The global mobility aids market is experiencing robust growth, driven by an aging population, rising prevalence of disabilities, and increasing focus on independent living. According to Mordor Intelligence, the global walking aids market—encompassing canes, crutches, walkers, and handicap handles—was valued at USD 2.4 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2030. Similarly, Grand View Research reports that the broader assistive technologies market is expanding steadily, fueled by advancements in ergonomics and accessibility standards worldwide. As demand for bathroom safety and accessible infrastructure grows, so does the need for high-quality handicap handles. These products are critical in preventing falls and enhancing mobility for elderly and disabled individuals, particularly in residential and healthcare settings. With stringent regulations and building codes increasingly mandating grab rail installations, manufacturers specializing in durable, ADA-compliant, and innovative designs are gaining prominence. The following analysis identifies the top 8 handicap handles manufacturers leading the industry through product excellence, compliance, and technological integration.

Top 8 Handicap Handles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bradley Corp

Domain Est. 1995

Website: bradleycorp.com

Key Highlights: Bradley is the industry’s leading manufacturer of commercial plumbing fixtures and washroom accessories. We have the right product for all industrial ……

#2 Manufacturers Grab bars

Domain Est. 2009

Website: archiproducts.com

Key Highlights: Grab bars. Search all manufacturers of Grab bars: discover prices, catalogues and new features….

#3 Luxury Handicap Bathroom Accessories Manufacturer & Suppliers …

Domain Est. 2011

Website: perkindia.com

Key Highlights: We are supplier, manufacturer, dealer and wholesaler of Stainless Steel luxury Bathroom & Toilet Accessories for disabled or handicapped in Delhi, Noida….

#4 Binson’s: Enroll Online for Medical Supplies

Domain Est. 1996 | Founded: 1953

Website: binsons.com

Key Highlights: Explore top-quality medical equipment, supplies, and services at Binson’s. Discover unparalleled care at our MI, IN, and FL stores. Trusted since 1953….

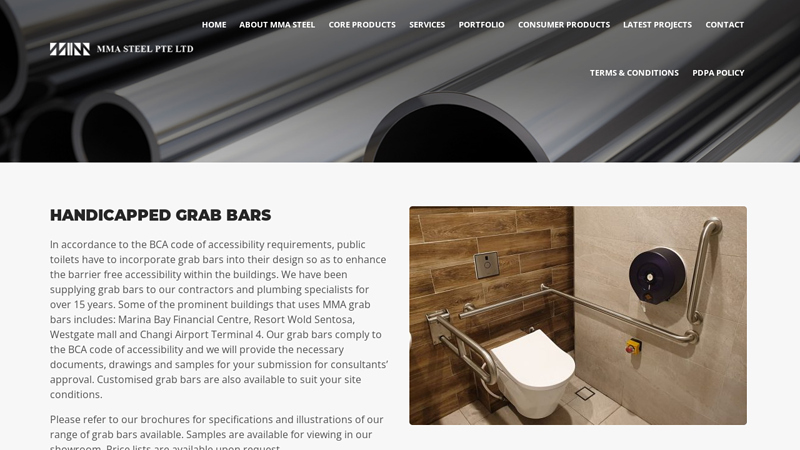

#5 BCA compliant handicapped grab bars supplier

Domain Est. 2000

Website: mma.com.sg

Key Highlights: MMA Steel supply handicapped grab bars, ambulant disabled grab bars and urinal grab bars. Our stainless steel toilet grab bars follows BCA compliance….

#6 Drive Medical

Domain Est. 2002

Website: drivemedical.com

Key Highlights: Built for healthcare professionals and caregivers, our 5000 products support mobility, safety, and care in settings from home to long-term care facilities….

#7 Handicap Grab Bars

Domain Est. 2018

Website: ydvalves.com

Key Highlights: High-Quality Handicap Grab Bars for Your Applications is Attainable With YD, Which is One of Leading Handicap Grab Bar suppliers in China. Send Your Inquiry Now….

#8 Furniture fittings, architectural hardware, electronic locking systems …

Website: hafele.com.de

Key Highlights: Häfele is an international company providing hardware and fitting systems and electronic access control systems. Around the world, customers from the furniture ……

Expert Sourcing Insights for Handicap Handles

H2: 2026 Market Trends for Handicap Handles

The global market for handicap handles, also known as grab bars or support handles, is poised for significant evolution by 2026, driven by demographic shifts, technological innovation, and increased accessibility awareness. This analysis outlines key trends shaping the handicap handles market in the coming years.

