The global HDPE (High-Density Polyethylene) furniture market has experienced steady growth, driven by rising demand for durable, weather-resistant, and low-maintenance outdoor and commercial furniture. According to Grand View Research, the global plastic furniture market was valued at USD 101.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with HDPE emerging as a preferred material due to its sustainability, recyclability, and resistance to moisture and UV degradation. As urbanization accelerates and outdoor living spaces gain prominence across residential, hospitality, and municipal sectors, manufacturers specializing in HDPE tables are well-positioned to meet evolving consumer demands. This growth is further amplified by increasing adoption in institutional and commercial applications, such as schools, parks, and healthcare facilities, where hygiene and longevity are critical. In this competitive landscape, a select group of manufacturers have distinguished themselves through innovation, scale, and product quality—setting the benchmark in design, durability, and environmental responsibility. Here are the top 8 HDPE table manufacturers leading the industry’s expansion.

Top 8 Hdpe Table Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HDPE Dining Table Sets

Domain Est. 2014

Website: winstarplastic.com

Key Highlights: We’re known as one of the most professional hdpe dining table sets manufacturers and suppliers. Please be free to buy high quality hdpe dining table sets ……

#2 HDPE Plastic for Weather

Domain Est. 1996

Website: piedmontplastics.com

Key Highlights: Durable HDPE plastic sheets offer manufacturers a weather-resistant, long-lasting solution for outdoor furniture and seating applications….

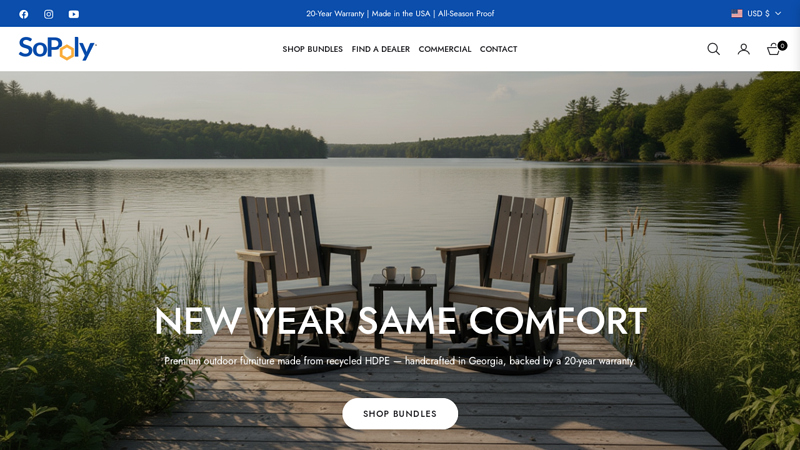

#3 SoPoly

Domain Est. 2017

Website: sopoly.com

Key Highlights: Free delivery 30-day returnsSoPoly is the fastest-growing outdoor furniture manufacturer in the Southeast — proudly made in Georgia from recycled HDPE poly lumber. With unmatched ….

#4 Plastic Lumber Manufacturers

Domain Est. 2020

Website: tangentmaterials.com

Key Highlights: Tangent Materials is the leading recycled poly lumber and plastic lumber manufacturer for residential, commercial, and structural markets. Learn more here….

