The global hermetically sealed connectors market is experiencing robust growth, driven by increasing demand for reliable, high-performance connectivity solutions in mission-critical applications across aerospace, defense, medical devices, and industrial automation. According to a 2023 report by Mordor Intelligence, the global market for hermetically sealed connectors was valued at USD 2.8 billion and is projected to grow at a CAGR of over 6.5% from 2023 to 2028. This expansion is fueled by the rising need for connectors capable of withstanding extreme environments, including high pressure, temperature fluctuations, and exposure to moisture and corrosive elements. Similarly, Grand View Research estimates that advancing miniaturization trends and the proliferation of implantable medical devices are further accelerating market growth. As industries prioritize durability and signal integrity, the demand for hermetically sealed connectors continues to surge—making the manufacturers leading this innovation pivotal to technological resilience and performance. Here are the top 8 companies at the forefront of this growth.

Top 8 Hermetically Sealed Connectors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

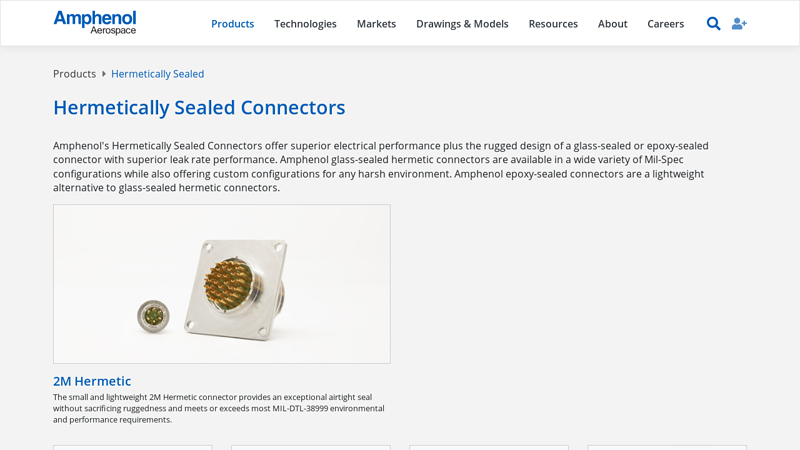

#1 Hermetically Sealed Connectors

Domain Est. 1996

Website: amphenol-aerospace.com

Key Highlights: Hermetically Sealed Connectors ranging from D38999 to micro-miniature utilizing glass-sealed and epoxy-seal hermetic technology for extreme environments….

#2 SEALTRON

Domain Est. 1996

Website: sealtron.com

Key Highlights: Sealtron is a leading manufacturer of hermetic connectors, providing commercial and military hermetic circular connectors for a wide range of applications….

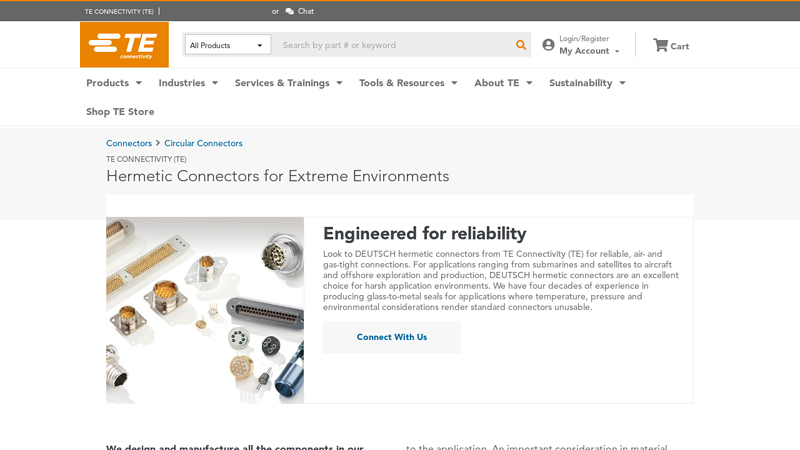

#3 Hermetic Connectors: DEUTSCH

Domain Est. 1992

Website: te.com

Key Highlights: DEUTSCH hermetic connectors are an excellent choice for harsh application environments. We have four decades of experience in producing glass-to-metal seals….

