The global heavy-duty turntable market is experiencing robust growth, driven by increasing automation across manufacturing, warehousing, and logistics sectors. According to Mordor Intelligence, the material handling equipment market — under which heavy-duty turntables fall — is projected to grow at a CAGR of over 6.5% from 2023 to 2028. Similarly, Grand View Research estimates that the global material handling equipment market was valued at USD 184.2 billion in 2022 and is expected to expand at a CAGR of 6.3% through 2030. This growth is fueled by rising demand for operational efficiency, space optimization, and automated material flow in industries such as automotive, food and beverage, and e-commerce fulfillment. As a critical component in conveyor systems, heavy-duty turntables enable seamless 90°, 180°, or 360° load rotation, supporting complex production layouts and high-throughput environments. With expanding industrial automation and smart factory initiatives worldwide, the need for reliable, precision-engineered turntable solutions has never been greater — making the manufacturers behind these innovations key players in modern material handling ecosystems.

Top 9 Heavy Duty Turntable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powered Conveyor Turntable Manufacturer

Domain Est. 1996

Website: iki.com

Key Highlights: Industrial Kinetics manufactures turntables with multiple deck configurations and sizes, with chain driven roller and belt driven live rollers….

#2 Standard and Heavy Duty Industrial Turntable Manufacturers

Domain Est. 2015

Website: hydraulicliftmanufacturers.com

Key Highlights: Locate leading standard-duty and heavy duty industrial turntable manufacturers and suppliers, who offer a large variety of powered or manual turntables….

#3 Industrial Turntables

Domain Est. 1997

Website: advancelifts.com

Key Highlights: Advance Lifts is your trusted source for heavy-duty industrial turntables. We offer excellent quality manufacturing turntables in a variety of styles: powered, ……

#4 Industrial Turntables

Domain Est. 1997

Website: hovair.com

Key Highlights: Industrial Turntables are a truly versatile product. They greatly assist work processes in shipping & manufacturing industries….

#5 Turntables

Domain Est. 1999

Website: albamfg.com

Key Highlights: Unlike other conveyor manufacturers, Alba provides pre-engineered turntables. Our standard turntable diameters range in various increments from 72″ to 82″….

#6 Industrial And Commercial Turntables

Domain Est. 2004

Website: carousel-usa.com

Key Highlights: We build and install turntables with upwards of 100′ diameters with 80 ton or higher capacities. Truck Turntables and Train Platforms….

#7 Beacon World Class

Domain Est. 1998

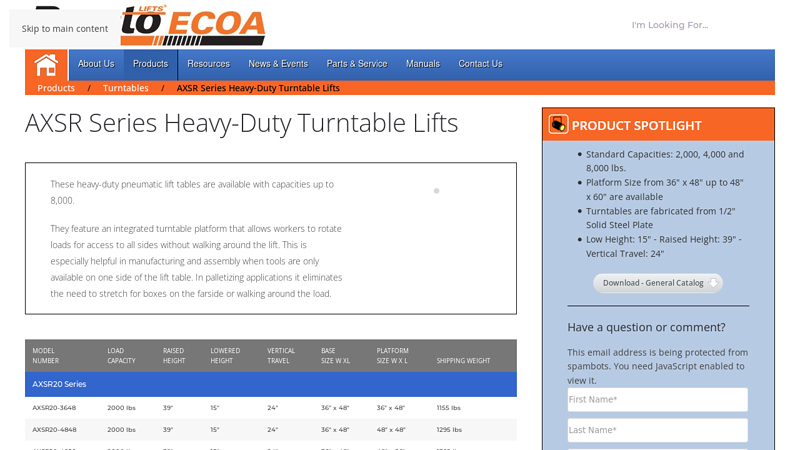

#8 AXSR Series Heavy

Domain Est. 2000

Website: prestolifts.com

Key Highlights: AXSR Series Heavy-Duty Turntable Lifts ; Model Number : AXSR20-3648. Load Capacity : 2000 lbs. Raised Height : 39″. Lowered Height : 15″. Vertical Travel : 24″….