-

Aging Population Driving Demand

A primary driver of market growth is the rapidly aging global population. By 2026, the number of individuals aged 65 and older is projected to exceed 700 million, particularly in developed regions like North America, Europe, and parts of Asia. With age comes an increased risk of mobility challenges and fall-related injuries, making handicap handles essential in both residential and public settings. Demand for bathroom safety products, including wall-mounted and floor-to-ceiling grab bars, will continue to rise in senior living facilities, assisted care homes, and age-friendly home renovations. -

Smart and Sensor-Integrated Handles

By 2026, a notable trend will be the integration of smart technology into handicap handles. Emerging products will feature embedded motion sensors, pressure detection, and connectivity to home automation systems. These smart handles can alert caregivers or emergency services if a fall is detected or if unusual usage patterns are observed. Some models may also include LED lighting that activates upon approach, enhancing safety in low-light environments. -

Focus on Universal Design and Aesthetics

Consumers and designers are increasingly prioritizing aesthetics without compromising functionality. Handicap handles are no longer seen as purely clinical or medical devices. In 2026, the market will see a surge in stylish, minimalist grab bars that blend seamlessly with modern bathroom and kitchen designs. Materials such as brushed nickel, matte black, and wood-look finishes will be in high demand, appealing to younger users and homeowners seeking universal design that accommodates all ages and abilities. -

Expansion in Emerging Markets

While North America and Europe remain dominant, growth in emerging markets—particularly in Asia-Pacific and Latin America—will accelerate by 2026. Rising middle-class populations, urbanization, and government initiatives promoting inclusive infrastructure are fueling demand. Countries like India, China, and Brazil are expected to implement stricter building codes for accessibility, driving adoption in public buildings, transportation hubs, and new housing developments. -

Sustainability and Eco-Friendly Materials

Environmental concerns will influence material choices and manufacturing processes. By 2026, manufacturers will increasingly adopt sustainable practices, using recyclable metals, low-impact coatings, and energy-efficient production methods. Consumers will favor brands that provide transparent sustainability reporting and offer long-lasting, low-maintenance products to reduce environmental footprint. -

E-Commerce and Direct-to-Consumer Growth

Online retail will continue to dominate the distribution landscape. By 2026, consumers will rely heavily on e-commerce platforms for researching, comparing, and purchasing handicap handles. Augmented reality (AR) tools will allow users to visualize how grab bars will look and function in their homes before buying. Subscription models for maintenance or upgrades may also emerge, especially for smart handle systems. -

Regulatory and Accessibility Standards

Governments and international organizations will tighten accessibility regulations, especially in public infrastructure and multi-family housing. The 2026 market will reflect stronger compliance with standards such as the ADA (Americans with Disabilities Act), ISO 21542 (building accessibility), and local codes. This regulatory push will create new opportunities for manufacturers who offer certified, code-compliant products.

In conclusion, the 2026 market for handicap handles will be shaped by a confluence of demographic, technological, and regulatory forces. Companies that innovate with smart features, embrace inclusive design, and expand into high-growth regions will be well-positioned to lead this expanding market.

Common Pitfalls When Sourcing Handicap Handles: Quality and Intellectual Property Concerns

When sourcing handicap handles—also known as grab bars or support handles for accessibility—businesses and procurement professionals often encounter challenges that can impact safety, compliance, and legal standing. Two major areas of concern are product quality and intellectual property (IP) risks. Understanding these pitfalls is essential to ensure reliable, safe, and legally compliant procurement.

1. Compromised Product Quality

One of the most frequent pitfalls in sourcing handicap handles is receiving substandard products that fail to meet safety and durability requirements. Key quality-related issues include:

-

Inadequate Material Strength: Some suppliers use inferior materials (e.g., thin-wall tubing or low-grade stainless steel) that cannot support required load capacities, posing serious safety risks.

-

Poor Surface Finishes: Handles with rough edges, sharp burrs, or inconsistent coatings can cause injuries and degrade over time, especially in humid environments like bathrooms.

-

Lack of Compliance with Safety Standards: Many low-cost suppliers fail to meet standards such as ANSI A117.1, ADA (Americans with Disabilities Act), or ISO 9001, leading to non-compliant installations.

-

Inconsistent Dimensional Accuracy: Misaligned mounting holes or incorrect lengths can result in improper installation, reducing effectiveness and creating liability concerns.

To mitigate these risks, it’s critical to conduct factory audits, request third-party test reports (e.g., load testing), and require samples before mass production.

2. Intellectual Property (IP) Infringement

Sourcing from overseas or unverified suppliers increases the risk of inadvertently procuring products that violate existing patents or design rights. Common IP-related pitfalls include:

-

Copycat Designs: Many generic handicap handles replicate patented designs from established brands. Using these may expose the buyer to legal action, especially in regulated markets like the U.S. or EU.

-

Unverified Supplier Claims: Suppliers may falsely claim design freedom or certifications. Without proper due diligence, buyers can unknowingly distribute infringing products.

-

Lack of IP Warranty: Most low-cost suppliers do not offer IP indemnification, leaving the buyer fully liable in case of infringement claims.

To avoid IP pitfalls:

– Conduct patent landscape searches before finalizing designs.

– Work with suppliers who provide IP warranties.

