The global handheld laser rust removal market is experiencing robust growth, driven by increasing demand for precision cleaning solutions across industrial maintenance, automotive, and maritime sectors. According to Grand View Research, the global laser cleaning equipment market was valued at USD 591.5 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 10.4% from 2023 to 2030. This surge is fueled by the technology’s non-abrasive, eco-friendly advantages over traditional methods like sandblasting and chemical treatments. As industries prioritize efficiency and sustainability, portable laser systems are becoming essential tools for corrosion control. With advancements in fiber laser technology and growing adoption in manufacturing hubs across North America, Europe, and Asia-Pacific, the competitive landscape is rapidly evolving. Here, we spotlight the top nine manufacturers leading innovation, performance, and market penetration in handheld laser rust removal systems.

Top 9 Handheld Laser Removes Rust Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: LPC-100 Laserpack is a laser cleaning backpack. P-laser teambuilding. QF-2000 Laser removes almost any other kind of contamination, including grease, rust….

#2 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#3 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: The SHARK P CL series is suitable for removing rust, paint, soot, carbon, mold, mildew, grease, weld residues, varnish, graffiti and other surface contaminants….

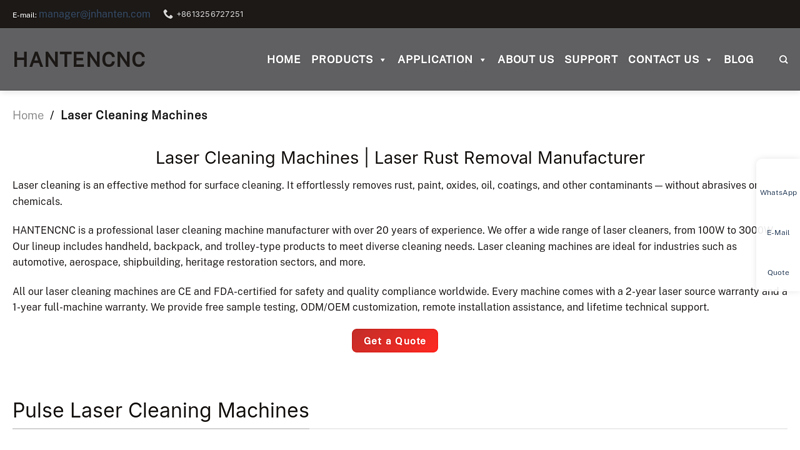

#4 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: HANTENCNC is a professional laser cleaning machine manufacturer with over 20 years of experience. We offer a wide range of laser cleaners, from 100W to 3000W….

#5 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: Laser cleaning machine often use to remove contaminants, such as rust, paint, oil, and coatings from the surface of a material. Laser cleaning is a non-contact, ……

#6 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#7 Laserax

Website: laserax.com

Key Highlights: Our laser cleaning solutions are used to remove a range of contaminants from metal surfaces such as rust, oxide, paint, and electrolyte. As contaminants are ……

#8 Laser Rust Removal

Website: powerlase-limited.com

Key Highlights: Watch this super fast rust removal from carbon steel panel with the new ultra-lightweight Vulcan handheld from Powerlase. The nature of laser cleaning ……

#9 Handheld Laser Cleaning Systems

Website: laserphotonics.com

Key Highlights: Utilize this laser cleaning machine for rust removal and coating removal, decontamination, degreasing, pre- and post-weld surface preparation, and texturing….

Expert Sourcing Insights for Handheld Laser Removes Rust

H2: Projected 2026 Market Trends for Handheld Laser Rust Removal

The global market for handheld laser rust removal systems is poised for substantial growth and transformation by 2026, driven by advancements in laser technology, increasing demand for eco-friendly surface treatment methods, and expanding industrial automation. This analysis explores key market trends expected to shape the industry under the H2 (second half) projection framework.

-

Technological Advancements and Efficiency Improvements

By H2 2026, handheld laser rust removal devices are expected to feature higher peak power outputs (up to 3,000W), improved beam quality, and enhanced portability. Innovations in fiber laser efficiency and thermal management will allow for longer continuous operation and faster rust removal rates—up to 10–15 m²/hour for mid-range models. Integration with AI-driven surface scanning and adaptive pulse control will enable smarter, real-time rust detection and selective ablation, minimizing substrate damage. -

Growing Adoption in Key Industries

Industries such as automotive restoration, shipbuilding, aerospace, and heritage conservation are projected to increase their adoption of handheld laser systems. In H2 2026, the maritime sector—especially offshore and shipyard maintenance—will represent a major growth driver due to stringent environmental regulations against sandblasting and chemical treatments. Similarly, the aerospace industry will increasingly use lasers for precision cleaning of sensitive metal components without compromising structural integrity. -

