The global heat-resistant fabrics market is witnessing robust expansion, driven by increasing demand across industries such as aerospace, automotive, construction, and personal protective equipment (PPE). According to Grand View Research, the market was valued at USD 7.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by stringent safety regulations, rising industrialization, and the growing emphasis on worker safety in high-temperature environments. Key materials such as aramid, fiberglass, basalt, and carbon fibers are seeing enhanced adoption due to their superior thermal stability and mechanical strength. As innovation accelerates and performance requirements intensify, a select group of manufacturers are leading the charge in R&D, production scalability, and global supply chain integration. Below, we spotlight the top 10 heat-resistant fabric manufacturers shaping the future of this critical industry segment.

Top 10 Heat Resistant Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Suntex

Domain Est. 2023 | Founded: 2004

Website: heatresistantfabric.com

Key Highlights: The largest manufacturer in China for heat resistant fabric. Since 2004, more than 20 years experience. ISO9001 certified, TUV/BV factory audited….

#2 Marina Textil

Domain Est. 2007

Website: marinatextil.com

Key Highlights: We design, manufacture and commercialise protective fire resistant fabrics used to produce personal protective equipment (PPEs)….

#3 Mount Vernon FR

Domain Est. 2011

Website: mvmfr.com

Key Highlights: Many of the world’s leading FR brands and apparel manufacturers turn to Mount Vernon FR for their flame resistant fabric needs. Check out who’s using Mount ……

#4 Nomex® Fibers

Domain Est. 1987

Website: dupont.com

Key Highlights: Nomex® is an inherently flame-resistant, high-temperature resistant fiber that will not melt, drip, or support combustion in air. It is offered in paper, felt, ……

#5 Textiles

Domain Est. 1994

Website: milliken.com

Key Highlights: From protective gear to interiors and infrastructure, our textiles power critical markets including flame resistant apparel, military, automotive, telecom, and ……

#6 Leader in FR/AR Protective Fabric

Domain Est. 1996

Website: westex.com

Key Highlights: At Westex, our flame-resistant and arc-rated (FR/AR) materials and technologies help keep hardworking men and women more comfortable and confident….

#7 Fabric Technologies

Domain Est. 1998

Website: polartec.com

Key Highlights: Polartec® Power Dry™ is an all-weather, lightweight bi-component knit base layer that wicks moisture and regulates temperature….

#8 SuperFabric® brand Materials

Domain Est. 1998

Website: superfabric.com

Key Highlights: Select SuperFabric® materials have Flame/Flame resistant properties. Highly Durable. SuperFabric materials are amongst the longest lastings fabrics in the world ……

#9 Fire resistant fabrics for extreme temperatures

Domain Est. 2012

Website: texfire.net

Key Highlights: Fabrics for extreme temperatures are technical fabrics developed to resist working temperatures from 300ºC up to 1,300ºC….

#10 Heat Resistant Fabric

Domain Est. 2020

Website: heaterk.com

Key Highlights: Free delivery over $50KUL-listed heat resistant fabric, withstand 550°C to 1700°C, ideal for metallurgy, power, and aerospace industries, providing exceptional high-temp ……

Expert Sourcing Insights for Heat Resistant Fabric

H2: Market Trends in Heat Resistant Fabric for 2026

The global heat resistant fabric market is poised for significant transformation by 2026, driven by technological innovation, rising industrial safety standards, and expanding applications across key sectors. As industries prioritize worker protection and operational efficiency, demand for advanced thermal protection materials continues to grow. Below are the major trends shaping the heat resistant fabric market in 2026:

1. Rising Demand in Industrial Safety and PPE

Stringent occupational health and safety regulations are pushing industries—particularly oil & gas, manufacturing, firefighting, and metal processing—to adopt high-performance personal protective equipment (PPE). Heat resistant fabrics are increasingly integrated into flame-resistant (FR) workwear to meet compliance with global safety standards such as NFPA, EN ISO, and OSHA. This regulatory push is a primary growth driver, especially in emerging economies enhancing workplace safety norms.

2. Growth in Aerospace and Automotive Applications

The aerospace and automotive sectors are adopting heat resistant fabrics for insulation, exhaust wraps, and thermal protection systems. With the rise of electric vehicles (EVs), there is increased need for thermal management solutions to protect battery systems and wiring. Similarly, advancements in hypersonic travel and space exploration are fueling demand for lightweight, high-temperature resistant textiles capable of withstanding extreme environments.

