The global door hardware market is experiencing robust growth, driven by rising construction activities, increasing urbanization, and growing demand for durable and aesthetically advanced building components. According to a report by Grand View Research, the global door hardware market size was valued at USD 25.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. Heavy duty door handles, in particular, are witnessing heightened demand in commercial, industrial, and high-traffic residential applications due to their superior strength, security, and longevity. With safety and accessibility standards becoming more stringent worldwide, manufacturers are innovating with materials like stainless steel, solid brass, and reinforced composites to meet performance requirements. As the market expands, a select group of manufacturers has emerged as leaders in engineering reliability and large-scale production—shaping the future of architectural hardware worldwide.

Top 10 Heavy Duty Door Handles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cal

Domain Est. 1997

Website: cal-royal.com

Key Highlights: For over 40 years Cal-Royal Products, Inc. has been a leading manufacturer of security door hardware, locksets, door closers, exit devices for residential, ……

#2 Industrial Door Hardware

Domain Est. 2002

Website: weilanddoors.com

Key Highlights: Weiland Doors offers commercial grade door hardware products made with high quality stainless steel. Learn more about our door hardware here….

#3 Adams Rite Products

Domain Est. 1996

Website: adamsrite.com

Key Highlights: Our door hardware solutions and accessories provide reliable solutions for narrow stile aluminum, hollow metal and wood door applications. Adams Rite ……

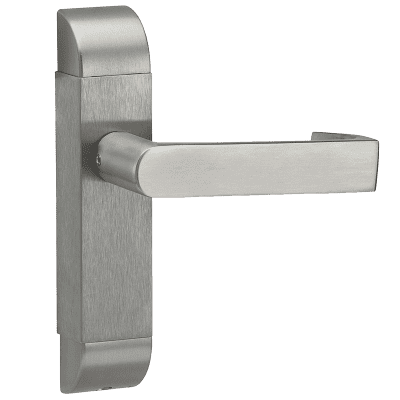

#4

Domain Est. 1998

Website: sargentlock.com

Key Highlights: SARGENT Manufacturing delivers trusted, high-performance door hardware built for today’s commercial and architectural demands….

#5 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#6 Tell Manufacturing

Domain Est. 1998

Website: tellmfg.com

Key Highlights: We produce high-quality, competitively priced commercial locksets, door closers, exit devices, hinges, trim hardware and commercial hollow metal doors….

#7 High-End Door Hardware

Domain Est. 1999

Website: rockymountainhardware.com

Key Highlights: Rocky Mountain Hardware’s selection of luxury door handles, luxury door knobs, and luxury door hardware including: door sets, door locks, and door accessories….

#8 Corbin Russwin:

Domain Est. 1999

Website: corbinrusswin.com

Key Highlights: Corbin Russwin provides high-quality, durable locking and door hardware solutions for commercial and institutional facilities….

#9 Brinks Commercial

Domain Est. 1999

Website: brinkslocks.com

Key Highlights: Brinks Commercial offers a full product line of high-quality door hardware fit for any commercial project. Select from light duty to heavy duty door closers….

#10 Top 10 Door Hardware Manufacturers in the USA

Domain Est. 2018

Website: aorbis.com

Key Highlights: Discover the top 10 door hardware manufacturers in the USA. Find trusted brands known for quality, innovation, and reliability….

Expert Sourcing Insights for Heavy Duty Door Handles

H2: 2026 Market Trends for Heavy Duty Door Handles

The global market for heavy-duty door handles is projected to experience significant transformation by 2026, driven by advancements in materials, rising demand in commercial and industrial sectors, and evolving architectural standards. Key trends shaping the industry include:

-

Growth in Construction and Infrastructure Development

Increased investments in infrastructure, healthcare facilities, educational institutions, and commercial real estate—particularly in emerging economies—are fueling demand for durable, long-lasting hardware. Heavy-duty door handles, known for their resilience in high-traffic environments, are becoming standard in public and institutional buildings. -

Shift Toward Sustainable and Corrosion-Resistant Materials

Manufacturers are increasingly adopting eco-friendly and durable materials such as recycled brass, stainless steel, and powder-coated zinc alloys. These materials offer enhanced resistance to wear, moisture, and corrosion—critical for exterior and high-moisture applications—while aligning with green building certifications like LEED and BREEAM. -

