The global adaptive driving controls market is witnessing steady growth, driven by increasing demand for vehicle accessibility among individuals with physical disabilities. According to a report by Mordor Intelligence, the Automotive Accessibility Market was valued at USD 5.6 billion in 2023 and is projected to reach USD 8.1 billion by 2029, growing at a CAGR of over 6.3% during the forecast period. This expansion is further supported by rising awareness, government initiatives promoting inclusive mobility, and advancements in ergonomic vehicle modification technologies. Within this landscape, hand controls for cars—especially those tailored for drivers with physical impairments—have become critical components in adaptive driving systems. As the need for dependable, user-friendly, and customizable solutions grows, manufacturers are investing in innovation to improve safety, responsiveness, and compatibility across vehicle types. Against this backdrop, the following eight manufacturers have emerged as leaders in designing and delivering top-performing handicap hand controls, combining engineering precision with accessibility standards to empower drivers worldwide.

Top 8 Handicap Hand Controls For Cars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kempf digital hand controls for cars and handicap vehicles for …

Domain Est. 2007

Website: kempf-usa.com

Key Highlights: Kempf adapts handicap vehicles with digital car hand controls, electronic left foot gas pedals and other handicap driving aids using leading edge technology….

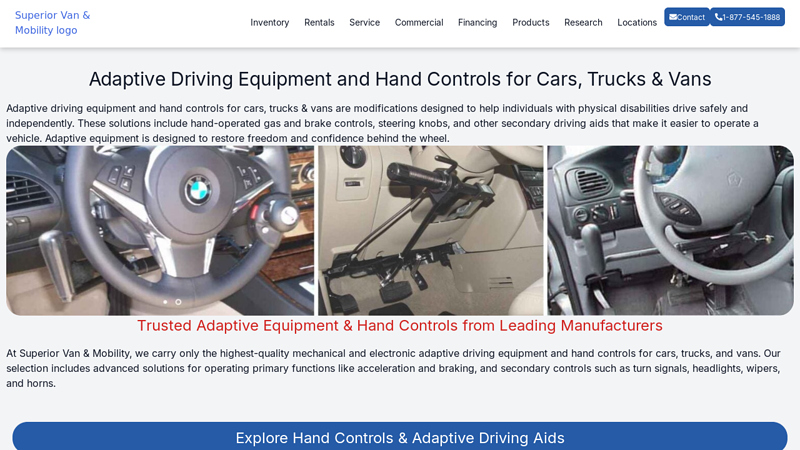

#2 Vehicle Hand Controls & Adaptive Driving Equipment

Domain Est. 1998

Website: superiorvan.com

Key Highlights: Explore adaptive driving equipment & hand controls for cars, trucks & vans. Compare top brands & find the right solution for your mobility needs….

#3 Adaptive Driving Aids, Controls, and Equipment

Domain Est. 2001

Website: unitedaccess.com

Key Highlights: Handicap driving controls provide grips, spinner knobs, and prosthetic hook and hand securement for your steering wheel. These grips allow you to steer and use ……

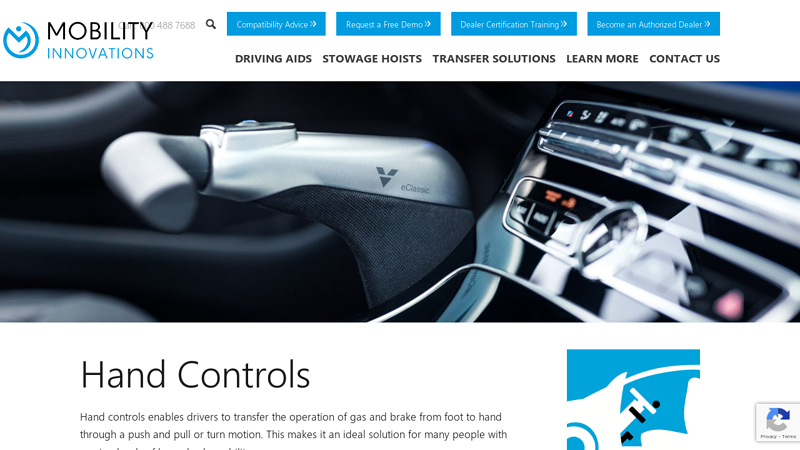

#4 Hand Controls For Disabled Drivers

Domain Est. 2005

Website: mobilityinnovations.com

Key Highlights: Hand controls enables drivers to transfer the operation of gas and brake from foot to hand through a push and pull or turn motion….

