The global engine stand market is experiencing steady growth, driven by rising demand from automotive repair and maintenance sectors, as well as increased industrial machinery servicing. According to a report by Mordor Intelligence, the global automotive lift market—which includes supporting equipment like engine stands—was valued at USD 1.86 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2028. Similarly, Grand View Research highlights expanding applications in commercial vehicle servicing and the growing emphasis on workshop safety and efficiency as key market drivers. With the manufacturing sector increasingly prioritizing durability, load capacity, and adaptability, heavy-duty engine stands have become essential workshop tools. This demand has given rise to a competitive landscape of manufacturers focused on innovation, load ratings (often exceeding 1,000 lbs), and structural robustness. In this context, the following six companies have emerged as leading heavy-duty engine stand manufacturers, distinguished by engineering excellence, global distribution, and strong market presence.

Top 6 Heavy Duty Engine Stand Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Rotators / Engine Stands

Domain Est. 2008

Website: longhornfabshop.com

Key Highlights: Free delivery 5-day returnsThe Adjustable Rotator | Raises and Lowers | Industrial Rotator | Rotisserie | Ultra Heavy Duty Engine Stand | 3500 ft-lbs of Torque | 201126….

#2 Manufacturers, Heavy Duty Rotating Engine Stand

Domain Est. 2015

Website: passca.com

Key Highlights: To choose the best heavy-duty engine stand for your professional uses, look no further than PASSCA’s tried and true equipment options….

#3 ES

Domain Est. 1998

Website: products.grayusa.com

Key Highlights: The heavy duty structure of the ES-6000 gives you a safe, durable and long lasting platform that can be paired with Gray Manufacturing’s universal engine ……

#4 Engine Stands, Automotive Lifting Tools

Domain Est. 2003

Website: imperialsupplies.com

Key Highlights: Free delivery over $400 365-day returns…

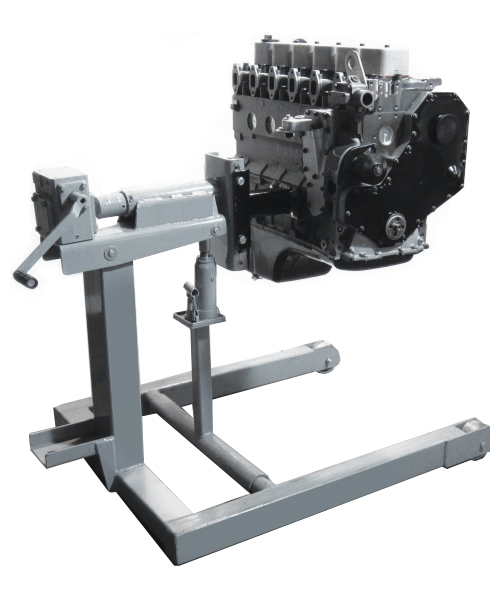

#5 Heavy Duty Rotating Engine Stand 2500 lb Capacity

Domain Est. 2003

Website: agkits.com

Key Highlights: In stock Free deliveryThis heavy duty engine stand can support up to 2500 lbs. The full rotation gearbox allows for a complete 360 degree rotation….

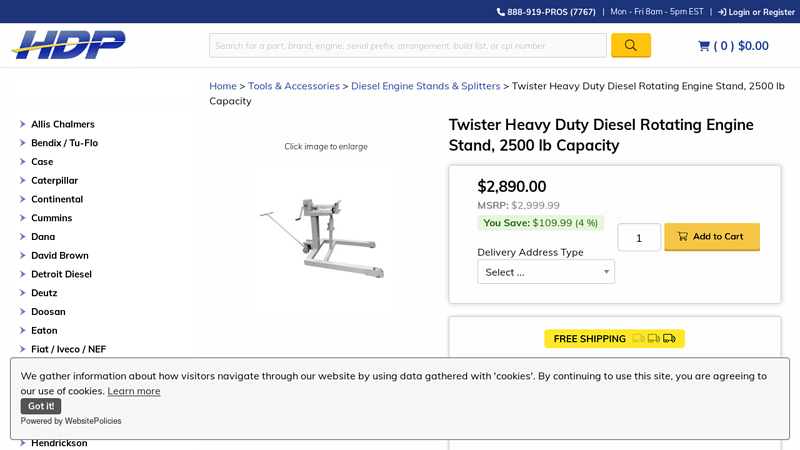

#6 Twister Heavy Duty Diesel Rotating Engine Stand, 2500 lb Capacity

Domain Est. 2019

Website: heavydutypros.com

Key Highlights: Our heavy duty Twister Engine Stand supports up to 2500 lbs and is ideal for medium to large sized engines. This engine stand also allows for smooth and ……