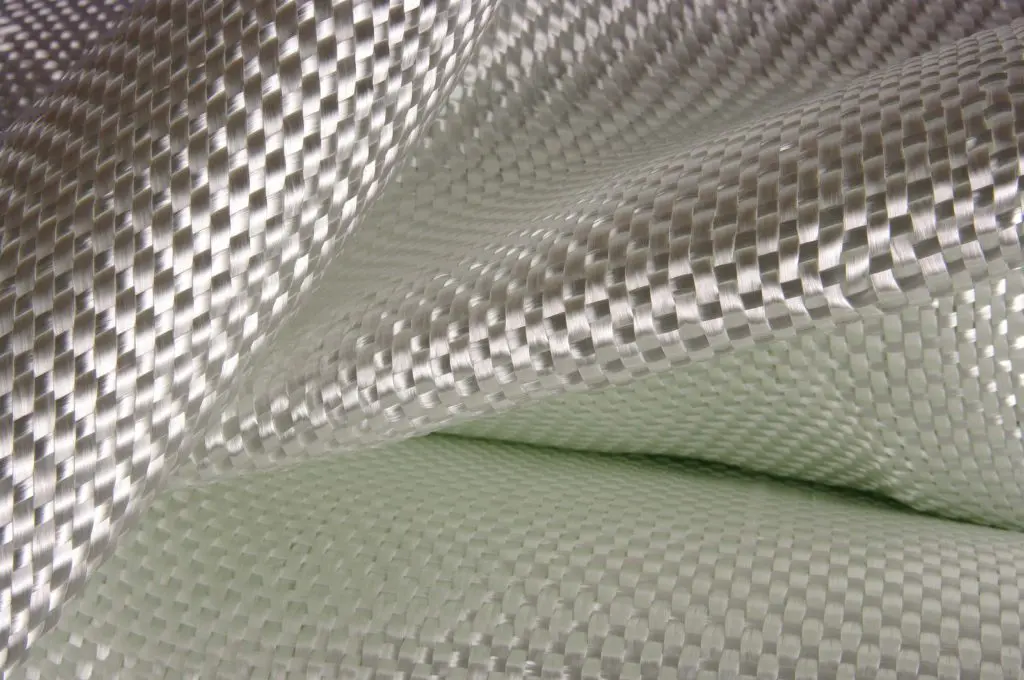

3. Innovation in Material Technology

By 2026, manufacturers are focusing on next-generation materials such as nanofiber composites, ceramic-coated fabrics, and hybrid textiles combining aramid, fiberglass, and basalt fibers. These innovations offer enhanced thermal resistance, improved flexibility, and greater durability. Bio-based and sustainable heat resistant fibers are also gaining traction as companies respond to environmental concerns and ESG (Environmental, Social, and Governance) commitments.

4. Expansion in Renewable Energy and Infrastructure

The growth of renewable energy projects—including concentrated solar power (CSP) and geothermal systems—requires materials that can endure prolonged exposure to high temperatures. Heat resistant fabrics are used in insulation, seals, and protective coverings in these installations. Additionally, urban infrastructure development in high-temperature zones is accelerating demand for fire-resistant construction textiles.

5. Geographic Shifts and Emerging Markets

Asia-Pacific remains the fastest-growing region for heat resistant fabrics, led by industrial expansion in China, India, and Southeast Asia. Increased investments in petrochemicals, power generation, and smart manufacturing are driving regional demand. Meanwhile, North America and Europe maintain strong markets due to technological leadership and high safety standards, with a growing emphasis on recyclable and sustainable fabric solutions.

6. Supply Chain Resilience and Localization

Following disruptions caused by global events in the early 2020s, manufacturers are reshoring production and diversifying supply chains. This trend enhances supply reliability and reduces lead times, particularly for mission-critical applications in defense and emergency services.

Conclusion

By 2026, the heat resistant fabric market will be characterized by technological sophistication, regulatory alignment, and cross-industry adoption. Companies that invest in R&D, sustainability, and application-specific solutions will be well-positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing Heat Resistant Fabric: Quality and Intellectual Property Risks

Sourcing heat resistant fabric is critical for industries such as automotive, aerospace, firefighting, manufacturing, and oil & gas, where safety and performance are paramount. However, organizations often encounter significant challenges related to quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to product failure, safety hazards, legal disputes, and reputational damage.

