The global sewing machine market, valued at USD 3.8 billion in 2023, is projected to grow at a CAGR of 5.2% through 2030, driven by rising demand in both industrial manufacturing and the expanding DIY consumer segment (Grand View Research, 2024). A critical component enabling precision in garment finishing—particularly in hemming—lies in specialized sewing machine feet. As automation and quality standards intensify across apparel production, manufacturers of hemming presser feet are witnessing increased demand. This growth is further amplified by trends in sustainable fashion, where durable, well-finished seams extend garment lifespan. With OEMs and aftermarket suppliers scaling innovation in material durability, compatibility, and ease of use, the competitive landscape for hemming foot manufacturers is evolving rapidly. These dynamics underscore the importance of identifying the top players shaping this niche yet essential segment of the textile machinery supply chain.

Top 9 Hemming Sewing Machine Foot Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SINGER® Rolled Hem Presser Foot

Domain Est. 1995

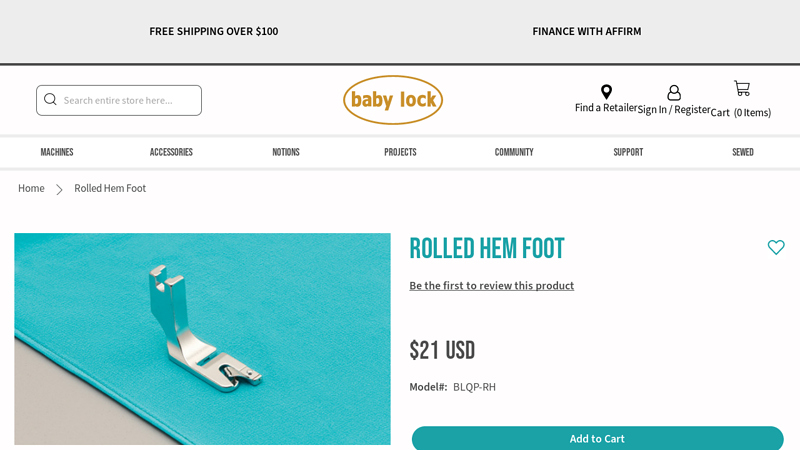

#2 Rolled Hem Foot

Domain Est. 1996

#3 Hemmer Foot

Domain Est. 2000

Website: bernette.com

Key Highlights: This special presser foot serves the purpose to create professional-looking seams. It folds the fabric twice which results in a nice rollhem….

#4 Brother SA127

Domain Est. 2000

Website: brother-usa.com

Key Highlights: This Genuine Brother Accessory has groove under the foot, which is designed to create a flat narrow hem on lightweight fabrics. Learn more now….

#5 Binding & Hemming Foot

Domain Est. 2008

Website: cutexsewingsupplies.com

Key Highlights: 4–7 day delivery 30-day returns…

#6 Find Your next Hem Presser Foot Online at GOLDEN EAGLE

Domain Est. 2023

#7 Sewing Machine Accessories

Website: juki.co.jp

Key Highlights: This presser foot is used for sewing blind hem stitches, which are sewn along the hems of pants and skirts to be invisible from the right side of the fabric….

