The global laser cleaning equipment market is experiencing robust growth, driven by increasing demand for eco-friendly and efficient surface treatment solutions across industries such as automotive, aerospace, and heavy manufacturing. According to a 2023 report by Mordor Intelligence, the handheld laser rust removal machine market is projected to grow at a CAGR of over 18% between 2023 and 2028, fueled by stringent environmental regulations and the phasing out of traditional abrasive and chemical cleaning methods. Similarly, Grand View Research valued the global laser cleaning market at USD 650 million in 2022 and forecasts continued expansion, citing advancements in fiber laser technology and rising adoption in precision maintenance applications. Amid this growth, a select group of manufacturers have emerged as leaders in innovation, reliability, and market reach. Below, we profile the top 10 handheld laser rust removal machine manufacturers shaping the future of industrial cleaning.

Top 10 Handheld Laser Rust Removal Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

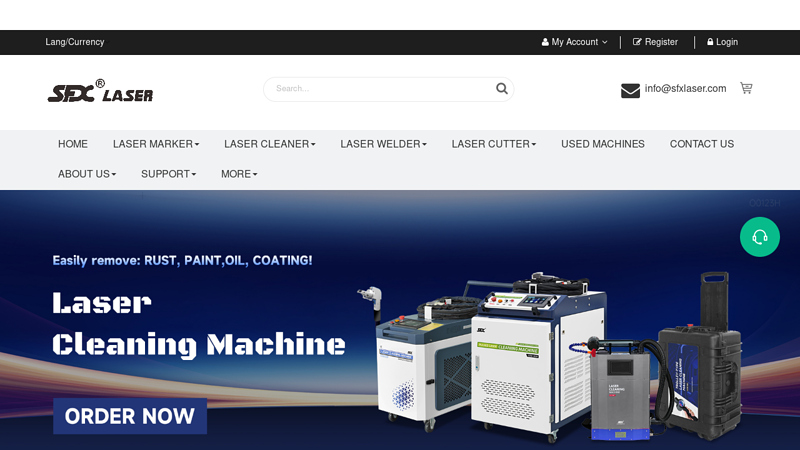

#3 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#4 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: HANTENCNC is a professional laser cleaning machine manufacturer with over 20 years of experience. We offer a wide range of laser cleaners, from 100W to 3000W….

#5 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: The SHARK P CL 500A is an air-cooled laser cleaning machine with 500 W output, combining high laser power with a compact and portable system design. AIRKNIFE ……

#6 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

#7 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#8 Handheld Laser Cleaning Systems

Website: laserphotonics.com

Key Highlights: Utilize this laser cleaning machine for rust removal and coating removal, decontamination, degreasing, pre- and post-weld surface preparation, and texturing….

#9 Laser Rust Removal

Website: powerlase-limited.com

Key Highlights: Achieve super fast rust removal rates with out lasers Powerlase redesigned the handheld tool making it compact enough to fit in tight spaces and easy to use ……

#10 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

Expert Sourcing Insights for Handheld Laser Rust Removal Machine

H2: Market Trends for Handheld Laser Rust Removal Machines in 2026

The global market for handheld laser rust removal machines is poised for significant transformation by 2026, driven by technological advancements, growing environmental regulations, and increasing demand for precision industrial cleaning solutions. As industries shift toward sustainable and efficient maintenance practices, the handheld laser rust removal segment is expected to experience robust growth, with several key H2 (second half) 2026 trends shaping its trajectory.

1. Increased Adoption in Manufacturing and Automotive Sectors

By H2 2026, the manufacturing and automotive industries are anticipated to be primary adopters of handheld laser rust removal technology. The push for automation, improved surface preparation standards, and reduced downtime during maintenance will drive demand. Automotive OEMs and repair facilities will increasingly favor laser-based systems for their ability to clean parts without damaging substrates, improving paint adhesion, and extending component lifespans.

2. Advancements in Portability and Battery Efficiency

A major trend in H2 2026 will be the proliferation of fully cordless, high-efficiency handheld laser units. Innovations in lithium-ion and solid-state battery technologies will enable longer operating times and greater power output, making on-site rust removal more practical for field operations in construction, marine, and infrastructure maintenance.

3. Integration with Smart Features and IoT

Handheld laser rust removal machines are expected to incorporate smart diagnostics, AI-assisted targeting, and IoT connectivity by late 2026. These features will allow real-time monitoring of cleaning efficiency, predictive maintenance alerts, and remote operation control via mobile apps or cloud platforms—enhancing user safety and operational precision.

