The global sewing machine market is experiencing steady growth, fueled by rising demand in both industrial and domestic sectors, particularly within the apparel and textile industries. According to Grand View Research, the global sewing machine market size was valued at USD 28.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is driven by increased automation in garment manufacturing, the proliferation of small-scale textile businesses, and growing interest in DIY and home sewing projects. As demand for precision and efficiency rises, specialized machines like hemming sewing machines have gained prominence in production lines for their ability to deliver clean, consistent edge finishes. With key players investing in advanced technologies such as servo motors, programmable logic controls, and IoT integration, the competitive landscape among manufacturers is intensifying. In this context, we examine the top 9 hemming sewing machine manufacturers leading innovation, market share, and technological advancement in a rapidly evolving industry.

Top 9 Hemming Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Yamato Sewing Machine Mfg. Co., Ltd.

Domain Est. 2000

Website: yamato-sewing.com

Key Highlights: Yamato Sewing Machine is a leading Japanese manufacturer of industrial sewing machines pioneering with innovative “FIRSTs” in industry solutions in ……

#2 Merrow® Sewing Machine Co. Manufacturer of Industrial Sergers …

Domain Est. 1996

Website: merrow.com

Key Highlights: The Merrow Sewing Machine Company makes over 360 models of production grade sewing machines, each one hand built to the highest quality and precision tolerances ……

#3 Hemming

Website: pegasus.co.jp

Key Highlights: We would show lineups of PEGASUS industrial sewing machines which can make the selected seam Hemming….

#4 Sewing machines — English

Domain Est. 2000

Website: pfaff-industrial.com

Key Highlights: Universal cylinder-bed machine for use in small leather goods, leather garments, upholstery, shoes, etc. Working on tubular or pre-attached articles….

#5 Utilities

Domain Est. 2021

Website: jack-sewing.com

Key Highlights: Jack Sewing Machines are the unquestioned world leaders in high quality budget range of Industrial Sewing Machinery. View the full range of Jack Sewing ……

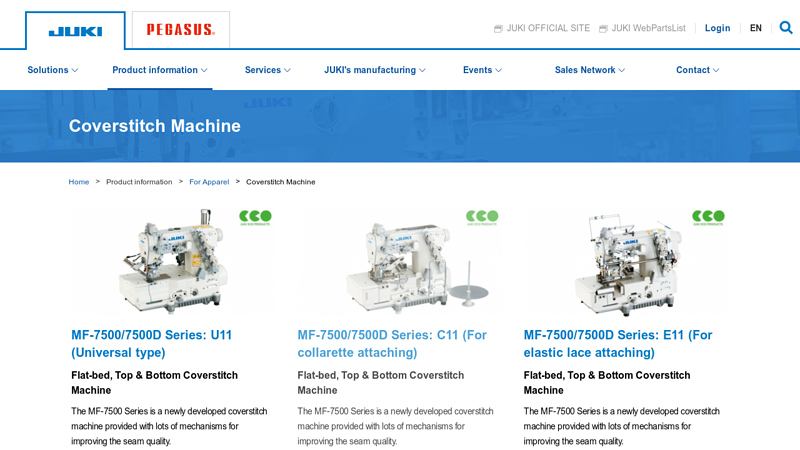

#6 Coverstitch Machine

Website: juki.co.jp

Key Highlights: 4-needle Flatseamer to prove JUKI’s original safety and ingenuity. Create beautiful seams on underwear, fleece wear, swimsuits, even on new materials….

#7 Jack Sewing Machines

Domain Est. 1999

Website: chinajack.com

Key Highlights: JACK 14 Years World NO.1 Who Provides a Great Number of High-Quality Precision Sewing Machines at Affordable Prices. Browse Our Vast Selection and Enjoy ……

#8 Hams Corporation|Kyoto Japan

Domain Est. 2000

Website: hams-jp.com

Key Highlights: Company History ; In 1972,, Developed hemming machine for cotton bed (Model MOV) ; In 1974,, Developed seat-belt sewing machines (Model MOB) ; In 1975,, Developed ……

#9 Shop Brother Serger Sewing Machines & Coverstitch Machines

Domain Est. 2000

Website: brother-usa.com

Key Highlights: Serge rolled hems and clean seams, apply sporty seam finishes, and craft other professional looking touches with Brother serger machines and coverstitch ……