Expert Sourcing Insights for Heavy Duty Engine Stand

2026 Market Trends for Heavy Duty Engine Stands

The global market for heavy-duty engine stands is poised for steady evolution by 2026, driven by technological advancements, shifting industry demands, and a growing emphasis on efficiency and safety. Here are the key trends shaping the landscape:

1. Increasing Demand from Commercial Vehicle and Off-Highway Sectors:

The robust growth in global freight transportation, construction, mining, and agricultural activities continues to drive demand for heavy-duty trucks, buses, and off-road machinery. As these fleets age and require more frequent maintenance and overhauls, the need for reliable, high-capacity engine stands in service centers, fleet maintenance depots, and repair shops will rise significantly by 2026.

2. Focus on Ergonomics and Operator Safety:

Workplace safety regulations are becoming more stringent worldwide. In response, manufacturers are prioritizing ergonomic designs in heavy-duty engine stands—featuring smoother height adjustment mechanisms, enhanced locking systems, improved stability, and anti-slip platforms. Stands with 360-degree rotation, adjustable arms, and integrated safety locks will gain favor to reduce technician fatigue and prevent accidents during engine handling.

3. Adoption of Advanced Materials and Lightweight Design:

While maintaining high weight capacities (often exceeding 2,000 lbs), there is a growing shift toward using high-strength steel alloys and optimized frame designs to reduce overall stand weight. This improves portability and ease of use in crowded workshops. Corrosion-resistant finishes will also become standard to enhance durability in harsh environments.

4. Rise of Smart and Modular Engine Stands:

By 2026, expect early adoption of “smart” features such as load sensors, digital leveling indicators, and compatibility with workshop management software in premium models. Additionally, modular designs that allow for quick reconfiguration to fit different engine types (e.g., V6, V8, inline-6) will appeal to multi-brand service centers seeking versatility and cost efficiency.

5. Growth in Aftermarket and Independent Repair Shops:

The expanding network of independent repair facilities—particularly in emerging markets—will drive demand for cost-effective yet durable heavy-duty engine stands. Affordable, reliable models with strong warranty support will see increased market penetration, encouraged by the rising cost of OEM maintenance.

6. Regional Market Expansion:

Asia-Pacific, particularly India and Southeast Asia, is expected to be a high-growth region due to industrialization, infrastructure development, and expanding logistics networks. North America and Europe will focus more on replacing aging equipment and upgrading to safer, compliant models in line with OSHA and CE regulations.

7. Sustainability and Longevity Focus:

With growing emphasis on sustainable practices, manufacturers are designing longer-lasting engine stands using recyclable materials and modular components that can be repaired rather than replaced. This reduces waste and total cost of ownership, appealing to environmentally conscious buyers.

In conclusion, the 2026 heavy-duty engine stand market will be characterized by innovation in safety, adaptability, and efficiency. Suppliers who invest in ergonomic design, smart features, and global distribution will be best positioned to capture growth across both developed and emerging markets.

Common Pitfalls When Sourcing Heavy Duty Engine Stands: Quality and Intellectual Property Risks

Sourcing heavy duty engine stands, especially from international or lower-cost suppliers, presents several risks related to both product quality and intellectual property (IP) protection. Overlooking these pitfalls can lead to safety hazards, operational inefficiencies, legal disputes, and reputational damage.

Poor Material and Construction Quality

One of the most critical risks is receiving engine stands made from substandard materials or with poor workmanship. Low-quality steel, inadequate welding, or imprecise machining can compromise structural integrity, leading to catastrophic failures when supporting heavy engines. Buyers may encounter stands with incorrect load ratings, insufficient thickness in critical components, or weak pivot mechanisms. These defects not only endanger technicians but also result in costly downtime and liability issues.

Misrepresentation of Load Capacity and Specifications

Suppliers may exaggerate load ratings or provide inaccurate technical specifications to win contracts. A stand advertised as supporting 2,000 lbs might be structurally incapable of safely handling that weight, especially under dynamic loads or off-center positioning. Misleading specifications often stem from non-compliance with recognized industry standards (e.g., ANSI, OSHA, or ISO), increasing the risk of accidents and voiding insurance coverage.