– Use legal agreements that shift liability to the supplier in case of infringement.

Conclusion

Sourcing handicap handles requires careful attention to both quality assurance and intellectual property compliance. Prioritizing certified suppliers, conducting rigorous testing, and performing IP due diligence can prevent safety hazards, legal disputes, and reputational damage. Always treat accessibility products as mission-critical components—cutting corners may lead to costly consequences.

Logistics & Compliance Guide for Handicap Handles

This guide outlines the essential logistics and compliance considerations for the manufacturing, distribution, and installation of Handicap Handles—devices designed to assist individuals with mobility challenges in residential, commercial, and public facilities.

Product Specifications and Standards Compliance

Handicap Handles must adhere to relevant accessibility and safety standards to ensure usability and legal compliance. Key requirements include:

- ADA Compliance: In the United States, Handicap Handles installed in public or commercial facilities must comply with the Americans with Disabilities Act (ADA) Standards for Accessible Design. This includes specific guidelines on:

- Mounting height (typically 34” to 38” from the floor)

- Clearance around the handle (1½” minimum between the wall and the handle)

- Diameter (between 1¼” and 1½”)

-

Secure installation capable of supporting 250 lbs. of force

-

ANSI/BHMA Standards: Follow ANSI/BHMA A117.1 Accessible and Usable Buildings and Facilities for additional technical specifications.

- Local Building Codes: Always verify compliance with state, county, or municipal building codes, which may impose additional requirements.

Manufacturing and Quality Assurance

Ensure consistent quality and safety through standardized manufacturing practices:

- Use corrosion-resistant materials such as stainless steel, brushed nickel, or powder-coated aluminum suitable for high-moisture environments (e.g., bathrooms).

- Conduct load testing on each batch to verify structural integrity (minimum 250 lbs. static load capacity).

- Implement ISO 9001 quality management protocols, if applicable, to maintain production consistency.

- Include clear labeling on packaging indicating compliance with ADA and other relevant standards.

Packaging and Labeling

Proper packaging ensures product safety during transit and provides essential information:

- Package each Handicap Handle in protective materials to prevent scratches or deformation.

- Label packages with:

- Product model and specifications

- Installation instructions

- Compliance marks (e.g., ADA-compliant, ASTM-certified)

- Manufacturer contact information and batch number for traceability

Shipping and Distribution Logistics

Efficient logistics planning supports timely delivery and inventory management:

- Use dimensional weight pricing strategies to optimize shipping costs, especially for lightweight but bulky packaging.

- Partner with freight carriers experienced in handling hardware and building supplies.

- Maintain inventory in regional distribution centers to reduce delivery time and support just-in-time delivery for contractors.

- Offer drop-shipping options for wholesalers and builders to streamline supply chains.

Installation Guidelines and Documentation

Ensure proper installation to maintain compliance and safety:

- Provide detailed, illustrated installation instructions with each unit, including:

- Required tools and wall anchors

- Step-by-step mounting procedures

- Surface compatibility (tile, drywall, wood, etc.)

- Recommend professional installation in commercial or public settings.

- Include a warranty card and registration option for end-users.

Regulatory and Documentation Compliance

Maintain records and documentation to support audits and liability protection:

- Keep Certificates of Compliance for ADA, ICC, and other applicable standards on file.

- Provide Safety Data Sheets (SDS) if finishes or coatings involve regulated chemicals.

- Maintain a product lifecycle record, including batch numbers, test results, and any corrective actions.

Sustainability and Environmental Considerations

Adopt eco-friendly practices across the supply chain:

- Source materials from sustainable or recycled content suppliers (e.g., recycled stainless steel).

- Minimize packaging waste through recyclable or biodegradable materials.

- Comply with environmental regulations such as RoHS (Restriction of Hazardous Substances) for metal finishes.

Training and Support

Equip stakeholders with knowledge for proper use and compliance:

- Offer training webinars or documentation for distributors, contractors, and facility managers on ADA requirements and correct installation.

- Provide customer support for compliance questions or product issues.

- Maintain an updated FAQ and resources section on your website.

By following this logistics and compliance guide, manufacturers and suppliers of Handicap Handles can ensure product safety, regulatory adherence, and customer satisfaction across all stages of the product lifecycle.

Conclusion for Sourcing Handicap Handles

In conclusion, sourcing handicap handles requires careful consideration of accessibility standards, material quality, durability, and ease of installation. Compliance with regulations such as the Americans with Disabilities Act (ADA) is essential to ensure safety, usability, and legal adherence. By evaluating factors like ergonomic design, resistance to wear and corrosion, and suitability for the intended environment—whether commercial, residential, or healthcare facilities—organizations can make informed procurement decisions. Partnering with reputable suppliers who provide certified, well-tested products further ensures long-term reliability and user satisfaction. Ultimately, investing in high-quality handicap handles not only promotes inclusivity and accessibility but also reflects a commitment to safety and universal design principles.