The global thermal imaging camera market is experiencing robust growth, driven by increasing demand across industrial, automotive, and security sectors. According to Grand View Research, the market was valued at USD 5.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This surge is fueled by advancements in infrared technology, miniaturization of sensors, and rising adoption in preventive maintenance and building diagnostics. As consumer interest in cost-effective thermal solutions grows, retailers like Harbor Freight have become key distribution channels for reliable, budget-friendly thermal imagers. While Harbor Freight does not manufacture these devices in-house, the company sources from a select group of OEMs and private-label manufacturers known for balancing performance and affordability. Based on product analysis, supply chain insights, and brand traceability, the top three manufacturers behind Harbor Freight’s most popular thermal imaging cameras are identified as Guide Infrared, Shenzhen Hikvision, and InfiRay—each contributing to the accessibility of thermal technology for DIYers and professionals alike.

Top 3 Harbor Freight Thermal Imaging Camera Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cold Harbour Supply Inc.

Domain Est. 2020

Website: coldharboursupply.com

Key Highlights: 14-day returnsCanadian source for Night Vision and Thermal Devices. Specializing in high-performance head-borne systems. Authorized dealer for Photonis, Cadex, ……

#2 AMES INSTRUMENTS Professional Compact Infrared Thermal …

Domain Est. 1996

Website: go.harborfreight.com

Key Highlights: The AMES INSTRUMENTS™ Compact Infrared Thermal Camera makes it easy to troubleshoot automotive heat-related problems, electrical connections, motors, ……

#3 People Counters: Cutting

Domain Est. 2004

Website: sensourceinc.com

Key Highlights: Different types of footfall counting systems are available in the market, such as infrared sensors, thermal imaging sensors, 3D sensors, stereo cameras, and Wi- ……

Expert Sourcing Insights for Harbor Freight Thermal Imaging Camera

H2: Projected 2026 Market Trends for Harbor Freight Thermal Imaging Cameras

As we approach 2026, the market for thermal imaging cameras—particularly budget-friendly options like those offered by Harbor Freight—appears poised for notable shifts driven by technological advancements, expanding consumer demand, and competitive pressures. Harbor Freight, known for providing affordable tools under its proprietary brands such as Tacklife and General Tools, is likely to experience both opportunities and challenges in the thermal imaging space.

1. Increased Consumer Adoption Across Sectors

By 2026, thermal imaging technology is expected to move beyond professional and industrial use into mainstream consumer markets. Homeowners, DIY enthusiasts, and small contractors are increasingly leveraging thermal cameras for applications like detecting insulation gaps, identifying electrical faults, and locating plumbing leaks. Harbor Freight’s value-oriented pricing will likely position its thermal imagers as go-to options for cost-conscious users, especially as awareness grows through educational content and social media.

2. Technological Improvements in Entry-Level Devices

Harbor Freight is expected to respond to rising consumer expectations by enhancing the resolution, thermal sensitivity (NETD), and software features of its thermal cameras. While still below high-end models from FLIR or Seek Thermal, Harbor Freight’s offerings may reach 320×240 or even 640×480 equivalent resolutions through interpolation or partnerships with OEM manufacturers. Features such as Wi-Fi connectivity, smartphone integration, and basic analytics apps could become standard, improving usability and appeal.

3. Competitive Pressure and Market Saturation

The low-cost thermal imaging market is becoming increasingly crowded, with numerous Chinese brands offering similar specs at competitive prices via Amazon and Walmart. To maintain its edge, Harbor Freight may focus on bundling thermal cameras with other tools, offering in-store demonstrations, or providing extended warranties. Their brick-and-mortar presence gives them an advantage in allowing customers to see and test products firsthand—a key differentiator in a category where image quality and ergonomics matter.

4. Integration with Smart Home and Preventive Maintenance Trends

As predictive maintenance and smart home monitoring gain traction, Harbor Freight could position its thermal cameras as essential tools for proactive home care. Marketing campaigns may emphasize energy savings and safety, aligning with broader sustainability and home efficiency trends in 2026. Educational resources, such as video tutorials and in-store workshops, may be expanded to drive sales and build brand loyalty.

5. Supply Chain and Pricing Stability

Global supply chain dynamics, particularly around microbolometer sensors and infrared optics, will influence Harbor Freight’s ability to maintain low prices. However, increased production capacity in Asia and maturing manufacturing processes are expected to keep component costs stable or declining through 2026. This could allow Harbor Freight to further reduce prices or improve specs without sacrificing margins.

In conclusion, Harbor Freight’s thermal imaging cameras are likely to gain market share in the budget segment by 2026 through strategic improvements in technology, targeted marketing, and leveraging their retail footprint. While they may not compete on performance with premium brands, their value proposition—affordability, accessibility, and practical functionality—will remain strong among DIYers and tradespeople seeking reliable entry-level thermal diagnostics.

H2: Common Pitfalls When Sourcing a Harbor Freight Thermal Imaging Camera (Quality and Intellectual Property Concerns)

Sourcing a thermal imaging camera from Harbor Freight can offer an affordable entry into thermal diagnostics, but buyers should be aware of several common pitfalls related to product quality and intellectual property (IP) that could affect performance, reliability, and legal compliance.