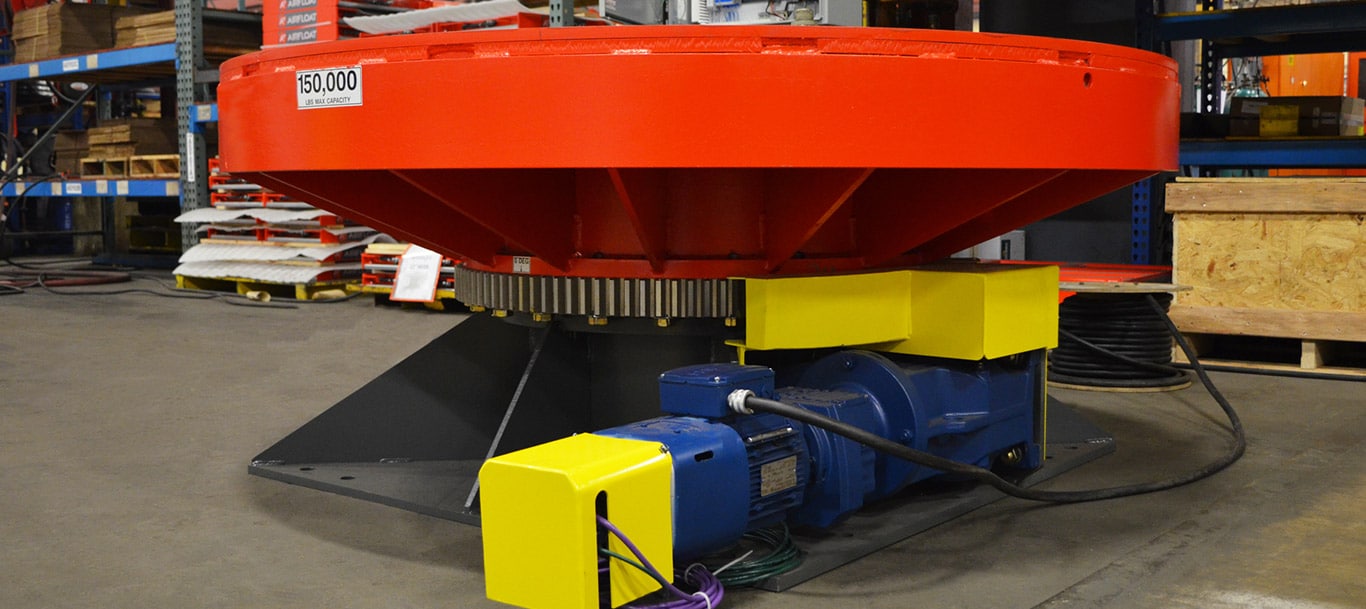

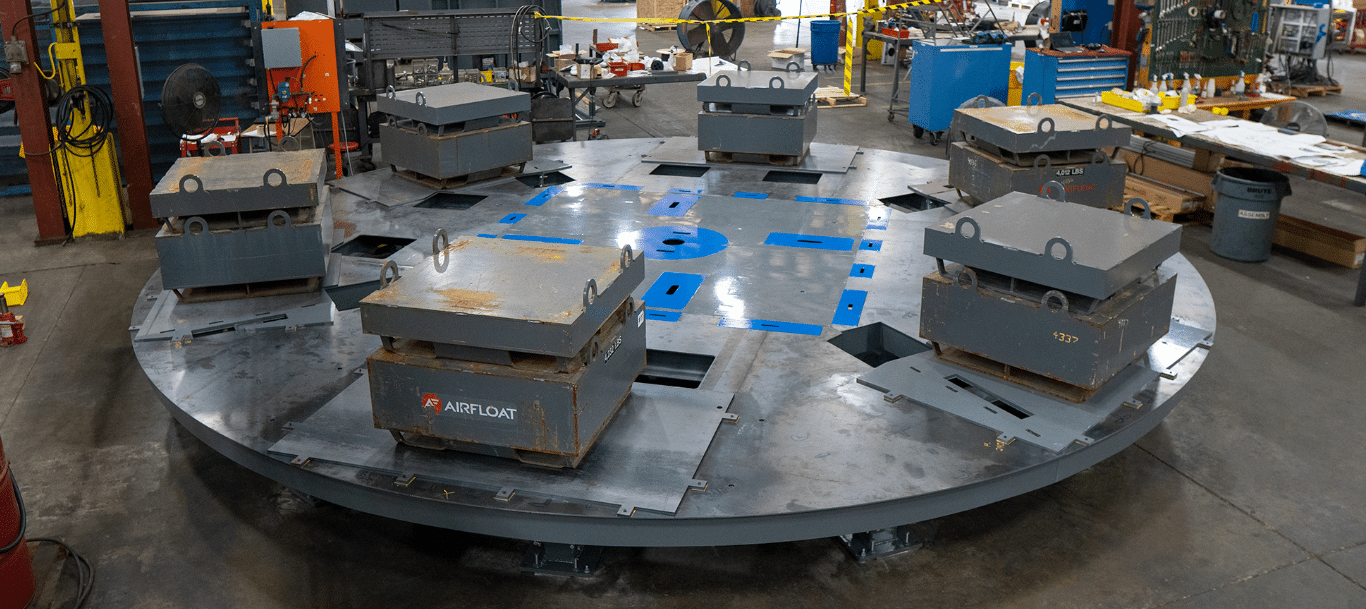

#9 Heavy Duty Mechanical Turntables

Domain Est. 2013

Website: alignproductionsystems.com

Key Highlights: Our Heavy Duty line of Mechanical Turntables are our highest capacity turntables, reaching upwards of 150,000 lbs. and beyond. The turntables are useful for ……