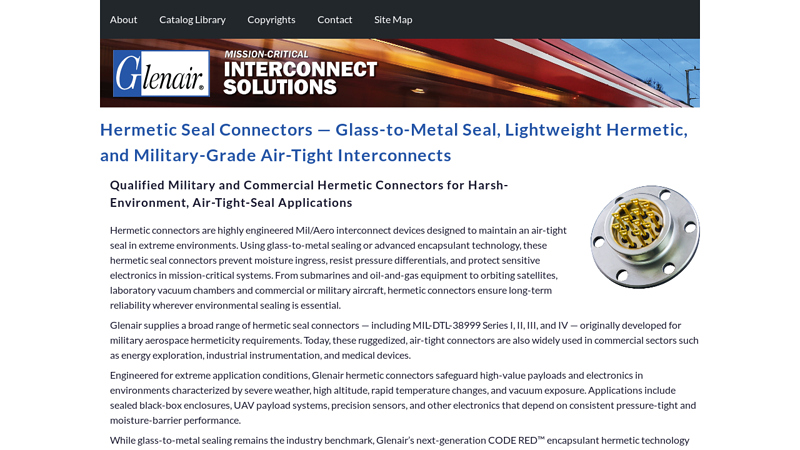

#4 Glass

Domain Est. 1995

Website: glenair.com

Key Highlights: Hermetic connectors are highly engineered Mil/Aero interconnect devices designed to maintain an air-tight seal in extreme environments. Using glass-to-metal ……

#5 Hermetically Sealed Connectors

Domain Est. 1997

Website: fischerconnectors.com

Key Highlights: Hermetic connectors designed for gas-tight applications in vacuum or pressurized environments. Reliable functionality and durability….

#6 AMETEK Hermetic Seal

Domain Est. 1998

Website: hermeticseal.com

Key Highlights: Hermetic single seals are manufactured by Hermetic Seal Corp, and are capable of handling harsh and extreme conditions. HSC is an integral part of AMETEK….

#7 Hermetic Connectors

Domain Est. 2010

Website: completehermetics.com

Key Highlights: The company manufactures both custom and standardized hermetically sealed connectors, hermetic terminals, hermetic packages and hermetic feedthroughs….

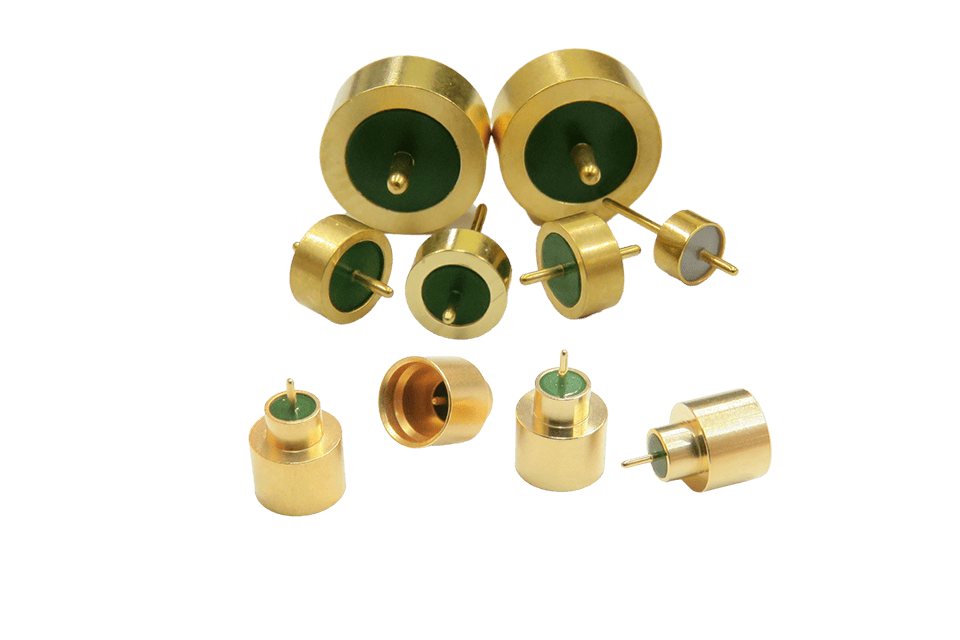

#8 Qnnect

Domain Est. 2022

Website: qnnectnow.com

Key Highlights: We specialize in innovative hermetic assemblies and packages that protect sensitive electronics in the most challenging environments including the Mil-Aero, ……

