The global handheld laser welder market is experiencing robust expansion, driven by rising demand for precision welding in automotive, aerospace, and heavy machinery sectors. According to Grand View Research, the global laser welding market size was valued at USD 4.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This surge is fueled by the increasing adoption of automation and lightweight materials in manufacturing, where handheld laser welding offers superior flexibility, speed, and weld quality compared to traditional methods. As industries seek cost-effective and portable welding solutions, manufacturers are innovating to balance performance with competitive pricing. In this evolving landscape, nine key players have emerged as leaders in offering reliable, high-quality handheld laser welders across diverse price points—catering to both small-scale workshops and large industrial operations. The following analysis explores these top manufacturers, using market data and performance metrics to evaluate their value proposition in today’s competitive environment.

Top 9 Handheld Laser Welder Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#2 Denaliweld

Website: denaliweld.com

Key Highlights: Ultra-portable laser welding machine (48.5 lbs) with dual welding/seam cleaning. Patented CUAL laser ensures precision on thin metals. Pre-set modes +….

#3 Portable Handheld Fiber Laser Welders

Website: dnelaserusa.com

Key Highlights: With a 20u spot size and advanced laser technology, these welders deliver up to 4x faster welding speeds than traditional welders, strong, uniform welds and ……

#4 Handheld Fiber Laser Welding Machine

Website: omtech.com

Key Highlights: In stock Free delivery… 1-Year Warranty. Buy Machine Get FREE 304 Stainless Steel Welding Wire. Handheld Fiber Laser Welding Machine. 0(0 Reviews). Price $6,09999 $6,099.99 Regul…

#5 Xlaserlab X1 Handheld Laser Welder for Metal

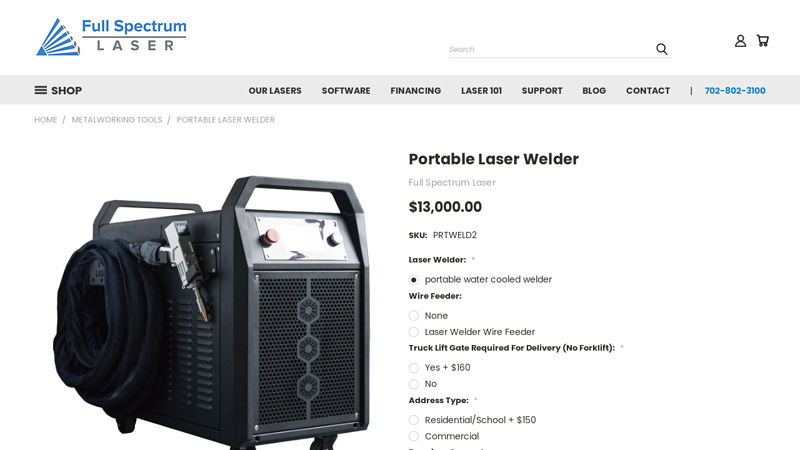

#6 Portable Laser Welder

#7 Handheld Laser Welding Machines

Website: theo.inc

Key Highlights: A compact, easy-to-use, and highly efficient handheld laser welding system that significantly improves welding speed, greatly reduces training time….

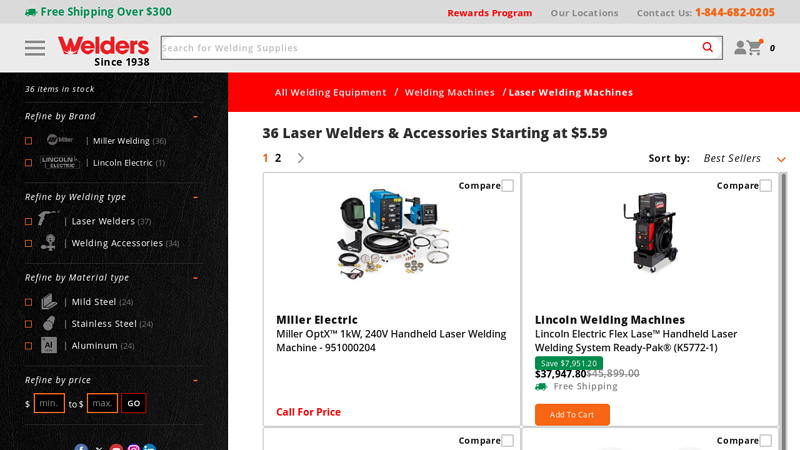

#8 36 Laser Welders & Accessories for sale from $5.59

Website: weldersupply.com

Key Highlights: Free delivery over $300 · 14-day returnsLincoln Welding Machines Lincoln Electric Flex Lase™ Handheld Laser Welding System Ready-Pak® (K5772-1). Save $7,951.20. $37,947.80. $45,89…

#9 HW series best handheld fiber laser welding machine

Website: hg-star.com

Key Highlights: Handheld fiber laser welding machine has the best fiber laser beam for fast welding speed, high quality weld seam and no consumables….

