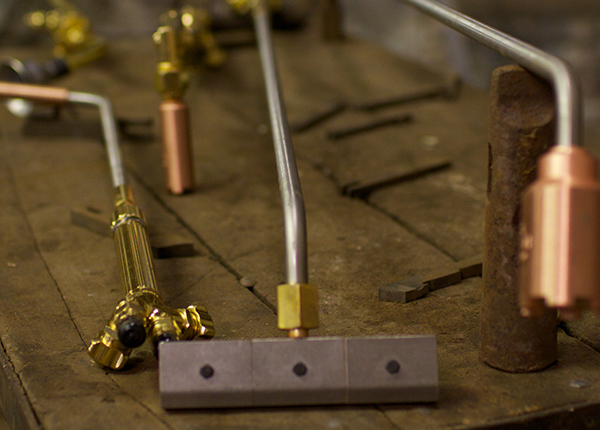

The global oxy-fuel welding and cutting equipment market is experiencing steady growth, driven by increasing demand from key industries such as construction, automotive, and metal fabrication. According to Grand View Research, the global welding equipment market was valued at USD 24.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this growth is attributed to the continued use of oxy-acetylene systems, particularly in repair, maintenance, and small-scale fabrication operations where portability and versatility are critical. In this evolving landscape, Harris Products Group has maintained a strong reputation for innovation and reliability in oxy-acetylene torches, regulators, and accessories. As demand for high-performance, safety-focused welding solutions rises, particularly in North America and emerging markets, the role of leading manufacturers like Harris becomes increasingly vital. This analysis highlights the top four manufacturers under the Harris brand, known for their technological advancements, adherence to industry standards, and robust product performance in professional and industrial applications.

Top 4 Harris Oxy Acetylene Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 [PDF] Turn to the

Domain Est. 1996

Website: ch-delivery.lincolnelectric.com

Key Highlights: Harris, on the other hand, is a manufacturer of brazing and soldering alloys and welding consumables. The merger resulted from a series of acquisitions by The ……

#2 Torch Kits

Domain Est. 2000

Website: harrisweldingsupplies.com

Key Highlights: Free delivery over $99Shop our welding and cutting torch kits today. We offer the lowest prices online for Harris and Victor torches and torch kits. Call us at 800-783-8833….

#3 – Harris Gas – Medical Gases

Domain Est. 2004

Website: harrisgas.com

Key Highlights: Large inventory of consumables for MIG, TIG, Oxy-Acetylene, and Plasma processes. Click for more information. Personal Protective Equipment. Heavy-duty ……

#4 Harris Products Group

Domain Est. 2006 | Founded: 1905

Website: harrisproductsgroup.com

Key Highlights: Since 1905, the Harris name has been identified with innovative people, practices, and products as the industry leader in gas distribution solutions….

Expert Sourcing Insights for Harris Oxy Acetylene

It appears there may be some confusion in your request. “Harris Oxy Acetylene” refers to welding and cutting equipment and gas systems produced by Harris Products Group, a leading manufacturer of brazing, soldering, and welding supplies. However, “Use H2” likely refers to hydrogen (H₂), which is an emerging clean energy fuel.

There is currently no direct product line known as “Harris Oxy Acetylene H2” in the traditional sense. That said, your query may be asking to analyze how hydrogen (H₂) could influence or intersect with oxy-fuel technologies—such as those used in Harris Oxy Acetylene systems—by the year 2026.

Below is an analysis of 2026 market trends at the intersection of traditional oxy-fuel welding/cutting (e.g., Harris Oxy Acetylene) and the growing role of hydrogen (H₂) in industrial applications:

Market Trends Analysis: Harris Oxy Acetylene and the Role of Hydrogen (H₂) by 2026

1. Transition from Acetylene to Alternative Fuels

By 2026, the industrial heating and metal fabrication sector is expected to experience a gradual shift away from acetylene due to its high cost, instability, and carbon footprint. While Harris Oxy Acetylene systems remain widely used for cutting, brazing, and welding, market trends indicate growing interest in alternative fuel gases—including hydrogen (H₂)—as cleaner, safer, and more cost-effective options.