4. Regulatory Push Toward Eco-Friendly Solutions

Environmental regulations restricting abrasive blasting and chemical cleaning methods will continue to favor laser-based alternatives. By H2 2026, stricter emissions and waste disposal laws in North America and the EU will accelerate the shift toward non-contact, waste-free laser rust removal, positioning it as a compliant and sustainable solution.

5. Expanding Applications in Heritage and Aerospace Industries

Beyond industrial uses, niche markets such as cultural heritage restoration and aerospace maintenance will see increased utilization of handheld laser systems. Their precision and non-abrasive nature make them ideal for cleaning delicate historical metal artifacts and critical aircraft components without compromising structural integrity.

6. Competitive Pricing and Market Democratization

As production scales and Chinese and European manufacturers improve manufacturing efficiency, prices for mid-range handheld laser units are expected to drop significantly by H2 2026. This price reduction will open the market to small and medium enterprises (SMEs), expanding the user base beyond large industrial players.

7. Regional Growth in Asia-Pacific

The Asia-Pacific region, particularly China, India, and South Korea, will emerge as a high-growth market due to rapid industrialization, infrastructure development, and government support for advanced manufacturing technologies. Local production and R&D investments will further fuel adoption.

Conclusion

By the second half of 2026, the handheld laser rust removal machine market will be defined by innovation, sustainability, and broader accessibility. As industries prioritize efficiency and environmental compliance, these devices will transition from niche tools to standard equipment in maintenance arsenals worldwide. Companies investing in R&D, user-friendly design, and global distribution networks are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing Handheld Laser Rust Removal Machines (Quality & IP)

Sourcing handheld laser rust removal machines from global suppliers—especially from regions with less stringent regulatory oversight—can expose buyers to significant risks related to product quality and intellectual property (IP). Being aware of these pitfalls is crucial for making informed procurement decisions and protecting your business.

Poor Build Quality and Component Sourcing

Many low-cost suppliers cut corners by using substandard materials and components to reduce prices. This often results in machines with inadequate heat dissipation, weak structural frames, or unreliable electrical systems. Inferior laser diodes, cooling fans, or power supplies can lead to frequent breakdowns, reduced laser efficiency, and shortened operational lifespans. Always verify the specifications and request third-party test reports or certifications (e.g., CE, FDA, ROHS) to assess build quality.

Inaccurate Power Ratings and Performance Claims

A common issue is misleading laser power labeling. Some suppliers advertise lasers as “1,000W” or higher, but this may refer to electrical input power rather than actual optical output power. Real laser output power might be significantly lower, resulting in poor rust removal performance. Always ask for optical output power test data under real operating conditions and consider independent verification before large purchases.

Lack of Safety Features and Compliance

Handheld laser devices pose serious safety risks, including eye and skin hazards. Some budget machines lack essential safety components such as emergency shut-offs, key switches, protective housings, or proper laser interlocks. Non-compliant machines may fail to meet international safety standards (e.g., IEC 60825), exposing users to danger and buyers to legal liability. Ensure that the product includes proper safety certifications and complies with regulations in your target market.

Intellectual Property (IP) Infringement Risks

Many low-cost suppliers replicate designs, firmware, or software from established brands without authorization. Purchasing such machines may inadvertently involve your business in IP violations, especially if the product is resold or used commercially in regulated markets. This can lead to customs seizures, legal disputes, or reputational damage. Conduct due diligence on the manufacturer’s originality—request proof of patents, design registrations, or IP ownership documentation.

Inadequate Technical Support and Software Lock-In

Some machines come with proprietary software that lacks updates, documentation, or compatibility with common systems. Poor technical support can make troubleshooting or integration difficult. In extreme cases, suppliers may lock users into specific service channels or charge exorbitant fees for repairs. Confirm the availability of firmware updates, API access (if needed), and responsive after-sales support before committing.

Short Warranty and Limited Service Network

Suppliers offering very low prices often provide minimal warranty coverage (e.g., 3–6 months) and lack service centers in your region. Repairing or returning defective units can become costly and time-consuming. Evaluate the supplier’s warranty terms, spare parts availability, and local support infrastructure to avoid long downtimes.

Conclusion

To mitigate these risks, conduct thorough supplier vetting, request product samples, verify certifications, and consult legal or technical experts when evaluating IP and compliance matters. Investing time upfront can prevent costly quality failures and legal complications down the line.

