The global heavy-duty shackle market is experiencing steady growth, driven by increasing demand across industries such as marine, construction, oil & gas, and material handling. According to a report by Mordor Intelligence, the global lifting and rigging equipment market—of which shackles are a critical component—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This growth is fueled by rising infrastructure development, offshore exploration activities, and stringent safety regulations mandating the use of high-load-rated hardware. With safety and reliability at the forefront, heavy-duty shackles made from forged steel and rated to rigorous international standards (such as ASME B30.26 and ISO 13889) have become indispensable in critical lifting operations. As demand climbs, a handful of manufacturers have distinguished themselves through innovation, quality control, and global supply chain scalability. Based on production capacity, compliance certifications, and market presence, here are the top 9 heavy-duty shackle manufacturers shaping the industry today.

Top 9 Heavy Duty Shackle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heavy Duty Lifting Shackles and Rigging Shackles

Domain Est. 2021

Website: murphylift.com

Key Highlights: Murphy Industrial Products, Inc., carries a full line of rigging shackles including alloy shackles, galvanized shackles & stainless steel shackles….

#2 B/A Products Co. Heavy

Domain Est. 1997

Website: baprod.com

Key Highlights: Made from forged alloy steel with a solid alloy pin, the shackles are designed for quick locking and unlocking action, which means less time spent in the “ ……

#3 Screw Pin Shackles

Domain Est. 2009

Website: hhilifting.com

Key Highlights: 2–5 day delivery 10-day returnsWe carry shackles from trusted manufacturers like Green Pin, Crosby, and Yoke. With a selection of over 200 products, our screw pin shackles are avai…

#4 Kito Crosby

Domain Est. 2022

Website: kitocrosby.com

Key Highlights: Heavy-duty shackle and hook against dark industrial background, showcasing robust construction and design … Highly flexible, tailor-made aluminum crane systems ……

#5 Rigging and Lifting

Domain Est. 1995

Website: store.olsenchain.com

Key Highlights: 30-day returnsCM Screw Pin Anchor Shackle (Made In USA). CM Super Strong Shackles are carbon-type shackles with strength ratings that are 17 to 50% stronger than comparable- …Mis…

#6 CM Lifting Shackles Made in USA

Domain Est. 1997

Website: cmco.com

Key Highlights: When it comes to shackles, Columbus McKinnon prides itself on providing the strongest and most reliable products on the market. Made in Chattanooga, TN….

#7 Shackles

Domain Est. 2004

Website: gmesupply.com

Key Highlights: Free delivery over $75 · 30-day returnsOur selection of shackles includes a variety of sizes and metal treatments so you can get the perfect shackle for your lifting and rigging s…

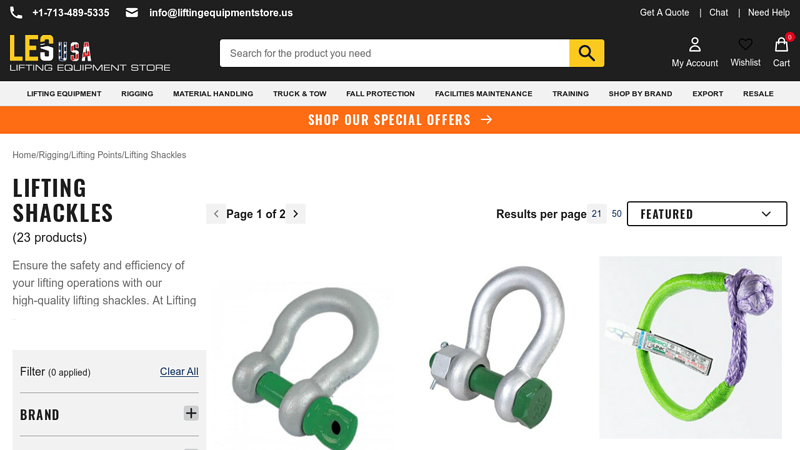

#8 Lifting Shackles

Domain Est. 2018

Website: liftingequipmentstore.us

Key Highlights: $26.50 delivery · 10-day returnsWe offer a wide range of heavy-duty shackles designed to handle even the most demanding loads. Our shackles are crafted from premium materials and …

#9 Heavy shackles for highest loads

Website: anker.de

Key Highlights: ASDO heavy-duty shackles are made with only the best quality materials, including high-grade and alloy steel, to resist wear and extreme weather conditions….

Expert Sourcing Insights for Heavy Duty Shackle

H2: 2026 Market Trends for Heavy Duty Shackles

The global heavy duty shackle market is poised for steady growth and transformation by 2026, driven by increasing infrastructure development, offshore energy expansion, and advancements in material engineering. As critical rigging and lifting components used across industries such as construction, marine, oil & gas, and renewable energy, heavy duty shackles are adapting to evolving safety standards, digitalization, and sustainability demands.