- Hydrogen as a Fuel Gas: Hydrogen is emerging as a viable substitute in oxy-fuel processes. Oxy-hydrogen (H₂ + O₂) systems offer a clean flame (producing only water vapor), high flame temperature (~2,800°C), and are suitable for precision cutting, brazing, and glassworking.

- Safety and Storage: Unlike acetylene, which requires special cylinder handling due to instability, hydrogen can be generated on-site via electrolysis or stored in modern high-pressure tanks, reducing logistics costs and risks.

2. Growth of Green Hydrogen Infrastructure (2023–2026)

Global investments in green hydrogen (produced via renewable-powered electrolysis) are accelerating. By 2026, several industrial hubs in North America, Europe, and Asia are expected to have localized hydrogen supply chains.

- Impact on Harris Products: Harris Products Group may adapt by developing or certifying their torches, regulators, and hoses for safe use with hydrogen. Early adopter industries (e.g., shipbuilding, automotive recycling) may retrofit existing oxy-acetylene systems for H₂ use.

- Hydrogen Compatibility: Harris regulators and mixing tips may require redesign to handle hydrogen’s low density and high diffusivity, but the core technology of oxy-fuel equipment is adaptable.

3. Regulatory and Environmental Drivers

Climate policies (e.g., U.S. Inflation Reduction Act, EU Green Deal) are incentivizing low-carbon industrial processes. By 2026, carbon pricing and emissions reporting may make acetylene less attractive.

- Carbon Footprint: Acetylene production is energy-intensive and emits CO₂. Green hydrogen, especially when produced on-site with solar/wind, offers a near-zero carbon alternative.

- Corporate ESG Goals: Fabrication shops and OEMs may switch to H₂-based heating to meet sustainability targets, favoring compatible equipment from brands like Harris.

4. Technological Integration and Hybrid Systems

By 2026, hybrid systems combining traditional oxy-fuel with hydrogen injection or dual-fuel capability may enter the market.

- Harris Innovation Opportunity: Harris could launch “H₂-Ready” torches or retrofit kits enabling existing customers to transition from acetylene to hydrogen with minimal downtime.

- On-Site Hydrogen Generators: Integration with small-scale electrolyzers could allow shops to produce hydrogen as needed, reducing cylinder dependence.

5. Market Adoption Barriers

Despite momentum, several challenges remain for H₂ adoption in place of acetylene:

- Energy Density: Hydrogen has lower volumetric energy density than acetylene, requiring higher flow rates for equivalent heating.

- Embrittlement Risk: Hydrogen can cause metal embrittlement; existing brass and copper components in some Harris gear may need material upgrades.

- Code and Standards: Oxy-hydrogen systems must comply with updated safety codes (e.g., CGA, NFPA). Regulatory clarity by 2026 will be critical.

6. Competitive Landscape

Other welding equipment manufacturers (e.g., Linde, Air Liquide, ESAB) are already piloting hydrogen-based solutions. Harris may need to innovate or partner to maintain market leadership.

- Strategic Positioning: Harris could position itself as a bridge between legacy oxy-fuel users and the hydrogen economy, offering transition solutions.

Conclusion: 2026 Outlook

By 2026, the traditional Harris Oxy Acetylene market will face increasing pressure from environmental regulations, cost factors, and technological advances. While acetylene will remain dominant in many high-precision applications, hydrogen (H₂) is expected to gain traction as a clean, efficient alternative—especially in sectors prioritizing decarbonization.

Harris Products Group has an opportunity to lead this transition by:

– Certifying and adapting equipment for safe hydrogen use.

– Partnering with green hydrogen suppliers.