Expert Sourcing Insights for Hermetically Sealed Connectors

H2: 2026 Market Trends for Hermetically Sealed Connectors

The global market for hermetically sealed connectors is poised for significant transformation by 2026, driven by technological advancements, increasing demand from critical industries, and evolving regulatory standards. These connectors—designed to prevent the ingress of gases and liquids through airtight seals—are essential in environments requiring high reliability, such as aerospace, defense, medical devices, oil and gas, and deep-sea exploration.

1. Rising Demand from Aerospace and Defense

The aerospace and defense sectors are expected to remain the largest consumers of hermetically sealed connectors by 2026. With the expansion of satellite constellations, unmanned aerial vehicles (UAVs), and next-generation fighter jets, the need for connectors that ensure signal integrity in extreme conditions is growing. Governments worldwide are increasing defense spending, directly boosting investments in ruggedized electronic systems, where hermetic sealing is non-negotiable for mission-critical performance.

2. Growth in Medical and Life Sciences Applications

The medical device industry is becoming a key growth driver. Implantable devices such as pacemakers, neurostimulators, and drug delivery systems require connectors that offer long-term reliability within the human body. By 2026, advancements in miniaturization and biocompatible materials are expected to fuel demand for smaller, more efficient hermetically sealed connectors. Regulatory approvals and a focus on patient safety will further incentivize manufacturers to adopt high-integrity sealing technologies.

3. Expansion in Oil & Gas and Subsea Technologies

The oil and gas sector, especially deepwater and offshore drilling operations, continues to demand robust connectors capable of withstanding high pressure, temperature fluctuations, and corrosive environments. As energy companies explore deeper reserves, the reliance on subsea control systems and sensors—dependent on hermetic sealing—will grow. This trend is expected to persist into 2026, supported by investments in digital oilfield technologies and energy infrastructure modernization.

4. Technological Innovations and Material Advancements

By 2026, manufacturers are anticipated to focus on advanced materials such as ceramic-to-metal seals, laser welding techniques, and composite housings to improve performance and reduce weight. Innovations in nano-coatings and additive manufacturing (3D printing) are enabling tighter tolerances and customized connector designs. These developments are helping meet stricter environmental and operational requirements, particularly in space and defense applications.

5. Regional Market Dynamics

North America is expected to lead the market due to its strong aerospace and defense industries, particularly in the U.S. However, Asia-Pacific will witness the fastest growth, driven by industrialization, rising defense budgets in countries like China and India, and expanding medical device manufacturing. Europe will maintain steady growth, supported by stringent safety regulations and investments in green aviation and space exploration.

6. Sustainability and Regulatory Pressures

Environmental regulations are pushing manufacturers toward lead-free soldering and RoHS-compliant materials. By 2026, there will be greater emphasis on recyclability and lifecycle analysis in connector design. Additionally, certification standards such as MIL-DTL-38999, ISO 13485 (for medical), and API standards (for oil & gas) will continue to shape product development and market entry strategies.

7. Supply Chain Resilience and Localization

Geopolitical tensions and supply chain disruptions experienced in recent years have prompted companies to localize production. By 2026, more manufacturers are expected to establish regional production hubs to ensure supply continuity, reduce lead times, and comply with national security requirements—especially for defense-grade components.

Conclusion

By 2026, the hermetically sealed connector market will be characterized by strong growth across high-tech industries, fueled by innovation, regulatory compliance, and increasing environmental challenges. Companies that invest in R&D, embrace advanced manufacturing techniques, and adapt to regional market needs will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Hermetically Sealed Connectors (Quality, IP)

Sourcing hermetically sealed connectors requires careful attention to detail, as these components are often critical for reliability in harsh environments such as aerospace, defense, medical, and industrial applications. Overlooking key aspects can lead to performance failures, safety risks, and costly field repairs. Below are common pitfalls related to quality and Ingress Protection (IP) ratings.