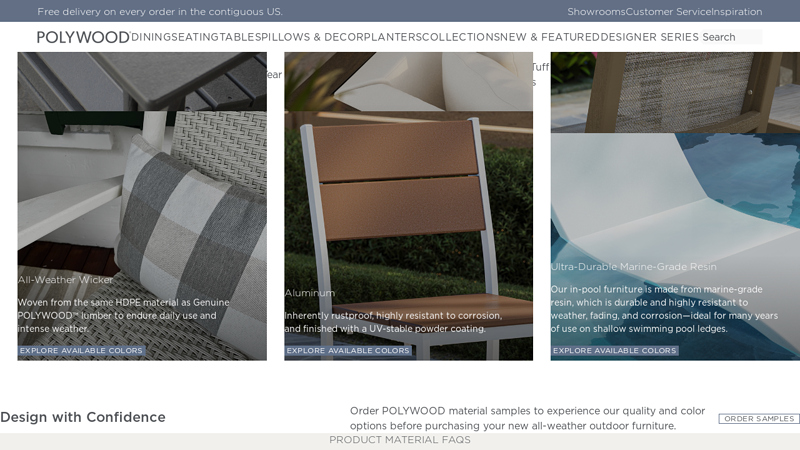

#5 Our Materials

Domain Est. 1996

Website: polywood.com

Key Highlights: Our proprietary all-weather lumber is made of infinitely recyclable high-density polyethylene (HDPE) that’s heavy-duty and easy to clean—the perfect material ……

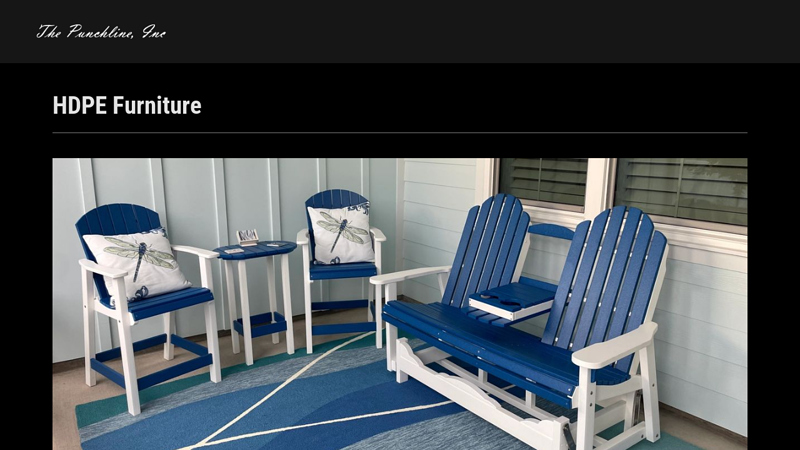

#6 HDPE Furniture

Domain Est. 2020

Website: punchlinemanufacturing.com

Key Highlights: Our Outdoor Furniture Selection · Dinette’s · Accessory Tables · Dinette’s · Chairs · Accessory Tables · Dinette’s · Balcony Sets · Accessory Tables….

#7 Heath 5

Domain Est. 2021

#8 HDPE Patio Furniture

Domain Est. 2021

Expert Sourcing Insights for Hdpe Table

H2: 2026 Market Trends for HDPE Tables

The global market for High-Density Polyethylene (HDPE) tables is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability imperatives, and advancements in material science. HDPE tables—known for their durability, weather resistance, and low maintenance—are increasingly favored across commercial, residential, and institutional sectors. The following trends are expected to shape the HDPE table market in 2026:

-

Sustainability as a Key Driver

Environmental concerns are reshaping material choices in furniture manufacturing. HDPE, particularly when sourced from recycled plastics (post-consumer or post-industrial waste), aligns with circular economy goals. By 2026, regulatory pressures and consumer demand for eco-friendly products will push manufacturers to increase the use of recycled HDPE content. Brands emphasizing carbon footprint reduction and recyclability will gain a competitive edge. -

Growth in Outdoor and Public Space Applications

Urbanization and investment in public infrastructure—especially in developing regions—are boosting demand for durable outdoor furniture. HDPE tables are ideal for parks, schools, transportation hubs, and recreational facilities due to their resistance to moisture, UV radiation, and pests. Municipalities and commercial developers are expected to prioritize long-term cost efficiency, favoring HDPE over traditional wood or metal alternatives. -

Innovation in Design and Aesthetics

Historically perceived as utilitarian, HDPE furniture is undergoing a design renaissance. Advances in extrusion and molding technologies allow for greater customization in color, texture, and form. By 2026, manufacturers will offer HDPE tables with modern, sleek profiles that rival premium materials like teak or aluminum. Integration with modular systems and smart features (e.g., built-in USB ports or solar charging) may emerge in high-end segments. -