Lack of Compliance with Safety and Industry Standards

Many low-cost suppliers fail to adhere to mandatory safety regulations or international quality standards. Engine stands that lack proper certifications (such as CE marking or UL listing) may not have undergone necessary stress testing or safety evaluations. Sourcing non-compliant equipment exposes businesses to regulatory penalties, workplace safety violations, and potential legal action in the event of an incident.

Intellectual Property Infringement

A significant but often overlooked risk is the potential for IP violations. Some manufacturers produce engine stands that closely mimic patented designs or branded products without authorization. Sourcing such knock-off products—whether knowingly or unknowingly—can expose the buyer to legal liability, including cease-and-desist orders, seizure of goods, or lawsuits for contributory infringement. This is particularly prevalent when purchasing from regions with weak IP enforcement.

Inadequate Documentation and Traceability

Reputable suppliers provide detailed manufacturing documentation, material certifications, and traceability records. However, many low-cost vendors offer little to no documentation, making it difficult to verify quality claims or investigate failures. The absence of clear records also complicates compliance with internal quality assurance programs and regulatory audits.

Counterfeit or Clone Products

Some suppliers market counterfeit versions of well-known engine stand models, replicating logos, branding, and design features. These clones often lack the rigorous testing and quality control of the original, posing safety risks and undermining trust in the supply chain. Buyers may unknowingly purchase these products through third-party distributors or online marketplaces.

Limited Warranty and After-Sales Support

Low-cost engine stands frequently come with inadequate or voidable warranties. When issues arise, buyers may find it difficult to obtain replacement parts, technical support, or repairs—especially if the supplier is located overseas. This lack of support increases total cost of ownership and disrupts maintenance operations.

Supply Chain Transparency and Ethical Concerns

Opaque supply chains may hide unethical labor practices, environmental violations, or use of conflict materials. Sourcing from suppliers without audited facilities can expose companies to reputational risk and non-compliance with corporate social responsibility (CSR) policies.

To mitigate these risks, buyers should conduct thorough due diligence, request product samples, verify certifications, audit suppliers, and consult legal counsel when necessary—especially when dealing with designs that may be protected by patents or trademarks.

Logistics & Compliance Guide for Heavy Duty Engine Stand

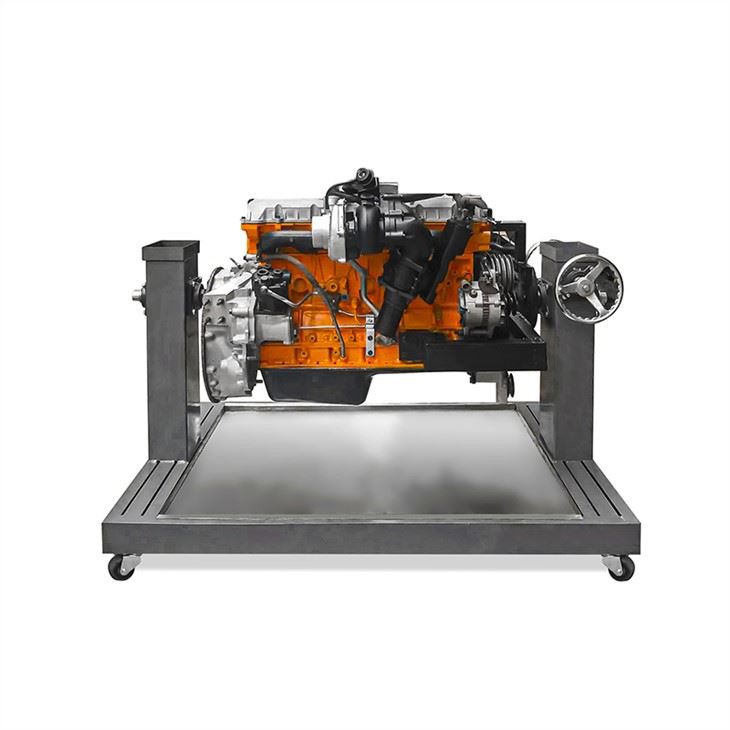

Product Description and Intended Use

The Heavy Duty Engine Stand is designed to securely support large internal combustion engines during maintenance, repair, and overhaul operations. Constructed from high-strength steel with a durable powder-coated finish, it features adjustable arms, a rotating base (typically 360°), and load capacities ranging from 750 to 2,000 lbs (340 to 907 kg), depending on model. This equipment is intended for industrial, automotive, and heavy machinery workshop environments.