Quality-Related Pitfalls

1. Inadequate Performance Verification

Many suppliers provide generic certifications or self-declared test results that may not reflect real-world conditions. Relying solely on datasheets without independent verification can result in fabrics that fail under actual operating temperatures or exposure durations. Always demand third-party test reports from accredited laboratories (e.g., ASTM, ISO, NFPA) relevant to your application.

2. Inconsistent Material Composition

Heat resistant fabrics often use high-performance fibers such as aramids (e.g., Nomex®, Kevlar®), PBI, or carbon fibers. Some suppliers may substitute premium fibers with lower-cost alternatives or blend ratios not disclosed upfront. This compromises thermal stability, strength, and longevity. Require detailed material specifications and conduct periodic batch testing.

3. Poor Workmanship and Variability

Inconsistent weaving, coating, or finishing processes can lead to weak spots, uneven heat distribution, or delamination. This is especially common with low-cost manufacturers lacking robust quality control systems. Conduct factory audits and request production samples before placing bulk orders.

4. Lack of Traceability and Documentation

Without batch-specific traceability and full documentation (e.g., Certificates of Conformance, test reports, raw material sourcing), it becomes difficult to investigate failures or ensure regulatory compliance. Ensure suppliers maintain full traceability from raw fiber to finished fabric.

Intellectual Property (IP) Pitfalls

1. Unauthorized Use of Proprietary Technologies

Some suppliers may claim to offer fabrics “similar to” or “compatible with” branded materials (e.g., Nomex®-like) without proper licensing. This can lead to IP infringement claims if your end product incorporates such materials. Always verify that the supplier has legitimate rights or licenses to produce and sell the fabric.

2. Misrepresentation of Brand Equivalency

Suppliers may falsely advertise their products as direct equivalents to patented fabrics, misleading buyers into thinking they are getting the same performance and legal safety. Challenge such claims and request proof of equivalence testing and non-infringement opinions when necessary.

3. Lack of IP Clarity in Custom Development

When co-developing a custom heat resistant fabric, failure to define IP ownership in contracts can result in disputes over design rights, formulations, or manufacturing processes. Clearly specify in writing who owns the IP—whether it’s the buyer, supplier, or jointly—and include confidentiality clauses.

4. Reverse Engineering and Design Theft

Sharing technical specifications or samples with unveted suppliers increases the risk of your proprietary requirements being copied or sold to competitors. Use non-disclosure agreements (NDAs) and limit technical disclosure to what is strictly necessary.

Best Practices to Mitigate Risks

- Conduct thorough due diligence on suppliers, including site visits and reference checks.

- Require independent, application-specific testing of samples.

- Include strict quality and IP clauses in procurement contracts.

- Work with legally vetted, authorized distributors or licensees of branded materials.

- Maintain internal records of all specifications, test data, and correspondence.

By proactively addressing these quality and IP pitfalls, organizations can ensure they source reliable, compliant, and legally sound heat resistant fabrics that meet both performance and safety standards.

Logistics & Compliance Guide for Heat Resistant Fabric

Overview

Heat resistant fabrics are specialized textile materials designed to withstand high temperatures, thermal exposure, and often flame, making them essential in industries such as aerospace, automotive, firefighting, industrial manufacturing, and oil & gas. Due to their critical safety function and unique properties, transporting and complying with regulations for these fabrics require careful attention to logistics, handling, and regulatory standards.

Classification and Identification

Heat resistant fabrics may be composed of materials such as aramid (e.g., Nomex®, Kevlar®), fiberglass, carbon fiber, ceramic fibers, or blends with modacrylics. Proper classification ensures appropriate handling and regulatory compliance. Key identifiers include:

– Material composition (e.g., 100% meta-aramid)

– Weight and thickness

– Certifications (e.g., NFPA, EN, ASTM)

– Intended use (e.g., protective clothing, insulation, gaskets)

Regulatory Compliance

Adherence to international, national, and industry-specific standards is mandatory for legal distribution and safe usage.

International Standards

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Ensure all fabric components are registered and do not contain restricted substances.

- RoHS (EU): Restriction of Hazardous Substances, applicable if fabric includes electronic or metallic elements.