Expansion in the Food Service and Healthcare Sectors

Hygiene and easy cleaning are paramount in commercial environments. HDPE’s non-porous, stain-resistant surface makes it ideal for restaurants, hospitals, and laboratories. The post-pandemic focus on sanitation will sustain demand in these sectors. HDPE tables with antimicrobial additives or seamless joints to prevent bacterial buildup are likely to see increased adoption. -

Regional Market Diversification

While North America and Europe remain strong markets due to early adoption and stringent environmental standards, Asia-Pacific is expected to be the fastest-growing region. Rapid urbanization in countries like India, Indonesia, and Vietnam, coupled with rising disposable incomes, will drive demand for affordable, long-lasting outdoor furniture. Localized manufacturing and supply chain optimization will support this growth. -

Price Volatility and Raw Material Challenges

HDPE pricing is closely tied to crude oil markets, making it susceptible to fluctuation. In 2026, geopolitical tensions or supply disruptions could impact production costs. However, increased recycling infrastructure and government incentives for recycled content may mitigate some of these pressures and stabilize long-term supply. -

E-Commerce and Direct-to-Consumer Models

Online retail platforms are transforming furniture distribution. HDPE tables, often lightweight and flat-packable, are well-suited for e-commerce logistics. By 2026, brands leveraging digital marketing, augmented reality (AR) for visualization, and fast delivery will capture a larger share of the consumer market, especially among younger, environmentally conscious buyers.

In conclusion, the 2026 HDPE table market will be defined by sustainability, innovation, and expanding applications. Companies that invest in recycled materials, design versatility, and regional market development will be best positioned to capitalize on these trends.

Common Pitfalls Sourcing HDPE Tables (Quality, IP)

When sourcing High-Density Polyethylene (HDPE) tables—commonly used in laboratories, cleanrooms, and industrial environments—organizations often encounter challenges related to material quality and Intellectual Property (IP) risks. Being aware of these pitfalls can help ensure durability, compliance, and legal safety.

Poor Material Quality and Misrepresentation

One of the most frequent issues is receiving HDPE tables made from substandard or recycled materials that do not meet required specifications. Suppliers may claim their products are “industrial-grade” or “virgin HDPE,” but in reality, they may use blends or lower-density polyethylene. This can result in poor chemical resistance, warping under heat, or premature wear. Always verify material certifications and request samples before bulk orders.

Lack of Third-Party Testing and Compliance Documentation

Many suppliers fail to provide independent test reports or compliance documentation such as ASTM, ISO, or FDA standards. Without these, it’s difficult to confirm that the HDPE table meets necessary requirements for load capacity, chemical resistance, or hygiene standards—especially critical in regulated industries like pharmaceuticals or food processing.

Inconsistent Manufacturing Tolerances

Poorly manufactured HDPE tables often suffer from uneven surfaces, misaligned joints, or inconsistent thickness. These flaws can compromise functionality, especially in precision work environments. Ensure the supplier uses CNC fabrication or other precision methods and conducts quality control checks.

Intellectual Property (IP) Infringement Risks

Copying patented designs—such as specific modular connections, edge profiles, or integrated features—is a significant IP risk when sourcing from generic or offshore manufacturers. Using or importing tables that mimic protected designs can lead to legal disputes, shipment seizures, or costly litigation. Always verify that the design does not infringe on existing patents, and consider working with suppliers who offer original, licensed designs.

Inadequate Warranty and After-Sales Support

Some suppliers offer little to no warranty or customer support, leaving buyers exposed if defects emerge post-purchase. A lack of service infrastructure can delay repairs or replacements, disrupting operations. Choose suppliers with clear warranty terms and responsive technical support.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request material data sheets, verify compliance certifications, inspect sample units, and consult legal experts on IP concerns. Sourcing HDPE tables wisely ensures long-term performance, regulatory compliance, and protection against legal and operational risks.