#5 Hand Controls For Disabled Drivers

Domain Est. 2008

Website: advancedwheels.com

Key Highlights: We sell, install and service almost all brands of hand controls on the market today including MPD, Viegel, and Sure-Grip….

#6 Hand Controls for Disabled Drivers

Domain Est. 2017

Website: fcausdriveability.com

Key Highlights: Hand controls & adaptive driving equipment for drivers with disabilities. ✓ Hand controls for cars ✓ Adaptive steering & More ▷ Explore customizable solutions….

#7 Electronic Mobility Controls

Domain Est. 2022

Website: electronicmobilitycontrols.com

Key Highlights: Electronic Mobility Controls, LLC is an international company based in Augusta, Maine and was founded with the goal of providing individuals with high level ……

#8 Hand controls

Website: veigel-automotive.de

Key Highlights: VEIGEL offers a large selection of hand controls for physically impaired individuals, combining ergonomically correct driving and driving pleasure….

Expert Sourcing Insights for Handicap Hand Controls For Cars

2026 Market Trends for Handicap Hand Controls for Cars

The market for handicap hand controls for cars is poised for significant transformation by 2026, driven by technological advancements, evolving regulations, demographic shifts, and increasing inclusivity demands. Here are the key trends shaping this specialized automotive sector:

Increased Integration with Advanced Driver Assistance Systems (ADAS)

By 2026, hand controls will increasingly integrate with ADAS features such as adaptive cruise control, lane-keeping assist, and automatic emergency braking. This convergence enhances safety and reduces driver workload, making independent driving more accessible. Manufacturers are developing modular systems that communicate seamlessly with vehicle electronics, allowing drivers with disabilities to leverage factory-installed safety technologies without compromising control functionality.

Shift Toward Electronic and Drive-by-Wire Systems

Mechanical push-pull hand controls are gradually being supplemented—and in some cases replaced—by electronic systems. These modern solutions offer smoother operation, customizable sensitivity settings, and easier installation. As more vehicles transition to drive-by-wire technology (removing mechanical linkages), hand control manufacturers are adapting with wireless and software-based interfaces that interface directly with electronic throttle and brake systems, improving responsiveness and reducing physical effort.

Growing Demand from an Aging Population

The global aging demographic, particularly the Baby Boomer generation, is a major driver of market growth. By 2026, a larger number of seniors with age-related mobility limitations will seek solutions to maintain driving independence. This shift is increasing demand for user-friendly, minimally invasive hand control systems that can be installed in a wide range of personal vehicles, not just specialized mobility vans.

Expansion of Customization and Personalization Options

Consumers are demanding more personalized solutions tailored to their specific physical capabilities and vehicle types. In 2026, expect broader availability of modular hand control systems with adjustable levers, programmable functions, and ergonomic designs. 3D scanning and AI-driven fitting tools may become standard in the assessment process, ensuring optimal comfort and control alignment for individual users.

Stronger Regulatory Support and Insurance Coverage

Governments and insurance providers are increasingly recognizing mobility as a critical aspect of independence and quality of life. By 2026, expanded reimbursement policies and incentives—such as tax credits or subsidies for vehicle modifications—are expected in regions like North America and Western Europe. This financial support lowers barriers to adoption and encourages broader market penetration.