– Introducing H₂-compatible product lines or retrofit solutions.

The convergence of oxy-fuel technology and hydrogen energy represents a pivotal market evolution—positioning H₂ not as a replacement for Harris Oxy Acetylene, but as its next-generation evolution.

Let me know if you’d like a SWOT analysis, regional breakdown, or financial projection based on this trend.

When sourcing Harris Oxy-Acetylene equipment or consumables—especially in applications involving hydrogen (H₂) as an alternative or supplementary fuel gas—several common pitfalls can compromise safety, quality, and intellectual property (IP) integrity. While Harris is a reputable brand (now part of Colfax Corporation, formerly owned by Xenco Medical and before that, Applica), confusion in sourcing can lead to substandard or counterfeit products. Below are key pitfalls to avoid, with specific attention to quality control and IP risks, particularly when using H₂ in place of or alongside acetylene.

⚠️ 1. Counterfeit or Non-Genuine Harris Products

Pitfall: Sourcing from unauthorized distributors may result in counterfeit or rebranded equipment that mimics Harris branding but lacks quality certification.

- Why it matters with H₂: Hydrogen has a much wider flammability range (4–75%) and lower ignition energy than acetylene. Substandard regulators, torches, or hoses not rated for H₂ can lead to leaks, backflash, or explosions.

- IP Risk: Counterfeit products infringe on Harris’ trademarks and design patents. Using them may expose your organization to liability or void warranties.

- Mitigation:

- Purchase only from authorized Harris distributors.

- Verify product serial numbers and certifications (e.g., CGA, CSA, UL).

- Look for tamper-evident seals and original packaging.

⚠️ 2. Using Acetylene-Rated Equipment for Hydrogen Service

Pitfall: Assuming Harris oxy-fuel equipment rated for acetylene is automatically safe for hydrogen.

- Quality/Performance Risk:

- Acetylene and H₂ have different pressure requirements, flow characteristics, and metallurgical compatibility.

- Acetylene hoses may use materials incompatible with H₂ (e.g., elastomers prone to hydrogen embrittlement or permeation).

- Safety Consequence: Hydrogen can permeate through standard rubber hoses, creating invisible, explosive mixtures in enclosed spaces.

- Mitigation:

- Use H₂-specific regulators, hoses, and torches—even if from Harris.

- Confirm CGA 350 (for H₂) vs. CGA 510 (acetylene) fittings.

- Specify hydrogen-rated equipment when ordering.

⚠️ 3. Lack of Certification and Traceability

Pitfall: Accepting undocumented or uncertified components (e.g.,二手 regulators, used torches).

- IP/Compliance Risk: Untraceable equipment may violate OEM IP and fail to meet OSHA, ASME B31.12, or ISO 11114-4 (gas cylinder compatibility) standards.

- Quality Risk: No assurance of prior use, maintenance, or exposure to incompatible gases.

- Mitigation:

- Require certificates of conformance (CoC) and material test reports (MTRs).

- Ensure Harris-branded products have valid batch/lot traceability.

⚠️ 4. Misunderstanding Hydrogen Compatibility in Materials

Pitfall: Assuming that because a Harris product is high quality, it’s suitable for H₂.

- Technical Risk:

- Hydrogen causes embrittlement in certain steels and alloys.

- Some Harris acetylene equipment uses brass or steel formulations not optimized for H₂ service.

- Example: Standard Harris welding tips may erode or crack under sustained H₂ use.

- Mitigation:

- Consult Harris technical data sheets for hydrogen compatibility.

- Use stainless steel or nickel-alloy components where H₂ is used.

- Consider retrofit kits or H₂-specific Harris product lines (if available).

⚠️ 5. Unauthorized Modifications or Reverse Engineering

Pitfall: Modifying Harris equipment to “adapt” it for hydrogen use (e.g., changing orifices, mixing tips).

- IP Risk: Reverse engineering or modifying patented designs (e.g., Harris’ SureFire torch tips) may infringe on utility or design patents.