Environmental and Regulatory Tailwinds

Environmental regulations in North America and the EU are expected to tighten further by 2026, phasing out traditional abrasive and chemical rust removal methods. Handheld laser systems, being non-contact, chemical-free, and producing minimal secondary waste, will benefit from these regulatory shifts. Compliance with ISO 12944 and other surface preparation standards will enhance market credibility and drive corporate procurement. -

Cost Reduction and Market Democratization

As production scales and Chinese and European manufacturers improve supply chains, the average price of handheld laser rust removers is expected to drop by 15–20% by H2 2026. Entry-level models under $5,000 will make the technology accessible to small businesses, auto shops, and independent contractors, broadening the customer base beyond large industrial users. -

Expansion of Service-Based Business Models

A trend toward Equipment-as-a-Service (EaaS) and rental platforms will emerge, especially in construction and infrastructure maintenance. Companies will offer laser rust removal as a contracted service, reducing upfront costs for clients and accelerating adoption. This model is expected to grow significantly in regions with high labor costs and aging infrastructure, such as Germany, Japan, and the U.S. Northeast. -

Geographic Market Shifts

Asia-Pacific, particularly China and India, will lead in both manufacturing and domestic consumption by H2 2026, driven by rapid industrialization and government support for green manufacturing. Meanwhile, North America and Western Europe will focus on high-precision and automated integration, with strong demand in defense and energy sectors. -

Safety and Training Standardization

With increased deployment comes a push for standardized safety protocols. By 2026, international certification programs for laser operators (aligned with IEC 60825 standards) are expected to become more widespread. Manufacturers will bundle training modules and smart safety features—such as automatic shutoff and real-time fume detection—into their devices.

In summary, the H2 2026 outlook for handheld laser rust removal is highly positive, characterized by technological maturity, regulatory support, broader affordability, and expanding application across industries. Companies that invest in user-friendly design, integrated software, and sustainable operations will be well-positioned to capture market share in this rapidly evolving sector.

H2: Common Pitfalls When Sourcing Handheld Laser Rust Removal Systems

Sourcing a handheld laser rust removal system requires careful consideration to ensure you receive a high-quality, reliable, and safe product. However, buyers often encounter several pitfalls related to quality and intellectual property (IP). Being aware of these issues can help avoid costly mistakes.

1. Compromised Build Quality and Performance

Many low-cost suppliers offer handheld laser rust removers with substandard components, such as inefficient cooling systems, poor laser diode quality, or inadequate power output. These shortcomings can lead to inconsistent rust removal, reduced operational lifespan, and frequent maintenance. Always verify technical specifications and request performance testing data before purchase.

2. Lack of Proper IP Protection and Counterfeit Products

A growing number of suppliers sell systems that replicate patented laser designs without authorization. These counterfeit or knockoff devices may infringe on existing intellectual property rights, exposing buyers to legal risks. Always confirm that the supplier holds proper IP rights or licenses, especially if importing or reselling the equipment.

3. Inadequate Safety Certifications

Laser systems must comply with international safety standards (e.g., FDA, CE, IEC 60825). Some suppliers falsify certifications or provide incomplete documentation. Without valid compliance, users risk workplace accidents and non-compliance with regulatory bodies.

4. Misleading Power Ratings

Some suppliers exaggerate laser power (e.g., listing peak power instead of average power) to make their products appear more capable. This misrepresentation can result in underperforming equipment unsuitable for industrial applications. Demand third-party verification or on-site demonstrations.

5. Poor After-Sales Support and Spare Parts Availability

Many overseas suppliers offer limited technical support or fail to provide essential spare parts and software updates. This can lead to prolonged downtime and increased operational costs. Evaluate the supplier’s service network and support infrastructure before committing.

6. Hidden Costs and Lack of Transparency

Initial quotes may exclude shipping, import duties, training, or warranty services. Ensure all costs are clarified upfront and included in the contract to avoid unexpected expenses.

By addressing these common pitfalls—particularly around quality assurance and intellectual property rights—buyers can make informed decisions and invest in a reliable, compliant, and high-performance handheld laser rust removal solution.

Logistics & Compliance Guide for Handheld Laser Rust Removers

Product Classification and Regulatory Overview

Handheld laser rust removers are industrial cleaning tools that use high-intensity laser beams to remove rust, paint, and contaminants from metal surfaces. Due to their use of laser technology, these devices are subject to various international and national regulations related to laser safety, electrical equipment, and environmental compliance.

International Shipping and Export Compliance

Export Classification (HTS/ECCN)

Determine the appropriate Harmonized Tariff Schedule (HTS) code and Export Control Classification Number (ECCN) for the device. Handheld laser equipment may fall under:

– HTS Code: 8543.70 (Electrical machines and apparatus having individual functions, not elsewhere specified)

– ECCN: 6A003.b.4 (Laser systems with specific power and performance characteristics) under the Wassenaar Arrangement

Verify classification with national export control authorities to ensure compliance with dual-use regulations.

