The global hardware bolts market continues to gain momentum, driven by sustained demand across construction, automotive, industrial machinery, and infrastructure development. According to Mordor Intelligence, the fasteners market—of which bolts are a critical component—is projected to grow at a CAGR of over 6.1% from 2024 to 2029. Expanding urbanization, increased investments in manufacturing, and rising residential and commercial construction activities are key contributors to this growth, especially in emerging economies across Asia-Pacific and Latin America. Grand View Research further supports this trajectory, estimating the global fasteners market size at USD 90.3 billion in 2023, with expectations to expand at a CAGR of 5.8% through 2030. As demand intensifies, manufacturers are focusing on product innovation, material durability, and compliance with international standards such as ISO, ASTM, and DIN. Against this backdrop, the following list highlights the top nine hardware bolts manufacturers that are shaping the industry through scale, quality, and technological advancement.

Top 9 Hardware Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Valley Forge & Bolt

Domain Est. 1997

Website: vfbolts.com

Key Highlights: We are an internationally renowned manufacturer of hot forged industrial fasteners. Our patented bolting products are trusted for their quality, performance ……

#2 mid

Domain Est. 1996

Website: midstatesbolt.com

Key Highlights: Mid-States Bolt & Screw’s endless selection of industrial fasteners and hardware ensures that we provide the perfect solution for any construction and ……

#3 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#4 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#5 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#6 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#7 NutsandBolts.com

Domain Est. 1996

Website: nutsandbolts.com

Key Highlights: Free delivery over $50 30-day returnsYour One-Stop Shop For Fasteners. Seamless shopping with expert support for your projects. Shop Now. Essential Fastener Kits….

#8

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

#9 American Bolt

Domain Est. 1998

Website: americanbolt.com

Key Highlights: American Bolt has been a trusted supplier of fasteners for many years, with a consistent focus: delivering reliable fastening solutions with unmatched service….

Expert Sourcing Insights for Hardware Bolts

H2: Projected 2026 Market Trends for Hardware Bolts

The global hardware bolts market is poised for steady growth by 2026, driven by advancements in manufacturing, rising infrastructure investments, and evolving demand across key industries. Several macro and microeconomic factors are shaping the trajectory of this essential fastener segment.

-

Increased Infrastructure and Construction Activity

Governments worldwide, particularly in emerging economies across Asia-Pacific, Africa, and Latin America, are investing heavily in transportation, urban development, and energy infrastructure. This surge in construction and civil engineering projects is directly boosting demand for high-strength and corrosion-resistant bolts used in structural steel frameworks, bridges, and high-rise buildings. By 2026, infrastructure-related procurement is expected to account for over 40% of total bolt consumption. -

Growth in Automotive and Electric Vehicle (EV) Production

The automotive sector remains a major consumer of precision-engineered bolts. The shift toward lightweight materials and electric vehicle (EV) manufacturing is driving demand for specialized fasteners that offer high tensile strength, thermal resistance, and reduced weight. Automotive OEMs are increasingly sourcing high-grade alloy and titanium bolts, particularly for battery enclosures and powertrain systems. The expansion of EV production facilities is expected to create new niches in the bolt market by 2026. -

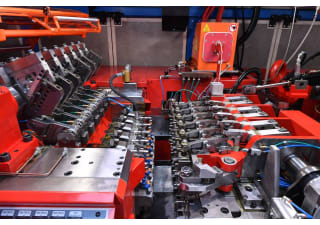

Adoption of Smart Manufacturing and Automation

Industry 4.0 technologies are transforming bolt production and quality control. By 2026, an increasing number of manufacturers are expected to integrate IoT-enabled sensors, AI-based inspection systems, and automated assembly lines to enhance precision and reduce waste. This trend improves product consistency and supports just-in-time (JIT) delivery models, aligning with lean manufacturing practices in aerospace, automotive, and industrial equipment sectors. -

Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are pushing bolt manufacturers to adopt greener practices. Recyclable materials, low-carbon steel, and coatings that reduce environmental impact (e.g., zinc-nickel, geocoatings) are gaining traction. Additionally, research into composite and bio-based fasteners may begin to influence niche applications, although metal bolts will remain dominant due to their mechanical reliability. -

Regional Market Shifts and Supply Chain Resilience

Post-pandemic supply chain reconfigurations are leading companies to nearshore or regionalize production. This trend is expected to benefit local bolt manufacturers in North America and Europe, reducing dependency on single-source suppliers from Asia. By 2026, regional self-sufficiency in fastener production is likely to increase, supported by trade policies and incentives for domestic manufacturing. -

Rising Demand in Renewable Energy Sectors

The expansion of wind and solar energy projects is creating robust demand for specialized bolts used in turbine towers, foundations, and solar mounting systems. Offshore wind farms, in particular, require high-performance, marine-grade fasteners resistant to saltwater corrosion. This segment is projected to be one of the fastest-growing end-use markets for hardware bolts by 2026.

In conclusion, the hardware bolts market in 2026 will be characterized by technological integration, material innovation, and strong demand from infrastructure, automotive, and renewable energy sectors. Manufacturers who adapt to these trends through product differentiation, sustainable practices, and supply chain agility will be best positioned for long-term growth.

Common Pitfalls Sourcing Hardware Bolts (Quality, IP)

1. Inconsistent Material Quality

Sourcing bolts from unreliable suppliers often leads to inconsistent material composition. Substandard alloys may not meet required tensile strength or corrosion resistance specifications, increasing the risk of mechanical failure in critical applications.

2. Misrepresentation of Grade and Standards

Many suppliers falsely claim compliance with international standards (e.g., ISO, ASTM, DIN). Bolts may be labeled as Grade 8.8 or A2-70 but fail testing, compromising structural integrity and safety.

