The global hard disc magnet market is experiencing steady growth, driven by the continued demand for high-performance data storage solutions and the rising adoption of hybrid and electric vehicles, which also utilize similar rare-earth magnet technologies. According to Grand View Research, the global rare-earth magnet market—encompassing neodymium-based magnets widely used in hard disc drives—was valued at USD 20.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 8.7% from 2023 to 2030. This growth is supported by persistent demand in consumer electronics, particularly in enterprise-level data storage systems where hard disc drives remain a cost-effective solution. Mordor Intelligence further highlights that increasing data center investments and the resilience of HDDs in archival and bulk storage applications continue to sustain the need for high-quality disc magnets. As the market evolves, a select group of manufacturers lead in innovation, production scale, and material efficiency—setting the standard in performance and reliability.

Top 10 Hard Disc Magnet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Neodynium Drive Magnetic Disk Magnets Hard Drive Magnets

Domain Est. 2016

Website: gme-magnet.com

Key Highlights: Great Magtech (Xiamen) Electric Co., Ltd is one of the most reliable manufacturers and suppliers of neodynium drive magnetic disk magnets hard drive magnets in ……

#2 Rochester Magnet

Domain Est. 2000

Website: rochestermagnet.com

Key Highlights: Rochester Magnet is your #1 source for the highest quality flexible magnets, rare-earth magnets, and magnet assemblies for retail, POP and industrial ……

#3 IBS MAGNET

Domain Est. 2005

Website: ibsmagnet.com

Key Highlights: We specialise in the manufacture and supply of permanent magnets from any magnetic material, particularly from the high-energy magnetic materials NdFeB and SmCo ……

#4 Custom Neodymium Disc Magnets Supplier

Domain Est. 2023

Website: mainrichmagnets.com

Key Highlights: With over 30 years of experience, Mainrich Magnets is a leading manufacturer and supplier of neodymium disc magnets in China. We offer customized sizes, grades ……

#5 Custom Neodymium Rare Earth Magnets

Domain Est. 1998

Website: stanfordmagnets.com

Key Highlights: Stanford Magnets manufactures and designs strong custom Neodymium Magnets in many shapes, sizes, and grades of NdFeB magnet….

#6 SuperMagnetMan

Domain Est. 2003

Website: supermagnetman.com

Key Highlights: SuperMagnetMan is the e-commerce brand of SM Magnetics, who specializes in custom magnets and magnetic assemblies for critical applications….

#7 7/16 x 3/16 Inch Neodymium Rare Earth Disc Magnet N42 d73

Domain Est. 2003

Website: kjmagnetics.com

Key Highlights: In stock $25.57 deliveryLeading supplier of the world’s strongest rare earth neodymium magnets. Huge inventory with over 100 million magnets in stock, volume discounts, same day …..

#8 totalElement: Strong Neodymium Magnets for Sale

Domain Est. 2012

Website: totalelement.com

Key Highlights: Our online magnet store stocks strong rare earth magnets in a variety of shapes including round disc shaped magnets, block magnets, and sphere magnets….

#9 Ceramic, Ferrite

Domain Est. 2013

Website: unionmaterials.com

Key Highlights: Union ceramic cutting tool is an inorganic material, die-pressed and sintered using very fine and pure raw materials….

#10 Hard Drive Magnets [Function Material Supplier]

Domain Est. 2019

Website: couragemagnet.com

Key Highlights: The primary purpose of using magnets in hard disk drives (HDDs) is to enable precise control of the head positioning system. In a traditional ……