-

Rising Demand from Infrastructure and Energy Sectors

The surge in public and private infrastructure investments—especially in emerging economies—will bolster demand for reliable lifting and rigging equipment. Additionally, the offshore wind energy sector is expected to be a key growth driver, requiring high-capacity shackles for turbine installation and maintenance. By 2026, the integration of shackles in renewable energy projects is projected to increase at a compound annual growth rate (CAGR) exceeding 6%, outpacing traditional oil and gas applications in some regions. -

Material Innovation and Lightweighting

Manufacturers are increasingly adopting high-tensile alloy steels and corrosion-resistant coatings to enhance shackle durability and load capacity. Innovations such as quenched and tempered (Q&T) steel components offer improved strength-to-weight ratios, enabling lighter yet stronger shackles. By 2026, expect broader adoption of advanced materials like duplex stainless steel and composite-reinforced designs, particularly for marine and subsea applications where corrosion resistance is critical. -

Emphasis on Safety and Smart Monitoring

Regulatory bodies and industry standards (e.g., ASME, WLL certifications, CE marking) are tightening safety requirements. In response, leading vendors are incorporating smart technologies into shackles—such as embedded load sensors and RFID tagging—for real-time monitoring of stress, usage cycles, and wear. By 2026, IoT-enabled “smart shackles” are anticipated to gain traction, especially in high-risk industrial environments, improving operational safety and predictive maintenance. -

Regional Market Shifts

Asia-Pacific will remain the dominant market, driven by rapid urbanization in India, Southeast Asia, and China. North America and Europe will see steady growth due to aging infrastructure rehabilitation and offshore wind farm development. Meanwhile, the Middle East and Africa are expected to witness increased demand from oil and gas and port expansion projects. -

Sustainability and Circular Economy

With growing environmental scrutiny, manufacturers are focusing on recyclable materials and energy-efficient production processes. By 2026, product lifecycle assessments and end-of-life recovery programs may become standard, aligning with ESG (Environmental, Social, and Governance) goals across supply chains.

In conclusion, the 2026 heavy duty shackle market will be shaped by technological innovation, regulatory evolution, and shifting end-user demands. Companies that invest in R&D, digital integration, and sustainable practices are likely to gain competitive advantage in this maturing yet dynamic sector.

Common Pitfalls When Sourcing Heavy Duty Shackles (Quality & Intellectual Property)

Sourcing heavy duty shackles involves significant risks if due diligence is not performed, particularly concerning product quality and intellectual property (IP) compliance. Overlooking these aspects can lead to safety hazards, project delays, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Inadequate Quality Assurance and Certification

One of the most critical mistakes is failing to verify the quality and certifications of heavy duty shackles. Low-quality or counterfeit products may not meet load-bearing requirements, leading to catastrophic failures under stress.

- Missing or Fake Certifications: Many suppliers provide forged or invalid certifications (e.g., CE, ISO, ASME, or DNV-GL). Always request certified mill test reports (MTRs) and third-party inspection documents.

- Incorrect Material Specifications: Some shackles may be made from substandard alloys or improperly heat-treated steel, reducing strength and durability. Ensure compliance with ASTM, EN, or other relevant material standards.

- Inconsistent Manufacturing Processes: Poor welding, surface finishing, or dimensional inaccuracies can compromise performance. Audit manufacturing facilities or use independent inspection services.

Ignoring Intellectual Property Rights

Using or sourcing shackles that infringe on patented designs or registered trademarks exposes buyers to legal liability and supply chain disruptions.

- Counterfeit or Knockoff Brands: Some suppliers offer “compatible” or “generic” versions of well-known branded shackles (e.g., Crosby, Gunnebo, or Slingmax), which may violate design patents or trademarks.

- Unlicensed Manufacturing: Factories may produce shackles using proprietary designs without authorization. Purchasing such products—even unknowingly—can lead to IP infringement claims.

- Lack of IP Due Diligence: Buyers often neglect to verify whether the supplier holds proper rights or licenses to manufacture and sell the product, especially when sourcing from low-cost regions.

Overlooking Traceability and Documentation

Proper traceability is essential for quality control and compliance, particularly in regulated industries like oil & gas, maritime, and construction.

- Poor Batch or Heat Traceability: Without clear markings and documentation linking a shackle to its material batch and manufacturing history, it’s impossible to verify authenticity or initiate recalls if needed.

- Incomplete or Missing Documentation: Lack of test reports, certificates of conformity, or user instructions increases risk and may fail safety audits.

Choosing Suppliers Based Solely on Price

Prioritizing low cost over quality and compliance often leads to long-term costs from equipment failure, downtime, or legal action.

- Hidden Costs of Failure: A cheaper shackle that fails in-service can result in injury, environmental damage, or project shutdowns—far exceeding initial savings.

- Unreliable Supply Chain Partners: Low-priced suppliers may lack quality systems, R&D investment, or ethical manufacturing practices, increasing risk exposure.

Failure to Audit or Verify Supplier Credentials

Relying solely on supplier claims without independent verification is a common oversight.

- No Onsite Audits or Third-Party Inspections: Without visiting manufacturing sites or hiring inspectors, it’s difficult to validate production standards and IP compliance.

- Unverified Claims of OEM Partnerships: Some suppliers falsely claim to be original equipment manufacturers (OEMs) or authorized distributors. Always verify through official channels.