Expert Sourcing Insights for Handheld Laser Welder Price

H2: 2026 Market Trends for Handheld Laser Welder Prices

The global market for handheld laser welders is poised for significant transformation by 2026, driven by technological advancements, increasing industrial automation, and growing demand across manufacturing, automotive, and construction sectors. Price trends for handheld laser welders in 2026 are expected to reflect a combination of cost optimization, competitive dynamics, and rising accessibility.

-

Price Decline Due to Technological Maturity and Economies of Scale

By 2026, continued improvements in fiber laser technology and mass production of key components—such as pump diodes and beam delivery systems—are expected to reduce manufacturing costs. As major players in China, Europe, and North America scale production, economies of scale will exert downward pressure on prices. Entry-level models (1,000–1,500W) are projected to see price reductions of 15–20% compared to 2023 levels, making them more accessible to small and medium enterprises (SMEs). -

Increased Competition Driving Price Differentiation

The market is becoming increasingly segmented, with a clear price divide between budget-friendly Chinese models and premium systems from German, Japanese, and U.S. manufacturers. In 2026, mid-range handheld laser welders (1,500–3,000W) are expected to dominate sales volume, with prices ranging from $12,000 to $25,000. Competitive pricing strategies, bundled software, and improved after-sales support will be key differentiators, further pressuring margins and encouraging price transparency. -

Rise of Smart Features and Integration Costs

Higher-end models featuring real-time monitoring, AI-assisted welding paths, and IoT connectivity are gaining traction in precision industries. These smart functionalities are likely to command a premium, with prices for advanced systems (3,000W+) potentially exceeding $40,000. However, as these technologies become standardized, their cost contribution is expected to decline post-2026. -

Regional Price Variations and Trade Dynamics

Trade policies, import tariffs, and localization efforts will influence pricing regional disparities. For instance, domestically produced units in China may sell for 20–30% less than imported equivalents in North America or Europe. Meanwhile, localization initiatives in India and Southeast Asia could create new low-cost manufacturing hubs, further intensifying global price competition. -

Total Cost of Ownership Influencing Purchase Decisions

Buyers are increasingly evaluating handheld laser welders based on total cost of ownership (TCO), including maintenance, power efficiency, and consumables. This shift is incentivizing manufacturers to offer durable, low-maintenance designs, which may initially carry higher price tags but offer long-term savings—thereby justifying premium pricing in industrial segments.

In summary, the 2026 handheld laser welder market will likely see overall price stabilization at lower average levels, driven by mass adoption, competition, and technological diffusion. While premium models with advanced capabilities will maintain higher price points, the broader trend points toward greater affordability and wider market penetration across global industries.

Common Pitfalls When Sourcing Handheld Laser Welders: Price vs. Quality and IP Rating

Logistics & Compliance Guide for Handheld Laser Welder Price

When evaluating the total cost of acquiring a handheld laser welder, it’s essential to go beyond the initial purchase price and consider all logistics and compliance-related factors. These elements can significantly impact the final delivered cost, operational readiness, and long-term viability of the equipment. Below is a breakdown of key considerations.

Shipping and Delivery Costs

The physical transportation of handheld laser welders involves various logistical expenses that must be factored into the total cost:

- Domestic vs. International Shipping: Importing from overseas manufacturers typically incurs higher freight charges, customs duties, and longer lead times compared to domestic suppliers.

- Freight Class and Weight: Laser welding systems, including power units and cooling components, can be heavy and classified under specific freight categories, affecting shipping rates.

- Insurance: High-value equipment should be insured during transit to protect against loss or damage.

- Incoterms Clarity: Ensure the pricing quote specifies the Incoterm (e.g., FOB, CIF, DDP) to understand who bears responsibility for shipping, tariffs, and insurance.

Import Duties and Tariffs

Cross-border procurement introduces customs-related costs that directly affect the final price:

- Harmonized System (HS) Code Classification: Handheld laser welders typically fall under HS codes related to industrial lasers (e.g., 8515.31 or 9013.20), which determine applicable duty rates.

