The global handrail systems market is experiencing steady expansion, driven by rising infrastructure development, stringent safety regulations, and growing demand for aesthetic architectural solutions in commercial and residential buildings. According to Grand View Research, the global railing systems market size was valued at USD 37.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is further fueled by urbanization, increased construction activities in emerging economies, and a shift toward modern, minimalist design trends that prioritize both functionality and visual appeal. As demand for durable, code-compliant, and customizable handrail profiles surges, manufacturers are innovating with materials like stainless steel, aluminum, and composite polymers to meet evolving performance and design standards. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining engineering precision, scalable production, and global distribution networks to capture significant market share. The following list highlights the top 10 handrail profile manufacturers shaping the industry through product innovation, sustainable practices, and data-backed performance metrics.

Top 10 Handrail Profiles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

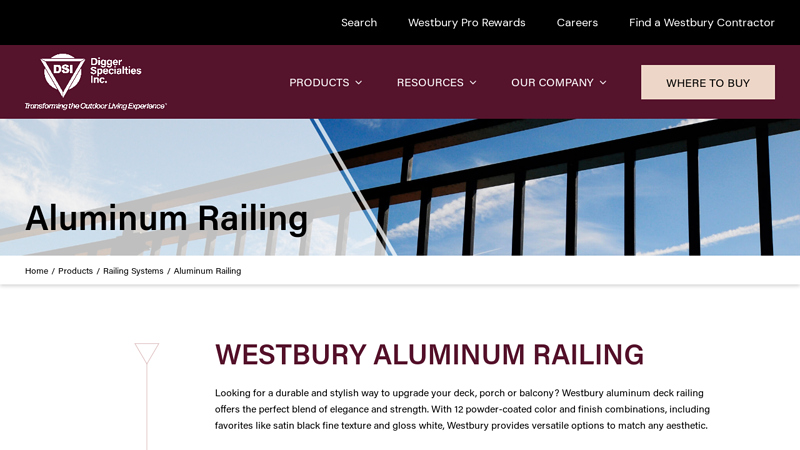

#1 Westbury Aluminum Deck Railing

Domain Est. 1998

Website: diggerspecialties.com

Key Highlights: Choose from a wide range of powder-coated colors and profiles and explore add-ons like aluminum deck railing with drink rails for ……

#2 Stair Products

Domain Est. 1998

Website: andersonwood.com

Key Highlights: When you think of stair parts, consider Anderson Wood, one of America’s largest producers of lineal stair components; handrail, bending rail, wall rail, shoe…

#3 Railcraft International

Domain Est. 1999 | Founded: 1985

Website: railcraft.com

Key Highlights: Railcraft has been the leading designer/manufacturer of high quality engineered powder coated aluminum railing products in North America since 1985….

#4 Aluminium Handrail Profiles Factory

Domain Est. 2016

Website: pailian-aluminium.com

Key Highlights: As a leading aluminum profile source factory, we specialize in the production of customized aluminum profiles, including handrail profiles….

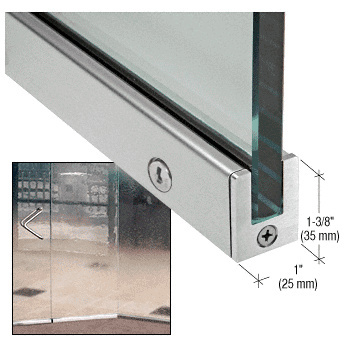

#5 CRL

Domain Est. 1995

Website: crlaurence.com

Key Highlights: The leading full-service provider of architectural metals, glass fittings & professional-grade glazing supplies. Shop CRL’s architectural hardware today….

#6 Architectural Metal Work Stock Components

Domain Est. 1996

Website: juliusblum.com

Key Highlights: Explore our extensive range of pre-engineered architectural stock components, crafted for handrails and decorative elements in structures….

#7 Handrails

Domain Est. 1997

Website: ljsmith.com

Key Highlights: Our handrail profiles of over 30 styles provide plenty of options to choose from. Explore the various coordinating handrail fittings….

#8 Glass and Stainless Steel Handrails

Domain Est. 2003

Website: comenza.com

Key Highlights: Comenza: the global company specializing in the development of glass railing systems and stainless steel modular handrails Unique projects!…

#9 Your specialist for railing systems

Domain Est. 2004

Website: q-railing.com

Key Highlights: Top quality and easy installation: at Q-railing you will find the largest selection of glass railings, handrails, handrail brackets, glass clamps and much ……

#10 Handrails

Domain Est. 2012

Website: boldmfg.com

Key Highlights: We offer two expertly crafted handrail profiles in lengths from 18″ up to 21′ long. Durable Satin Matte Black Powder Coated Finish. Custom Lengths? No Problem….