Expert Sourcing Insights for Hard Disc Magnet

H2: Market Trends for Hard Disc Magnets in 2026

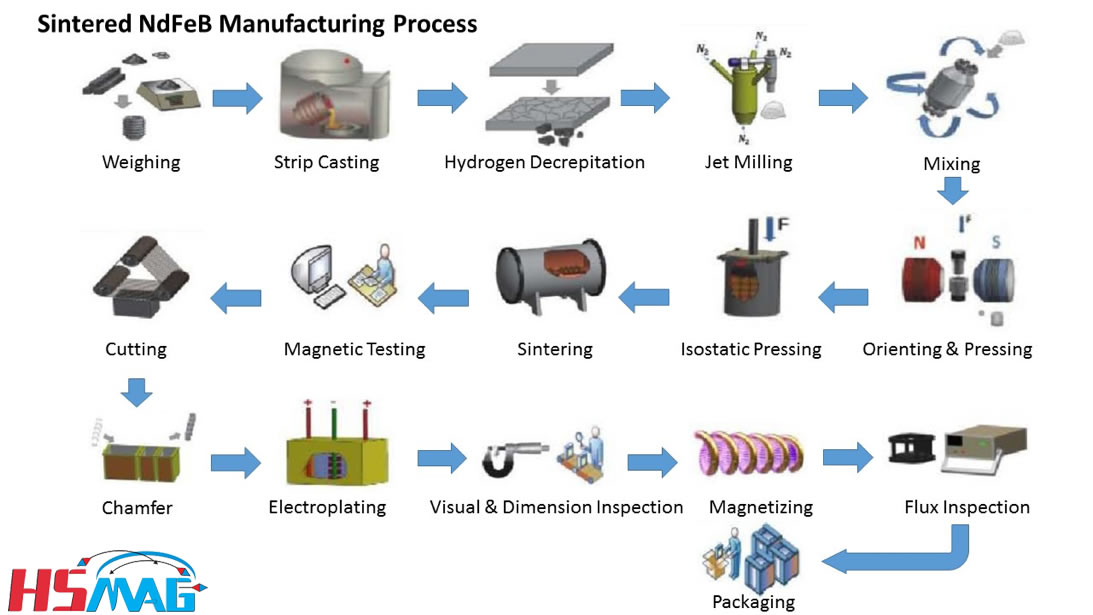

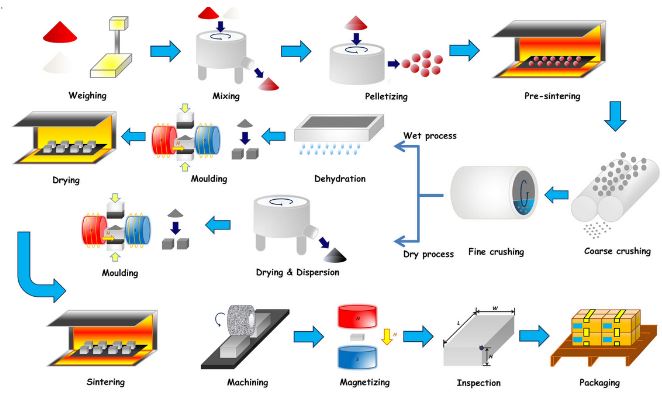

As of 2026, the global market for hard disc magnets—primarily neodymium-iron-boron (NdFeB) rare-earth magnets used in hard disc drives (HDDs)—is undergoing a period of transformation driven by evolving data storage demands, technological advancements, and shifting supply chain dynamics.

-

Stable but Niche Demand in HDDs

Despite the continued rise of solid-state drives (SSDs), hard disc drives maintain a strong foothold in data centers, enterprise storage, and archival applications due to their cost-effective high-capacity storage. This sustains steady, albeit mature, demand for high-performance magnets in voice coil motors (VCMs) that position read/write heads in HDDs. In 2026, HDD manufacturers are focusing on increasing areal density through technologies like heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR), which require enhanced magnetic precision and reliability—thus supporting continued use of premium-grade rare-earth magnets. -

Competition from SSDs Limits Growth

The broader adoption of SSDs in consumer electronics and enterprise systems has suppressed HDD volume growth. However, HDDs still dominate in cold and warm data storage, where cost per terabyte is critical. As a result, the hard disc magnet market is not expanding rapidly but remains stable, with demand concentrated in high-capacity enterprise drives (18TB and above), where magnet performance is crucial for fast actuator response and precision. -