- Country-Specific Tariffs: Duty rates vary by country (e.g., 2.5%–7.5% in the U.S., potentially higher in other regions). Check local customs databases for accurate figures.

- Trade Agreements: Leverage free trade agreements (e.g., USMCA, ASEAN) that may reduce or eliminate tariffs on imported equipment.

Regulatory Compliance Requirements

Laser equipment is subject to stringent safety and technical regulations across regions:

- Laser Safety Standards:

- U.S.: FDA/CDRH compliance under 21 CFR 1040.10 and 1040.11 (laser product reporting, labeling, safety features).

- EU: Compliance with IEC 60825-1 (laser radiation safety) and CE marking under the Machinery Directive and Radio Equipment Directive (if applicable).

- Other Regions: China (CCC), Canada (RCM), Australia (RCM) — each may require specific certifications.

- Electromagnetic Compatibility (EMC): Must meet EMC directives (e.g., FCC Part 15 in the U.S., EU EMC Directive 2014/30/EU).

- Electrical Safety: Certification to standards such as UL, CSA, or IEC 62368-1 for safety of machinery.

Environmental and Hazardous Materials Compliance

Laser systems may contain components subject to environmental regulations:

- RoHS (Restriction of Hazardous Substances): Required in the EU and adopted by other regions; restricts lead, mercury, cadmium, etc.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals — applies to materials used in manufacturing.

- Battery Shipping Regulations: If the unit includes lithium-ion batteries (e.g., portable models), UN 38.3 testing and proper packaging for air/ground transport are mandatory.

Installation, Training, and Onboarding Logistics

Operational readiness involves logistical planning beyond delivery:

- Site Preparation: Ensure adequate power supply (voltage, phase), ventilation, and workspace layout.

- Technical Installation: May require on-site technician support, adding travel and labor costs.

- Operator Training: Compliance with OSHA (U.S.) or local workplace safety laws often mandates laser safety training, which may be included or offered as a paid service.

After-Sales Support and Spare Parts Logistics

Long-term cost of ownership includes service and maintenance:

- Warranty Terms: Clarify whether warranty covers parts, labor, and return shipping.

- Spare Parts Availability: Assess lead times and shipping costs for consumables (e.g., lenses, nozzles) and critical components.

- Service Network: Evaluate the manufacturer’s or distributor’s service reach — local support reduces downtime and travel charges.

Documentation and Recordkeeping

Proper documentation is crucial for compliance and customs clearance:

- Commercial Invoice and Packing List: Required for customs; must accurately reflect product value and specifications.

- Certificate of Conformity (CoC): Proof of compliance with regional standards (e.g., CE, FCC).

- Laser Safety Manual: Must be provided in the local language and include hazard warnings, operating procedures, and maintenance guidelines.

Total Cost of Ownership (TCO) Consideration

When comparing handheld laser welder prices, include all logistics and compliance costs to determine true value:

- Hidden costs such as duties, compliance testing, and training can add 15%–30% to the base price.

- Choosing a supplier with established compliance credentials and regional support can reduce risk and long-term expenses.

By thoroughly assessing these logistics and compliance factors, businesses can make informed purchasing decisions and avoid unexpected delays or penalties.

Conclusion on Sourcing Handheld Laser Welder Prices

Sourcing a handheld laser welder requires a comprehensive evaluation of various factors that influence price, including power output, build quality, brand reputation, included features (such as cooling systems, software integration, and portability), and after-sales support. Market research indicates a wide price range—typically from $5,000 for basic models to over $20,000 for high-end, industrial-grade units—reflecting differences in performance and durability.

When evaluating suppliers, it is essential to balance cost with long-term value. While lower-priced options from emerging manufacturers, particularly in Asia, may offer attractive upfront savings, they may lack reliability, service networks, or technical support. Conversely, premium brands from Europe or North America often come with higher price tags but provide proven performance, safety certifications, and comprehensive warranties.

Ultimately, the optimal sourcing decision depends on your specific application, production volume, and quality requirements. Conducting a total cost of ownership analysis—including maintenance, training, consumables, and downtime—will help identify the most cost-effective solution. Additionally, requesting product demonstrations, checking customer reviews, and negotiating service packages can further ensure a wise investment.

In summary, prioritizing quality, support, and suitability over initial price alone will lead to better operational efficiency and return on investment when sourcing a handheld laser welder.