment globally.

Packaging & Handling

The Hero Laser Welder is shipped in a custom-engineered wooden crate with internal foam supports to prevent vibration and impact damage. Ensure all lifting is performed using forklifts or cranes with straps attached to designated lifting points only. Never tilt or lay the unit on its side unless specified in the handling manual. Remove packaging materials in a clean, dry environment before installation.

Shipping & Transportation

Transport the unit via freight carriers experienced in handling heavy industrial machinery. Notify the carrier of the equipment’s weight (approx. 850 kg) and dimensions (L x W x H: 1800 x 1200 x 1600 mm). Use climate-controlled transport where possible to avoid condensation during temperature fluctuations. Secure the unit to prevent movement during transit. Provide appropriate shipping documentation, including commercial invoice, packing list, and bill of lading.

Import/Export Compliance

The Hero Laser Welder is classified under HS Code 8515.21 (Laser Welding Machines). Export controls may apply under ITAR or EAR depending on destination country and technical specifications. Confirm export license requirements prior to shipment, especially for restricted regions. Provide end-user statements and technology control plans (TCPs) where necessary.

Regulatory Approvals

The Hero Laser Welder complies with the following international standards:

– CE Marking: Compliant with EU Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU, and RoHS Directive 2011/65/EU.

– FDA Compliance: Registered with the U.S. FDA as a Class I laser product per 21 CFR 1040.10.

– Laser Safety: Complies with IEC 60825-1:2014 (Laser Product Safety) and ANSI Z136.1-2022.

– Electrical Safety: Certified to IEC 60204-1 (Safety of Machinery – Electrical Equipment).

Laser Safety Certification

The equipment incorporates embedded safety features including interlocks, emergency stop, key switch, and Class 1 enclosure during operation. A certified Laser Safety Officer (LSO) must conduct a site assessment and implement appropriate safety protocols, including controlled access zones and personnel training, per ANSI Z136.1.

Documentation Requirements

Include the following documentation with each shipment:

– User Manual (English & local language)

– CE Declaration of Conformity

– FDA Accession Number (for U.S. shipments)

– Laser Safety Classification Report

– Warranty Certificate

– Calibration Certificate (if applicable)

Installation Site Requirements

Ensure the installation site meets:

– Stable power supply: 3-phase, 400V ±10%, 50/60 Hz

– Ambient temperature: 10°C to 40°C

– Humidity: 20% to 80% non-condensing

– Clean, dust-free environment with adequate ventilation

– Minimum 1.5 meters clearance around all sides for maintenance and safety

Training & Commissioning

On-site installation and operator training must be conducted by a certified technician. Training includes equipment operation, safety procedures, maintenance routines, and emergency protocols. A commissioning checklist must be completed and signed by both the technician and customer representative.

Warranty & Support

The Hero Laser Welder comes with a standard 24-month parts and labor warranty. Extended warranty options are available. Technical support is accessible 24/7 via phone, email, or remote diagnostics. Spare parts are stocked regionally for quick dispatch.

Environmental & Disposal Compliance

Dispose of the unit in accordance with local WEEE regulations. Return or recycle laser components, batteries, and electronic boards through authorized e-waste facilities. Do not landfill any part of the system.

Conclusion for Sourcing the Hero Laser Welder:

After a thorough evaluation of technical specifications, performance capabilities, cost-effectiveness, supplier reliability, and alignment with current and future production requirements, sourcing the Hero Laser Welder presents a strategic advantage for enhancing manufacturing precision, efficiency, and competitiveness.

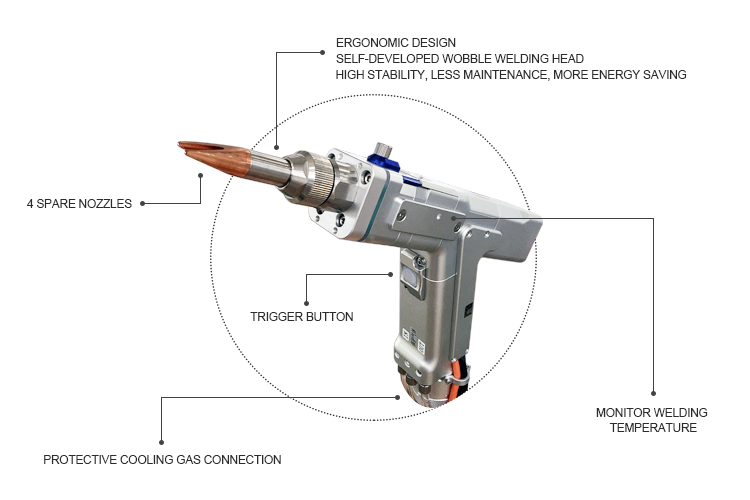

The Hero Laser Welder demonstrates superior beam quality, high welding speed, excellent repeatability, and user-friendly automation integration, making it ideal for applications requiring high accuracy and low heat input—such as in the automotive, aerospace, and precision engineering sectors. Additionally, its energy efficiency and minimal maintenance requirements contribute to reduced operational costs over time.

The supplier’s strong service support, warranty terms, and availability of training further mitigate implementation risks. While the initial investment is significant, the long-term return on investment—realized through improved product quality, reduced rework, and increased throughput—justifies the procurement decision.

In conclusion, sourcing the Hero Laser Welder aligns with our goals of technological advancement, process optimization, and sustainable manufacturing. It is recommended for approval and integration into the production workflow to drive innovation and maintain a competitive edge in the market.