Expert Sourcing Insights for Heavy Duty Turntable

H2: Projected Market Trends for Heavy Duty Turntables in 2026

The global market for heavy duty turntables is poised for significant transformation by 2026, driven by advancements in automation, increased industrial digitization, and rising demand across key sectors such as manufacturing, logistics, and material handling. Below are the major trends expected to shape the heavy duty turntable landscape in 2026:

-

Growing Adoption in Automated Material Handling Systems

The integration of heavy duty turntables into automated guided vehicle (AGV) systems and automated storage and retrieval systems (AS/RS) is accelerating. As industries prioritize efficiency and labor cost reduction, turntables are being increasingly used to enable seamless directional changes in conveyor and robotic workflows. This trend is especially prominent in e-commerce fulfillment centers and automotive assembly lines. -

Increased Demand for Customization and High Load Capacity

End users are demanding turntables capable of handling loads exceeding 50 tons, particularly in heavy industries like steel, aerospace, and shipbuilding. Customizable solutions—such as variable rotation speeds, precision indexing, and integration with IoT sensors—are becoming standard requirements, pushing manufacturers to offer modular and scalable designs. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific (especially India, Vietnam, and Indonesia) and the Middle East is fueling demand for robust material handling equipment. Infrastructure development, government initiatives to boost manufacturing (e.g., “Make in India”), and growth in cold chain logistics are key drivers for heavy duty turntable deployment in these regions. -

Integration with Industry 4.0 and Smart Manufacturing

By 2026, smart turntables equipped with condition monitoring, predictive maintenance capabilities, and real-time performance tracking via IoT platforms will dominate the market. These intelligent systems allow for remote diagnostics, reduced downtime, and improved overall equipment effectiveness (OEE), aligning with broader Industry 4.0 objectives. -

Sustainability and Energy Efficiency Focus

Manufacturers are shifting toward energy-efficient motors, regenerative braking systems, and eco-friendly materials in turntable construction. Regulatory pressures and corporate sustainability goals are prompting demand for greener solutions, particularly in Europe and North America. -

Consolidation and Technological Innovation Among Suppliers

The competitive landscape is expected to see increased mergers and partnerships as companies seek to expand their technological capabilities. Innovations such as magnetic drive systems, contactless power transmission, and AI-driven motion control are setting new benchmarks in reliability and performance. -

Impact of Supply Chain Resilience Strategies

Post-pandemic supply chain reconfiguration is leading companies to invest in resilient, flexible production systems. Heavy duty turntables, as critical components in adaptable manufacturing layouts, are benefiting from this shift, especially in hybrid production environments that support rapid retooling.

In conclusion, the 2026 heavy duty turntable market will be defined by technological sophistication, regional expansion, and alignment with smart and sustainable industrial practices. Companies that invest in innovation, customization, and digital integration will be best positioned to capture growing market opportunities.

Common Pitfalls When Sourcing Heavy Duty Turntables (Quality & IP)

Sourcing heavy-duty turntables requires careful attention to both mechanical quality and intellectual property (IP) considerations. Overlooking these aspects can lead to operational failures, safety hazards, legal disputes, and financial losses. Here are key pitfalls to avoid:

Inadequate Load and Duty Cycle Assessment

Selecting a turntable based solely on static load capacity without considering dynamic loads, impact forces, or continuous operation requirements can result in premature wear or catastrophic failure. Always verify the manufacturer’s specifications for peak load, rotational inertia, and duty cycle (e.g., continuous vs. intermittent use) to ensure compatibility with your application.

Poor Material and Construction Quality

Low-quality materials such as substandard steel, inadequate bearing systems, or weak welds compromise durability. Ensure the turntable uses hardened steel races, precision-ground surfaces, and high-grade bearings (e.g., roller or slewing bearings). Inspect for proper surface treatments like galvanization or powder coating to prevent corrosion, especially in harsh environments.

Misunderstanding IP Rights and Design Infringement

Using designs, mechanisms, or patented technologies (e.g., specific bearing arrangements, drive systems, or locking mechanisms) without proper licensing can expose your business to legal action. Conduct thorough IP due diligence—review patent databases and consult legal experts—to confirm that the turntable design does not infringe on existing patents, particularly for innovative features.