- Safety Risk: Altered equipment may fail under H₂ pressure or cause unstable flame dynamics.

- Mitigation:

- Use only factory-approved accessories.

- Engage Harris technical support for H₂ compatibility guidance.

- Document modifications only if approved and compliant with ASME and local codes.

⚠️ 6. Inadequate Training and Procedures for H₂ Use

Pitfall: Applying oxy-acetylene procedures directly to H₂ without re-evaluation.

- Quality/Operational Risk: H₂ flames are hotter and less visible; improper setup leads to poor weld quality or equipment damage.

- Safety Risk: Invisible flame and high diffusivity increase risk of undetected leaks.

- Mitigation:

- Train personnel specifically for oxy-hydrogen (not just oxy-acetylene) processes.

- Use flame visualization tools or UV detectors.

- Follow Harris’ guidelines (if published) for alternative fuels.

✅ Best Practices Summary

| Area | Recommendation |

|——|—————-|

| Sourcing | Buy only from authorized Harris distributors; verify authenticity. |

| Hydrogen Use | Use H₂-rated equipment—do not assume acetylene gear is interchangeable. |

| Certification | Request CoC, MTRs, and compliance with CGA, ISO, and ASME standards. |

| Materials | Confirm compatibility with H₂ (avoid susceptible alloys). |

| IP Protection | Avoid counterfeits and unauthorized modifications. |

| Training | Implement H₂-specific safety and operational protocols. |

Final Note

While Harris does not currently market a dedicated “oxy-hydrogen” product line widely, their equipment can be adapted—only when technically validated. Always consult Harris technical support or a qualified engineer before substituting acetylene with H₂, even with genuine Harris gear.

🔧 Pro Tip: For hydrogen applications, consider specialized brands like Nabertherm, Hogen, or HyGear, or explore Harris-compatible H₂ retrofit kits if available.

By avoiding these pitfalls, you ensure both equipment integrity and regulatory compliance, while protecting against IP and safety risks.

H2: Logistics & Compliance Guide for Harris Oxy-Acetylene Equipment

This guide outlines the essential logistics and compliance requirements for the safe handling, storage, transportation, and use of Harris oxy-acetylene equipment and associated gases (oxygen and acetylene). Adherence to these standards ensures regulatory compliance, operational safety, and product integrity.

H2.1: Regulatory Compliance Overview

All operations involving Harris oxy-acetylene systems must comply with the following key regulations:

- OSHA 29 CFR 1910.102 – Safety requirements for oxygen and acetylene use in welding and cutting.

- NFPA 51 – Standard for the Design and Operation of Oxygen and Acetylene Systems for Metal Cutting and Welding.

- DOT 49 CFR Parts 171–180 – U.S. Department of Transportation regulations for the safe transportation of hazardous materials, including compressed gases.

- CGA (Compressed Gas Association) Standards – Best practices for gas cylinder handling and safety.

- EPA & Local Environmental Regulations – For waste disposal and emissions control (if applicable).

H2.2: Cylinder Handling & Storage

Handling:

– Always secure cylinders with chains or restraints during transport and storage.

– Use proper cylinder caps when valves are not in use to prevent damage.

– Never roll, drag, or drop cylinders; use a suitable hand truck designed for gas cylinders.

– Open valves slowly using appropriate tools (do not use wrenches on acetylene cylinder valves unless specified).

– Use only Harris-approved regulators, hoses, and torches rated for oxy-fuel service.

Storage:

– Store oxygen and acetylene cylinders separately in well-ventilated, dry, fire-resistant areas.

– Maintain a minimum separation of 20 feet (6 meters) between fuel gases (acetylene) and oxidizers (oxygen), or use a 5-foot (1.5-meter) fire barrier of at least 1/2-hour fire resistance.

– Cylinders must be stored upright and secured to prevent tipping.