#8 Singer Rolled Hem Snap

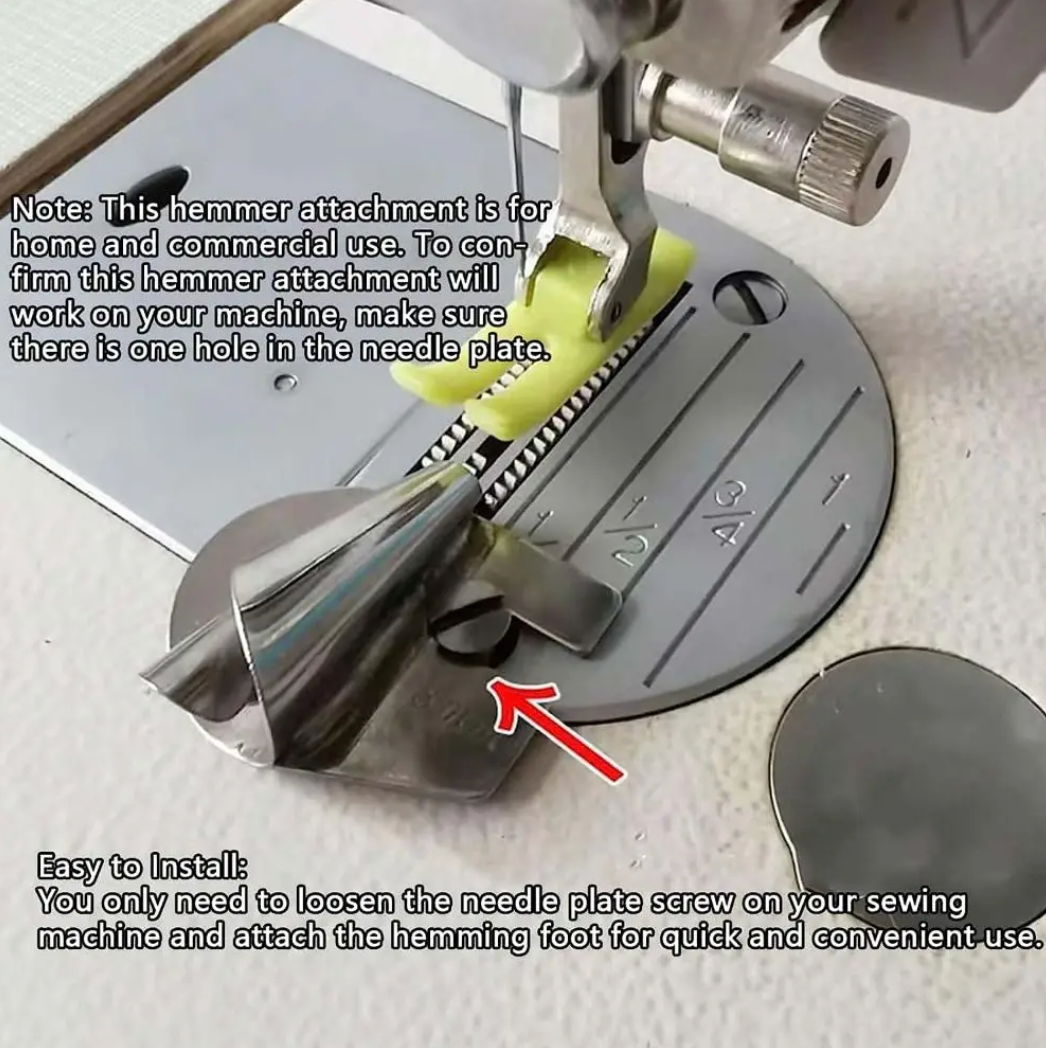

#9 Edge Guide Hemming Presser Foot For Industrial Sewing Machine

Domain Est. 2006

Expert Sourcing Insights for Hemming Sewing Machine Foot

H2: Market Trends for Hemming Sewing Machine Feet in 2026

As the global textile and apparel industry evolves, demand for specialized sewing accessories like hemming sewing machine feet is expected to grow steadily by 2026. Driven by advancements in home sewing technology, rising interest in DIY fashion, and the expansion of automated garment production, the hemming foot market is poised for transformation. Key trends shaping the landscape include increased demand for multi-functional and adjustable hemming feet, integration with smart sewing machines, and the influence of sustainability on product design.

One of the dominant trends in 2026 is the growing consumer preference for versatile and precision-focused accessories. Modern hemming feet—especially rolled hem, blind hem, and double-fold variants—are being redesigned with improved materials (such as non-stick coatings and durable polymers) to enhance performance on lightweight and stretchable fabrics. This shift responds to the rising popularity of activewear, lingerie, and eco-friendly textiles, which require delicate and consistent hemming techniques.