Expert Sourcing Insights for Hemming Sewing Machine

H2: Projected 2026 Market Trends for Hemming Sewing Machines

The global market for hemming sewing machines is poised for steady growth by 2026, driven by advancements in automation, rising demand from the apparel and textile industries, and increasing adoption of specialized sewing equipment in both industrial and small-scale manufacturing settings. Key trends shaping the market include:

-

Increased Automation and Smart Technology Integration

By 2026, hemming sewing machines are expected to feature enhanced automation, including programmable stitching patterns, automatic thread cutting, and IoT-enabled monitoring systems. These smart features improve precision, reduce labor costs, and increase production efficiency, making them highly attractive to mid-to-large-scale garment manufacturers. -

Growth in the Fast Fashion and Custom Apparel Sectors

The fast fashion industry’s need for rapid turnaround times is fueling demand for high-speed hemming machines. Additionally, the rise of made-to-order and customized clothing is encouraging investment in versatile hemming solutions that can handle diverse fabric types and hem styles efficiently. -

Expansion in Emerging Markets

Countries in Southeast Asia, South Asia, and parts of Africa are witnessing growth in textile manufacturing due to lower labor costs and favorable government policies. This expansion is boosting demand for cost-effective and durable hemming sewing machines tailored to local production needs. -

Sustainability and Energy Efficiency

As environmental concerns grow, manufacturers are developing energy-efficient hemming machines with reduced power consumption and minimal waste generation. Machines that support eco-friendly practices—such as reduced thread waste and quieter operations—are gaining preference among environmentally conscious brands. -

Shift Toward Compact and Multi-Functional Machines

Small businesses and home-based entrepreneurs are driving demand for compact, user-friendly hemming machines that offer multi-functionality. By 2026, expect to see a rise in hybrid models that combine hemming with other sewing functions, catering to niche markets and craft industries. -

Impact of E-Commerce and Direct-to-Consumer Models

The proliferation of online apparel sales has increased the need for scalable production, including efficient finishing processes like hemming. This trend is pushing both established and new entrants to innovate in machine design and after-sales support, including remote diagnostics and digital training tools.

In summary, the hemming sewing machine market in 2026 will be characterized by technological innovation, regional market expansion, and a strong focus on efficiency and sustainability, positioning it for sustained growth across diverse segments of the textile and apparel industry.

Common Pitfalls When Sourcing Hemming Sewing Machines (Quality and Intellectual Property)

Sourcing hemming sewing machines, especially from overseas suppliers, presents several risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for making informed procurement decisions and safeguarding your business interests.

Overlooking Build Quality and Component Standards

Many low-cost hemming machines are constructed with substandard materials and imprecise manufacturing. Buyers often encounter machines with weak metal frames, poor welds, or plastic gears that wear down quickly under industrial use. Overlooking these quality indicators can lead to frequent breakdowns, increased maintenance costs, and reduced production efficiency. Always request detailed specifications, material certifications, and conduct factory audits or third-party inspections before placing bulk orders.

Assuming All Machines Meet Industry Performance Claims

Suppliers may exaggerate machine capabilities, such as stitch precision, speed, or fabric compatibility. For instance, a machine advertised for “high-speed blind hemming” might fail under continuous operation or on heavier fabrics. Without independent testing or verified performance data, buyers risk investing in equipment that doesn’t meet production requirements. Insist on live demonstrations, sample stitching tests, or third-party lab reports to validate performance claims.

Ignoring After-Sales Support and Spare Parts Availability

A major pitfall is focusing solely on initial cost while neglecting long-term support. Some suppliers, particularly smaller or newer manufacturers, may lack reliable customer service, technical documentation, or available spare parts. This can result in extended machine downtime and costly repairs. Evaluate the supplier’s service network, spare parts inventory, and response time before committing to a purchase.

Falling for Counterfeit or IP-Infringing Machines

Some suppliers sell hemming machines that closely mimic patented designs from established brands (e.g., Juki, Brother, or Mitsubishi), infringing on intellectual property rights. While these clones may appear cheaper, importing or selling them can expose your business to legal action, product seizures, or reputational damage. Always verify the manufacturer’s IP ownership, request proof of design patents or licensing agreements, and avoid suppliers offering “brand copy” models.