Inadequate Verification of True Hermeticity

One of the most critical mistakes is assuming that a connector labeled “hermetically sealed” meets the required leak-tight standards. True hermeticity means the connector prevents the passage of gases and liquids at a molecular level, typically measured via helium leak testing (e.g., per MIL-STD-883 Method 1014). Without verified test data or certification, suppliers may offer merely “environmentally sealed” connectors, which do not provide the same level of protection.

Overreliance on IP Ratings Alone

While IP (Ingress Protection) ratings indicate resistance to dust and water (e.g., IP67, IP68), they do not guarantee hermetic sealing. IP tests are conducted under specific conditions—often with water immersion or spraying—but do not assess long-term gas permeability or performance under vacuum or extreme pressure. Relying solely on IP ratings may result in selecting connectors that fail in high-altitude or vacuum applications.

Poor Material and Construction Quality

Low-quality materials—such as inferior glass-to-metal seals, substandard epoxy seals, or poorly plated contacts—can compromise sealing integrity. For example, epoxy-sealed connectors may degrade over time due to thermal cycling or exposure to chemicals, leading to microcracks and leaks. Always verify the sealing method (e.g., glass, ceramic, or metal weld) and ensure materials are suitable for the operating environment.

Lack of Traceability and Certification

Hermetic connectors used in critical applications require full traceability and compliance with industry standards (e.g., MIL-DTL-38999, MIL-DTL-26482, or ASTM E493). Sourcing from unauthorized or uncertified distributors increases the risk of counterfeit parts. Ensure suppliers provide full documentation, including lot numbers, test reports, and compliance certificates.

Incompatibility with Environmental Stresses

Even high-quality hermetic connectors can fail if not selected for the specific environmental conditions. Factors such as extreme temperature cycling, vibration, shock, and exposure to corrosive chemicals must be considered. Using a connector rated for IP68 in a high-vibration aerospace system without verifying mechanical durability can lead to premature failure.

Incorrect Installation or Mating Procedures

Hermetic performance depends on proper installation. Over-torquing or under-torquing threaded couplings, using incorrect tools, or damaging seals during assembly can break the hermetic seal. Always follow the manufacturer’s recommended installation procedures and use calibrated tools.

Failure to Conduct In-House Testing or Validation

Assuming supplier claims without in-house validation is risky. Implement incoming inspection protocols such as helium leak testing, visual inspection under microscopy, and electrical continuity checks. This helps catch defects early and ensures compliance with internal quality standards.

Choosing Based on Price Over Performance

Opting for the lowest-cost option often leads to compromised reliability. Hermetic connectors involve precision manufacturing and rigorous testing—corner-cutting to reduce cost typically results in lower quality. Invest in connectors from reputable manufacturers with a proven track record in mission-critical applications.

By avoiding these common pitfalls, engineers and procurement teams can ensure they source hermetically sealed connectors that deliver long-term reliability and meet the stringent demands of high-performance applications.

Logistics & Compliance Guide for Hermetically Sealed Connectors

Overview and Definition

Hermetically sealed connectors are specialized electrical components designed to maintain a gas-tight seal, preventing the ingress of moisture, dust, gases, and other environmental contaminants. These connectors are critical in industries such as aerospace, defense, medical devices, oil and gas, and subsea systems, where reliability under extreme conditions is essential. This guide outlines key logistics and compliance considerations for the procurement, handling, transportation, storage, and regulatory adherence of hermetically sealed connectors.

Regulatory and Industry Standards Compliance

Hermetically sealed connectors must comply with a range of international and industry-specific standards to ensure performance, safety, and traceability. Key compliance requirements include:

- MIL-DTL-38999 / MIL-DTL-26482: U.S. military specifications for circular connectors used in high-reliability applications.

- ISO 9001: Quality management systems ensuring consistent manufacturing and testing processes.

- AS9100: Aerospace-specific quality standard for design and production of aviation, space, and defense products.

- IEC 60512: International standard for testing and measurement techniques for electrical connectors.

- RoHS (Restriction of Hazardous Substances): Compliance with EU directives restricting the use of lead, cadmium, mercury, and other hazardous materials.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): EU regulation on chemical substance management.

- ITAR (International Traffic in Arms Regulations): Controls export of defense-related articles and services; applicable if connectors are used in military systems.

- ATEX / IECEx: Required for connectors used in explosive atmospheres (oil & gas, chemical processing).