Additionally, the proliferation of computerized and smart sewing machines has led to the development of hemming feet compatible with automated stitch patterns and digital settings. Manufacturers are increasingly aligning their foot designs with major sewing machine brands (e.g., Brother, Singer, Janome) to ensure seamless integration. This interoperability is becoming a competitive differentiator in both consumer and industrial markets.

Sustainability is also influencing design and production. By 2026, an increasing number of manufacturers are adopting eco-conscious materials and production methods for sewing feet, responding to environmental concerns across the supply chain. Recyclable packaging, reduced metal usage, and modular designs that extend product life are becoming standard practices.

Geographically, the Asia-Pacific region is projected to lead market growth due to its robust garment manufacturing sector and expanding middle class with interest in home sewing. Meanwhile, North America and Europe maintain strong demand fueled by the maker movement, custom tailoring, and online sewing communities.

In summary, the 2026 market for hemming sewing machine feet will be shaped by innovation in design, compatibility with smart technology, and a focus on sustainability—positioning the product as an essential tool for both hobbyists and professionals in an increasingly automated and environmentally aware industry.

Common Pitfalls When Sourcing a Hemming Sewing Machine Foot (Quality and Intellectual Property)

Sourcing specialized sewing machine accessories like a hemming foot requires attention to detail, especially regarding quality consistency and intellectual property (IP) concerns. Overlooking these areas can lead to production delays, increased costs, or legal risks. Below are key pitfalls to avoid:

Poor Material Quality and Construction

One of the most frequent issues is receiving hemming feet made from substandard materials. Low-grade metals or plastics may wear quickly, warp under heat, or fail to guide fabric properly. This leads to inconsistent hems, machine damage, or frequent replacements. Always verify material specifications (e.g., hardened steel, wear-resistant polymer) and request samples before bulk ordering.

Inconsistent Tolerances and Fit

Hemming feet must fit precisely on specific sewing machine models (e.g., Brother, Juki, Singer). Poor manufacturing tolerances can result in wobbling, misalignment, or improper attachment, affecting stitch quality and safety. Confirm compatibility with your machine model and insist on dimensional drawings or sample testing.

Lack of Durability Testing

Many suppliers, especially overseas OEMs, skip rigorous durability testing. A foot might work in initial trials but fail under prolonged use. Ask about stress tests, cycle testing, and real-world performance data to ensure long-term reliability.

Misrepresentation of Brand Compatibility

Some suppliers falsely advertise their feet as “compatible with” or “original equivalent to” major brands like Bernina or Janome. While functional compatibility may exist, these claims can mislead buyers into thinking they are getting genuine parts. Always clarify whether the product is genuine, OEM, or a third-party replica.

Intellectual Property (IP) Infringement

Using or sourcing hemming feet that copy patented designs or branded features can expose your business to legal action. Many original equipment manufacturers (OEMs) hold design patents or trademarks on their accessory shapes and logos. Sourcing generic equivalents is acceptable, but avoid products that replicate distinctive, protected designs.

No IP Clearance or Legal Safeguards

Suppliers in some regions may not respect IP laws, increasing the risk of counterfeit or infringing goods. Ensure your supplier provides IP indemnification or confirms that their products do not violate existing patents. Conduct due diligence, especially when sourcing from low-cost manufacturing regions.

Inadequate Quality Control Processes

Without proper QC, batches can vary significantly in performance. Look for suppliers with documented quality management systems (e.g., ISO 9001) and request audit reports or QC checklists. Third-party inspections can also help verify consistency.

Hidden Costs from Returns and Downtime

Low upfront pricing can be misleading if poor quality leads to machine downtime, rework, or return shipping fees. Factor in total cost of ownership, including reliability and after-sales support, rather than focusing solely on unit price.

Avoiding these pitfalls requires thorough vetting of suppliers, clear communication of technical and legal expectations, and a focus on long-term performance over short-term savings.

Logistics & Compliance Guide for Hemming Sewing Machine Foot

Product Overview

The Hemming Sewing Machine Foot is a specialized attachment designed for sewing machines to create clean, professional hems on various fabrics. It is commonly used in garment manufacturing, textile production, and home sewing applications. Proper logistics handling and compliance with international and regional regulations are essential for safe and legal distribution.