- GHS (Globally Harmonized System): Requires standardized labeling and Safety Data Sheets (SDS) for hazardous materials, if applicable.

Industry-Specific Standards

- NFPA 2112 (USA): Standard on flame-resistant garments for industrial personnel.

- EN 11612 / EN 11611 (EU): Performance requirements for protective clothing against heat and flame.

- ASTM F1959/F1959M: Standard test method for determining arc rating of materials.

- OSHA 29 CFR 1910.132: General requirements for personal protective equipment (PPE) in the U.S.

Manufacturers and distributors must provide certified test reports and product compliance documentation with shipments.

Packaging and Handling

Proper packaging preserves fabric integrity and ensures safety during transit.

Packaging Requirements

- Use moisture-resistant, durable packaging (e.g., sealed polyethylene bags inside corrugated cartons).

- Avoid compression of bulk rolls to prevent deformation.

- Clearly label packages with:

- Product name and specification

- Lot/batch number

- Flame-resistant or heat-resistant warning symbols

- Handling instructions (e.g., “Keep Dry,” “Do Not Crush”)

Handling Precautions

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Avoid contact with oils, solvents, or strong oxidizing agents unless fabric is chemically resistant.

- Use gloves when handling to prevent contamination, especially for fabrics used in clean environments.

Transportation and Shipping

Transport regulations depend on material composition and form (rolls, cut pieces, finished goods).

Domestic Shipping (e.g., USA, EU)

- Standard freight classification applies (e.g., NMFC code for textiles).

- No special hazardous designation unless fabric contains treated chemicals or coatings subject to DOT/IATA rules.

- Use pallets and stretch wrapping for roll stability.

International Shipping

- Harmonized System (HS) Code: Typically under Chapter 59 (Impregnated, Coated, or Laminated Textiles) or Chapter 63 (Other Made-Up Textile Articles). Example: 5903.20 (Plastic-coated woven fabrics, over 150g/m²).

- Export Controls: Verify if fabric has dual-use potential (e.g., military applications) under ITAR or EAR regulations.

- Customs Documentation: Include commercial invoice, packing list, certificate of origin, and compliance certifications.

Air and Sea Freight

- Non-hazardous heat resistant fabrics can generally be shipped via standard air or sea freight.

- Provide SDS if requested by carrier, even if not classified as hazardous.

- Avoid exposure to extreme humidity or temperature during ocean transport.

Storage Guidelines

- Temperature: Store between 10°C and 30°C (50°F–86°F).

- Humidity: Maintain relative humidity below 65% to prevent moisture absorption.

- Shelf Life: Most aramid and fiberglass fabrics have a shelf life of 3–5 years if stored properly. Check manufacturer’s recommendations.

- Stacking: Limit stack height to prevent bottom-layer compression.

Documentation and Traceability

Maintain complete records for compliance and quality assurance:

– Batch-specific test reports (flame resistance, tensile strength, etc.)

– Certificates of Compliance (CoC)

– Safety Data Sheets (SDS) – required under OSHA HazCom and EU REACH/CLP

– Chain of custody documentation for regulated industries

End-of-Life and Sustainability

- Recycling: Most heat resistant fabrics (especially aramids) are not easily recyclable. Check with specialized textile recyclers.

- Disposal: Incineration may be appropriate under controlled conditions; consult local waste regulations.

- Environmental Claims: Avoid unsubstantiated “green” claims unless fabric meets recognized sustainability standards (e.g., bluesign®, OEKO-TEX®).

Summary

Safe and compliant logistics for heat resistant fabric require precise classification, adherence to international safety standards, proper packaging and storage, and thorough documentation. By following this guide, supply chain stakeholders can ensure product integrity, regulatory compliance, and end-user safety across global markets.

In conclusion, sourcing heat-resistant fabric requires a careful evaluation of material properties, application requirements, industry standards, and supplier reliability. Key factors such as temperature resistance, durability, flexibility, and compliance with safety regulations must be thoroughly assessed to ensure optimal performance and safety. Popular materials like fiberglass, aramid (e.g., Nomex, Kevlar), and PBI each offer distinct advantages depending on the operating environment. Establishing partnerships with reputable suppliers who provide certified, high-quality products and consistent technical support is crucial. By aligning technical specifications with end-use demands, businesses can ensure they select the most suitable heat-resistant fabric, enhancing safety, efficiency, and longevity in high-temperature applications.