The global personal protective equipment (PPE) market has seen robust growth, driven by increasing safety regulations and rising industrial automation. According to Grand View Research, the global gloves market size was valued at USD 9.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030, fueled by demand in construction, manufacturing, and oil & gas sectors. Mordor Intelligence further highlights that the growing emphasis on worker safety, particularly in emerging economies, is accelerating the adoption of high-performance gloves, with heavy-duty leather variants remaining a preferred choice due to their durability, abrasion resistance, and thermal protection. As industries prioritize hand safety, manufacturers specializing in premium leather gloves are expanding their production capabilities and investing in ergonomic innovation. This growing market momentum underscores the importance of identifying leading suppliers who deliver both quality and compliance. Below are the top 8 heavy-duty leather glove manufacturers shaping the PPE landscape worldwide.

Top 8 Heavy Duty Leather Gloves Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ironclad® Protective Work Gloves

Domain Est. 1996

#2 Mechanix Wear

Domain Est. 1997

Website: mechanix.com

Key Highlights: Mechanix Wear uses technology to bring you the best in all work, safety, and tactical gloves. Whether that is the durability of Durahide leather gloves; ……

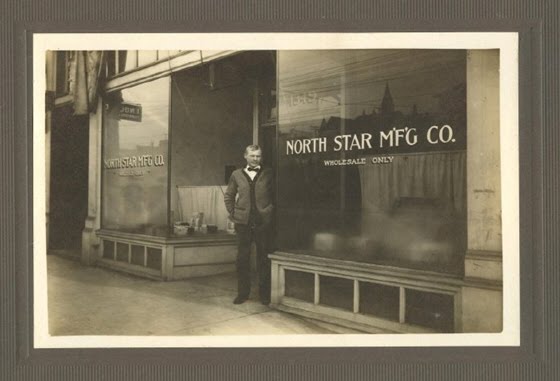

#3 North Star Glove

Domain Est. 1999

Website: northstarglove.com

Key Highlights: Discover our premium leather gloves—crafted in Tacoma, WA, and sourced globally for unmatched durability, comfort, and protection. Perfect for workers and ……

#4 John Tillman Co.

Domain Est. 1999

Website: jtillman.com

Key Highlights: Tillman 1940 Premium Top Grain Goatskin MIG & Metalworking Glove, Tillman 1408 Performance Top Grain Cowhide Drivers Glove….

#5 High-Performance Arm & Hand Protection

Domain Est. 2003

Website: mcrsafety.com

Key Highlights: MCR Safety’s Arm and Hand Protection category provides an extensive range of gloves and sleeves designed to safeguard workers across various industries….

#6 Leather palm gloves built for rugged, heavy

Domain Est. 2013

Website: us.pipglobal.com

Key Highlights: Leather Palm Gloves utilize various grades of Cowhide Leather to deliverabrasion resistance, heat dissipation, shock absorption and ……

#7 Bear Knuckles: Pre

Domain Est. 2017

Website: buybearknuckles.com

Key Highlights: Free delivery over $39 30-day returnsWe Provide Leather Work, Winter, Welding & Safety Gloves Using A Patented Design That Is Built For The Natural Curve Of Your Fingers….

#8 Hestra Pro Gloves

Website: hestrapro.us

Key Highlights: Heavy-duty, highly water-resistant full goatskin leather winter work glove for use in cold and wet environments. That leather has been waterproofed, but without ……

Expert Sourcing Insights for Heavy Duty Leather Gloves

H2: 2026 Market Trends for Heavy Duty Leather Gloves

The global market for heavy-duty leather gloves is poised for steady growth through 2026, driven by increasing industrial safety regulations, rising demand from key end-use sectors, and advancements in glove technology. Several key trends are expected to shape the industry landscape in the coming years.

1. Rising Industrial Safety Regulations and Compliance Standards

Governments and regulatory bodies worldwide are strengthening occupational health and safety norms, particularly in industries such as construction, manufacturing, oil & gas, and mining. Stricter enforcement of personal protective equipment (PPE) mandates is compelling employers to provide high-quality, certified protective gear, including heavy-duty leather gloves. This regulatory push is a major driver of market expansion through 2026.