Logistics & Compliance Guide for HDPE Tables

This guide outlines the essential logistics considerations and compliance requirements for the transportation, handling, and sale of HDPE (High-Density Polyethylene) tables. Adhering to these guidelines ensures product integrity, regulatory compliance, and customer satisfaction.

Product Specifications and Packaging

HDPE tables must be manufactured and packaged according to defined specifications. Each table should be constructed from food-grade or commercial-grade HDPE, depending on intended use. Packaging should include protective corner guards, stretch wrap, and, where appropriate, palletization to prevent damage during transit. Clearly label packages with product details, weight, dimensions, and handling instructions (e.g., “Do Not Stack,” “This Side Up”).

Transportation and Handling

Use flatbed or enclosed trucks for shipping, securing pallets with straps to prevent shifting. HDPE tables are durable but can be affected by extreme temperatures; avoid prolonged exposure to direct sunlight or freezing conditions during transport. Forklifts or pallet jacks should be used for loading and unloading to reduce risk of impact damage. Ensure warehouse storage is dry, level, and away from heat sources.

Import/Export Compliance

For international shipments, ensure compliance with destination country regulations. Provide accurate HS (Harmonized System) codes—typically under 3926.30 (other articles of plastics) or 9403.60 (plastic furniture). Complete all required export documentation, including commercial invoices, packing lists, and certificates of origin. Verify that HDPE material complies with REACH (EU), TSCA (USA), and other relevant chemical substance regulations.

Environmental and Safety Standards

HDPE tables must meet applicable environmental standards. Confirm that the HDPE resin is recyclable (Resin Identification Code #2) and that manufacturing processes comply with local environmental protection laws. For indoor or food-contact applications (e.g., cafeteria tables), ensure compliance with FDA 21 CFR or EU Framework Regulation (EC) No 1935/2004 for food-safe plastics. Provide safety data sheets (SDS) upon request.

Labeling and Certification Requirements

Label each product or package with manufacturer details, material composition, country of origin, and compliance marks (e.g., CE marking for EU, FCC if applicable). If used in commercial or public settings, verify compliance with regional fire safety standards (e.g., California TB 117, BS 5852 in the UK) where required. Maintain records of third-party testing and certifications.

End-of-Life and Sustainability

Support circular economy principles by designing for disassembly and recyclability. Provide end-users with guidance on proper disposal or recycling of HDPE tables. Communicate sustainability attributes such as recycled content percentage and recyclability to meet green procurement standards in public and corporate sectors.

Quality Assurance and Documentation

Implement a quality control process to inspect tables pre-shipment for defects. Maintain detailed records of material sourcing, production batches, compliance testing, and shipping documentation. This ensures traceability and facilitates response to any compliance audits or customer inquiries.

Conclusion on Sourcing HDPE Tables

Sourcing HDPE (High-Density Polyethylene) tables presents a sustainable, durable, and cost-effective solution for a wide range of environments, including schools, outdoor public spaces, parks, and industrial facilities. HDPE tables offer exceptional resistance to moisture, UV radiation, and temperature fluctuations, ensuring long-term performance with minimal maintenance. Their inherent strength and resistance to rot, corrosion, and pests reduce lifecycle costs and support long-term sustainability goals.

When sourcing HDPE tables, it is essential to consider factors such as material quality (preferably post-consumer recycled content), warranty, manufacturing standards, and supplier reputation. Partnering with reliable suppliers who provide certifications for environmental compliance and product durability ensures that the tables meet both performance and sustainability criteria.

In conclusion, HDPE tables are a smart investment for organizations seeking resilient, eco-friendly, and low-maintenance furniture solutions. By carefully evaluating suppliers and product specifications, procurement teams can make informed decisions that align with environmental objectives, operational needs, and budget constraints—ultimately delivering long-term value and user satisfaction.