Underestimating Compliance and Certification Requirements

Hemming machines must meet safety and electromagnetic compatibility standards (e.g., CE, UL, or CCC) depending on the destination market. Sourcing non-compliant machines can result in customs delays, fines, or inability to operate legally. Confirm that the supplier provides necessary certifications and that machines are tested according to regional regulations.

Relying Solely on Online Listings Without Verification

Digital platforms often showcase appealing product photos and specs that don’t reflect reality. Buyers who skip due diligence—such as requesting factory references, conducting site visits, or using inspection services—risk receiving machines that differ significantly from what was promised. Always validate claims through independent verification and documented quality checks.

Avoiding these common pitfalls requires thorough supplier vetting, technical evaluation, and legal awareness—particularly regarding quality consistency and IP compliance. Investing time upfront can prevent costly disruptions and legal exposure down the line.

Logistics & Compliance Guide for Hemming Sewing Machines

This guide outlines key logistics considerations and compliance requirements for the import, export, distribution, and operation of hemming sewing machines. Adhering to these guidelines ensures smooth transportation, regulatory approval, and safe usage.

Shipping and Transportation

Package hemming sewing machines securely using robust materials to prevent damage during transit. Use wooden crates or heavy-duty cardboard with internal foam or polyurethane supports to protect the machine head, arm, and electrical components. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Choose carriers experienced in handling industrial machinery and ensure proper insurance coverage. Maintain stable temperatures and low humidity during transit to avoid condensation and corrosion.

Import and Export Regulations

Verify export controls and import restrictions based on the country of origin and destination. Hemming sewing machines may be subject to general industrial equipment regulations, but specific components (e.g., motors, electronic controls) might have additional requirements. Ensure compliance with the Harmonized System (HS) code classification—typically under 8452 (sewing machines). Provide accurate commercial invoices, packing lists, and certificates of origin. Check for export licenses if shipping to sanctioned regions or if machines include controlled technology.

Safety and Electrical Compliance

Hemming sewing machines must comply with electrical safety standards in the target market. In the European Union, CE marking is mandatory, requiring conformity with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. In the United States, machines should meet UL 61010 or similar standards for industrial equipment. Ensure grounding systems, emergency stop mechanisms, and protective covers are installed and tested. Provide multilingual safety warnings and operating instructions.

Environmental and RoHS Compliance

Ensure the machine complies with environmental regulations such as the EU’s Restriction of Hazardous Substances (RoHS) Directive, which limits the use of lead, mercury, cadmium, and other hazardous materials in electrical equipment. Provide a Declaration of Conformity and material composition documentation upon request. Properly dispose of packaging materials in accordance with local recycling and waste management laws.

Customs Documentation and Duties

Prepare complete customs documentation including bill of lading, commercial invoice, packing list, and any required permits. Accurately declare the value, weight, and technical specifications of the hemming sewing machine to avoid delays or penalties. Research applicable import duties and VAT rates in the destination country. Consider using a customs broker to facilitate clearance, especially for first-time shipments.

Installation and Operational Compliance

Upon delivery, follow manufacturer guidelines for installation, including proper ventilation, stable power supply (voltage and frequency), and anchoring to prevent vibration. Train operators on safe use, maintenance procedures, and lockout/tagout (LOTO) protocols. Maintain service records and comply with local occupational health and safety regulations, such as OSHA standards in the U.S. or similar frameworks elsewhere.

After-Sales and Service Support

Ensure spare parts and technical support are available in the target market to meet warranty and service obligations. Provide documentation in local languages and comply with consumer protection laws regarding repair timelines and product returns. Register machines with relevant national product safety databases if required.

Conclusion:

After a thorough evaluation of suppliers, machine capabilities, cost considerations, and long-term operational requirements, sourcing a hemming sewing machine is a strategic investment that can significantly enhance production efficiency, product quality, and overall output consistency. The selected machine should align with specific fabric types, hemming styles, and production volume needs, ensuring optimal performance and durability.

Considering factors such as automation level, maintenance support, energy efficiency, and after-sales service plays a crucial role in the decision-making process. Partnering with a reputable supplier who offers reliable technical support and training will further ensure smooth integration into existing workflows.

In conclusion, the right hemming sewing machine not only improves stitching precision and reduces labor costs but also contributes to increased productivity and competitiveness in the market. A well-informed sourcing decision today sets the foundation for sustained operational excellence and growth in the textile or apparel manufacturing process.