2. Growth in Construction and Manufacturing Sectors

The continued global investment in infrastructure development—especially in emerging economies across Asia-Pacific, Latin America, and Africa—is fueling demand for durable hand protection. Expansion in manufacturing activities, including automotive and heavy machinery production, further amplifies the need for gloves that offer cut, abrasion, and heat resistance. Leather, known for its durability and natural protective qualities, remains a preferred material in these high-risk environments.

3. Technological Advancements and Hybrid Material Integration

While traditional full-grain leather gloves remain popular, manufacturers are increasingly integrating synthetic materials (e.g., Kevlar, Dyneema, and nitrile coatings) to enhance performance. These hybrid gloves offer improved dexterity, grip, and resistance to chemicals and heat while maintaining the ruggedness of leather. By 2026, smart gloves with embedded sensors for monitoring hand fatigue or environmental exposure may begin to enter niche industrial markets.

4. Sustainability and Ethical Sourcing Concerns

Environmental and ethical concerns surrounding leather production are influencing product development. Leading brands are responding by adopting responsibly sourced leather, pursuing eco-certifications, and offering transparent supply chains. Some are exploring bio-based or lab-grown leather alternatives as part of long-term sustainability strategies, though traditional leather is expected to dominate the heavy-duty segment due to performance requirements.

5. E-Commerce and Direct-to-Consumer Growth

Online distribution channels are transforming how heavy-duty gloves are sold. Industrial suppliers and brands are investing in e-commerce platforms and digital procurement solutions, enabling easier access for small businesses and individual buyers. Customization options, bulk ordering, and digital safety compliance tools are enhancing the online purchasing experience.

6. Regional Market Dynamics

The Asia-Pacific region is projected to lead market growth by 2026, supported by rapid industrialization, a large workforce in manufacturing and construction, and increasing safety awareness in countries like India and Vietnam. North America and Europe will maintain strong demand due to stringent safety regulations and high replacement rates in mature industrial sectors.

In conclusion, the heavy-duty leather gloves market in 2026 will be shaped by a confluence of regulatory, technological, and economic factors. Continued innovation, compliance adherence, and sustainability initiatives will differentiate market leaders and drive long-term growth.

Common Pitfalls When Sourcing Heavy Duty Leather Gloves

Sourcing heavy duty leather gloves requires careful attention to quality and intellectual property (IP) considerations. Overlooking key factors can lead to substandard products, compliance issues, supply chain disruptions, or legal risks. Below are the most common pitfalls to avoid.

Poor Material Quality and Misrepresentation

One of the most frequent issues is receiving gloves made from inferior leather or misrepresented materials. Suppliers may use corrected grain, split leather, or synthetic blends instead of full-grain or top-grain leather, significantly reducing durability and protection. Always verify the leather type through material certifications, lab testing, or on-site inspections. Be cautious of vague terms like “genuine leather,” which can include lower-quality options.

Inconsistent Craftsmanship and Construction

Inconsistent stitching, uneven leather thickness, or poorly attached liners can compromise glove performance and safety. Mass-produced gloves from unreliable manufacturers often suffer from inconsistent quality control. Request production samples, conduct pre-shipment inspections, and audit factories to ensure consistent craftsmanship across batches.

Lack of Compliance with Safety Standards

Heavy duty gloves must meet industry-specific safety standards (e.g., EN 388 for mechanical risks, ANSI/ISEA 138 for impact protection). Sourcing gloves without proper certification or with falsified test reports is a major risk. Always verify compliance documentation and, if necessary, conduct third-party testing to confirm performance claims.

Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers that replicate branded glove designs—such as those from Ansell, Honeywell, or Mechanix—exposes buyers to IP infringement. Even if the supplier claims the design is “inspired by,” copying patented features, logos, or unique structural elements can lead to legal action, seized shipments, and reputational damage. Conduct due diligence on designs and require suppliers to warrant they do not infringe on existing patents or trademarks.

Hidden Costs and Unclear MOQs

Suppliers may quote low prices but hide additional costs in tooling, packaging, or shipping. Minimum order quantities (MOQs) may also be misleading or inflexible, leading to overstocking or production delays. Clarify all cost components and negotiate MOQs upfront to ensure scalability and budget control.

Supply Chain and Lead Time Reliability

Unreliable lead times and poor communication from suppliers can disrupt operations, especially when gloves are needed for safety-critical environments. Assess supplier reliability through references, past performance, and clear contractual delivery terms. Consider dual sourcing or safety stock for critical applications.