Classification and Harmonized System (HS) Code

- HS Code: 8448.39.90 (Applicable in most countries for sewing machine parts and accessories)

- Description: Parts and accessories of sewing machines, not incorporating the functions of other appliances, n.e.s.

- Note: Confirm the exact HS code based on the destination country, as minor variations may exist.

Packaging and Labeling Requirements

- Packaging: Use anti-static, moisture-resistant packaging to prevent corrosion or damage. Individual units should be sealed in polybags and packed in sturdy cardboard boxes.

- Labeling:

- Product name: “Hemming Sewing Machine Foot”

- Model number and compatibility (e.g., fits Singer, Brother, Janome models)

- Manufacturer name and contact information

- Country of origin

- Batch/lot number and production date

- CE or other relevant certification marks (if applicable)

Import/Export Documentation

Ensure the following documents are prepared for international shipments:

– Commercial Invoice (with detailed product description, quantity, value, and HS code)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (required by some countries for tariff determination)

– Import/Export License (if required by the destination country)

Regulatory Compliance

CE Marking (European Union)

- Required if the product is sold in the EU.

- Although sewing feet are generally exempt from CE directives like the Machinery Directive, they may fall under the scope if marketed as part of a safety system.

- Ensure compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regarding restricted substances.

RoHS Compliance (EU and Other Regions)

- Verify that the product does not contain restricted substances such as lead, cadmium, mercury, etc., especially if made from metal or plastic components.

FCC and Other U.S. Regulations

- Not typically applicable, as the Hemming Sewing Machine Foot is a mechanical accessory without electronic components.

- Comply with general consumer product safety standards under the CPSIA if marketed for consumer use.

UKCA Marking (United Kingdom)

- Required for products sold in Great Britain (England, Scotland, Wales).

- Similar to CE marking; apply UKCA if placing the product on the UK market post-Brexit.

Transport and Handling

- Mode of Transport: Suitable for air, sea, or land freight.

- Handling Instructions: “Fragile,” “Do Not Stack,” and “Keep Dry” labels should be visible.

- Storage Conditions: Store in a dry, temperature-controlled environment. Avoid exposure to direct sunlight or high humidity.

Customs Clearance Considerations

- Provide accurate product valuation to avoid delays or penalties.

- Declare any applicable free trade agreements (e.g., USMCA, RCEP) to benefit from reduced tariffs.

- Be prepared for customs inspections; maintain digital and physical copies of all compliance documents.

Environmental and Sustainability Compliance

- Follow WEEE (Waste Electrical and Electronic Equipment) guidelines if the product includes electronic elements (rare for sewing feet).

- Encourage recyclable packaging and provide disposal guidance where applicable.

After-Sales and Warranty Compliance

- Include multilingual user instructions if selling in multiple regions.

- Adhere to local warranty and return policy regulations (e.g., 2-year legal warranty in the EU for consumer goods).

Contact Information for Compliance Inquiries

- Designate a compliance officer or department for handling regulatory questions.

- Provide customer support contact details on packaging and documentation.

By following this guide, suppliers and distributors can ensure smooth logistics operations and maintain full compliance when importing, exporting, or selling Hemming Sewing Machine Feet globally.

In conclusion, sourcing a hemming sewing machine foot requires careful consideration of several key factors, including compatibility with your specific sewing machine model, the type of hemming techniques you intend to use (such as blind hem, rolled hem, or double-fold hem), and the material types you’ll be working with. It’s essential to choose a high-quality foot from a reputable manufacturer or supplier to ensure durability, precision, and smooth operation. Whether purchasing from authorized dealers, online marketplaces, or specialty sewing supply stores, verifying product specifications and reading customer reviews can help make an informed decision. Ultimately, the right hemming foot enhances sewing efficiency, improves finished garment quality, and contributes to a more professional result, making it a worthwhile investment for both hobbyists and professionals in the textile and apparel industry.