Supply Chain and Geopolitical Pressures

China continues to dominate the production of rare-earth elements and sintered NdFeB magnets, accounting for over 80% of global supply. In 2026, geopolitical tensions and export controls have prompted HDD component manufacturers to diversify sourcing. Initiatives in the U.S., EU, and Japan to develop domestic rare-earth processing and magnet production are gaining momentum, driven by national security and supply chain resilience concerns. This could lead to increased investment in recycling technologies and alternative magnet materials over the medium term. -

Sustainability and Recycling Focus

Environmental regulations and ESG (Environmental, Social, and Governance) considerations are pushing the industry toward more sustainable practices. In 2026, there is growing interest in recycling rare-earth magnets from end-of-life HDDs and electronic waste. Pilot programs and partnerships between tech firms and recycling startups are emerging, aiming to recover neodymium and dysprosium for reuse—potentially reducing reliance on virgin materials and lowering environmental impact. -

Innovation and Material Substitution

While no immediate replacement for NdFeB magnets in HDD actuators has emerged, research into alternative materials—such as ferrite hybrids or improved permanent magnet designs—continues. However, performance trade-offs in size, speed, and energy efficiency have limited commercial adoption. As a result, the hard disc magnet market remains dependent on high-grade rare-earth magnets, though incremental improvements in magnet efficiency are contributing to smaller, more power-efficient HDDs.

Conclusion:

In 2026, the hard disc magnet market is characterized by stable demand within a mature HDD ecosystem, supported by ongoing innovation in high-capacity storage and heightened focus on supply chain security and sustainability. While long-term structural shifts toward SSDs and new storage technologies may eventually reduce reliance on HDDs, the need for high-performance magnets in enterprise and cloud storage ensures that the hard disc magnet segment remains relevant, albeit in a niche and specialized role.

Common Pitfalls in Sourcing Hard Disc Magnets (Quality, IP)

Sourcing hard disc magnets—typically high-performance neodymium (NdFeB) magnets recovered from decommissioned hard disk drives—can offer cost advantages, but introduces significant risks related to quality consistency and intellectual property (IP) compliance. Buyers must be aware of the following common pitfalls:

Inconsistent and Unpredictable Quality

Hard disc magnets are reclaimed from various manufacturers, models, and production batches, leading to inherent variability in magnetic properties such as grade (e.g., N35 to N52), coercivity, and dimensional tolerances. Without rigorous testing and sorting, sourced magnets may not meet the performance requirements of the target application, resulting in product failures or inefficiencies.

Lack of Traceability and Certification

Unlike commercially produced magnets, recycled hard disc magnets rarely come with material certifications, test reports, or traceable supply chain documentation. This absence complicates compliance with industry standards (e.g., ISO, RoHS) and undermines quality assurance processes, especially in regulated sectors like medical or aerospace.

Undisclosed or Degraded Magnetic Performance

Magnet performance degrades over time and with exposure to heat, corrosion, or mechanical stress. Hard disc magnets extracted from used drives may already be demagnetized or weakened, yet be sold as functional. Vendors may not disclose prior exposure to adverse conditions, leading to underperformance in end-use applications.

Intellectual Property and Legal Risks

Hard disc drives often contain proprietary magnet configurations, coatings, or assembly techniques protected by patents. Reusing or reverse-engineering these magnets without proper IP clearance may constitute infringement, exposing buyers to legal liability, especially when integrating them into commercial products.

No Warranty or Supplier Accountability

Most hard disc magnet suppliers operate in informal or secondary markets and do not offer warranties, return policies, or technical support. If a batch fails, recourse is limited, increasing operational risk and potentially disrupting production timelines.