Manufacturers and suppliers must provide certification documentation, such as Certificates of Conformance (CoC), material test reports, and traceability records (e.g., lot and batch numbers).

Packaging and Handling Requirements

Proper packaging and handling are critical to preserving the hermetic seal and preventing contamination or physical damage:

- Use ESD-safe packaging materials to protect against electrostatic discharge.

- Seal connectors in moisture-barrier bags (MBB) with desiccant and humidity indicator cards, especially for long-term storage.

- Avoid direct handling of contact pins and sealing surfaces; use clean gloves to prevent contamination.

- Do not remove protective caps or plugs until ready for installation.

- Clearly label packages with handling symbols (e.g., ESD-sensitive, fragile, moisture-sensitive).

Storage Conditions

To maintain connector integrity prior to use:

- Store in a clean, dry, temperature-controlled environment (typically 15°C to 30°C, 30–60% relative humidity).

- Avoid exposure to corrosive gases, salt spray, or direct sunlight.

- Rotate stock using FIFO (First In, First Out) to prevent aging of seals or lubricants.

- For long-term storage (>12 months), periodic inspection and retesting may be required per manufacturer guidelines.

Transportation and Shipping

During transit, ensure connectors are protected from mechanical shock, vibration, and environmental exposure:

- Use rigid, shock-absorbent outer packaging with internal immobilization (foam inserts, clamshells).

- Comply with IATA, IMDG, or other transport regulations when shipping hazardous materials (e.g., beryllium copper components).

- For ITAR-controlled items, use authorized carriers and ensure proper export documentation (e.g., DSP-5, ECCN classification).

- Maintain chain-of-custody documentation for high-reliability or mission-critical components.

Traceability and Documentation

Full traceability is essential for compliance and quality assurance:

- Each connector or batch must have a unique identifier (part number, serial number, lot code).

- Maintain records of manufacturing date, test results (e.g., helium leak testing), inspection reports, and calibration data.

- Digital traceability systems (e.g., ERP or MES integration) are recommended for audit readiness.

Testing and Quality Verification

Before deployment, verify hermeticity and performance:

- Conduct helium leak testing per MIL-STD-883 Method 1014 or equivalent for seal integrity.

- Perform continuity, insulation resistance, and contact retention tests.

- Retest after any repair or field rework.

- Maintain a documented inspection and test plan (ITP) for each batch or shipment.

End-of-Life and Disposal

Dispose of or recycle hermetically sealed connectors in accordance with environmental regulations:

- Separate hazardous materials (e.g., plating metals, beryllium) for proper recycling.

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

- Document disposal procedures for audit and compliance purposes.

Conclusion

Hermetically sealed connectors require stringent logistics and compliance controls due to their critical role in high-reliability applications. Adherence to industry standards, proper handling, secure documentation, and robust traceability systems are essential to ensure long-term performance and regulatory compliance. Organizations should establish clear internal procedures aligned with this guide to mitigate risk and maintain supply chain integrity.

Conclusion for Sourcing Hermetically Sealed Connectors:

Sourcing hermetically sealed connectors requires a strategic approach that balances performance, reliability, cost, and compliance with industry standards. These connectors are critical in applications exposed to extreme environments—such as aerospace, defense, medical devices, and deep-sea instrumentation—where protection against moisture, gases, and contaminants is essential to ensure long-term functionality and safety.

Key considerations in the sourcing process include material compatibility, sealing technology (e.g., glass-to-metal or ceramic-to-metal seals), temperature and pressure resistance, electrical performance, and regulatory certifications (e.g., MIL-DTL-38999, ASTM E493). Engaging with reputable suppliers who offer proven quality control, traceability, and customization capabilities is vital to meet specific application requirements.

Furthermore, evaluating total cost of ownership—rather than initial purchase price—helps account for potential savings from reduced failure rates, maintenance, and downtime. Partnering with manufacturers that provide technical support and rapid prototyping can accelerate development and reduce time-to-market.

In conclusion, successfully sourcing hermetically sealed connectors involves a comprehensive assessment of technical specifications, supplier reliability, and lifecycle performance. By prioritizing quality, compliance, and long-term value, organizations can ensure robust connectivity solutions capable of withstanding the most demanding operational environments.