Rise of Retrofit Solutions for EVs and Hybrids

As electric and hybrid vehicles dominate new car sales, hand control manufacturers are rapidly adapting their products for these platforms. The unique acceleration and braking profiles of EVs require specialized tuning. By 2026, retrofit kits optimized for popular EV models (e.g., Tesla, Ford Mustang Mach-E, Hyundai IONIQ) will be widely available, ensuring accessibility keeps pace with automotive electrification.

Emphasis on Seamless Aesthetics and Minimal Installation Impact

Consumers increasingly prefer hand controls that maintain the vehicle’s original look and functionality. In response, manufacturers are developing sleeker, low-profile designs that install with minimal drilling or permanent modifications. This trend supports vehicle resale value and appeals to users who prioritize discretion and integration.

Growth in Telehealth and Remote Fitting Services

The use of telehealth for driver evaluations and remote diagnostics is expanding. By 2026, certified driving rehabilitation specialists may conduct initial assessments and system adjustments via secure video platforms, supported by connected hand control systems that transmit usage and performance data. This improves access to expert services, especially in rural or underserved areas.

In summary, the 2026 market for handicap hand controls will be defined by smarter, safer, and more personalized technologies that align with broader automotive trends. As inclusivity becomes a central design principle in the auto industry, these adaptive solutions will play a crucial role in empowering individuals with disabilities to maintain autonomy and mobility.

Common Pitfalls Sourcing Handicap Hand Controls for Cars: Quality and Intellectual Property Issues

Poor Build Quality and Material Standards

One of the most significant risks when sourcing handicap hand controls is encountering substandard build quality. Many low-cost manufacturers, particularly in regions with minimal regulatory oversight, use inferior materials such as weak plastics, low-grade metals, or poorly engineered mechanisms. These components may fail under stress or repeated use, posing serious safety hazards to users. Buyers should verify compliance with automotive safety standards (such as FMVSS No. 105 or ISO 9001) and insist on third-party testing certifications to ensure durability and reliability.

Lack of Regulatory Compliance

Hand controls must meet specific regulatory requirements depending on the target market—such as the U.S. Department of Transportation (DOT) standards, CE marking in Europe, or Transport Canada approvals. Sourcing from suppliers who do not provide documented compliance can result in legal liabilities, import restrictions, or product recalls. Always confirm that the product has undergone proper crash testing and meets applicable vehicle integration standards.

Inadequate Customization and Ergonomics

A common pitfall is sourcing “one-size-fits-all” hand control systems that fail to accommodate the diverse physical needs of users with disabilities. Poor ergonomics can lead to user discomfort, reduced control precision, and long-term strain. High-quality suppliers offer customizable options (e.g., adjustable levers, modular configurations), but these features may be absent or poorly implemented in lower-tier products.

Intellectual Property (IP) Infringement Risks

Many established manufacturers of adaptive driving equipment hold patents on specific hand control mechanisms, ergonomic designs, and installation systems. Sourcing from suppliers that replicate these patented designs without authorization exposes buyers to IP litigation and customs seizures. Conduct thorough due diligence by reviewing patent databases and requesting proof of IP ownership or licensing agreements from suppliers.

Counterfeit or Clone Products

The adaptive vehicle equipment market is vulnerable to counterfeit or cloned products that mimic reputable brands. These copies often lack rigorous testing and may use misleading labeling to appear compliant. To avoid this, purchase only through authorized distributors or directly from original equipment manufacturers (OEMs) with verifiable track records.

Inconsistent Installation and Integration Support

Even high-quality hand controls can underperform if not properly installed. Some suppliers provide inadequate technical documentation or fail to offer trained installation support. This can lead to improper vehicle integration, malfunctioning systems, or voided vehicle warranties. Ensure suppliers offer comprehensive installation guides, training, and post-sale technical support.

Hidden Costs from Poor Quality Control

Initially low-priced hand controls may result in higher total costs due to frequent returns, repairs, or replacements. Poor quality control processes—such as inconsistent manufacturing tolerances or lack of batch testing—can lead to reliability issues. Insist on supplier audits, sample testing, and warranties to mitigate long-term financial and reputational risks.