Overlooking Customization and Reverse Engineering Risks

While custom turntables offer tailored solutions, replicating a competitor’s patented design—even with minor modifications—can constitute IP infringement. Avoid reverse engineering protected products. Instead, work with reputable manufacturers who can provide original, certified designs and documentation proving IP compliance.

Insufficient Environmental and IP Rating Verification

Heavy-duty turntables used in washdown, outdoor, or explosive environments require appropriate Ingress Protection (IP) ratings (e.g., IP65, IP67). Falsified or unverified IP claims are common. Request third-party test reports and certification documents to confirm the turntable’s resistance to dust, moisture, and other contaminants.

Lack of Traceability and Certification

Procuring from suppliers who cannot provide material test reports (MTRs), quality certifications (e.g., ISO 9001), or design validation data increases the risk of receiving subpar or non-compliant products. Ensure full traceability of components and adherence to industry standards (e.g., FEM, CMAA) to guarantee reliability and safety.

Choosing Suppliers Without IP Integrity

Some manufacturers may offer “copycat” versions of well-known turntables at lower prices, but these often violate IP rights and lack performance guarantees. Partner with suppliers who respect IP, offer transparent design ownership, and provide warranties—this reduces legal risk and ensures long-term support and spare parts availability.

Logistics & Compliance Guide for Heavy Duty Turntable

This guide provides essential information for the safe, efficient, and compliant handling, transportation, and operation of Heavy Duty Turntables. Adhering to these guidelines ensures regulatory compliance, minimizes risks, and extends equipment life.

Shipping and Handling

Ensure the Heavy Duty Turntable is securely packaged and protected during transit to prevent damage. Use appropriate lifting equipment rated for the unit’s weight, attaching slings to designated lift points only. Never lift by the turntable platform, drive mechanism, or control panel. Confirm the receiving location is prepared with adequate space, floor strength, and access for unloading. Inspect the unit immediately upon arrival for any shipping damage and document with photos if necessary.

Weight and Load Capacity Compliance

Verify that the turntable’s rated load capacity (static and dynamic) aligns with the intended application. Never exceed the manufacturer-specified maximum load. Ensure the transporting vehicle, handling equipment, and installation site flooring can support the combined weight of the turntable and maximum load. Non-compliance may result in structural failure, safety hazards, and voided warranties.

Transportation Regulations

When transporting the turntable by road, ensure compliance with local and international weight, dimension, and securing requirements (e.g., FMCSA in the U.S., ADR in Europe). Securely fasten the unit to the transport vehicle using rated tie-downs to prevent shifting. For oversized loads, obtain necessary permits and use appropriate signage. Air and sea freight must adhere to IATA and IMDG regulations respectively, including proper documentation and packaging.

Installation Site Requirements

Install the turntable on a level, stable, and structurally sound surface capable of bearing the load. Maintain required clearances around the unit for safe operation and maintenance access. Ensure proper drainage if installed outdoors. Verify electrical supply meets voltage, phase, and grounding specifications. Follow all local building and safety codes during installation.

Electrical and Operational Safety Standards

The turntable must comply with applicable electrical safety standards such as NEC (NFPA 70), IEC 60204-1, or local equivalents. Use only certified components and grounding methods. Emergency stop functions, guarding, and warning labels must be operational and clearly visible. Regularly inspect wiring, motors, and control systems for wear or damage.

Regulatory Certifications and Documentation

Ensure the Heavy Duty Turntable carries required certifications (e.g., CE, UKCA, UL, CSA) based on the region of operation. Retain all compliance documentation, including test reports, conformity declarations, and installation manuals. Provide operators with training and access to safety instructions in the local language.

Maintenance and Inspection Compliance

Follow the manufacturer’s recommended maintenance schedule to ensure continued compliance and safe operation. Document all inspections, repairs, and component replacements. Periodic load testing and safety checks may be required by local regulations or industry standards (e.g., OSHA, ISO). Retain records for audit and compliance verification.

Environmental and Disposal Regulations

Dispose of worn or obsolete turntable components in accordance with local environmental regulations, particularly for oils, greases, and electrical parts. Recycle metal components where possible. Minimize noise and vibration impact in sensitive environments, adhering to local noise ordinances.

In conclusion, sourcing a heavy-duty turntable requires careful consideration of load capacity, rotational mechanism, material construction, environmental conditions, and long-term maintenance needs. It is essential to select a supplier that offers reliable engineering support, proven product quality, and compliance with industry standards to ensure durability and optimal performance. By prioritizing factors such as customization potential, lead times, and total cost of ownership, businesses can secure a turntable solution that enhances operational efficiency, supports workflow automation, and delivers lasting value. Conducting thorough due diligence and comparing multiple vendors will ultimately lead to a successful procurement decision tailored to specific application requirements.