Expert Sourcing Insights for Handrail Profiles

H2: 2026 Market Trends for Handrail Profiles

The global handrail profiles market is projected to experience significant transformation by 2026, driven by advancements in materials, shifting architectural preferences, and increasing emphasis on safety and accessibility. Key trends shaping the industry include:

1. Rising Demand for Sustainable and Recyclable Materials

Environmental concerns are pushing manufacturers and architects toward eco-friendly handrail solutions. Aluminum and recycled stainless steel are gaining favor due to their durability and low carbon footprint. By 2026, an increasing number of handrail profiles are expected to be manufactured using sustainable processes, aligning with green building certifications such as LEED and BREEAM.

2. Growth in Modern Architectural Design

Contemporary building aesthetics emphasize minimalism, transparency, and seamless integration. As a result, frameless glass balustrades with sleek aluminum or stainless steel handrail profiles are becoming standard in both residential and commercial spaces. The demand for custom-designed, aesthetically pleasing handrails—particularly in high-end urban developments—is a major growth driver.

3. Expansion in the Aging Population and Accessibility Needs

With global demographics trending toward an older population, there is heightened focus on universal design and accessibility. Regulatory standards such as the Americans with Disabilities Act (ADA) and similar regional codes are mandating compliant handrail installations in public and private buildings. This is increasing demand for ergonomic, slip-resistant, and height-adjustable handrail profiles.

4. Technological Integration and Smart Rail Systems

By 2026, smart building technologies are beginning to influence handrail design. Some high-end installations are incorporating handrails with embedded sensors for occupancy monitoring, temperature control, or emergency alerts. While still in early adoption, this trend signals a shift toward multifunctional structural components.

5. Regional Market Growth and Construction Booms

Asia-Pacific, particularly China and India, is expected to lead market expansion due to rapid urbanization and infrastructure development. Meanwhile, North America and Europe continue to grow steadily, driven by renovation projects and stringent safety regulations. The commercial construction sector—especially in healthcare, hospitality, and transit hubs—remains a key end-user segment.

6. Advancements in Manufacturing and Customization

Extrusion technologies, particularly in aluminum profiles, are enabling greater design flexibility and faster production cycles. Digital fabrication and 3D modeling allow for precise customization, reducing waste and installation time. By 2026, made-to-order handrail systems are expected to dominate premium market segments.

In conclusion, the handrail profiles market in 2026 will be defined by innovation, sustainability, and regulatory compliance. Companies that prioritize design versatility, material efficiency, and smart integration will be best positioned to capture growing opportunities across global construction sectors.

Common Pitfalls Sourcing Handrail Profiles (Quality, IP)

When sourcing handrail profiles for construction, architectural, or industrial applications, overlooking critical quality and intellectual property (IP) considerations can lead to safety risks, legal complications, and increased long-term costs. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting handrail profiles based solely on upfront cost. Low-cost suppliers may use substandard materials—such as inferior-grade aluminum, plastic, or poorly extruded metals—that compromise durability, structural integrity, and finish quality. Over time, this can lead to premature wear, corrosion, or even safety failures, especially in high-traffic or outdoor environments.

Tip: Evaluate material specifications (e.g., ASTM standards for aluminum or steel), wall thickness, and surface finish quality. Request samples and third-party test reports when possible.

2. Inconsistent Dimensional Tolerances

Poorly manufactured handrail profiles often exhibit inconsistent dimensions, making installation difficult and leading to misaligned joints, gaps, or the need for custom modifications. This is especially problematic in large-scale projects where uniformity is critical.

Tip: Specify tight tolerance requirements in procurement contracts and verify samples before committing to bulk orders.

3. Lack of Compliance with Safety and Building Codes

Handrail profiles must meet regional safety standards (e.g., ADA in the U.S., BS EN in Europe) regarding height, diameter, grip comfort, and structural load capacity. Sourcing non-compliant profiles can result in project delays, rework, or regulatory penalties.

Tip: Confirm compliance with relevant codes during the supplier vetting process. Request documentation such as certificates of conformance or third-party certifications.

4. Overlooking Surface Finish and Durability

The finish of a handrail profile affects not only aesthetics but also longevity and maintenance. Poor anodizing, powder coating, or polishing can lead to chipping, fading, or corrosion—especially in humid or high-touch environments.

Tip: Specify finish types and performance standards (e.g., AAMA 2604 for coatings) and conduct salt spray or abrasion testing on samples.

5. Ignoring Intellectual Property Rights

Many handrail profile designs—especially custom or architecturally distinctive ones—are protected by design patents, trademarks, or copyrights. Sourcing generic copies or “look-alike” products from suppliers who replicate protected designs can expose your project or company to IP infringement claims.

Tip: Verify that the design is either licensed, in the public domain, or sufficiently differentiated. Request indemnification clauses in supplier contracts regarding IP liability.