Environmental and Ethical Compliance Gaps

Recycling processes for extracting magnets may not adhere to environmental regulations (e.g., improper handling of hazardous materials like nickel coatings or rare earth residues). Sourcing without verifying responsible recycling practices can expose companies to reputational risks and non-compliance with ESG (Environmental, Social, Governance) standards.

To mitigate these pitfalls, buyers should prioritize suppliers with transparent sourcing, independent quality testing, and IP due diligence—or consider investing in newly manufactured magnets with guaranteed specifications and compliance.

Logistics & Compliance Guide for Hard Disc Magnets

Hard disc magnets, typically made from rare-earth materials like neodymium (NdFeB), are powerful permanent magnets recovered from discarded hard disk drives (HDDs). Due to their strength and composition, they present specific logistics and compliance considerations for handling, shipping, recycling, or resale. This guide outlines key requirements and best practices.

Regulatory Classification and Hazard Identification

Hard disc magnets are subject to international and national regulations due to their magnetic strength and material composition.

- Magnetic Field Strength: Magnets with a magnetic field exceeding 0.00525 gauss measured at 7 feet (2.1 meters) are regulated as “magnetized material” under IATA Dangerous Goods Regulations (DGR) and IMDG Code.

- UN Number: Typically classified as UN2803, “Magnetized Material,” Class 9 – Miscellaneous Dangerous Goods.

- Hazard Labeling: Packages containing regulated magnets must display the Class 9 miscellaneous hazardous material label.

- Exemptions: Small quantities or weak magnets not exceeding the field threshold may be exempt, but verification via gauss meter measurement is required.

Packaging and Handling Requirements

Proper packaging is essential to ensure safety and regulatory compliance during transport.

- Shielding: Use ferromagnetic shielding (e.g., steel plates or containers) to contain magnetic fields and prevent interference with navigation equipment, pacemakers, and electronic devices.

- Separation: Keep magnets separated using non-magnetic spacers to prevent snapping together, which can cause injury or damage.

- Secure Containment: Pack in rigid, non-conductive containers (e.g., plastic or wooden crates) to prevent breakage and movement during transit.

- Demagnetization Option: For bulk transport, consider partial demagnetization to reduce field strength below regulatory thresholds (if acceptable for end-use).

International and Domestic Shipping Regulations

Shipping hard disc magnets requires adherence to multiple regulatory frameworks.

- IATA DGR (Air Transport):

- Must comply with Packing Instruction 953 for magnetized material.

- Requires proper documentation, including Shipper’s Declaration for Dangerous Goods when applicable.

-

Airlines may impose additional restrictions; pre-approval is recommended.

-

IMDG Code (Sea Freight):

- Class 9, UN2803 applies.

- Packages must pass the 7-foot magnetic field test.

-

Stowage away from sensitive cargo required.

-

DOT 49 CFR (U.S. Ground Transport):

- Regulated under Hazardous Materials Regulations (HMR).

- Similar packaging and labeling requirements as air/sea.

-

Non-hazardous if magnetic field test passes.

-

ADR (European Road Transport):

- Class 9, UN2803 applies.

- Requires appropriate labeling and documentation.

Documentation and Declarations

Accurate paperwork is critical for customs and safety compliance.

- Safety Data Sheet (SDS): Required under GHS; must include physical hazards, handling precautions, and disposal considerations.

- Shipper’s Declaration for Dangerous Goods: Mandatory when shipping regulated quantities by air or sea.

- Commercial Invoice and Packing List: Clearly describe contents as “Hard Disc Magnets” or “Recycled Neodymium Magnets,” noting weight, quantity, and UN classification if applicable.

- Export Controls: Check for ITAR or EAR restrictions if exporting from the U.S., especially for high-grade rare-earth materials.

Environmental and Recycling Compliance

Due to their rare-earth content, hard disc magnets may fall under environmental regulations.

- Waste Electrical and Electronic Equipment (WEEE): If sourcing from e-waste, ensure collection and processing comply with local WEEE directives.