By addressing these pitfalls proactively—through thorough vetting, quality assurance, IP checks, and clear contracts—buyers can source high-performing, compliant, and legally safe heavy duty leather gloves.

Logistics & Compliance Guide for Heavy Duty Leather Gloves

Product Classification & HS Code

Heavy duty leather gloves typically fall under specific Harmonized System (HS) codes for international trade. The most relevant classification is:

– HS Code: 4203.29 – Gloves, mittens, and mitts, of leather or composition leather (other than for sport or for domestic use).

This classification is critical for determining import duties, taxes, and customs clearance requirements in most countries. Confirm the exact code with local customs authorities, as sub-classifications may vary by destination.

Import/Export Regulations

- Country-Specific Restrictions: Verify if the importing country imposes restrictions on leather products, especially those derived from certain animal types (e.g., endangered species). CITES (Convention on International Trade in Endangered Species) compliance may be required if exotic leathers are used.

- Labeling Requirements: Ensure packaging and product labels comply with destination country regulations. This includes:

- Country of origin

- Material composition (e.g., 100% cowhide leather)

- Care instructions

- Size designation

- Safety certifications, if applicable (e.g., CE marking in the EU)

- Documentation: Prepare standard shipping documents such as commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Additional documentation may be required for customs clearance.

Safety & Compliance Standards

Heavy duty leather gloves may be subject to occupational safety regulations if marketed for industrial or protective use:

– EU (CE Marking): If gloves are intended for protection (e.g., against mechanical risks), compliance with EN 420 (general requirements) and EN 388 (mechanical risks) is mandatory. Testing and technical documentation must be maintained.

– USA (OSHA/ANSI): Gloves used in workplace settings should meet ANSI/ISEA 105 standards for hand protection. OSHA may require appropriate personal protective equipment (PPE) in certain industries.

– Other Regions: Check local PPE regulations in Canada (CSA), Australia (AS/NZS), or other markets.

Packaging & Shipping Requirements

- Packaging: Use durable packaging to prevent damage during transit. Individual polybagging or boxed units help maintain product integrity.

- Storage Conditions: Store in a dry, well-ventilated area away from direct sunlight and moisture to prevent mold or leather degradation.

- Shipping: Standard freight methods (air, sea, or ground) apply. Declare accurate weight and dimensions for freight calculation. Consider using pallets for bulk shipments to ensure stability.

Environmental & Ethical Compliance

- Leather Sourcing: Ensure leather is sourced responsibly. Compliance with REACH (EU regulation on chemicals) and Proposition 65 (California) may be required if chemical treatments (e.g., tanning agents) are used.

- Sustainability Claims: If marketing gloves as eco-friendly or sustainable, ensure claims are substantiated and compliant with FTC Green Guides or similar regulations.

Returns & Warranty Handling

- Return Logistics: Establish clear return policies, especially for international orders. Include return authorization processes and designate return centers if applicable.

- Warranty: Define warranty terms (e.g., material defects, workmanship) and communicate them clearly. Track warranty claims for quality control and compliance audits.

Record Keeping & Audits

Maintain detailed records of:

– Supplier certifications

– Test reports (for safety standards)

– Shipping and customs documentation

– Compliance audits

These records support regulatory compliance and facilitate audits by authorities or certification bodies.

Adhering to this guide ensures smooth logistics operations and regulatory compliance for the global trade of heavy duty leather gloves. Always consult with legal and customs experts for market-specific requirements.

In conclusion, sourcing heavy-duty leather gloves requires a strategic approach that balances quality, durability, cost, and supplier reliability. Prioritizing gloves made from premium materials such as full-grain or split-grain leather ensures enhanced protection and longevity, especially for demanding industrial applications. Evaluating suppliers based on certifications, manufacturing standards, and compliance with safety regulations (such as EN 420 and ANSI/ISEA) is essential to guarantee product performance and worker safety. Additionally, considering factors like glove design, comfort, and specific industry requirements—whether for construction, welding, or mechanical work—helps in selecting the most suitable product. Establishing long-term relationships with reputable suppliers, conducting regular quality audits, and staying informed about innovations in protective gear further support effective procurement. Ultimately, investing in high-quality heavy-duty leather gloves not only protects workers but also reduces long-term costs associated with injuries and frequent replacements, contributing to a safer and more efficient workplace.