Logistics & Compliance Guide for Handheld Laser Rust Removal Machine

Product Classification & Regulatory Overview

Handheld laser rust removal machines are classified as Class 4 laser products under international safety standards (e.g., IEC 60825-1). These devices emit high-power laser radiation capable of causing severe eye and skin injuries, fires, and material damage if misused. As such, they are subject to strict regulations in manufacturing, labeling, shipping, import/export, and end-user operation.

Export & Import Compliance

Ensure compliance with destination country regulations before shipping. Key considerations include:

– Laser Product Registration: Many countries (e.g., U.S. FDA, EU member states, Canada) require laser devices to be registered with national regulatory bodies. In the U.S., compliance with 21 CFR 1040.10 and 1040.11 is mandatory.

– Customs Documentation: Provide accurate Harmonized System (HS) codes (typically 8543.70 or 9013.20, depending on configuration), commercial invoices, packing lists, and certificates of origin.

– Restricted Destinations: Verify if the destination country restricts or prohibits high-power laser devices. Some nations require special permits or end-user undertakings.

Packaging & Shipping Requirements

Proper packaging is essential to ensure safety and regulatory compliance during transit:

– Secure Packaging: Use shock-resistant, tamper-evident packaging with internal cushioning to protect optics and electronics.

– Hazard Labeling: Clearly affix Class 4 Laser Warning labels (per IEC 60825) on the outer packaging. Include caution labels for “Do Not Operate During Transport” and “Fragile.”

– Battery Considerations: If the unit includes lithium-ion batteries, comply with IATA/IMDG/ADR regulations for dangerous goods. Batteries may require UN38.3 testing certification, proper containment, and Class 9 hazardous material labeling.

Safety Certification & Standards

Verify that the device meets relevant international safety and electromagnetic compatibility (EMC) standards:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and laboratory use.

– EMC Directives: CE marking (EU) requires compliance with EMC Directive 2014/30/EU and RoHS 2011/65/EU.

– FCC Certification: Required for sale in the U.S. (Part 15/18 for radio frequency and laser compliance).

Labeling & User Documentation

Include mandatory safety and compliance information:

– Product Labels: Permanent warning labels indicating laser class, wavelength, maximum output power, and manufacturer details.

– User Manual: Must contain laser safety instructions, operating procedures, maintenance guidelines, and emergency response protocols. Include multilingual translations if distributing internationally.

– Laser Safety Officer (LSO) Guidance: Recommend that industrial users appoint an LSO and conduct workplace hazard assessments per ANSI Z136.1 (U.S.) or equivalent standards.

End-User Training & Liability Mitigation

Ensure end-users are properly trained to reduce risk and liability:

– Provide certified training materials or arrange on-site instruction.

– Require users to sign safety acknowledgment forms.

– Recommend personal protective equipment (PPE), including laser safety goggles specific to the device’s wavelength.

Environmental & Disposal Compliance

Follow local and international regulations for end-of-life disposal:

– Comply with WEEE (EU) and similar e-waste directives.

– Laser components may contain hazardous materials; dispose of through certified electronic waste handlers.

– Avoid landfill disposal of batteries or optical components.

Summary

Shipping and operating a handheld laser rust removal machine requires adherence to laser safety standards, customs regulations, hazardous material rules, and regional compliance frameworks. Proactive documentation, proper labeling, and user education are essential for legal distribution and safe deployment globally.

In conclusion, sourcing a handheld laser rust removal machine presents a forward-thinking and efficient solution for modern surface cleaning and restoration applications. This advanced technology offers numerous advantages over traditional methods, including precision, environmental friendliness, minimal substrate damage, and reduced maintenance costs. When sourcing such equipment, it is essential to evaluate factors such as laser power, pulse duration, portability, safety features, and after-sales support to ensure optimal performance and long-term reliability.

Additionally, selecting a reputable supplier with proven experience, positive customer feedback, and compliance with international safety standards is crucial for a successful investment. While the initial cost may be higher than conventional tools, the long-term benefits—such as lower operating costs, improved worker safety, and enhanced cleaning efficiency—justify the expenditure, particularly in industries like automotive, marine, aerospace, and heritage conservation.

Ultimately, sourcing a handheld laser rust removal machine represents a strategic move toward adopting sustainable, high-precision technology that aligns with future industry trends and environmental regulations. With careful supplier selection and proper training, organizations can significantly enhance their maintenance and restoration capabilities while staying at the forefront of technological innovation.