- RoHS Compliance: Verify magnets do not contain restricted substances (e.g., lead, cadmium), though raw magnets typically comply.

- End-of-Life Disposal: Encourage recycling through certified rare-earth recovery programs; do not dispose of in general waste due to environmental impact.

Safety Precautions During Handling

Strong magnets pose physical and electronic risks.

- Personal Protection: Use gloves and eye protection to prevent pinching injuries or flying fragments.

- Pacemaker Warning: Maintain safe distance (minimum 6 inches) from individuals with medical implants.

- Electronics: Keep away from phones, credit cards, laptops, and monitors to avoid data loss or damage.

- Workplace Safety: Post warning signs in handling areas and train staff on magnet hazards.

Best Practices Summary

- Test magnetic field strength before shipping.

- Use certified hazardous materials packaging when required.

- Maintain complete documentation for traceability.

- Partner with licensed recyclers for end-of-life management.

- Stay updated on evolving regulations (e.g., EU Battery Regulation, U.S. EPA guidelines).

Adhering to this guide ensures safe, legal, and environmentally responsible logistics for hard disc magnets across global supply chains.

Conclusion on Sourcing Hard Disk Magnets

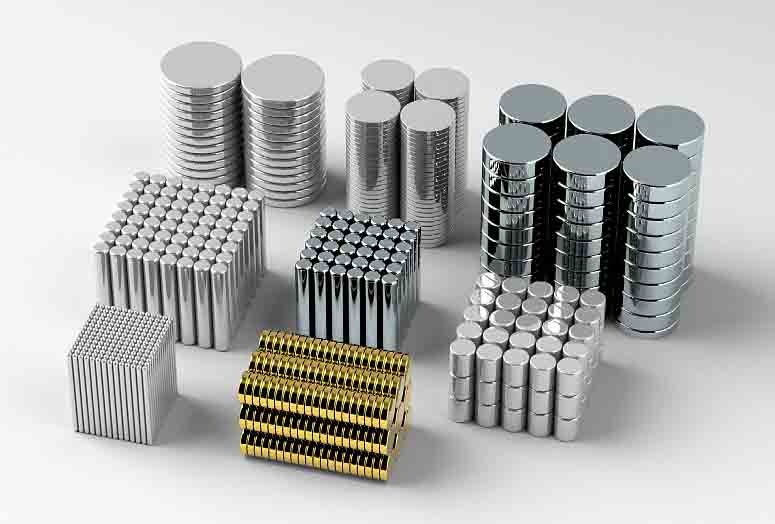

Sourcing magnets from hard disk drives (HDDs) presents a viable and cost-effective method for obtaining strong neodymium magnets, commonly used in DIY projects, engineering prototypes, and educational demonstrations. These magnets are known for their high magnetic strength, durability, and compact size, making them highly desirable for various applications such as motors, sensors, magnetic couplings, and science experiments.

When sourcing hard disk magnets, it is important to consider several factors: availability of used or discarded HDDs (often obtainable from e-waste recycling centers, IT departments, or online marketplaces), safety during disassembly (including protection from sharp components and brittle magnet fragments), and proper handling due to the powerful magnetic fields that can interfere with electronic devices or cause injuries if not managed carefully.

While extracting magnets from HDDs is economical and supports recycling efforts, it may not be suitable for large-scale or industrial applications due to inconsistencies in size, strength, and quantity. For such needs, purchasing commercially manufactured neodymium magnets may be more practical and reliable.

In summary, sourcing magnets from hard disk drives is an efficient, sustainable, and affordable option for hobbyists, educators, and small-scale innovators. With proper safety precautions and realistic expectations, reusing these high-performance magnets contributes to both cost savings and environmental responsibility.

![Hard Drive Magnets [Function Material Supplier]](https://www.sohoinchina.com/wp-content/uploads/2026/01/hard-drive-magnets-function-material-supplier-261.jpg)