– Keep away from heat sources, direct sunlight, flammable materials, and electrical circuits.

– Acetylene cylinders must never be stored on their side; they contain porous material and acetone that can leak if inverted.

H2.3: Transportation Requirements

- Transport cylinders only in vehicles equipped with secure restraints and ventilation.

- Never transport cylinders in passenger compartments; always in the cargo area.

- Acetylene cylinders must be kept upright during transit.

- Placard vehicles when transporting large quantities (as required by DOT regulations; typically more than 1,001 lbs aggregate gross weight of hazardous materials).

- Ensure cylinders are capped and valves closed before transport.

- Avoid extreme temperatures; do not leave cylinders in vehicles exposed to direct sunlight for prolonged periods.

H2.4: Usage & Operational Safety

- Inspect all equipment (regulators, hoses, torches) before each use for leaks, cracks, or wear.

- Use color-coded hoses: red for acetylene, green (or blue) for oxygen.

- Never use oil, grease, or lubricants on oxygen equipment—risk of explosion.

- Follow proper lighting and shutdown procedures per Harris equipment manuals.

- Acetylene must not be used at pressures exceeding 15 psig (1 bar) to prevent decomposition.

- Use flashback arrestors on both oxygen and acetylene lines for added safety.

- Prohibit smoking and open flames in work areas.

H2.5: Inspection & Maintenance

- Perform regular visual inspections of cylinders for corrosion, dents, or damage.

- Check hydrostatic test dates; cylinders must be requalified per DOT standards (typically every 5 or 10 years, depending on type).

- Replace damaged or expired hoses, regulators, and safety devices immediately.

- Only trained personnel should perform maintenance or repairs on Harris equipment.

- Keep records of inspections, maintenance, and cylinder test dates.

H2.6: Emergency Procedures

- In case of gas leak:

- Shut off cylinder valves immediately.

- Evacuate area and ventilate.

- Do not use electrical switches or create sparks.

- Contact emergency services if uncontrolled.

- Fire involving acetylene:

- Evacuate and call emergency services.

- If safe, cool cylinders with water spray from a distance.

- First aid:

- Oxygen enrichment increases fire risk—evacuate and ventilate.

- Treat burns or inhalation per OSHA first aid guidelines.

H2.7: Training & Documentation

- Provide OSHA-compliant training for all personnel involved in handling, storing, or using oxy-acetylene systems.

- Maintain records of safety training, equipment inspections, and incident reports.

- Display safety data sheets (SDS) for oxygen and acetylene gases in accessible locations.

- Conduct periodic safety audits and drills.

H2.8: Disposal & Cylinder Return

- Do not attempt to empty or dispose of cylinders independently.

- Return empty or damaged cylinders to the supplier or authorized service center.

- Follow local, state, and federal regulations for hazardous waste disposal.

- Harris cylinders are typically owned by the gas supplier (e.g., Airgas, Praxair); return per supplier agreement.

Adhering to this H2-level guide ensures safe, compliant, and efficient use of Harris oxy-acetylene equipment in industrial, construction, and maintenance environments. Always consult the latest Harris product manuals and regulatory updates for specific model requirements.

Conclusion: Sourcing Harris Oxy-Acetylene Equipment

In conclusion, sourcing Harris oxy-acetylene equipment proves to be a reliable and strategic choice for welding, cutting, and brazing applications. Harris is a well-established brand known for its high-quality torches, regulators, and accessories, offering durability, precision, and safety compliance. The wide availability of Harris products through authorized distributors and industrial supply channels ensures easy access for both industrial and repair operations. Additionally, the company’s strong reputation for innovation and customer support enhances long-term value. By sourcing Harris oxy-acetylene systems, organizations can ensure consistent performance, reduce downtime, and maintain adherence to industry standards—making it a sound investment for professional-grade metalworking needs.

![[PDF] Turn to the](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-turn-to-the-346.png)