Regulatory Compliance Standards

The Heavy Duty Engine Stand must conform to relevant safety and industrial equipment standards to ensure user protection and market legality. Key compliance standards include:

– OSHA 29 CFR 1910.23: Covers general requirements for walking-working surfaces and fall protection, indirectly applicable to equipment stability.

– ANSI/ISEA A12.1-2020: Standard for identification and labeling of safety equipment.

– ISO 9001: Quality management systems (if manufacturer is certified).

– CE Marking (for EU): Compliance with Machinery Directive 2006/42/EC, including essential health and safety requirements.

– UKCA Marking (for UK): Post-Brexit equivalent to CE marking.

– RoHS and REACH (EU/UK): Restrictions on hazardous substances in electrical and mechanical components (if applicable).

Packaging and Handling Requirements

Proper packaging ensures the engine stand arrives undamaged and ready for safe use:

– Units are shipped flat-packed or fully assembled, secured on standard 48” x 40” pallets.

– Components are protected with corner guards, bubble wrap, and corrugated cardboard.

– Weight of packaged unit: 120–200 lbs (54–91 kg), depending on model.

– Forklift or pallet jack access required for unloading; do not drag or drop.

– Store in a dry, indoor environment to prevent rust or coating damage prior to use.

Shipping and Transportation Guidelines

Transportation must maintain structural integrity and comply with freight regulations:

– Classify under HTS Code 8431.39.0090 (Parts for lifting/handling machinery).

– Use freight carriers experienced in handling industrial equipment.

– Secure load with straps to prevent shifting; do not stack other items on top.

– For international shipments, provide commercial invoice, packing list, and bill of lading.

– Lithium batteries (if included with optional accessories) must follow IATA/IMDG regulations for air/sea freight.

Import and Export Documentation

Ensure all required documentation is prepared to avoid customs delays:

– Commercial Invoice: Includes product description, value, country of origin, and buyer/seller details.

– Packing List: Specifies quantity, dimensions, weight, and packaging type.

– Certificate of Origin: Required for preferential tariff treatment under trade agreements.

– Bill of Lading (BOL): Issued by carrier for freight tracking and proof of shipment.

– Compliance Declaration: CE/UKCA Declaration of Conformity, if applicable.

– Export License: Not typically required, but verify based on destination country restrictions.

Installation and User Safety Compliance

Safe installation and operation are critical to prevent accidents:

– Assemble according to manufacturer instructions using provided hardware and tools.

– Place on level, non-slip surface; ensure area is clear of obstructions.

– Verify load capacity matches engine weight; never exceed maximum rating.

– Use locking mechanisms on rotating base during maintenance.

– Conduct routine inspections for weld cracks, bolt looseness, or wear.

– Train personnel in safe handling practices per OSHA 1910 Subpart N and internal safety protocols.

Environmental and Disposal Considerations

End-of-life management must follow environmental regulations:

– Steel components are recyclable; disassemble and separate materials.

– Powder coating and lubricants should be disposed of per local hazardous waste rules.

– Follow EPA and local regulations for industrial scrap metal disposal.

– Do not incinerate plastic or coated parts.

Warranty and Technical Support

Manufacturer typically provides:

– 1-year limited warranty against defects in materials and workmanship.

– Technical support via phone, email, or online portal for assembly and troubleshooting.

– Replacement parts available upon request; retain proof of purchase.

Revision History

- Version 1.0 – Initial release (Month, Year)

- Version 1.1 – Updated HTS code and added UKCA requirements (Month, Year)

Conclusion: Sourcing a Heavy-Duty Engine Stand

In conclusion, sourcing a heavy-duty engine stand requires careful consideration of load capacity, durability, adjustability, mobility, and safety features to ensure compatibility with the intended engines and workshop requirements. Prioritizing quality construction—such as robust steel frames, reliable locking mechanisms, and swivel casters—enhances both performance and long-term value. Whether purchasing new or considering used options, it is essential to evaluate supplier reputation, warranty offerings, and compliance with industry standards. Additionally, balancing initial cost with long-term reliability and safety contributes to an efficient and secure working environment. By aligning specifications with operational needs and sourcing from reputable suppliers, businesses and technicians can make a sound investment that supports precision, productivity, and safety in engine repair and maintenance operations.