Limited After-Sales Service and Spare Parts Availability

When sourcing from obscure or offshore manufacturers, buyers often discover that spare parts or repair services are difficult to obtain. This can leave end-users stranded without functioning controls. Prioritize suppliers with established service networks and readily available replacement components to ensure long-term usability.

Logistics & Compliance Guide for Handicap Hand Controls for Cars

Product Overview and Classification

Handicap hand controls for cars are adaptive driving devices designed to enable individuals with lower limb disabilities to operate vehicles safely. These systems typically replace or supplement standard foot pedals, allowing acceleration and braking via hand-operated levers, rings, or push-pull mechanisms. They are classified as automotive adaptive equipment and often fall under the broader category of mobility aids.

Regulatory Compliance Standards

Hand controls must comply with federal and international safety standards to ensure reliability and user safety. In the United States, compliance with the Department of Transportation (DOT) and National Highway Traffic Safety Administration (NHTSA) regulations is mandatory. Key standards include FMVSS No. 135 (Light Vehicle Brake Systems) and FMVSS No. 121 (Air Brake Systems, where applicable). Additionally, manufacturers should adhere to ISO 10542 (Adaptive Driving Controls) for international market access.

Certification and Installation Requirements

Hand controls must be certified by a qualified mobility equipment dealer or Authorized Driving Rehabilitation Specialist (ADRS). Installation must follow manufacturer guidelines and be performed by a certified technician. Post-installation, a vehicle inspection and road test are required to ensure functionality and compliance. Documentation, including a certificate of installation and compliance, must be provided to the end-user.

Shipping and Distribution Logistics

Due to their specialized nature, hand controls should be shipped in protective packaging to prevent damage. Logistics partners must handle units as sensitive automotive components. Inventory management should account for product variants (e.g., left-hand vs. right-hand drive, mechanical vs. electronic systems). Tracking systems should provide real-time visibility throughout the supply chain.

Import/Export Considerations

When shipping internationally, exporters must comply with destination country regulations. This includes obtaining necessary certifications (e.g., CE marking in Europe, CCC in China) and ensuring product labeling meets local language and safety requirements. Harmonized System (HS) Code 8708.29 is typically used for vehicle control apparatus. Importers should verify local accessibility laws and tax exemptions for medical devices.

Warranty and Post-Sale Support

Manufacturers must offer a minimum 1-year warranty covering defects in materials and workmanship. Technical support and service networks should be established to assist with troubleshooting, repairs, and user training. Replacement parts must be readily available, and service turnaround times should be clearly communicated.

User Training and Documentation

Compliance includes providing comprehensive user manuals in the local language, detailing installation, operation, maintenance, and emergency procedures. Mandatory driver training with a certified occupational therapist or driving rehabilitation specialist is required before independent use. Training records should be retained for compliance verification.

Recordkeeping and Audit Readiness

Distributors and installers must maintain detailed records of sales, installations, certifications, and service history for a minimum of 7 years. These records support compliance audits and warranty claims. Digital record systems should be secure and accessible for regulatory review.

Accessibility and ADA Compliance

While hand controls themselves are not directly governed by the Americans with Disabilities Act (ADA), their distribution and sales processes must comply with ADA standards for accessibility. This includes accessible retail locations, websites (WCAG 2.1 compliance), and customer service support to ensure equal access for individuals with disabilities.

In conclusion, sourcing handicap hand controls for cars requires careful consideration of individual needs, vehicle compatibility, and the various types of control systems available. Whether mechanical, electronic, or combination systems, selecting the right hand controls is essential for ensuring safety, independence, and ease of use for drivers with physical disabilities. It is highly recommended to consult with occupational therapists or certified driving rehabilitation specialists to assess specific requirements and ensure proper installation. Additionally, exploring reputable manufacturers, checking compliance with safety standards, and understanding warranty and support options are critical steps in making an informed decision. With the right research and professional guidance, sourcing and installing handicap hand controls can significantly enhance mobility and improve quality of life for individuals with limited lower-body function.