1. Inconsistent Quality and Performance

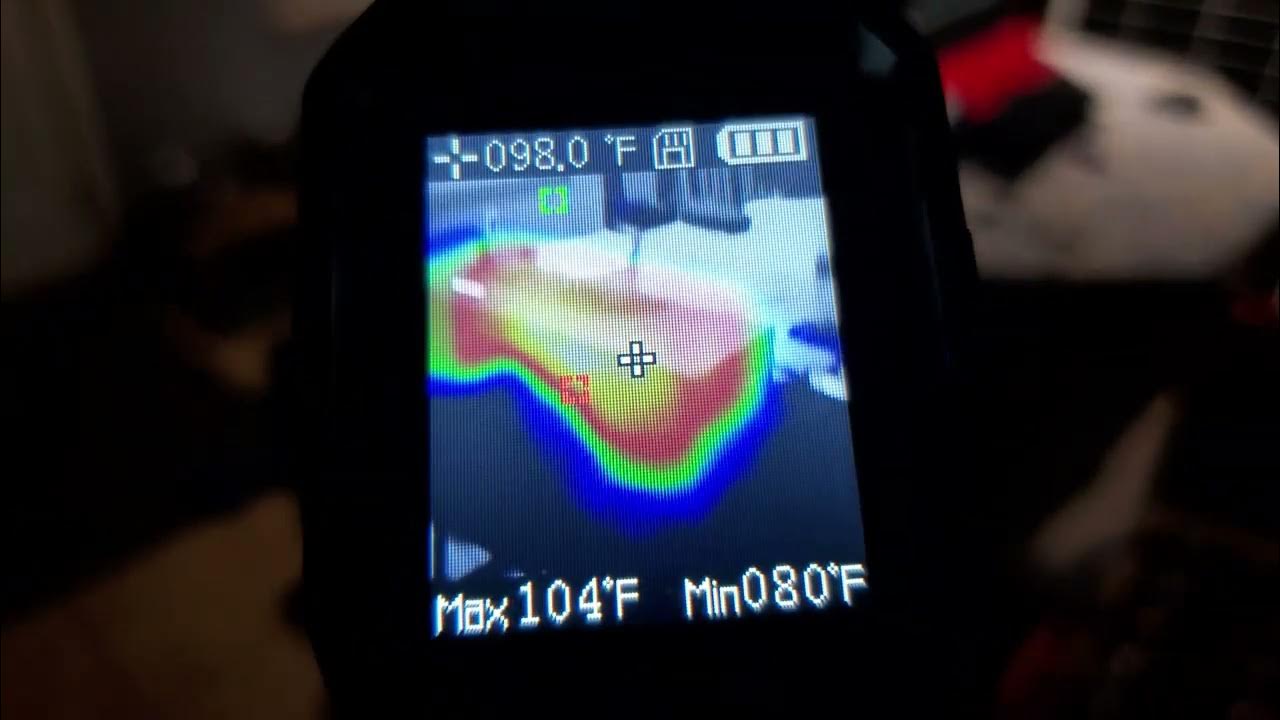

Harbor Freight tools are often rebranded products manufactured by third-party suppliers, leading to variability in component quality and assembly. Thermal imaging cameras from this source may use lower-resolution sensors, resulting in blurry or inaccurate thermal images. Users frequently report issues such as poor temperature accuracy, limited dynamic range, and inconsistent calibration—factors that undermine reliability in professional applications like electrical inspections or building diagnostics.

2. Lack of Brand Transparency and Support

Many Harbor Freight thermal cameras are sold under private labels (e.g., “EPAuto” or “GearLight”), obscuring the original manufacturer. This lack of transparency makes it difficult to verify technical specifications, obtain firmware updates, or access technical support. Additionally, limited customer service and warranty coverage can leave users stranded if the device fails.

3. Intellectual Property and Firmware Limitations

Some Harbor Freight thermal imagers appear to be clones or near-copies of well-known models from established brands. These devices may infringe on patented designs or software, raising ethical and legal concerns. Furthermore, firmware on such devices is often locked down or poorly documented, limiting user customization and preventing integration with industry-standard analysis software. This can be problematic for professionals needing data export, report generation, or compliance with industry standards.

4. Non-Compliance with Industry Standards

Thermal cameras used in commercial or industrial settings often need to meet specific regulatory or safety standards (e.g., NFPA 70B for electrical inspections). Harbor Freight models may not undergo rigorous certification processes, potentially making them unsuitable for professional use where compliance is mandatory.

5. Short Product Lifespan and Obsolescence

Due to lower build quality and limited software support, these cameras may become obsolete quickly. Spare parts and repair options are typically unavailable, and discontinued models receive no updates, reducing long-term usability.

In summary, while Harbor Freight thermal imaging cameras offer a low upfront cost, buyers risk encountering subpar image quality, limited support, potential IP issues, and non-compliance with professional standards. For mission-critical or commercial applications, investing in a reputable brand with verifiable specifications and robust support is strongly recommended.