6. Working with Unverified Suppliers

Sourcing from manufacturers without proper credentials, quality control systems, or traceability increases the risk of receiving counterfeit or non-conforming products. This is particularly common when sourcing from overseas markets without due diligence.

Tip: Conduct supplier audits, request ISO certifications, and use trusted procurement channels. Consider on-site inspections or third-party quality checks for large orders.

7. Inadequate Documentation and Traceability

Lack of material test reports (MTRs), manufacturing certifications, or batch traceability makes it difficult to verify quality or respond to failure investigations. This is critical for projects requiring compliance documentation for insurance or regulatory purposes.

Tip: Require full documentation packages with every delivery and maintain records for the project lifecycle.

Conclusion

Avoiding these common pitfalls requires a proactive approach to sourcing—emphasizing quality assurance, regulatory compliance, and IP due diligence. Investing time upfront in vetting suppliers and specifications ensures safer, more durable installations and protects against legal and reputational risks.

Logistics & Compliance Guide for Handrail Profiles

This guide outlines the essential logistics considerations and compliance requirements for the manufacturing, transportation, handling, and installation of handrail profiles, ensuring safety, regulatory adherence, and efficient supply chain operations.

Material Sourcing & Specifications

Ensure raw materials (e.g., stainless steel, aluminum, wood, or composite) meet industry standards such as ASTM, EN, or ISO specifications. Verify mill certifications for metals and moisture resistance ratings for wood-based profiles. Source from suppliers with documented quality management systems (e.g., ISO 9001) to maintain consistency and traceability.

Manufacturing Standards & Quality Control

Manufacturing processes must adhere to applicable building codes and standards, including:

– International Building Code (IBC)

– Americans with Disabilities Act (ADA) Standards for Accessible Design

– OSHA regulations (for workplace safety during production)

– Regional standards such as BS EN 1090 (for metal structures in Europe)

Implement in-line quality checks for dimensional accuracy, surface finish, and structural integrity. Maintain batch records and non-conformance reports to support compliance audits.

Packaging & Handling Requirements

Handrail profiles must be packaged to prevent damage during transit:

– Use protective wrapping (e.g., plastic film, foam corners) for scratch-sensitive materials.

– Secure long profiles in crated or bundled configurations to avoid bending.

– Label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and product details (length, material grade, finish).

Transportation & Shipping

Coordinate logistics based on profile length, weight, and destination:

– Use enclosed or covered vehicles to protect against weather and contamination.

– Comply with load securement regulations (e.g., US DOT, ADR in Europe).

– For international shipments, ensure adherence to ISPM 15 for wood packaging materials and prepare accurate customs documentation (e.g., HS codes, certificates of origin).

Storage & Site Handling

Store handrail profiles in a dry, level environment off the ground:

– Protect from moisture, UV exposure (for composites), and chemical contact.

– Avoid stacking heavy materials on top of profiles to prevent warping or deformation.

– On-site, use proper lifting equipment and follow safe handling procedures to reduce worker injury risk.

Installation Compliance

Ensure installation follows jurisdiction-specific building codes:

– Handrail height must comply with IBC/ADA (typically 34–38 inches above stair nosing).

– Continuous gripping surface without obstructions.

– Proper spacing and support intervals (e.g., max 4 feet between brackets for metal rails).

– Provide required clearances (e.g., 1.5 inches from wall for graspability).

Engage certified installers and conduct post-installation inspections to verify conformance.

Documentation & Traceability

Maintain complete records for compliance and liability purposes:

– Material test reports (MTRs)

– Certificates of compliance (CoC)

– As-built drawings and installation records

– Third-party inspection reports (if applicable)

These documents should be readily available for auditors, building inspectors, or clients.

Environmental & Safety Compliance

Adhere to environmental regulations during production and disposal:

– Manage metal shavings, coatings, and chemical waste per EPA or local environmental laws.

– Use low-VOC finishes where applicable.

– Follow workplace safety protocols (e.g., PPE, machine guarding) in accordance with OSHA or equivalent bodies.

By following this logistics and compliance framework, stakeholders can ensure handrail profiles are delivered and installed safely, legally, and to the highest quality standards.

In conclusion, sourcing handrail profiles requires a careful balance of material quality, design compatibility, regulatory compliance, and cost-efficiency. The selection process should prioritize durability, safety standards (such as ADA and building code requirements), and aesthetic alignment with the overall architectural vision. Whether choosing stainless steel, aluminum, wood, or composite materials, it is essential to partner with reliable suppliers who offer consistent product quality, customization options, and timely delivery. Additionally, considering long-term maintenance and lifecycle costs can lead to more sustainable and economical choices. By conducting thorough research, evaluating multiple vendors, and ensuring clear specifications, project stakeholders can secure handrail profiles that meet both functional and design objectives, ultimately contributing to safer and more cohesive built environments.