Required Export Documentation

Prepare the following for international shipments:

– Commercial invoice with detailed product description

– Packing list

– Certificate of Origin

– Export license (if required based on destination and ECCN)

– Technical specifications (laser class, power output, wavelength)

Laser Safety Certification

IEC 60825-1 Standard

Ensure the device complies with IEC 60825-1: Safety of Laser Products – Part 1: Equipment Classification and Requirements. This standard governs:

– Laser class designation (typically Class 4 for industrial rust removers)

– Labeling requirements (warning labels, aperture labels)

– Safety interlocks and protective housings

– Emission duration and power limits

FDA/CDRH Compliance (USA)

For U.S. import and sale:

– Register the product with the FDA’s Center for Devices and Radiological Health (CDRH)

– Submit a Laser Product Report (LPR) including:

– Product classification

– Performance data

– Safety features

– Include required labeling per 21 CFR 1040.10 and 1040.11

Electrical and EMC Compliance

CE Marking (European Union)

To sell in the EU, ensure compliance with:

– Low Voltage Directive (LVD) 2014/35/EU – Electrical safety

– EMC Directive 2014/30/EU – Electromagnetic compatibility

– RoHS Directive 2011/65/EU – Restriction of hazardous substances

Testing must be conducted by an accredited laboratory, and technical documentation must be maintained.

UKCA Marking (United Kingdom)

Post-Brexit, UKCA marking is required for sale in Great Britain. Requirements mirror CE marking but apply to UK regulations.

FCC Compliance (USA)

If the device includes electronic controls or wireless components:

– Comply with FCC Part 15 for electromagnetic emissions

– Perform radiated and conducted emissions testing

– Include FCC ID on the product if applicable

Battery and Energy Storage (If Applicable)

If the handheld unit uses rechargeable batteries (e.g., Li-ion):

– Comply with UN 38.3 testing for lithium batteries

– Package per IATA Dangerous Goods Regulations (DGR) for air transport

– Include proper shipping name: “Lithium ion batteries, UN3480”

– Mark packages with Class 9 hazard label and handling instructions

Import Requirements by Region

United States

- Customs entry via CBP with HTS code declaration

- FDA laser product registration

- FCC certification (if applicable)

European Union

- CE marking verification

- EU Representative appointment (if manufacturer is outside EU)

- Declaration of Conformity on file

Canada

- ICES-003 compliance (EMC)

- Health Canada laser safety requirements (similar to FDA)

- Safety certification from accredited body (e.g., CSA)

Australia and New Zealand

- RCM mark for electrical and EMC compliance

- Compliance with AS/NZS IEC 60825.1

Packaging and Labeling Requirements

Safety Labels

Devices must display:

– Laser warning symbol (IEC 60825-1)

– Laser class (e.g., “Class 4 Laser Product”)

– Wavelength and maximum output power

– Manufacturer/importer contact information

Multilingual Labeling

For international markets, include safety instructions and warnings in the local language(s).

Training and User Documentation

Provide end users with:

– Operator manual in local language

– Laser safety training guide

– Personal protective equipment (PPE) requirements (e.g., laser safety goggles)

– Maintenance and troubleshooting instructions

Environmental and Disposal Compliance

- Comply with WEEE Directive (EU) for electronic waste recycling

- Provide take-back instructions for end-of-life units

- Avoid restricted substances per RoHS

Summary of Key Compliance Steps

- Classify the product for export (HTS/ECCN)

- Obtain laser safety certification (IEC 60825-1)

- Fulfill regional electrical and EMC requirements (CE, FCC, UKCA, etc.)

- Prepare shipping documentation and comply with dangerous goods rules (if batteries)

- Label product with required safety and compliance marks

- Provide user training and documentation

- Ensure end-of-life disposal compliance

Adherence to this guide ensures legal distribution and safe operation of handheld laser rust removers across global markets.

In conclusion, sourcing a handheld laser for rust removal offers a highly efficient, precise, and eco-friendly alternative to traditional methods such as sandblasting or chemical treatments. With advancements in laser technology, these portable devices provide industrial users with the ability to clean metal surfaces quickly, without damaging the underlying material or producing hazardous waste. When selecting a handheld laser rust removal system, key factors to consider include laser power, portability, ease of use, safety features, and cost-effectiveness over time. While the initial investment may be higher than conventional tools, the long-term benefits—such as reduced maintenance, increased productivity, and compliance with environmental regulations—make it a worthwhile solution for industries ranging from automotive and marine to manufacturing and heritage restoration. As the technology continues to evolve and become more accessible, handheld laser rust removers are poised to become a standard tool in surface preparation and maintenance.