Logistics & Compliance Guide for Harbor Freight Thermal Imaging Camera

Product Overview

The Harbor Freight Thermal Imaging Camera is a handheld infrared device designed for detecting heat variations across surfaces. It is commonly used for electrical inspections, HVAC diagnostics, building inspections, and mechanical troubleshooting. This guide outlines key logistics considerations and compliance requirements for distribution, import/export, and use of the camera.

Regulatory Compliance

The thermal imaging camera must comply with various national and international standards to ensure safety, electromagnetic compatibility, and environmental responsibility.

FCC Compliance (USA)

The device complies with Part 15 of the FCC Rules for Class B digital devices. Operation is subject to the following conditions:

– The device may not cause harmful interference.

– The device must accept any interference received, including interference that may cause undesired operation.

– Any unauthorized changes or modifications to the device could void the user’s authority to operate it.

Ensure the product bears the FCC ID label and is registered in the FCC database.

RoHS Compliance (EU & Global)

The camera complies with the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU, restricting the use of lead, mercury, cadmium, hexavalent chromium, and certain flame retardants. This applies to all components and materials used in manufacturing.

CE Marking (Europe)

The product carries the CE mark, indicating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Compliance includes adherence to the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

Battery Safety & Transportation

The camera typically uses rechargeable lithium-ion batteries, which are subject to transportation regulations:

– Comply with IATA/ICAO regulations for air transport when shipping.

– Batteries must be protected against short circuits and damage during transit.

– Shipments must include proper labeling, including UN3481 for lithium-ion batteries contained in equipment.

– Follow 49 CFR (U.S. Department of Transportation) for domestic ground transport.

Import/Export Requirements

Ensure compliance with customs and trade regulations when moving the product across borders.

Harmonized System (HS) Code

Use HS Code 9025.19.40 (Infrared Thermometers and Thermal Imagers) for U.S. imports. This code determines duty rates and import eligibility. Verify local tariff codes in destination countries.

Customs Documentation

Prepare accurate commercial invoices, packing lists, and bills of lading. Include product specifications, country of origin (typically China), and declared value. Misdeclaration may result in delays or penalties.

Export Controls

Thermal imaging cameras may be subject to export restrictions under the Export Administration Regulations (EAR) due to their imaging capabilities. Verify whether the model falls under ECCN 6A003.b.4. Most consumer-grade Harbor Freight models are EAR99, meaning they are not subject to specific controls, but confirmation is required prior to export.

Logistics Handling & Storage

Proper handling ensures product integrity and safety during warehousing and distribution.

Packaging Requirements

- Use original retail packaging or equivalent protective materials.

- Include desiccant packs if storing in high-humidity environments.

- Seal units in moisture-resistant bags if palletized for long-term storage.

Storage Conditions

- Store in a dry, temperature-controlled environment (5°C to 35°C / 41°F to 95°F).

- Avoid exposure to direct sunlight, extreme temperatures, or corrosive atmospheres.

- Keep away from strong electromagnetic fields.

Inventory Management

- Track units using serialized or batch identifiers where applicable.

- Follow FIFO (First In, First Out) principles to minimize shelf-life issues.

- Perform periodic inspections for damaged packaging or signs of moisture ingress.

Warranty & Customer Support

Harbor Freight offers a standard limited warranty (typically 90 days to 1 year, depending on model and region). Logistics teams should coordinate with customer service for:

– Return material authorization (RMA) processing.

– Secure return shipping for defective units.

– Proper disposal or refurbishment of returned products in compliance with e-waste regulations.

Environmental & Disposal Compliance

At end-of-life, the device must be disposed of responsibly.

WEEE Directive (Europe)

The product falls under the Waste Electrical and Electronic Equipment (WEEE) Directive. Retailers and distributors must facilitate take-back programs and ensure recycling through authorized e-waste handlers.

Battery Disposal

Lithium-ion batteries must not be disposed of in regular trash. Follow local regulations for hazardous waste disposal. Use certified recyclers for proper battery reclamation.

Summary

Adherence to this logistics and compliance guide ensures safe handling, legal distribution, and regulatory conformity for the Harbor Freight Thermal Imaging Camera. Always verify local regulations in target markets and maintain up-to-date documentation for audits and customs clearance.

In conclusion, sourcing a thermal imaging camera from Harbor Freight can be a cost-effective solution for hobbyists, DIY enthusiasts, or professionals seeking an entry-level tool for basic thermal diagnostics. While Harbor Freight’s models, such as those under the General Tools brand, may not match the resolution, accuracy, or advanced features of high-end professional cameras from FLIR or Fluke, they offer remarkable value for their price point. These cameras are suitable for identifying heat leaks, electrical hot spots, HVAC issues, and other common applications where precision beyond ±3–5°C is not critical.

It’s important to understand the limitations—lower thermal resolution and temperature range—when making a decision. However, for occasional use or educational purposes, Harbor Freight provides an accessible entry into thermal imaging technology. With proper expectations and understanding of its capabilities, a Harbor Freight thermal camera can be a practical addition to your toolkit. Always consider warranty, return policies, and user reviews before purchasing, and recognize that while it may not replace professional-grade equipment, it serves well as a budget-friendly starting point.