Integration of Smart Technology

The convergence of mechanical robustness with digital security is leading to the rise of smart heavy-duty handles with embedded access control systems (e.g., RFID, biometric scanners, and Bluetooth connectivity). These hybrid solutions are gaining traction in secure facilities such as data centers, hospitals, and government buildings. -

Focus on Accessibility and Universal Design

Regulatory requirements, including the Americans with Disabilities Act (ADA) and similar international standards, are pushing for ergonomic, easy-to-operate handles. Lever-style heavy-duty handles with low operational force are becoming preferred for compliance and inclusivity in public spaces. -

Regional Market Expansion

Asia-Pacific is expected to dominate market growth due to rapid urbanization and construction booms in countries like India, China, and Vietnam. Meanwhile, North America and Europe maintain steady demand, driven by retrofitting projects and stringent safety codes. -

Customization and Aesthetic Flexibility

Architects and designers are increasingly demanding heavy-duty handles that do not compromise on aesthetics. As a result, manufacturers are offering customizable finishes (brushed nickel, matte black, antique bronze) and contemporary designs that blend durability with visual appeal. -

Supply Chain Resilience and Localized Manufacturing

In response to post-pandemic disruptions, companies are shifting toward localized production and digital inventory management to reduce lead times and improve responsiveness. This trend enhances supply stability and supports just-in-time delivery models.

In summary, the 2026 heavy-duty door handle market will be defined by innovation in materials and technology, regulatory compliance, and sustainability. Stakeholders who adapt to these trends—particularly through smart integration and eco-conscious manufacturing—will be best positioned for long-term success.

Common Pitfalls When Sourcing Heavy Duty Door Handles (Quality & IP)

Sourcing heavy duty door handles requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Quality Materials and Construction

One of the most frequent issues is selecting handles made from substandard materials. Opting for low-grade metals (such as inferior zinc alloys or thin-walled stainless steel) can result in premature wear, corrosion, or breakage under heavy use. Always verify material specifications—look for handles made from solid brass, 304 or 316 stainless steel, or high-strength engineered polymers. Insist on third-party test reports for load capacity, cycle testing, and corrosion resistance.

Inadequate Ingress Protection (IP) Ratings

Heavy duty handles used in outdoor, industrial, or high-moisture environments require appropriate IP ratings to resist dust and water ingress. A common mistake is assuming all metal handles are weatherproof. Always confirm the IP rating (e.g., IP65 or higher for harsh environments) matches the intended application. Lack of proper sealing around fixings or internal mechanisms can compromise performance and longevity.

Ignoring Certifications and Compliance

Failing to verify compliance with regional building codes, fire safety regulations (e.g., panic hardware requirements), or accessibility standards (like ADA) can lead to failed inspections or liability. Ensure handles meet relevant standards such as ANSI, BS EN, or DIN, especially when sourcing from overseas suppliers unfamiliar with local regulations.

Overlooking Intellectual Property Risks

Sourcing from manufacturers that replicate patented or trademarked handle designs exposes buyers to legal risk. Unlicensed copies, especially from regions with weak IP enforcement, can result in customs seizures, lawsuits, or forced product recalls. Always conduct due diligence: request proof of design rights, review supplier portfolios for original designs, and include IP indemnity clauses in contracts.

Inconsistent Finish Durability

Aesthetic finishes like PVD (Physical Vapor Deposition), powder coating, or electroplating on heavy duty handles must withstand abrasion and chemicals. Cheap finishes may tarnish, chip, or corrode quickly in high-traffic areas. Request samples and perform adhesion and salt spray tests to evaluate finish longevity before bulk ordering.

Hidden Costs from Poor Supplier Verification

Choosing suppliers solely on price often leads to hidden costs from quality failures, shipping delays, or communication gaps. Verify supplier credentials, audit factories if possible, and conduct pre-shipment inspections. Lack of transparency in manufacturing processes increases the risk of receiving non-conforming products.