3. Poor Surface Finish and Corrosion Protection

Inadequate or improperly applied coatings (e.g., zinc plating, hot-dip galvanizing) reduce corrosion resistance. This is especially problematic in outdoor or high-moisture environments, leading to premature degradation.

4. Tolerance and Dimensional Inaccuracy

Low-quality bolts often exhibit poor thread accuracy or dimensional deviations. This can result in improper fit, cross-threading, or uneven load distribution, weakening joints and assemblies.

5. Counterfeit or Non-Compliant Products

Counterfeit hardware is common in global supply chains. These products lack proper certification and may infringe on intellectual property rights, exposing buyers to legal and safety risks.

6. Lack of Traceability and Certification

Reputable suppliers provide mill test certificates (e.g., EN 10204 3.1) confirming material and mechanical properties. Sourcing without proper documentation makes quality verification impossible and increases liability.

7. Intellectual Property (IP) Infringement

Copying patented bolt designs (e.g., specialized thread profiles or anti-theft mechanisms) without authorization can lead to legal disputes. Buyers may unknowingly purchase infringing products, resulting in supply chain disruptions or financial penalties.

8. Inadequate Testing and Quality Control

Suppliers may skip essential quality control steps such as hardness testing, load testing, or salt spray testing. Without rigorous QC, defects go undetected until failure occurs in the field.

9. Supply Chain Transparency Issues

Opaqueness in the manufacturing and distribution chain increases the risk of receiving non-compliant or uncertified bolts. This is particularly concerning when sourcing from subcontractors or third-party distributors.

10. Failure to Meet Application-Specific Requirements

Using standard bolts in high-stress, high-temperature, or safety-critical applications (e.g., aerospace, automotive, construction) without proper specification matching can lead to catastrophic failures.

Logistics & Compliance Guide for Hardware Bolts

Overview

This guide outlines key logistics and compliance considerations for the international shipping, handling, and regulatory adherence of hardware bolts. Whether sourcing, manufacturing, or distributing bolts, organizations must ensure compliance with transportation regulations, material standards, and import/export requirements.

Classification & Product Specifications

Hardware bolts are typically categorized under industrial fasteners. Accurate classification includes:

– Material Type: Steel, stainless steel, alloy, or specialty metals

– Grade/Strength Rating: e.g., Grade 8.8, 10.9 (metric), or SAE Grade 5, 8 (imperial)

– Finish: Zinc-plated, galvanized, black oxide, etc.

– Standards Compliance: ISO, ASTM, DIN, or ANSI specifications

Ensure all product documentation reflects these specifications for regulatory and quality assurance purposes.

Packaging & Handling Requirements

Proper packaging ensures product integrity and safety during transit:

– Use moisture-resistant packaging to prevent corrosion

– Secure bulk bolts in labeled, sealed containers or palletized crates

– Include protective measures (e.g., desiccants) for long-distance or maritime shipping

– Clearly label packages with contents, weight, and handling instructions (e.g., “Fragile,” “Keep Dry”)

Transportation & Logistics

- Mode of Transport: Bolts are generally non-hazardous and suitable for road, rail, air, and sea freight

- Weight & Dimensions: Optimize packaging to reduce volume and shipping costs

- Documentation: Include commercial invoices, packing lists, and bills of lading

- Customs Clearance: Accurate HS codes (e.g., 7318.15 for threaded steel bolts) are essential for tariff classification and duty assessment

Regulatory & Compliance Standards

- International Standards: Ensure bolts meet ISO 898-1 (mechanical properties), ISO 4014/4017 (dimensions), or equivalent

- RoHS & REACH (EU): Verify compliance if bolts are used in electrical or consumer goods

- Conflict Minerals (U.S. Dodd-Frank Act): If applicable, document sourcing of raw materials (e.g., steel containing tantalum, tin, tungsten, gold)

- Country-Specific Regulations: Some markets require certification marks (e.g., CE in Europe, GOST in Russia)

Import/Export Controls

- Export Licenses: Generally not required for standard bolts, but may apply if intended for military or aerospace applications

- Sanctions & Embargoes: Screen end-users and destinations against OFAC, EU, or UN sanctions lists

- Dual-Use Considerations: Bolts exceeding certain strength or corrosion-resistance specifications may fall under dual-use export controls (e.g., Wassenaar Arrangement)

Quality Assurance & Traceability

- Maintain batch/lot traceability for recall and warranty purposes

- Conduct periodic audits to verify compliance with material and dimensional standards

- Provide mill test certificates (MTCs) upon request, especially for critical applications

Environmental & Safety Considerations

- Recyclable metal content supports sustainability goals

- No special hazardous handling required under normal conditions

- Dispose of packaging materials according to local waste regulations

Conclusion

Effective logistics and compliance management for hardware bolts involves precise classification, robust packaging, adherence to international standards, and thorough documentation. Staying compliant minimizes delays, avoids penalties, and ensures product reliability across global supply chains.

Conclusion for Sourcing Hardware Bolts

In conclusion, sourcing hardware bolts requires a comprehensive approach that balances quality, cost, availability, and compliance with industry standards. Selecting the right type of bolt—considering material, size, strength grade, finish, and application requirements—is critical to ensuring structural integrity and long-term performance. Establishing relationships with reliable suppliers, conducting thorough supplier evaluations, and implementing quality control measures help mitigate risks associated with substandard or counterfeit products. Additionally, leveraging bulk purchasing, exploring global supply options, and staying informed about market trends can lead to cost savings and improved supply chain efficiency. Ultimately, a strategic and well-documented sourcing process ensures that hardware bolts meet technical specifications and project demands while supporting operational reliability and safety.