Avoiding these pitfalls requires a proactive sourcing strategy that emphasizes certification validation, IP compliance checks, supplier audits, and lifecycle cost analysis over upfront price. Engaging with reputable suppliers and legal experts can mitigate risks and ensure safe, compliant operations.

Logistics & Compliance Guide for Heavy Duty Shackle

Product Overview

A Heavy Duty Shackle is a robust coupling or lifting device typically made from forged steel, designed to connect rigging components under high load conditions. Commonly used in lifting, towing, marine, and construction applications, these shackles must adhere to rigorous safety and compliance standards.

Regulatory Standards & Certifications

Heavy Duty Shackles must comply with recognized international and regional standards to ensure safety and performance. Key certifications include:

– ASME B30.26 – Safety standard for below-the-hook lifting devices (U.S.)

– EN 13889 – European standard for shackles used in lifting equipment

– ISO 2415 – International standard specifying dimensions and performance

– CE Marking – Required for sale in the European Economic Area (EEA)

– UKCA Marking – Required for sale in the United Kingdom (post-Brexit)

– OSHA Compliance – Mandatory in U.S. workplaces for lifting equipment safety

Manufacturers must provide a Certificate of Conformity (CoC) or Material Test Report (MTR) with each batch, verifying compliance and material traceability.

Marking & Identification

Each Heavy Duty Shackle must be permanently marked with the following:

– Manufacturer’s name or trademark

– Working Load Limit (WLL)

– Size or model number

– Compliance standard (e.g., “EN 13889”)

– Serial or batch number (for traceability)

Ensure markings are legible and not compromised during use or transport.

Packaging & Handling

Proper packaging prevents damage and ensures safe transport:

– Shackles should be individually wrapped or bundled to prevent surface abrasion.

– Use protective caps on threaded pins (if applicable).

– Pack in strong, moisture-resistant containers or wooden crates for bulk shipments.

– Clearly label packages with “Fragile,” “This Side Up,” and “Heavy Lifting Equipment.”

Handle with care using appropriate lifting gear; avoid dropping or impact loading.

Storage Conditions

Store Heavy Duty Shackles in a dry, well-ventilated environment to prevent rust and corrosion:

– Keep off the ground using pallets or shelves.

– Avoid exposure to saltwater, chemicals, or extreme temperatures.

– Inspect periodically for signs of corrosion, deformation, or wear.

Keep shackles organized by size and type to prevent cross-contamination or misuse.

Transportation Requirements

When shipping Heavy Duty Shackles:

– Use secure, non-damaging restraints in containers or trucks.

– Prevent shifting during transit to avoid impact damage.

– For international shipments, comply with IMDG Code (if transported by sea) and IATA Dangerous Goods Regulations (only if packaged with other hazardous materials).

– Include proper shipping documentation: commercial invoice, packing list, CoC, and safety data sheet (SDS) if applicable.

Import & Export Compliance

Ensure compliance with destination country regulations:

– Verify tariff classification (HS Code typically 7326.90 for forged iron or steel articles).

– Provide accurate Export Declarations and obtain necessary Export Licenses (if required).

– Comply with EAR (Export Administration Regulations) or ITAR (if military-grade or dual-use).

– For the EU, complete a Customs Declaration and provide CE documentation.

– For the U.S., ensure adherence to Customs and Border Protection (CBP) requirements.

Inspection & Maintenance

Before and after each use, inspect shackles for:

– Cracks, deformation, or wear on the body and pin.

– Corrosion or pitting that may compromise strength.

– Proper pin fit and securing mechanism (e.g., cotter pins, threaded collars).

Retire shackles immediately if any defect is found. Follow manufacturer’s maintenance guidelines and conduct periodic load testing as needed.

Safety & Training

Only trained personnel should handle and use Heavy Duty Shackles. Training must cover:

– Correct selection based on load and application.

– Proper rigging techniques and angle load considerations.

– Recognition of damaged or unsafe equipment.

– Emergency procedures in case of failure.

Enforce a strict safety protocol in accordance with OSHA, HSE (UK), or local regulations.

Disposal & Recycling

At end-of-life:

– Do not reuse damaged or expired shackles.

– Recycle through certified metal recycling facilities.

– Follow local environmental regulations for scrap metal disposal.

– Maintain records of disposal for compliance audits.

Documentation & Recordkeeping

Maintain comprehensive records including:

– Certificates of Conformity and Material Test Reports

– Inspection logs and maintenance records

– Shipping and customs documentation

– Training records for personnel

Retention period: Minimum 5 years, or as required by local regulations.

In conclusion, sourcing heavy-duty shackles requires careful consideration of quality, material specifications, load capacity, safety standards, and supplier reliability. It is essential to prioritize certified products that comply with recognized international standards such as ASME, WLL (Working Load Limit), and CE marking to ensure safety and performance in demanding applications. Evaluating suppliers based on reputation, traceability, testing reports, and after-sales support helps mitigate risks associated with equipment failure. Additionally, considering environmental factors and application-specific requirements—such as marine, construction, or lifting operations—ensures optimal selection. Ultimately, investing time and due diligence in sourcing the right heavy-duty shackles contributes to operational safety, efficiency, and long-term cost savings.