By proactively addressing these pitfalls—focusing on material integrity, correct IP ratings, regulatory compliance, and IP legitimacy—buyers can ensure reliable, durable, and legally sound sourcing of heavy duty door handles.

Logistics & Compliance Guide for Heavy Duty Door Handles

This guide outlines key logistical considerations and compliance requirements for the manufacturing, distribution, and installation of Heavy Duty Door Handles. Adhering to these standards ensures product safety, durability, and legal conformity across markets.

Product Specifications and Documentation

Maintain comprehensive technical documentation for all heavy duty door handle models, including detailed specifications such as material composition (e.g., stainless steel, brass, zinc alloy), load ratings, dimensions, finish types, and intended applications (e.g., commercial, industrial, fire-rated doors). Ensure all product labels and packaging include model numbers, compliance marks, and handling instructions. Documentation must be available in local languages for international shipments.

Regulatory Compliance Standards

Heavy duty door handles must comply with regional and international safety and performance standards. Key regulations include:

- EN 1906:2010 (Europe) – Specifies requirements for mechanical strength, operational durability, corrosion resistance, and safety for building hardware, including door handles.

- ANSI/BHMA A156.13 (North America) – Covers cycle testing, strength, and finish performance for door trim and related hardware.

- UKCA Marking (UK) – Required for products sold in the UK; compliance with BS EN standards typically fulfills these requirements.

- UL 10C or UL 10B (Fire-Rated Applications) – Mandatory if handles are used on fire-rated doors; ensures the product does not compromise fire resistance.

- RoHS and REACH (EU) – Restricts hazardous substances in electrical and electronic components and chemical substances in products.

Ensure third-party certification where required and maintain test reports and certification documents for audit purposes.

Packaging and Handling Requirements

Use robust, environmentally appropriate packaging to prevent damage during transit. Include corner protectors, void fill, and moisture barriers as needed. Clearly label packages with handling symbols (e.g., “Fragile,” “Do Not Stack,” “This Side Up”) and include barcodes for inventory tracking. For export shipments, comply with ISPM 15 regulations for wooden packaging materials.

Import/Export and Customs Compliance

Prepare accurate commercial invoices, packing lists, and certificates of origin for international shipments. Classify products under the correct HS Code (e.g., 8302.41 or 8302.42 for base metal mountings). Verify import regulations in destination countries, including conformity assessment procedures and labeling requirements. Utilize bonded warehouses or free trade zones where advantageous for inventory management.

Transportation and Distribution

Choose carriers experienced in handling hardware and building materials. Use insured freight for high-value shipments and ensure temperature and humidity controls where finishes are sensitive. Optimize pallet configurations to reduce shipping costs and prevent shifting. Implement a tracking system for real-time visibility throughout the supply chain.

Installation and End-Use Compliance

Provide clear installation instructions and torque specifications to ensure proper mounting. Confirm compatibility with door types (e.g., hollow metal, wood, fire-rated) and locking mechanisms. Educate installers on adherence to building codes such as the International Building Code (IBC) or local fire safety regulations, which may dictate handle height, operability, and accessibility (e.g., ADA compliance in the U.S.).

Sustainability and Environmental Considerations

Source materials from certified sustainable suppliers where possible. Recycle manufacturing waste and offer end-of-life take-back programs. Comply with WEEE directives if applicable and minimize packaging waste. Document environmental impact metrics to support corporate sustainability reporting.

Quality Assurance and Audit Preparedness

Implement an internal audit process to verify compliance with all standards. Conduct periodic third-party testing and maintain a non-conformance tracking system. Be prepared for regulatory inspections by keeping records of certifications, test results, and supply chain due diligence.

In conclusion, sourcing heavy-duty door handles requires careful consideration of material quality, durability, load capacity, finish, and compliance with industry standards or building codes. Whether for commercial, industrial, or high-traffic residential applications, investing in robust hardware ensures long-term performance, safety, and user satisfaction. By evaluating suppliers based on reputation, certifications, warranty offerings, and cost-effectiveness, organizations can secure reliable products that meet both functional and aesthetic requirements. Ultimately, a well-informed sourcing strategy for heavy-duty door handles contributes to enhanced security, reduced maintenance costs, and improved overall building integrity.